Sustainability

Environment

Environmental Sustainability Vision 2050

The company’s new Environmental Sustainability Vision 2050 positions environmental protection as an even greater corporate priority and stipulates increased initiatives toward this end. The vision establishes Mitsubishi Electric’s future course for implementing key initiatives based on its Environmental Declaration and Three Environmental Action Guidelines toward 2050.

Financial information based on recommendations of the task force on climate-related financial disclosures (TCFD)

Strategy for climate change

The structure of our environmental management system

Environmental considerations for Value Chain Management

Implementation of environmentally conscious design

Resource recycling initiatives

Research and development of products and technologies to solve environmental issues

Evaluating the status of environmental initiatives by our suppliers

Reducing CO2 from plants and offices

Effective utilization of plastic waste

Reducing water usage

Managing chemical substances

Reducing the use of disposable packaging materials

Reducing CO2 from logistics

Contribution to reducing CO2 from product usage

Closed-loop recycling of plastic

Biodiversity preservation activities

Creating a society in tune with nature

Fiscal 2021 environmental topics

We have been selected by the international non-governmental organization CDP as the highest rated "A List Company" in the three fields of "Climate Change," "Water" and "Supplier Engagement."

Recycling technologies

Bringing water back to life through the powers of electricity, bubbles, and ozone

Here we present entirely new water recycling technology that utilizes the power of electricity to break down substances in water that were previously difficult to manage. We discuss the features of this technology and give some examples of its applications, including "microbubbles" that remove grime with the power of bubbles, and ozone generators called "ozonizers" that produce delicious, safe, clear water with the power of ozone.

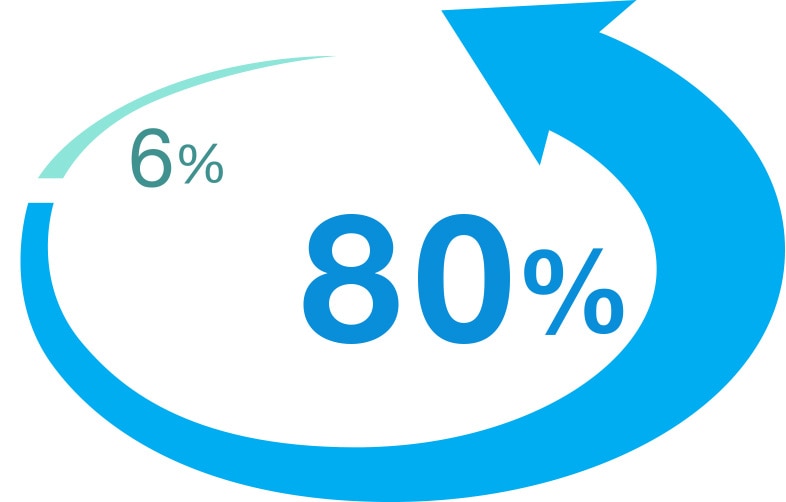

A model business for a sustainable future

Until now, it was considered difficult to recirculate plastics, or recycle them from home electronics appliances for reuse in new home electronics appliances, as only 6% of the material could be recycled. However, Japan's first large-scale, high-purity plastics recycling system has raised that rate to 80%, more than 10 times the previous level. We will introduce the secret behind this technology, and how it evolved.