Simple Motion module Features-RD77GF

RD77GF

- CC-Link IE Field Network

- Servo Amplifier MR-J4-GF

- CC-Link IE Field Network Master Station

- Functional Safety

- Diagnosis and Parameter Settings

- Motion control

- PLCopen® Motion Control FB

- Functions List

- Related Link

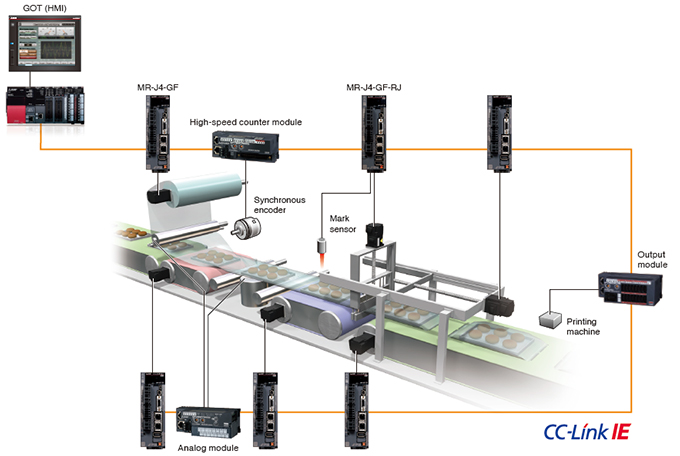

CC-Link IE Field Network

All-in-One Network

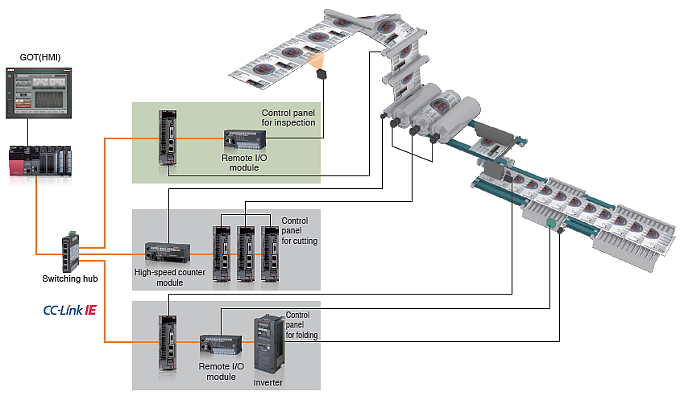

CC-Link IE Field Network - Integration of IA components on ONE single network

CC-Link IE Field Network is a single network which combines the versatility of Ethernet and highly accurate synchronous operation for Motion control. With the single network, various field devices, such as servo amplifiers, I/O modules, and high-speed counter modules, are connected flexibly.

CC-Link IE Field Network enables a further upgrade of your machine with the flexible servo system configuration.

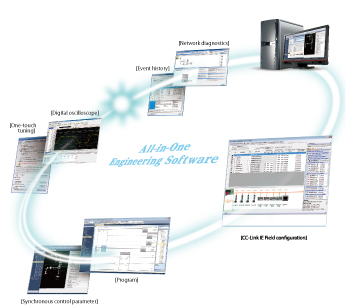

All-in-One Engineering Software

Covering all aspects of the product development cycle - From Easy Settings to Diagnosis with ONE engineering software

To meet customer needs, such as easy programming, easy startup, and easy maintenance, we offer the All-in-One engineering software as an easy manipulation tool with various new functions and technology.

Various tasks, such as Simple Motion parameter settings, servo adjustment, and debugging as well as creating a sequence program, such as a function block (FB), are performed only with this All-in-One engineering software.

Synchronization of Inputs and Outputs with Servo Control

Various data, such as synchronous encoder values, sheet tension values, and text data, are inputted and outputted in accordance with the servo command communication cycle, enabling a wide range of Motion control applications.

[An example of inputs and outputs synchronized with the command communication cycle of a servo amplifier]

Flexible network topology

Star, line, and star/line mixed topologies are available for a network configuration by using a switching hub. An easy topology created only by a cable being connected to a free port of the switching hub allows field devices to be added to the system more flexibly.

CC-Link IE Field Network Servo Amplifier MR-J4-GF

- Having a superior control function of MR-J4 series, MR-J4-GF supports CC-Link IE Field network.

- Together with the Simple Motion module, advanced synchronous control and interpolation control are enabled.

- Two types of modes are available according to your needs: Motion mode for a wide range of motion control such as positioning of multiple axes, synchronous control, etc., and I/O mode for positioning of one axis.

(Note-1): MR-J4-GF with software version of A4 or later supports CC-Link IE Field Network Basic.

Synchronous control up to μsec precision, suitable for high-accuracy positioning

This system configuration is suited for a wide range of high-accuracy motion control, such as multi-axis interpolation, synchronous, and speed-torque control.

