Human-Machine Interfaces(HMIs)-GOT GOT SIMPLE Series

Reduce design, setup, and maintenance cost

Reduce mass production installation setup costs

Start from SD memory card

Transfer the screen data and all the necessary system data to make a GOT operate to a SD memory card in advance. Then the GOT can be used just by inserting the SD memory card. Useful for replacement or maintenance of GOT.

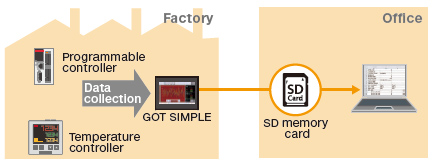

Industrial devices data collection

Logging function

GOT manages the data of all connected industrial devices. The data can be collected at any arbitrary timing and can be used for data analysis and feedback.

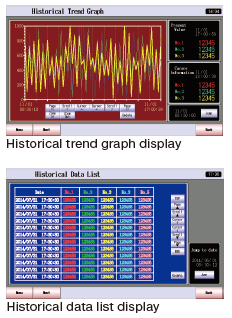

Logged data can be displayed on the GOT as a graph, so status change such as temperature change can be understood in a single glance.

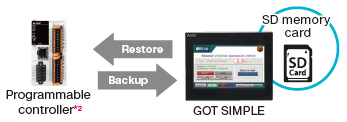

Backup important programs

Backup/Restoration function

Sequence programs can be replaced even without a personal computer. When the programs and parameters are backed up to GOT*1, the data and machine operation can instantly be restored even if an unexpected failure occurs.

- *1A separate SD memory card is required.

- *2The target connection devices are QCPU, LCPU, FX5CPU and FXCPU.

For the details of connectable devices, please refer to the

Setup and modification on-site

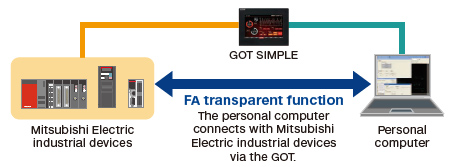

FA transparent function

Set up and modify devices without changing cable connections.

The GOT acts as a transparent gateway to enable programming, start up, and adjustment of Mitsubishi Electric industrial devices.

Remote maintenance

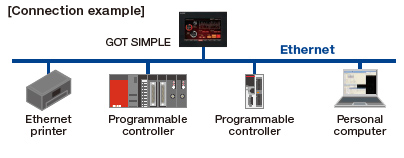

Ethernet connection

Office personal computer can connect to GOT on the factory floor for maintenance via Ethernet. With Ethernet, it is possible to connect a system of mixed vendors and models, expanding the possibilities at the factory floor. In addition, Ethernet printers*1 are supported so that the data (such as reports and screen images) can be printed by an Ethernet printer on the network, thus reducing hardware cost.

- *1For the connectable printers, please refer to the Technical Bulletin (GOT-A-0160).

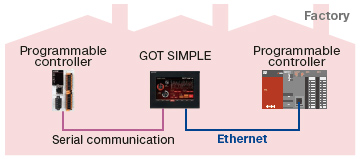

Use GOT SIMPLE to control industrial devices

Multi-channel function

GOT supports various industrial devices and connection types. With the multi-channel function, two channels of industrial devices can be monitored on a single GOT.

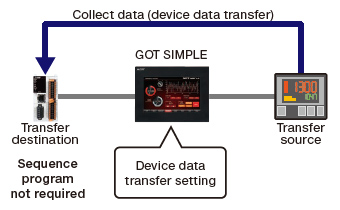

Easily collect data from connected devices

Device data transfer function

Using GT Works3, simply set source devices, destination devices, and triggers and you can transfer data between industrial devices. Data on the connected devices can be collected in the programmable controller without a sequence program.

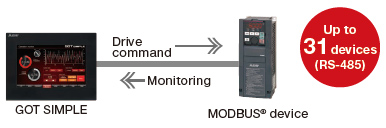

MODBUS®communication also supported

MODBUS®communication

As a master station, GOT can communicate with a MODBUS®/RTU slave device. Up to 31 devices (RS-485) can be connected for monitoring of production line, etc.

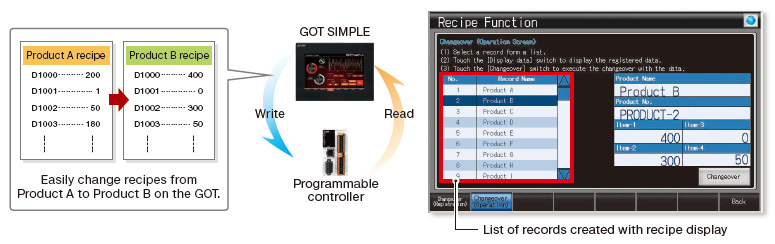

Simple, easy-to-understand setup

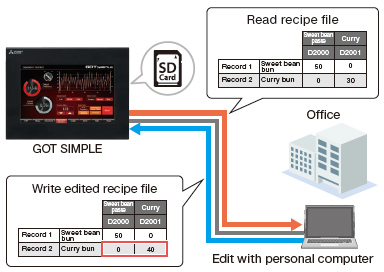

Recipe function & recipe display (record list)

GOT saves the recipe information (device values) such as material blend and machine conditions. You can change the recipe on the GOT and write it to a programmable controller to quickly perform the changeover. Changing recipes (changeover) is easy on a user-created screen or on the utility screen. The users can easily create screens by using the recipe display (record list).

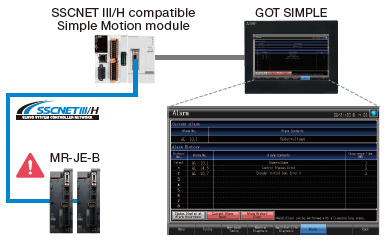

Display industrial devices alarms

Alarm function

Use the GOT to display and check alarms set by the users. Alarms of the connected device can be monitored and the equipment status can be checked. When a problem occurs, you can quickly troubleshoot the problem.

Increase efficiency of maintenance work

Reading/writing resource data

The GOT resource data can be read out to the personal computer, corrected, and then written back*1. The efficiency of maintenance work is enhanced as there is no need to exchange data with an SD memory card.

- *1For the details on resource data that can be read and written, please refer to the

Monitor device value and set values for timer, etc.

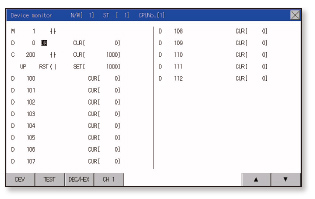

Device monitor function

Monitor and change internal device ON/OFF status, word values, timer and counter values of connected devices such as MELSEC programmable controllers.

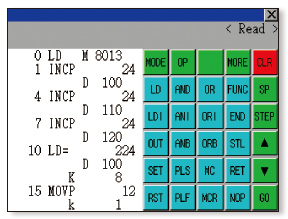

Program change without a personal computer on-site

MELSEC FX list editor

With the GOT, sequence programs of FX Series programmable controllers*1 can be edited in the list format.

Convenient for minor on-site program changes.

- *1FX5CPU is not supported. For the details of connectable devices, please refer to the