Product Features

Servo System

- *1. Motion controllers are not supported by MR-JE-B servo amplifiers.

- *2. MR-J5-B(-RJ)/MR-J5W2-B/MR-J5W3-B servo amplifiers support RnMTCPU/RD77MS/Q17nDSCPU/QD77MS.

- *3. A power regeneration converter unit is required for a drive unit.

Servo Amplifiers

A wide range of products includes: MELSERVO-J5 series supporting the new network, CC-Link IE TSN; MELSERVO-J4 series supporting SSCNET III/H; and the one-touch servo, MELSERVO-JN series.

The Mitsubishi Electric's servo amplifiers support motors from rotary servo motors to linear servo motors and direct drive motors, and greatly

enhance system performance.

MELSERVO-J5 series

~Create new value with MELSERVO-J5. Unlock performance with a total drive solution.~

- Maximize system performance

- Progressiveness : For evolution of machines

- Connectivity : For flexible system configurations

- Usability : For quick operation start

- Maintainability: For prompt detection and diagnosis of failures

- Heritage : For utilization of existing devices

MR-J5-G(-RJ) *1

MR-J5W2-G/MR-J5W3-G

CC-Link IE TSN-compatible servo amplifier

Supports Ethernet-based CC-Link IE TSN, featuring high-speed, large-capacity communication (1 Gbps).

Communication cycle of ≥ 31.25 μs and speed frequency response of 3.5 kHz enable advanced motion control.

The 2-axis and 3-axis servo amplifiers are available for operating two and three servo motors, respectively. These servo amplifiers enable an energy-saving and compact machine.

| Command interface | CC-Link IE TSN *2 | |

| Control mode | Position/Velocity/Torque/Fully closed loop control *4 | |

| Power supply specifications | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 7 kW | 0.6 kW to 3.5 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor | |

MR-J5D1-G4 *3

MR-J5D2-G4 *3

MR-J5D3-G4 *3

CC-Link IE TSN-compatible drive unit

The drive unit is a converter separate type servo amplifier (1/2/3-axis type available). Combined with an MR-CV_4 power regeneration converter unit, the drive unit can create an energy-saving servo system.

| Command interface | CC-Link IE TSN *2 |

| Control mode | Position/Velocity/Torque/Fully closed loop control *4 |

| Power supply specifications | 400 V AC |

| Capacity range | 1 kW to 7 kW *5 |

| Compatible servo motor | Rotary servo motor |

MR-J5-B(-RJ) *1

MR-J5W2-B/MR-J5W3-B

SSCNET III/H-compatible servo amplifier

Supports optical network SSCNET III/H. Communication cycle of ≥ 0.222 ms and speed frequency response of 3.5 kHz enable advanced motion control.

The 2-axis and 3-axis servo amplifiers are available for operating two and three servo motors, respectively. These servo amplifiers enable an energy-saving and compact machine.

| Command interface | SSCNET III/H | |

| Control mode | Position/Velocity/Torque/Fully closed loop control *4 | |

| Power supply specifications | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 7 kW | 0.6 kW to 3.5 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor | |

MR-J5-A(-RJ) *1

General purpose interface-compatible servo amplifier

Enables position control by pulse train command and speed/torque control by analog voltage command. The maximum command pulse frequency is 4 Mpulses/s.

| Command interface | Pulse train/Analog voltage | |

| Control mode | Position/Speed/Torque/Fully closed loop control | |

| Power supply specifications | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 7 kW | 0.6 kW to 3.5 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor | |

- *1. MR-J5-G-RJ, MR-J5-B-RJ and MR-J5-A-RJ are servo amplifiers with special specifications. Model Designation

- *2. MR-J5-G(-RJ)/MR-J5D1-G4 are also compatible with CC-Link IE Field Network Basic.

- *3. A power regeneration converter unit is required for a drive unit.

- *4. Fully closed loop control is supported by the following:

・MR-J5-G/MR-J5W2-G

・MR-J5D1-G4/MR-J5D2-G4

・MR-J5-B/MR-J5W2-B - *5. A capacity of 1 kW and 2 kW is available for MR-J5D3-G4.

