Simple Motion module Features-RD77MS

RD77MS

- Concept

- Features

- SSCNET III/H

- Positioning Control

- Advanced Synchronous Control

- Cam Function

- Simulation

- Multi-axis Adjustment Function

- Helical Interpolation

- Control Flow

- Functions List

- Related Link

Concept

The MELSEC iQ-R series is provided with sophisticated dual engines: the PLC CPU engine for machine control and the Motion CPU engine for Motion control. The engines respectively process different types of control based on the characteristic of each engine while working together on data through a high-speed system bus. CPU loads are significantly distributed by these dual engines compared with a single engine, enabling any equipment to maximize its performance, even for a load change machine or multi-axis equipment.

The MELSERVO-J4 series servo amplifier is an environmentally and user friendly product, while offering industry-leading level of performance. Connecting the amplifiers to "SSCNETIII/H" optical network enables high-speed and high-accuracy control with the MR-J4 dedicated engine and high-resolution encoder.

Select the most suitable combination of CPU engines that can reduce cost and maximize machine performance to the fullest from our extensive product line. Efficiency in designing and debugging is also improved.

Programming efficiency matters when it comes to productivity. The MELSEC iQ-R series optimizes all procedures, from designing, debugging, to startup.

Equipped with advanced dual engines that are only possible with our cutting-edge iQ platform technology, the MELSEC iQ-R series takes a step further to accelerate the equipment revolution by collaborating with our partner companies. Now, a wide variety of SSCNETIII/H compatible partner products are available, such as stepping motors and direct drive motors.

Features

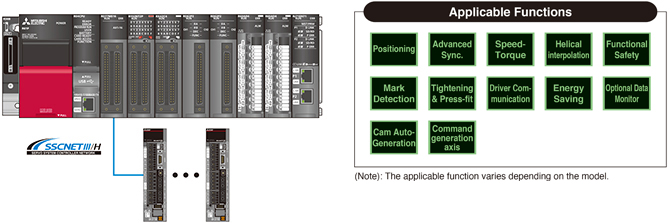

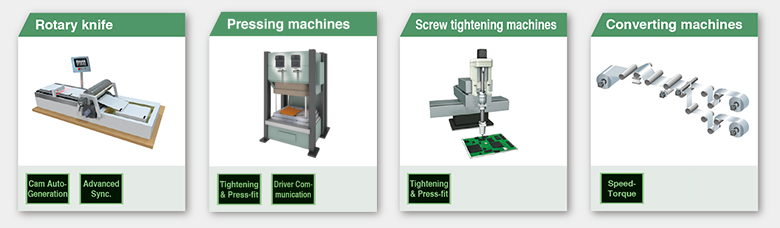

- Wide-range, sophisticated Motion controls, such as advanced synchronous control, cam control, speed-torque control (tightening & press-fit control) can be achieved just with sequence programs including function blocks.

- All the functions of QD75MH are included in the Simple Motion module.

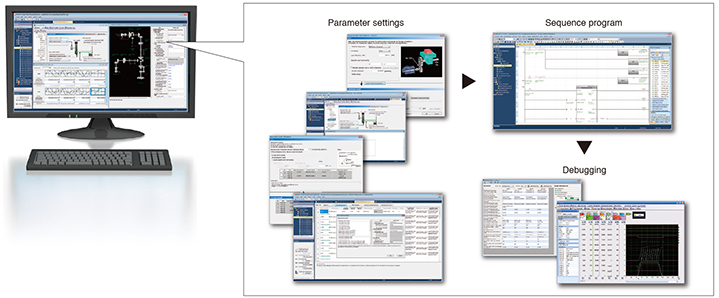

- From programming to servo amplifier configuration, everything is packed into an easy-to-use engineering software (MELSOFT GX Works3).

Superb Functionality for Wide-range Applications

All-in-one Engineering Tool

Various features have been consolidated in one software (MELSOFT GX Works3), covering from programming to debugging for a servo system consisting of Simple Motion modules and servo amplifiers.

Basic Performance

Tact time is dramatically reduced by improving basic performance of the Simple Motion module.

