Inverters-FREQROL-A800 Plus Series FREQROL-A800 Plus Liquid cooled type

FR-A800 Plus Liquid cooled type

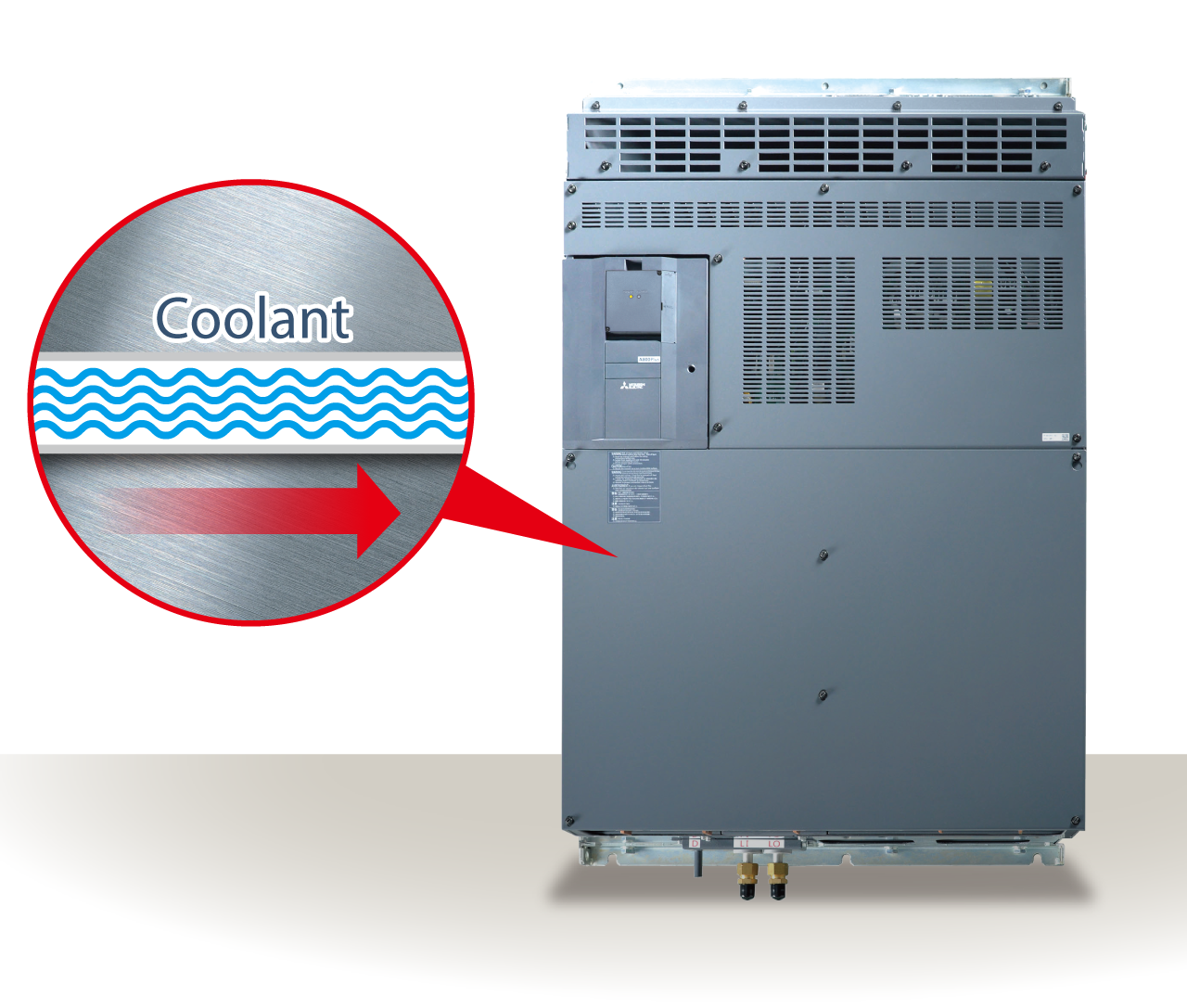

Release of the new liquid cooled type inverter, FR-A800-LC

Coolant is used for cooling the inside of the inverter. Liquid cooling enables new applications in the environments where heat is difficult to be dissipated.