MR-J5-G-(RJ)N1 *1

MR-J5W2-G-N1/MR-J5W3-G-N1

MR-J5D1-G4-N1/MR-J5D2-G4-N1/

MR-J5D3-G4-N1

EtherCAT®-compatible servo amplifier

EtherCAT®-compatible servo amplifiers are available, enabling higher-performance MR-J5 servo amplifiers with enhanced functions on the EtherCAT® system.

The servo amplifiers *5 support the touch probe. (Latch accuracy: 1 μs)

| Communication specification | CANopen over EtherCAT® (CoE) | |

| Ethernet over EtherCAT® (EoE) | ||

| Safety over EtherCAT® (FSoE) | ||

| Drive profile | CiA 402 | |

| Communication cycle *2 | 125 μs, 250 μs, 500 μs, 1 ms, 2 ms, 4 ms, 8 ms |

|

| Control mode | Cyclic synchronous position mode (csp) | |

| Cyclic synchronous velocity mode (csv) | ||

| Cyclic synchronous torque mode (cst) | ||

| Profile position mode (pp) | ||

| Profile velocity mode (pv) *3 | ||

| Profile torque mode (tq) *3 | ||

| Homing mode (hm) | ||

| Power supply specifications | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 7 kW | 0.6 kW to 7 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor *4 | |

- *1. MR-J5-G-RJN1 are servo amplifiers with special specifications.

- *2. The minimum communication cycle varies by the model type.

- *3. The control modes (pv/tq) are not supported by MR-J5W2-G-N1/MR-J5W3-G-N1/MR-J5D2-G4-N1/MR-J5D3-G4-N1.

- *4. MR-J5D-G4-N1 supports only the rotary servo motors.

- *5. Use MR-J5-G-N1 manufactured in June 2021 or later. Note that, depending on the stock status, the servo amplifiers with both the former and the new specifications may be distributed in the market around the same time. Contact the local sales office when the touch probe function is needed.

MELSERVO-JET series

~All-in-One World Class Servo~

- Optimize system performance

- Easy, Simple & Practical

- Superior Performance

- Better Flexibility

MR-JET-G

CC-Link IE TSN-compatible servo amplifier

Supports Ethernet-based CC-Link IE TSN, featuring high-speed, large-capacity communication

(1 Gbps). Speed frequency response of 2.5 kHz enable advanced motion control.

| Command interface | CC-Link IE TSN *1 |

| Control mode | Position/Velocity/Torque |

| Power supply specifications | 200 V AC |

| Capacity range | 0.1 kW to 3 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor |

- *1. MR-JET-G also supports CC-Link IE Field Network Basic.

MR-JET-G-N1

EtherCAT®-compatible servo amplifier

Configure an EtherCAT® system with the high-performance MR-JET series servo amplifiers.

MR-JET-G-N1 servo amplifiers support EtherCAT®.

| Communication specification | CANopen over EtherCAT® (CoE) |

| Control mode | Cyclic synchronous position mode (csp) |

| Cyclic synchronous velocity mode (csv) | |

| Cyclic synchronous torque mode (cst) | |

| Homing mode (hm) | |

| Power supply specifications | 200 V AC |

| Capacity range | 0.1 kW to 3 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor |

MELSERVO-J4 series

~Man, Machine, and Environment in Perfect Harmony~

MELSERVO-J4 series is the member to the MELSERVO family, backed by Mitsubishi Electric's leadership in all-digital technology.

With safety, Ethernet-based CC-Link IE Field Network, SSCNET III/H high-speed optical communication and energy-efficient design of MELSERVO-J4 series - man, machine, and environment can at last work together in perfect harmony.