High-speed Synchronous Network SSCNETIII/H

- Communications speed is increased to 150 Mbps full duplex (equivalent to 300 Mbps half duplex), three times faster than the conventional speed.

System response is dramatically improved. - Smooth control of a machine is possible using high-speed serial communications with a cycle time of 0.222 ms.

- Synchronous communications are achieved with SSCNETIII/H, offering technical advantages for machines that require deterministic control.

- Long distance wiring is possible up to 3200 m (10498.69 ft.) per system (maximum of 100 m (328.08 ft.) between stations x control axes up to 32 axes), suitable for large-scale systems.

- SSCNETIII/H compatible and SSCNETIII compatible servo amplifiers can be used together.

(The communications speed when SSCNETIII compatible products are used together in the same system: 150 Mbps full duplex)

(Note): SSCNET (Servo System Controller Network)

Positioning Control

Positioning control is easily executed using a Motion profile table.

Basic Positioning Control

- To respond to various application needs, the Simple Motion module offers various control methods, such as linear interpolation, 2-axis circular interpolation, fixed-pitch feed, and continuous path control.

- Automatic operation can be executed easily by setting positioning addresses, speeds, and other setting items in a sequence program.

- Powerful sub-functions, such as M-code output, skip, speed change, and target position change functions, are available.

Advanced Synchronous Control

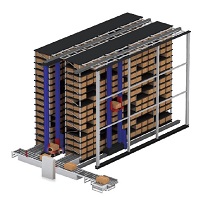

The advanced synchronous control is software-based synchronous control as an alternative to mechanical control, such as gear, shaft, clutch, speed change gear and cam. In addition, cam control becomes even easier with cam auto-generation function.

The synchronous control can be flexibly started/ended for each axis, allowing the synchronous control axis and positioning control axis to be used within the same program.

All axes are synchronized using a synchronous encoder axis or a servo input axis.

Packing machines, printing machines,

diaper manufacturing machines,

tire molder

Only two axes are in synchronization. The other axes are in positioning control.

Tandem configuration

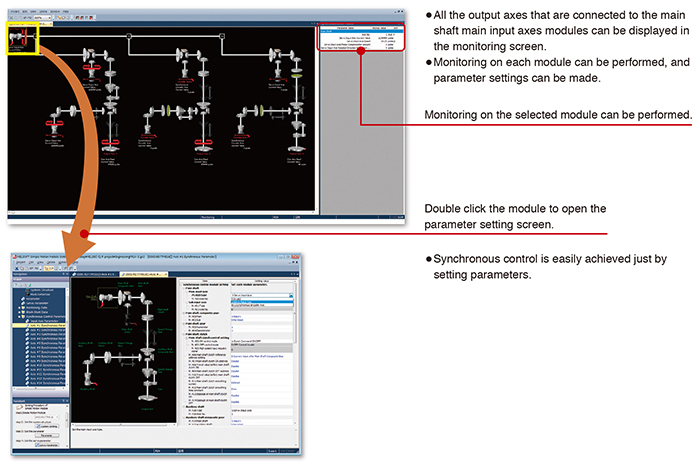

Module configuration of synchronous control

The whole module configuration of the advanced synchronous control can be displayed in one screen, and monitoring of the target modules can be also viewed, which enables more efficient debugging.

Cam Function

The output axis for synchronous control is operated with a cam.

The following three operations can be performed with the cam functions: Linear operation, Two-way operation, and Feed

operation; therefore any of the three can be selected to suit your application.

Simulation

The MELSOFT GX Works3 simulation enables a program operation to be checked without an actual machine even during the debugging process and hence a shorter startup time. In addition, multiple Simple Motion modules can be simulated at the same time.

