Inverters-FREQROL-A800 Plus Series -FREQROL-A800 Plus for Automated warehouse- Features

FREQROL-A800 Plus for Automated warehouse

Release of the new inverter for logistics and transportation

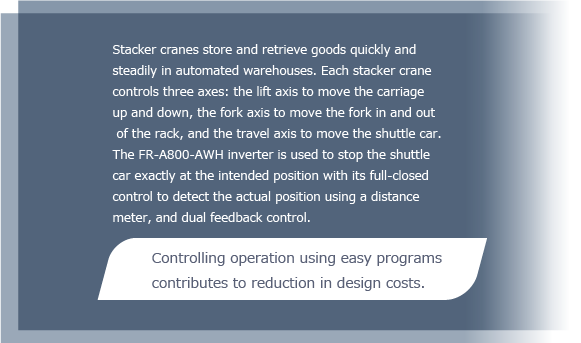

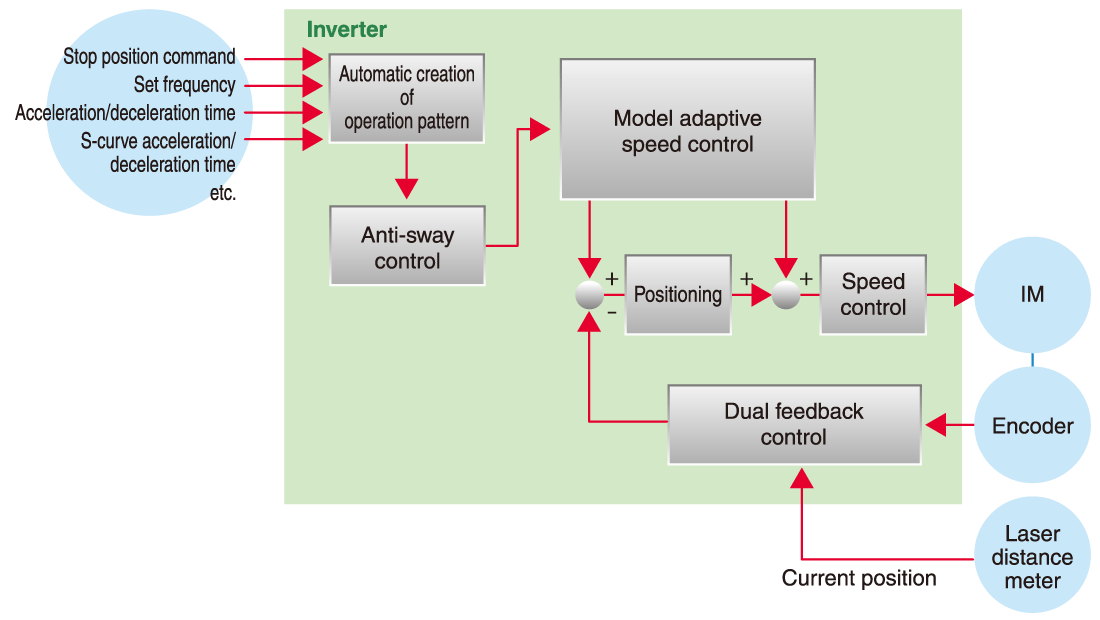

The FR-A800-AWH inverters are ideal for logistics and transportation, supporting dual feedback control,

full-closed control, and nine types of distance sensors.

Full-closed control

This function is used to operate logistics/transport equipment in combination with distance meters and the host controller.

The logistics/transport equipment is moved while position loop is compensated by inputting the feedback of the position detected by the distance meter.

Dual feedback control

Changes in the distance meter feedback used for position control can be suppressed. This function is useful when the values measured by the distance meter are not stable and operation becomes unstable.