MR-J4-GF(-RJ) *1

CC-Link IE Field Network-

compatible servo amplifier

This servo amplifier is compatible with CC-Link IE Field Network. Together with the Simple Motion module, advanced synchronous control and interpolation control by sequential commands are enabled. The servo amplifier has a built-in point table function, offering easy positioning with a combination with a master module.

| Command interface | CC-Link IE Field Network CC-Link IE Field Network Basic |

||

| Control mode | Position/Velocity/Torque/Positioning function/Fully closed loop | ||

| Power supply specifications | 100 V AC | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 0.4 kW | 0.1 kW to 22 kW | 0.6 kW to 22 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor | ||

MR-J4-B(-RJ) *1

MR-J4W2-B/MR-J4W3-B

SSCNET III/H-compatible servo amplifier

A complete synchronous system with SSCNET III/H can be configured using 0.222 ms cycle high-speed serial communication between the controller and the servo amplifier. 2-axis/3-axis servo amplifiers are also available, enabling energy-conservative, less-wiring, compact machine.

| Command interface | SSCNET III/H | ||

| Control mode | Position/Speed/Torque/Fully closed loop *2 | ||

| Power supply specifications | 100 V AC | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 0.4 kW | 0.1 kW to 37 kW | 0.6 kW to 55 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor | ||

MR-J4-A(-RJ) *1

General purpose interface-

compatible servo amplifier

Pulse train and analog input, etc., are provided as a standard for the command interface. The control mode can be switched accordingly for position, speed or torque control. The MR-J4-A-RJ has a built-in positioning function, being compatible with MODBUS®, simple cam, and mark sensor input compensation.

| Command interface | Pulse train/Analog voltage/RS-422/MODBUS® RTU | ||

| Control mode | Position/Speed/Torque/Positioning function/Fully closed loop | ||

| Power supply specifications | 100 V AC | 200 V AC | 400 V AC |

| Capacity range | 0.1 kW to 0.4 kW | 0.1 kW to 37 kW | 0.6 kW to 55 kW |

| Compatible servo motor | Rotary servo motor, linear servo motor, DD motor | ||

MR-J4W2-0303B6

MR-J4-03A6(-RJ) *1

Ultra-small capacity servo amplifier

This servo amplifier is compatible with the ultra-compact HG-AK servo motor series (10 W to 30 W) and two types of main circuit power supply of 48 V DC and 24 V DC, being suitable for compact machines. 2-axis servo amplifiers are also available.

| Command interface | SSCNET III/H or Pulse train/Analog voltage/RS-422 | ||

| Control mode | Position/Speed/Torque | ||

| Power supply specifications | 48 V DC/24 V DC | ||

| Capacity range | 10 W to 30 W | ||

| Compatible servo motor | Rotary servo motor | ||

- *1. MR-J4-GF-RJ, MR-J4-B-RJ, MR-J4-A-RJ and MR-J4-03A6-RJ are servo amplifiers with special specifications. Model Designation

- *2. Fully closed loop control is supported by the following:

・MR-J4-B(-RJ)

・MR-J4W2-B

MELSERVO-JE series

~Reliable Basic Performance and Advanced Ease-of-Use~

[Easy To Use]

- ● Advanced one-touch tuning adjusts servo gains with one-touch ease.

- ● Instantaneous power failure tough drive function and a large capacity capacitor reduce machine downtime.

[High Performance]

- ● The dedicated engine enables speed frequency response of 2.0 kHz, shortening the cycle time.

- ● The large capacity main circuit capacitor allows the regenerative energy to be used effectively.

[Global Standard]

- ● Global servo, MR-JE series, complies with global standards as standard.

- ● Command pulse input and digital input/output are compatible with both sink and source type connections.

MR-JE-B

SSCNET III/H-compatible servo amplifier

MR-JE-B is compatible with SSCNET III/H, optical servo system controller network that enables a high-response and multi-axis system with high synchronous performance and less wiring. In addition, absolute position detection system can be configured easily with the MR-JE-B servo amplifiers.

| Command interface | SSCNET III/H | ||

| Control mode | Position/Speed/Torque | ||

| Power supply specifications | 200 V AC | ||

| Capacity range | 0.1 kW to 3 kW | ||

| Compatible servo motor | Rotary servo motor | ||

MR-JE-A

General purpose interface-

compatible servo amplifier

Pulse train and analog input, etc., are provided as a standard for the command interface. The control mode can be switched accordingly for position, speed or torque control. The MR-JE-A has a built-in positioning function, being compatible with MODBUS®, simple cam, and mark sensor input compensation.