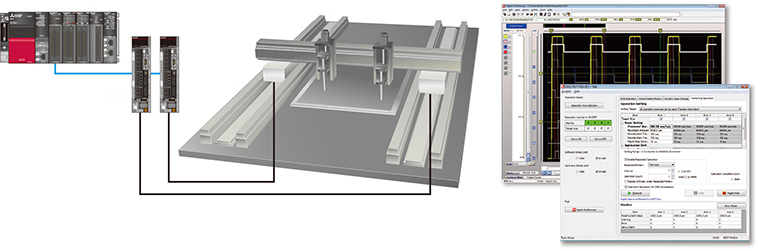

Multi-axis Adjustment Function

The multi-axis adjustment function enables simpler servo adjustment and quicker startup for machines executing multi-axis simultaneous operation, such as a tandem configuration.

- Multi-axis simultaneous JOG operation by specifying speed and acceleration/deceleration time

- Multi-axis simultaneous positioning

- Multi-axis simultaneous tuning by the same settings

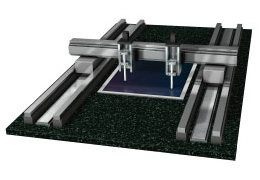

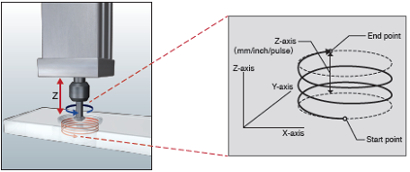

Helical interpolation

Helical interpolation draws a helical path by a linear interpolation axis (Z-axis) following to 2-axis circular interpolation control (X-axis and Y-axis).

For applications that require the boring of deep, large holes, usually the helical interpolation of the three axes must be taken into consideration.

- Milling is done in a circle, with the X and Y axes synchronized to achieve the pre-set size.

- The depth of the hole is simultaneously controlled along the Z axis, ensuring minimal deviation in the cutting bit position.

Control Flow

Various positioning controls such as linear interpolation can be performed just by writing positioning data to the buffer memory using a sequence program or a function block.

Functions List

| Simple Motion Module | ||||

|---|---|---|---|---|

| RD77MS16 | RD77MS8 | RD77MS4 | RD77MS2 | |

| Number of control axes (Virtual servo amplifier axis included) |

Up to 16 axes | Up to 8 axes | Up to 4 axes | Up to 2 axes |

| Operation cycle [ms] (Operation cycle settings) |

0.444, 0.888, 1.777, 3.555 | |||

| Servo amplifier connection method |

SSCNETIII/H (150Mbps) | |||

| Maximum distance between stations [m(ft.)] |

100(328.08) | |||

| Connectable servo amplifier |

MR-J5-B, MR-J5W-B More details MR-J4-B, MR-J4W-B More details MR-JE-B More details |

|||

| Control modes | Position control, Speed control, Torque control, Speed-torque control, Speed-position switching control, Position-speed switching control, Path control (Linear, arc, and helical) |

|||

| Positioning control | Speed control, Linear interpolation (Up to 4 axes), Circular interpolation (2 axes), Helical interpolation (3 axes), Fixed-pitch feed, Continuous path, Speed-position switching control, Position-speed switching control, Current value change, Current value change. Loop control |

|||

| Acceleration/ deceleration process |

Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration | |||

| Number of positioning data | 600 data (positioning data No. 1 to 600)/axis | |||

| Home position return method | Proximity dog method, Count method 1, Count method 2, Data set method, Scale home position signal detection method, Driver home position return method (Note-1) |

|||

| Manual control | JOG operation, Manual pulse generator operation, Inching operation | |||

| Expansion control | Speed-torque control, Advanced synchronous control | |||

| Auxiliary functions |

Forced stop function, Hardware stroke limit function, Software stroke limit function, Absolute position system, Speed change, Torque change, M-code output function, Digital oscilloscope function, Cam auto-generation function, Target position change function |

|||

| Common functions | Amplifier-less operation, Optional data monitor, Mark detection, Event history | |||

| Engineering Environment | MELSOFT GX Works3 | |||

| Number of I/O occupying points | 32 points (I/O allocation: Intelligent function module, 32 points) | |||

| 5VDC internal current consumption [A] |

1.0 | |||

| Mass [kg] | 0.23 | 0.22 | ||

- (Note-1):

- The home position return method set in a driver (a servo amplifier) is used.