Reducing tact time

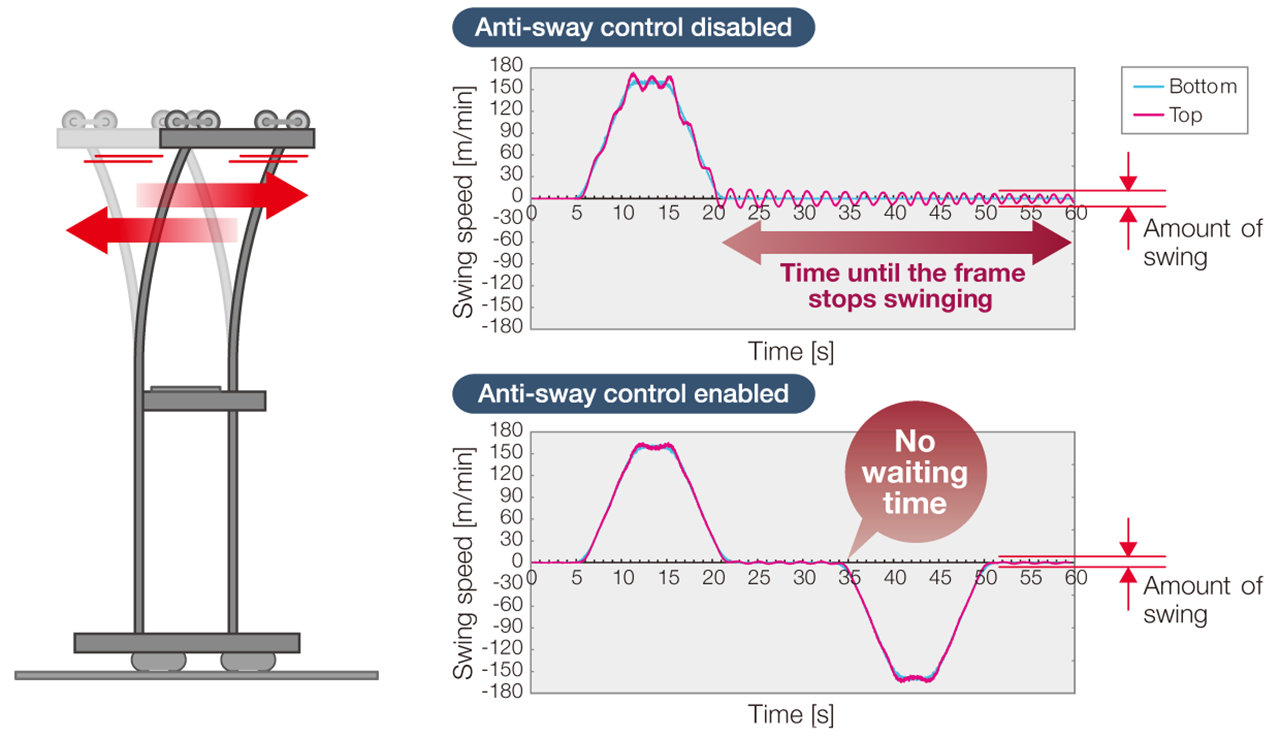

■ Anti-sway control

This function minimizes the swinging of the crane frame while the shuttle car is traveling.

This will contribute to tact time reduction as less time is required for the swinging to stop.

■ S-curve acceleration/deceleration

The patterns of S-curve acceleration/deceleration can be selected.

It is possible to prevent load shifting during transportation.