| Command interface | Pulse train/Analog/RS-422/MODBUS® RTU | ||

| Control mode | Position/Speed/Torque | ||

| Power supply specifications | 200 V AC | ||

| Capacity range | 0.1 kW to 3 kW | ||

| Compatible servo motor | Rotary servo motor | ||

Servo Motors

From rotary to linear and direct drive motors

Rotary servo motors are available in capacities from 10 W to 220 kW.

Linear servo motors and direct drive motors satisfy new needs in driving control by providing high rigidity, performance and flexibility in system configurations unique to a direct drive.

Rotary servo motor

A wide range of capacities and series for various system applications

HK series

for MELSERVO-J5 series

HK-KT series

Small capacity, low inertia

The single connector connects the single cable for the power supply, encoder, and electromagnetic brake by one-touch lock.

The servo motors come equipped with a batteryless absolute position encoder, making it possible to configure absolute position systems without the use of batteries.

Capacity: 0.05 kW to 2 kW

Rated speed: 3000 r/min *1

Maximum speed: 6700 r/min *1

[Application example]

● Belt drives ● Robots ● Mounters ● X-Y tables ● Semiconductor manufacturing systems

● Battery manufacturing systems

HK-MT series

Small capacity, ultra-low inertia

The single connector connects the single cable for the power supply, encoder, and electromagnetic brake by one-touch lock.

The servo motors come equipped with a batteryless absolute position encoder, making it possible to configure absolute position systems without the use of batteries. *2

The high-speed type models (maximum speed: 10000 r/min) are also available. *2

Capacity: 0.05 kW to 1 kW

Rated speed: 3000 r/min

Maximum speed: 10000 r/min *1

[Application example]

● Ultra-high-throughput material handling systems ● Inserters ● Mounters ● Sewing machines

● Textile machinery ● Molding machines ● Lithography systems ● Machine tools

HK-ST series

Medium capacity, medium inertia

The cables for the encoder, the electromagnetic brakes, and the power can be connected by one-touch lock.

The servo motors come equipped with a batteryless absolute position encoder, making it possible to configure absolute position systems without the use of batteries.

Capacity: 0.5 kW to 7 kW

Rated speed: 2000 r/min and 3000 r/min *1

Maximum speed: 6700 r/min *1

[Application example]

● Material handling systems ● Robots ● X-Y tables ● Battery manufacturing systems

HK-RT series

Medium capacity, ultra-low inertia

The compact, high power rate servo motors offer high-speed operations.

The servo motors come equipped with a batteryless absolute position encoder, making it possible to configure absolute position systems without the use of batteries.

Capacity: 1 kW to 7 kW

Rated speed: 3000 r/min

Maximum speed: 6700 r/min *1

[Application example]

● Ultra-high-throughput material handling systems ● Inserters ● Mounters ● Sewing machines

● Textile machinery ● Molding machines ● Lithography systems

- *1. The speed varies by the model type.

- *2. The high-speed type models are equipped with an incremental encoder.

HG series

for MELSERVO-JET series

HG-KNS series

Small capacity, low inertia

Perfect for general-purpose industrial machines.

Capacity: 0.1 kW to 0.75 kW

Rated speed: 3000 r/min

Maximum speed: 6000 r/min

[Application example]

● Inserters, mounters and bonders ● PCB drilling machines ● In-circuit testers and label printers ● Knitting and embroidery machines ● Compact robots and robot hand sections

HG-SNS series

Medium capacity, medium inertia

Suitable for machines having large load inertia.

Capacity: 0.5 kW to 3 kW

Rated speed: 2000 r/min

Maximum speed: 3000 r/min *1

[Application example]

● Material handling systems ● Dedicated machines ● Robots ● Loaders and unloaders ● Winders, tension units ● Turrets ● X-Y tables

- *1. The speed varies by the model type.