Features

- Effective solution for downsizing of the enclosure

A smaller enclosure can be used since the quantity of the heat dissipated in the enclosure is reduced. - Dedicated monitoring functions

A sensor (flow switch) is attached at the inlet of coolant to send a signal to the inverter. When the coolant flow rate decreases, a warning is output, enabling quick, direct detection of system faults. - Lineup of 690 V class inverters

The power supply voltage of 690 VAC is supported. A wider range of power supply voltage is covered.

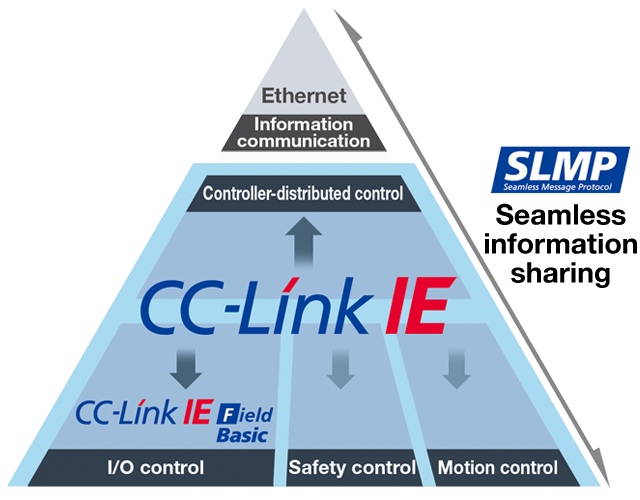

- The following functions (protocols) are available via general-purpose Ethernet communication.

- CC-Link IE Field Network Basic

- MELSOFT / FA product connection

- SLMP*1

- MODBUS/TCP

- *1SLMP is a common protocol for seamless communication between applications. Users do not have to be concerned with network layers or boundaries.

- *2MELSOFT / FA product connection, SLMP, etc.

What is CC-Link IE Field Network Basic?

CC-Link IE Field Network Basic is a new application of the lineup for CC-Link IE (Ethernet-based integrated network). CC-Link IE enables seamless data transfer between network layers, from higher-order information systems to lower-order field systems, which contributes to the visualization of the production data.

- Cyclic communication (communication speed:100 Mbps)

- Integrated Ethernet network in combination with the TCP or UDP IP connection*2 (no need for dedicated control wiring)

- Simple and inexpensive system construction by general-purpose Ethernet without installing any plug-in option

- Remote monitoring

The FR-A800-E-LC inverter can be remotely operated via Ethernet using FR Configurator2, which will be upgraded soon. Parameter setting, monitoring, and maintenance (for example, parts lifespan diagnosis) of the FR-A800-E-LC inverter is possible through network. Adjustment time and downtime of the inverter can be reduced.