Contributing to the cost reduction

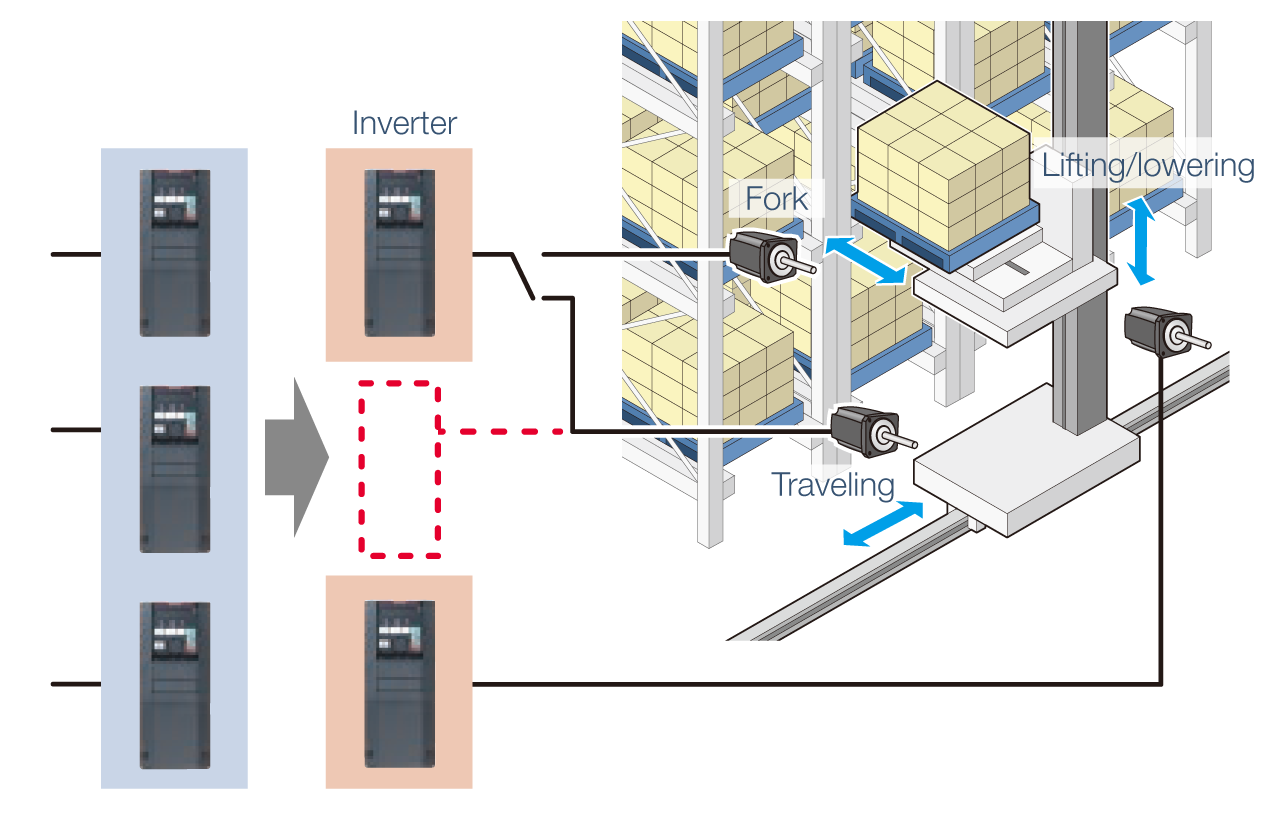

Selecting fork control

The fork of logistics/transport equipment is moved based on the set frequency while the start command is given through communication.

Three inverters are used to control the travel axis, lift axis, and fork axis.

Alternatively, it is possible to use two inverters to control the three axes. The inverter for the travel axis motor or the lift axis motor can be used for the fork axis motor.

Controlling three motors by two inverters contributes to cost reduction.

System support

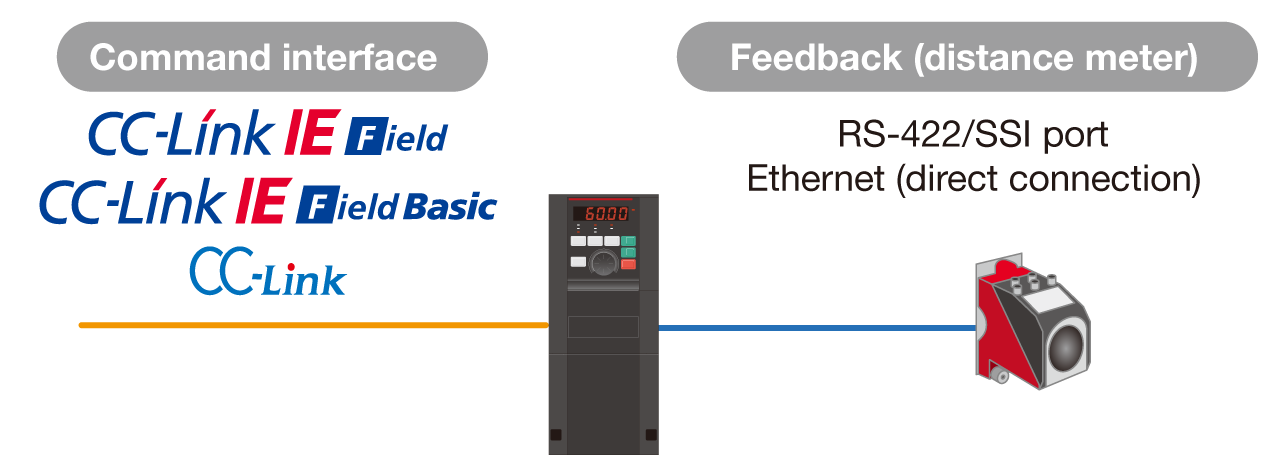

Network

The master gives the start command, speed command, or stop position command to the inverters through communication for the driving control.