HG series

for MELSERVO-J4 series

HG-KR series/HG-MR series

HG-KR: Small capacity, low inertia Perfect for general-purpose industrial machines.

HG-MR: Small capacity, ultra-low inertia Perfect for high-throughput operations.

Capacity: 50 W to 750 W

Rated speed: 3000 r/min

Maximum speed: 6000 r/min

[Application example]

● Inserters, mounters and bonders ● PCB drilling machines ● In-circuit testers and label printers ● Knitting and embroidery machines ● Compact robots and robot hand sections

HG-SR series

Medium capacity, medium inertia

Suitable for machines having large load inertia.

Capacity: 0.5 kW to 7 kW

Rated speed: 1000 r/min and 2000 r/min

Maximum speed: 3000 r/min *1

[Application example]

● Material handling systems ● Dedicated machines ● Robots ● Loaders and unloaders ● Winders and tension units ● Turrets ● X-Y tables

HG-JR series

Medium/large/ultra-large capacity, low inertia

Perfect for high-throughput positioning or high acceleration/deceleration operations.

Capacity: 0.5 kW to 220 kW

Rated speed: 1000 r/min, 1500 r/min, 2000 r/min and 3000 r/min

Maximum speed: 6000 r/min *1

[Application example]

● Food packaging machines ● Printers ● Injection molding machines ● Press machines

HG-AK series

Ultra-compact size, ultra-small capacity with flange size of 25 mm. Suitable for small machines.

Capacity: 10 W to 30 W

Rated speed: 3000 r/min

Maximum speed: 6000 r/min

[Application example]

● Mounters and bonders ● Semiconductor manufacturing equipment ● Compact robots ● Electric component manufacturing machines ● Compact X-Y table

HG-RR series

Medium capacity, ultra-low inertia

Perfect for high-throughput operation.

Capacity: 1 kW to 5 kW

Rated speed: 3000 r/min

Maximum speed: 4500 r/min

[Application example]

● Roll feeders ● Loaders and unloaders ● Ultra high-throughput material handling systems

HG-UR series

Medium capacity, flat type

Perfect for applications with limited mounting space.

Capacity: 0.75 kW to 5 kW

Rated speed: 2000 r/min

Maximum speed: 3000 r/min *1

[Application example]

● Robots ● Conveyors ● Winders and tension machines ● Food processing machines

- *1. The speed varies by the model type.

HG series

for MELSERVO-JE series

HG-KN series

Small capacity, low inertia

Perfect for general-purpose industrial machines.

Capacity: 0.1 kW to 0.75 kW

Rated speed: 3000 r/min

Maximum speed: 5000 r/min *1

[Application example]

● Inserters, mounters and bonders ● PCB drilling machines ● In-circuit testers and label printers ● Knitting and embroidery machines ● Compact robots and robot hand sections

HG-SN series

Medium capacity, medium inertia

Suitable for machines having large load inertia.

Capacity: 0.5 kW to 3 kW

Rated speed: 2000 r/min

Maximum speed: 3000 r/min *2

[Application example]

● Material handling systems ● Dedicated machines ● Robots ● Loaders and unloaders ● Winders, tension units ● Turrets ● X-Y tables

- *1. The speed can be set to 6000 r/min with the parameter of servo amplifiers.

- *2. The speed varies by the model type.

Linear servo motor

Suitable for linear motion systems requiring high speed and accuracy

LM series

for MELSERVO-J5 series/MELSERVO-J4 series/MELSERVO-JET series

LM-H3 series

Core type

Core type suitable for space-saving, high speed and high acceleration/deceleration.

Maximum speed: 3 m/s

Rated thrust: 70 N to 960 N

LM-AJ series

Core type

Low installation height, and suitable for compact X-Y tables.

Maximum speed: 2 m/s to 6.5 m/s

Rated thrust: 68.1 N to 446.8 N

LM-F series

Core type (natural/liquid cooling)

Compact core type linear servo motors.

The integrated liquid-cooling system doubles the continuous thrust.