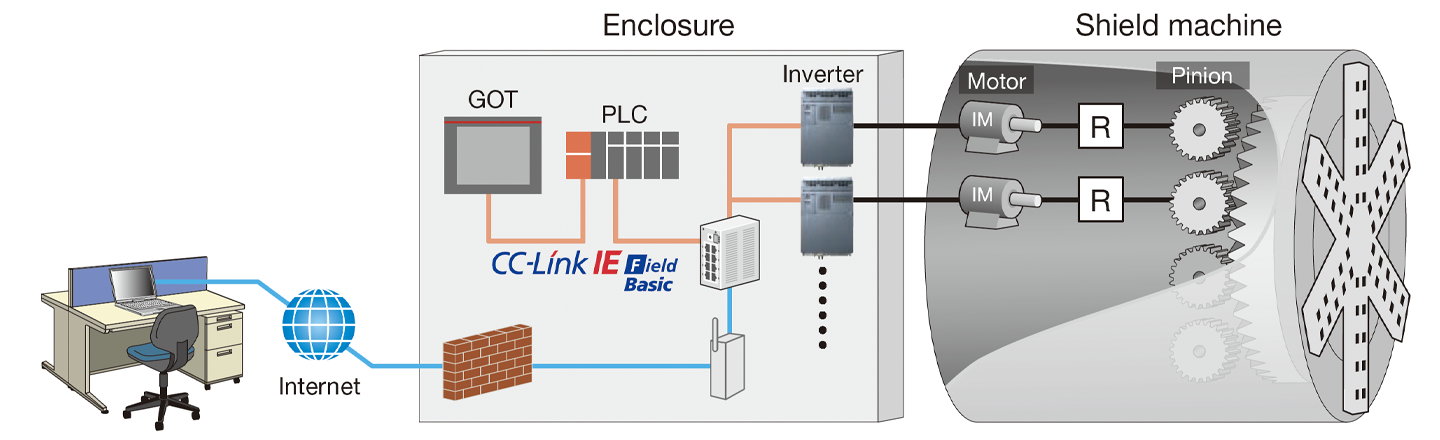

Application examples

Shield machine

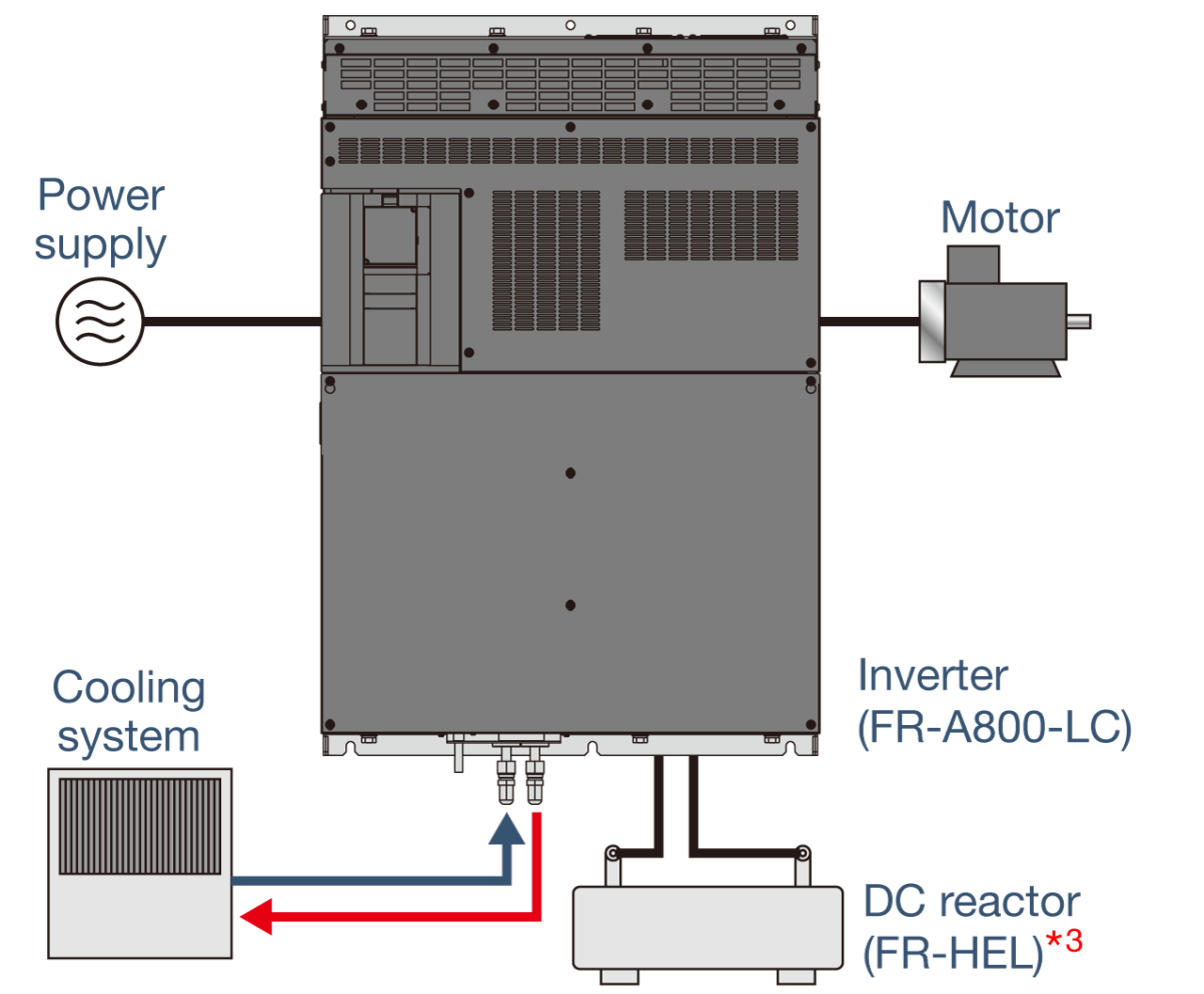

Chiller

System configuration example

*3Always connect a DC reactor appropriate to the applied motor capacity.

Model