| Type | Network | Remarks |

|---|---|---|

| Command interface |

CC-Link IE Field | When used with FR-A8NCE |

| CC-Link IE Field Basic | Ethernet models only | |

| CC-Link | When used with FR-A8NC | |

|

Feedback (distance meter) |

RS-422 | RS-485 models only |

| Ethernet | Ethernet models only | |

| SSI | When used with FR-A8APS-02 |

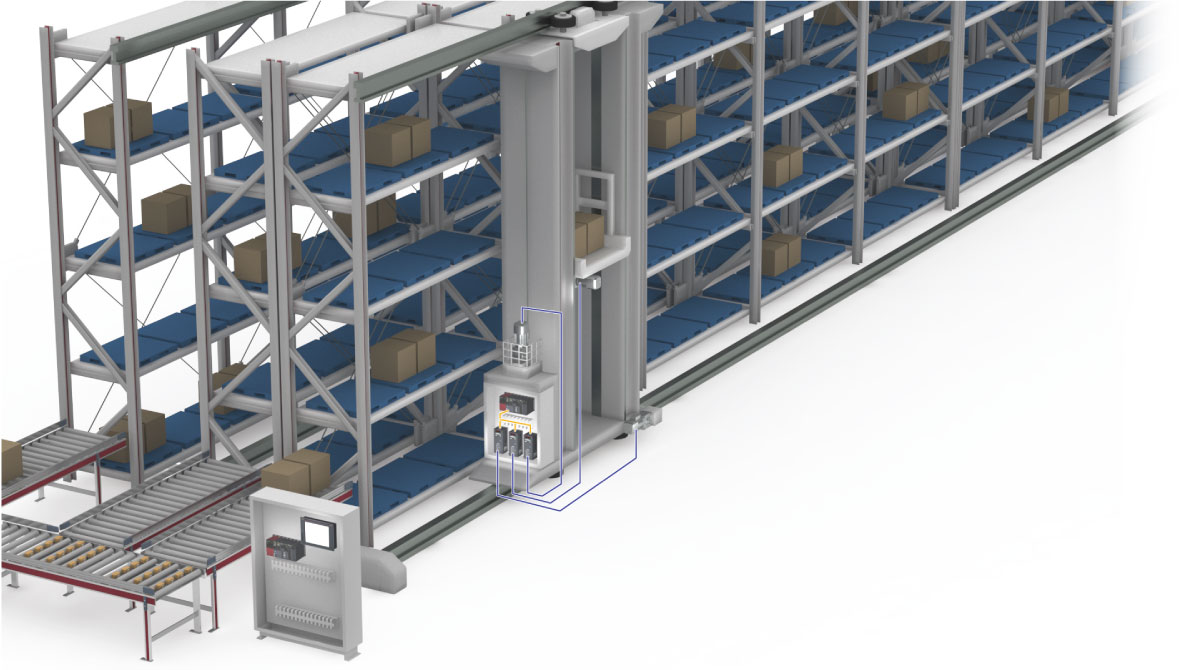

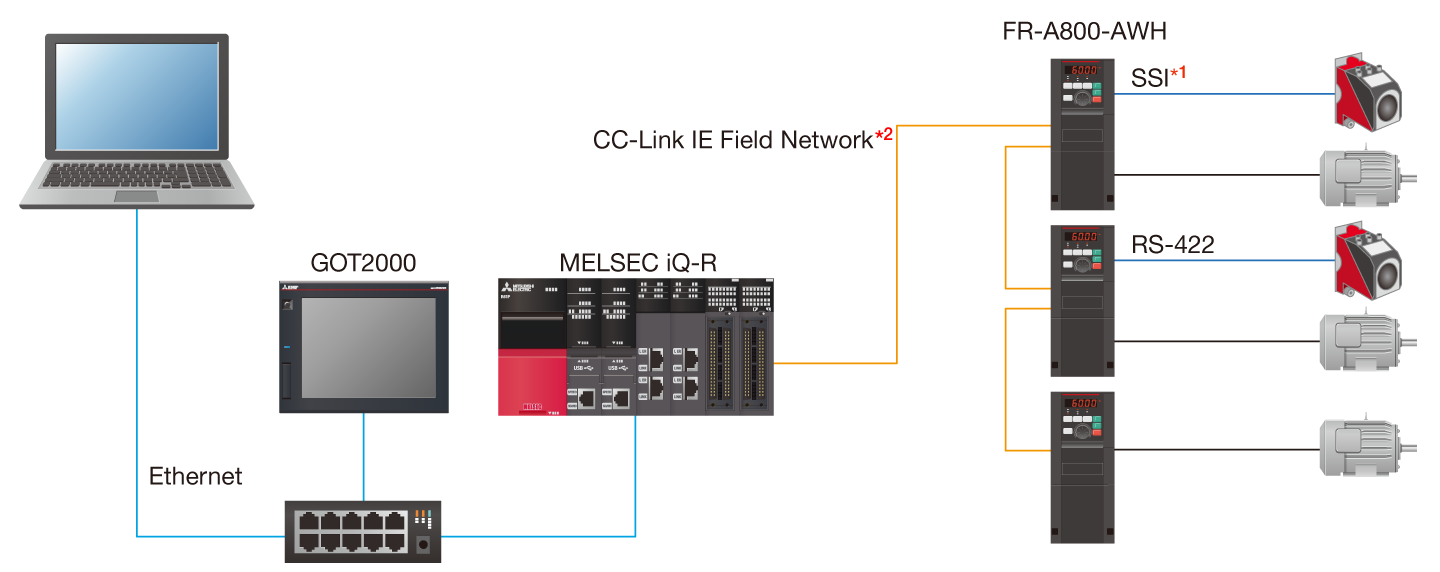

Application example

FR-A8NCE (CC-Link IE Field Network communication)

- *1When the FR-A8APS-02 is used.

- *2For compatible command interfaces, refer to page 3.

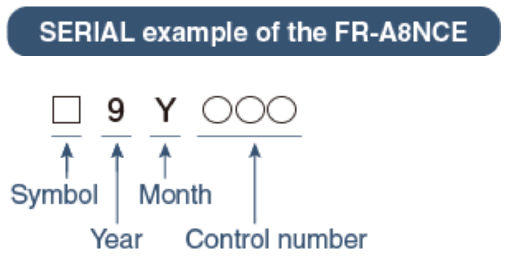

Compatible FR-A8NCE

The FR-A8NCE manufactured in November 2019 or later can be used.

Check the SERIAL number indicated on the circuit board for the production year and month.

Compatibility depends on the SERIAL number as shown in the table on the right.

| SERIAL number of the FR-A8NCE | FR-A800-AWH |

|---|---|

| □ 9 X ◯◯◯ or earlier (October 2019 or earlier) |

Not compatible (E1 error) |

| □ 9 Y ◯◯◯ or later (November 2019 or later) |

Compatible |

The SERIAL consists of one symbol, two characters indicating the production year and month, and three characters indicating the control number.

The last digit of the production year is indicated as the Year, and the Month is indicated by 1 to 9, X (October), Y (November), or Z (December).

Supported distance meter models

| Inverter | Distance meter | |||

|---|---|---|---|---|

| Model | Manufacturer | Measurement method | Communication method | |

| RS-485 model | DME5000*1 | SICK | Laser | RS-422 |

| OLM100-1003 | SICK |

Laser (reading bar codes) |

||