[Simple Motion module]

[Motion mode]

A high flexibility enabling versatile control with Motion and I/O modes

This system configuration allows a single axis for positioning to be flexibly added to a machine which requires a wide range of high-accuracy motion control, such as multi-axis interpolation, synchronous, and speed-torque control.

[Simple Motion module]

[Motion mode]

[[I/O modes]

Covering a wide range of applications for positioning control

This system configuration allows a single axis for positioning to be flexibly connected to a master station, such as a CC-Link IE embedded CPU without the Simple Motion module.

[CC-Link IE embedded CPU]

[[I/O modes]

CC-Link IE Field Network Master Station

The CC-Link IE Field Network Simple Motion module covers the functionality that a CC-Link IE Field Network master/ local module provides (Note-1).

The Simple Motion module can function as a master module, and is also equipped with link devices equivalent to a master/local module.

This leads to reduced cost on system because it includes functions of both Simple Motion module and a master module.

(Note-1): Excludes the function of a sub-master station.

■Maximum link points per network

| Item | RD77GF | Master module |

|---|---|---|

| Remote input (RX)/Remote output (RY) | 16k points each (16384 points, 2k byte) | 16k points each (16384 points, 2k byte) |

| Remote register (RWw, RWr) | 8k points each (8192 points, 16k byte) | 8k points each (8192 points, 16k byte) |

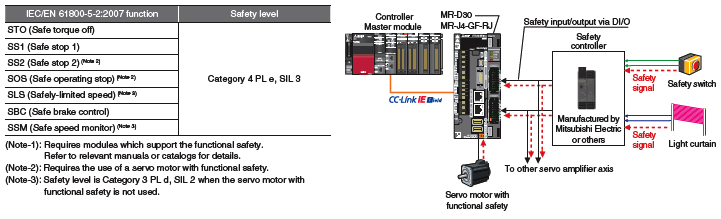

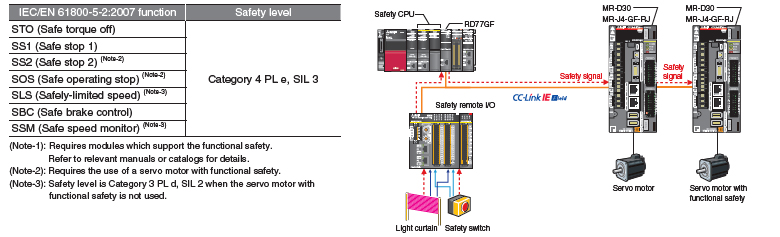

Functional Safety

Achieving Category 4 PL e, SIL 3

By wiring to MR-D30 functional safety unit (Note-1)

Safety level is Category 4 PL e, SIL 3 when the safety signals are inputted directly to MR-D30 functional safety unit. The safety observation function is operated on the MR-D30 by parameter setting, and therefore expansion of the safety observation function is possible independent of controllers.

By CC-Link IE Field Network (Note-1)

Safety signals are monitored by a combination of the safety CPU and RD77GF Simple Motion module.The safety CPU checks the safety signals received via the safety remote I/O module and outputs the safety signals (STO, etc.) to the servo amplifiers. Since the safety signals are outputted through CC-Link IE Field Network, wiring of the safety signals to each functional safety unit are not necessary.

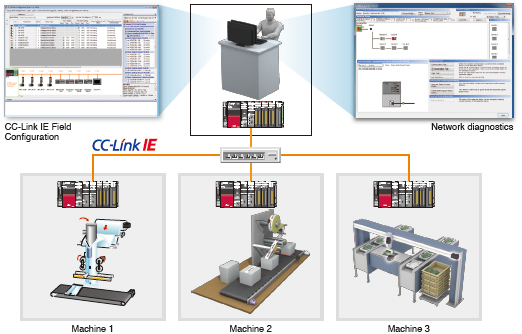

Diagnosis and Parameter Settings

Setting parameters and collecting information of field devices are possible from any-network connected point including a computer or shop floor device.

Easy parameter settings

Selecting each field device on the screen of CC-Link IE Field configuration via drag & drop enables easy parameter settings.

Easy diagnosis of network

Engineering software enables users to identify network errors at a glance. The users can instantly identify the cause of trouble when it occurs thus downtime will be shortened.

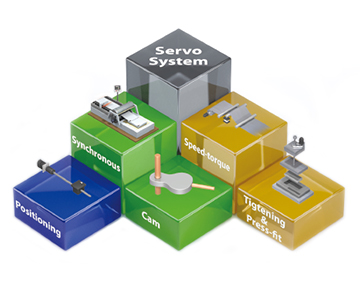

Extensive Motion control

A wide range of control, such as positioning, speed-torque, cam, and synchronous control, is applicable to various machines, such as X-Y tables, packaging machines, and converting machines. Selecting the best suitable control methods and functions for your machine achieves an optimal solution.

Positioning control (Interpolation Function and Trajectory Control)

Positioning control is easily performed with a Motion profile table in the sequence program.