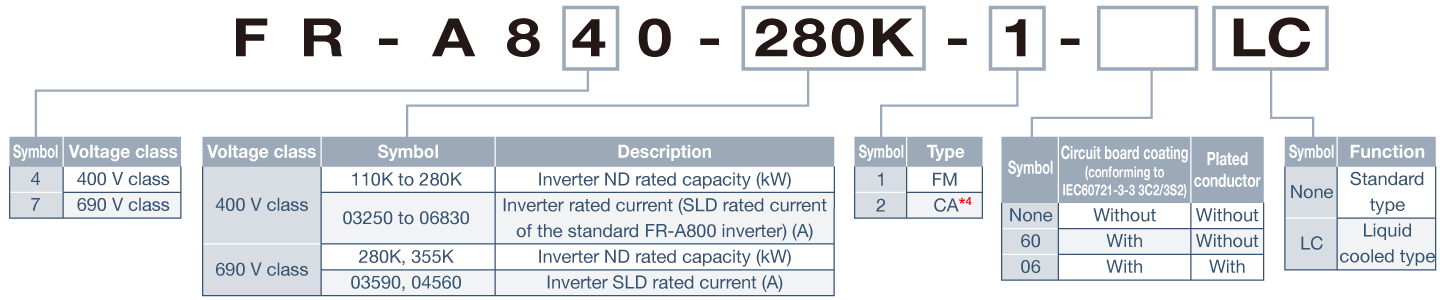

■ Inverter

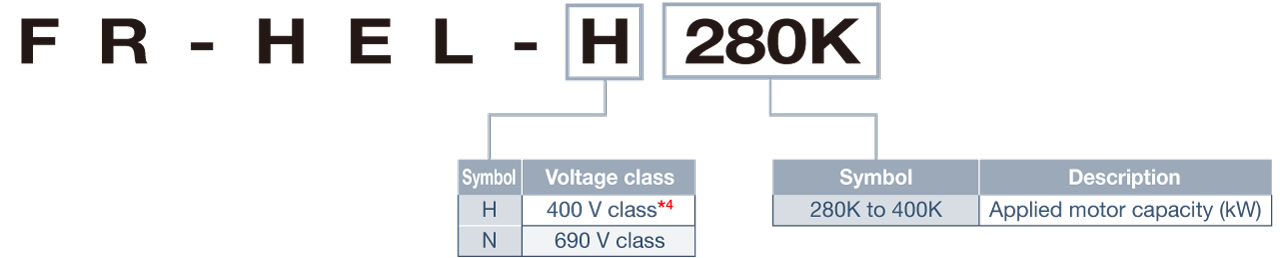

■ DC reactor

- *4For the CA type, the monitor output terminal FM/CA operates as terminal CA (analog current output: 0 to 20 mADC), not as terminal FM (pulse train output).