| DL100pro*2 | SICK | Laser | ||

| AMS300i*3 | Leuze | Laser | ||

| CEV58M-00884 | TR-electronic | Absolute encoder | ||

| Ethernet model | AMS308i*4 | Leuze | Laser | Ethernet |

| RS-485 model/ Ethernet model (only when used with the FR-A8APS-02) |

BPS307i | Leuze |

Laser (reading bar codes) |

SSI |

| AMS304i | Leuze | Laser | ||

| CMV58M-00002 | TR-electronic | Absolute encoder | ||

- *1DME5000-113 and DME5000-213 support the inverter.

- *2DL100-21AA2103, DL100-21HA2103, DL100-22AA2103, DL100-22HA2103, DL100-23AA2103, and DL100-23HA2103 support the inverter.

- *3AMS300i-40H, AMS300i-120H, AMS300i-200H, and AMS300i-300H support the inverter.

- *4AMS308i-40H, AMS308i-120H, AMS308i-200H, and AMS308i-300H support the inverter.

Easy setup

Communication registers

The inverter supports special commands for logistics/transport applications such as the 32-bit stop position command, the acceleration/deceleration time command, and the command used to monitor the current value.

Easy controller programming reduces the setup effort.Slippage prevention

Slippage prevention

Brake sequence

This function is useful in preventing load slippage at a start due to poor mechanical brake timing and overcurrent alarm in stop status and enable secure operation. (This function is enabled when full-closed control is selected.)

Improved environmental resistance

Circuit board coating

Using the inverter in the dusty environment may cause fault such as a short circuit.

Inverters with circuit board coating (conforming to IEC 60721-3-3 3C2/3S2) and plated conductors ensure reliability even in poor environments.

("-60" or "-06" is affixed to the end of the inverter model name.)