- To respond to various application needs, the Simple Motion module offers various control methods, such as linear interpolation, 2-axis circular interpolation, fixed-pitch feed, and continuous trajectory control.

- Automatic operation can be executed easily by setting positioning addresses, speeds, and other setting items in a sequence program.

- Powerful sub-functions, such as M-code output, skip, speed change, and target position change functions, are available.

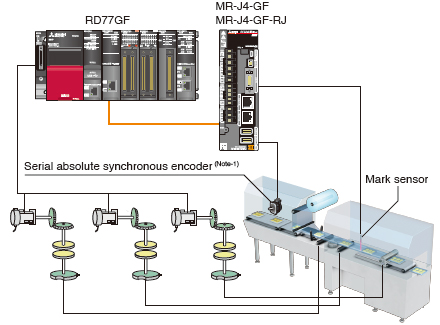

Advanced Synchronous Control

The advanced synchronous control is software-based synchronous control as an alternative to mechanical control, such as gear, shaft, clutch, speed change gear, and cam. In addition, cam control becomes even easier with cam auto-generation function.The synchronous control can be simply started/ended for each axis, allowing the synchronous control axis and positioning control axis to be used within the same program.

(Note-1): MR-J4-GF-RJ is required when the serial absolute synchronous encoder is used.

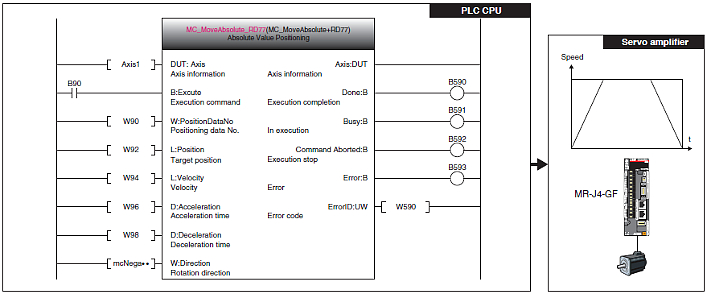

PLCopen® Motion Control FB

Simple Motion modules and servo amplifiers with built-in positioning are used to execute Motion control. Each device uses specific programming, thus the time and cost involved in understanding how each device works is a burden. PLCopen® Motion Control FB is a standardized interface, which provides the following benefits:

- Reduced workload for programming, saving time and reducing costs.

- People other than the program designer can understand the programming, leading to reduced maintenance time.

Conforms to IEC 61131-3

GX Works3 realizes structured programming such as ladder and ST, making project standardization across multiple users even easier.

The sequence program using FBs is created with the same interface regardless of whether the motion mode or the I/O mode is used.

Functions List

| Simple Motion module | ||||

|---|---|---|---|---|

| RD77GF32 | RD77GF16 | RD77GF8 | RD77GF4 | |

| Number of control axes (Virtual servo amplifier axis included) |

Up to 32 axes | Up to 16 axes | Up to 8 axes | Up to 4 axes |

| Servo amplifier connection method |

CC-Link IE Field Network (1Gbps) | |||

| Maximum distance between stations [m(ft.)] |

100(328.08) | |||

| Connectable servo amplifier |

MR-J4-GF , MR-J4-GF-RJ | |||

| Operation cycle[ms] (Operation cycle settings) |

0.5, 1.0, 2.0, 4.0 | |||

| Engineering Environment | MELSOFT GX Works3 | |||

| Control modes | Positioning control, Position control, Speed control, Torque control, Speed-torque control, Cam control, Advanced synchronous control, 2 axes/3 axes/4 axes Linear interpolation, 2 axes Circular interpolation, Trajectory control, Speed/position switching control(ABS/INC), Position/speed switching control(INC) |

|||

| Control unit | mm, inch, degree, pulse | |||

| Positioning data | 600 data (positioning data No. 1 to 600)/axis | |||

| Acceleration/ deceleration process |

Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration | |||

| Manual control | JOG operation, Manual pulse generator operation, Inching operation | |||

| Functions that change control details |

Current value change,Target position change function, Torque change function, Speed change function, Override function, Acceleration/deceleration time change function |

|||

| Home position return method |

Driver home position return (Note-1) | |||

| Auxiliary functions | Forced stop function, Hardware stroke limit function, Software stroke limit function, Absolute position system, Amplifier-less operation function, Unlimited length feed, Optional data monitor function, Mark detection function, Flash ROM backup, M-code output function, Event history function, Digital oscilloscope function, Cam auto-generation function |

|||

| Number of occupied I/O points |

64 points (I/O allocation: Intelligent function module, 64 points) |

32 points (I/O allocation: Intelligent function module, 32 points) | ||

| 5VDC internal current consumption [A] |

1.1 | |||

| Mass [kg] | 0.23 | |||

- (Note-1):

- The home position return method set in a driver (a servo amplifier) is used.