Maximum speed: 2 m/s

Rated thrust: 300 N to 3000 N (natural cooling), 600 N to 6000 N (liquid cooling)

LM-K2 series

Core type with magnetic attraction counter-force

Longer life of the linear guides due to the magnetic attraction counter-force structure.

Low audible noise.

Maximum speed: 2 m/s

Rated thrust: 120 N to 2400 N

LM-U2 series

Coreless type

No cogging, small speed fluctuation.

No magnetic attraction force, longer life of the linear guides.

Maximum speed: 2 m/s

Rated thrust: 50 N to 800 N

LM-AU series ![]()

Coreless type

No cogging, small speed fluctuation.

No magnetic attraction force, longer life of the linear guides.

Maximum speed: 2 m/s to 4.5 m/s

Rated thrust: 28 N to 350 N

Application Example

- Machine tools XYZ stage

- Semiconductor/FPD manufacturing systems

Electrical parts assembling/manufacturing systems

- Screen printing systems and large FPD coaters

- Material handling systems

- Multi-head material handling between machines

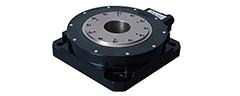

Direct drive motor

For compact and simplified machine driving part with high-accuracy control

TM series

for MELSERVO-J5 series/MELSERVO-J4 series

TM-RG2M series

Low-profile flange type

Low-profile for space and weight saving

Motor outer diameter: ø130 mm, ø180 mm, ø230 mm

Rated torque: 2.2 N·m to 9 N·m

TM-RU2M series

Low-profile table type

Low-profile for space and weight saving

Motor outer diameter: ø130 mm, ø180 mm, ø230 mm

Rated torque: 2.2 N·m to 9 N·m

TM-RFM series

High-rigidity

High torque for high-weight capacity

Motor outer diameter: ø130 mm, ø180 mm, ø230 mm, ø330 mm

Rated torque: 2 N·m to 240 N·m

Application Example

Suitable for low speed and high torque applications.

- Coating and vapor deposition systems

- Spin-type cleaning systems for FPD/semiconductor

- FPD/semiconductor testing systems (XYθ tables)

- Index table for machine tools

- Rotary axis for polishing systems

- Rotary axis for material handling robots

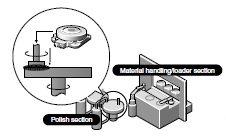

Servo System solutions

Industry leading performance MELSERVO supports various system configurations.

Going beyond servo amplifiers and servo motors, Mitsubishi Electric offers system level solutions that include programmable controllers, Motion controllers, and networks to satisfy a broad scope of needs.

![]()

Improve productivity and realize flexibility in different automotive assembly lines with high-accuracy motion control, including linear/circular interpolation and electric cam profile.

![]()

Realize advanced logistics coordination and eliminate errors in repetitive processes. Servo-based high-speed material handling and highly accurate positioning improve productivity and reduce energy consumption.

![]()

Realize improvements in various packaging applications such as high-speed filling, which requires a highly accurate, continuous feed rate and precision.

![]()

In today's semiconductor manufacturing process, wafer diameter is getting larger and components smaller. To meet the requirements of higher quality and productivity, Mitsubishi Electric's high-performance servos and high-resolution encoder achieve fast and accurate positioning at stable speeds.

![]()

Flexible mounting of electronic components with high speed and density is demanded in printed circuit board applications. Mitsubishi Electric offers a high level of servo system solutions for rapid mounting of highly miniaturized components and for flexible mounting of irregular shapes.

![]()

In addition to the high-speed and high-accuracy positioning control, linear servos and a broad array of other actuators play important roles in the manufacturing of constantly evolving flat panel displays.

![]()

Mitsubishi Electric provides high-accuracy synchronous system solutions for the paper feeding, printing, cutting, and assembly functions within the printing process, achieving high-speed and high-quality converting applications.

![]()

The integrated system with the advanced motion control supports high-accuracy molding in injection molding machines, which consist of various control sections.

![]()

High-performance servos enable fast and accurate positioning, and support high-speed handling of works. We promote the sophisticated machining capabilities that are a key part of the world's most advanced manufacturing.