Energy Measuring Unit EcoMonitorLight

Product Line Up

| Model | Standard Model | High Performance Model | General current transformer Model | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model name | EMU4-BD1-MB | EMU4-HD1-MB | EMU4-FD1-MB | ||||||||||||||||||||||||||||

| Appearance |  |

|

|

||||||||||||||||||||||||||||

| Function |

|

|

|

Optional unit

| Model | Logging Unit | CC-Link Communication Unit |

CC-Link IE Field Network Basic Communication Unit | MODBUS TCP Communication Unit *1 |

|---|---|---|---|---|

| Model name | EMU4-LM | EMU4-CM-C | EMU4-CM-CIFB | EMU4-CM-MT |

| Appearance |  |

|

|

|

| Function | Collect measurement data into a SD memory card from EcoMonitorLight. | Connect to CC-Link communication. | Connect to CC-Link IE Field Network Basic communication. | Connect to MODBUS TCP communication. |

*1 This unit is applicable to only General current transformer Model (EMU4-FD1-MB).

Features

Easy and Low-Cost Measurement

Simple Measurement/Installation

The built-in LCD screen enables the settings, measurements, and displays required for measuring energy with a single unit.

Easy to install inside of the panel by using IEC rail.

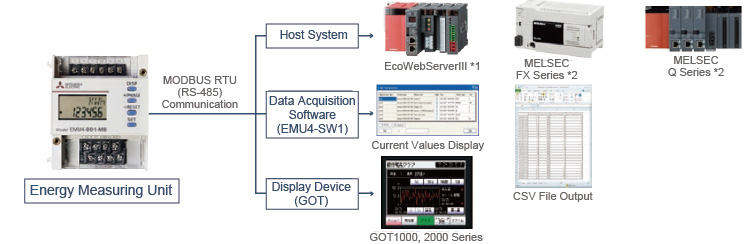

MODBUS RTU (RS-485) Communication as Standard Equipment

Providing MODBUS RTU (RS-485) Communication as standard equipment allows you to connect with the functions listed below, and use it for energy management and as a system terminal.

![]() Host systems (such as EcoWebServerIII*1 or PLC*2, etc.)

Host systems (such as EcoWebServerIII*1 or PLC*2, etc.)

![]() Data Acquisition Software (EMU4-SW1)

Data Acquisition Software (EMU4-SW1)

![]() Display device (GOT)

Display device (GOT)

- *1: A unit compatible with MODBUS TCP <-> MODBUS RTU is required if connecting with a EcoWebServerIII.

- *2: A unit compatible with MODBUS RTU (RS-485) communication is required if connecting with a PLC.

Data Acquisition Software (EMU4-SW1) can be downloaded for free from here.

Expansion by use of Logging and Communication Units

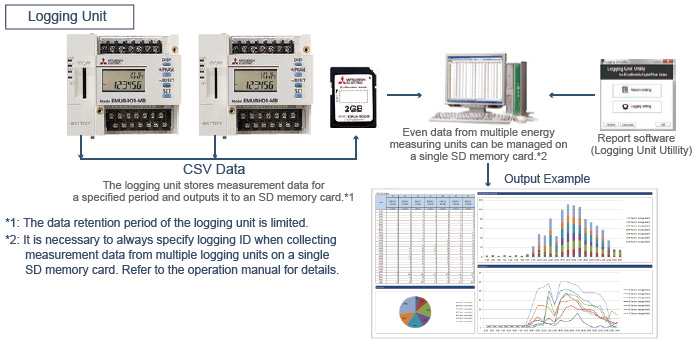

Logging Unit

Use of a logging unit allows you to output various energy (such as current, voltage and power) data measured by the energy measuring unit in CSV file format on an SD memory card for easy data management.

Logging Unit Utility can be downloaded for free from here.

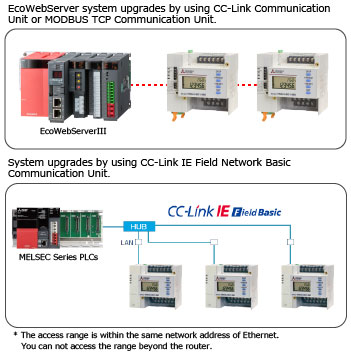

Communication Unit (CC-Link Communication)

A communication unit can be connected to the system using CC-Link communication for system upgrades.

Communication Unit (CC-Link IE Field Network Basic Communication)

A communication unit can be connected to the system using CC-Link IE Field Network Basic communication (Ethernet) for system upgrades.

Communication Unit (MODBUS TCP Communication)

A communication unit can be connected to the system using MODBUS TCP communication (Ethernet) for system upgarades.

* This unit is applicable to only General current transformer Model (EMU4-FD1-MB).

Measurement Functions

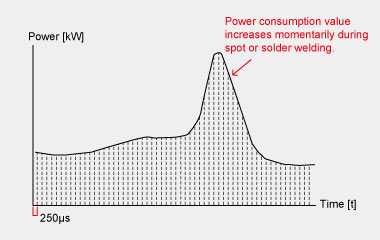

High-Precision Measurement

The continuous measurement of energy at sampling cycles of approximately 250 µs allows for measuring even short-cycle loads such as that for spot or solder welding.

* Data of measured values, including power use as well as voltage, current and similar items, is acquired at update cycles of 250 ms.

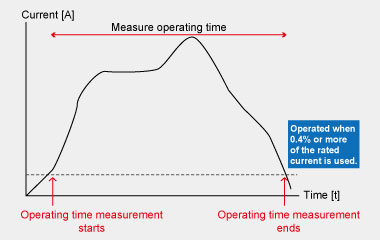

Operating Time Measurement

The current measurement time can be calculated in seconds and the equipment operating time can be displayed in hours (h) in order to utilize the data in diagnosing production equipment service life and for performing preventive maintenance.

* Operating time can also be output to the host system as CSV data.

Advantage of High-Precision (Short-Cycle)

Measurement

It is possible for measurements to be missed when performing continuous measurement of short-cycle loads because the power used for spot or solder welding is used for an extremely short period. The EcoMonitorLight provide high-precision measurement so that the measurements of short-cycle loads are not missed.

Operating Time Measurement

with Specified Inputs as a Trigger

You can specify contact inputs to the energy measuring unit (High Performance Model only) as triggers for the start and end of operating time in order to be able to measure operating time according to actual equipment operation.

Support Functions

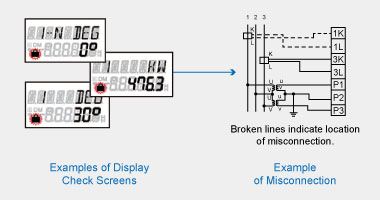

Misconnection Determination Support

This function displays items such as current and voltage phase angles, and energy, current and voltage values for each phase. By checking each displayed value, distinction of whether there is a misconnection in current or voltage input used for measuring is supported.

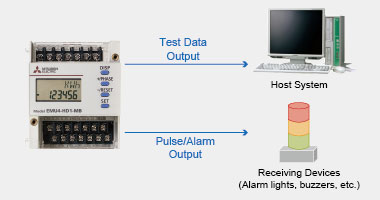

Test Function

This function enables communication of test data to the host system without voltage or current input. By enabling alarm and pulse test signal output, it becomes easy to check wiring and perform system testing.

* The above examples are sample images.

Refer to the operation manual for actual screens, the check method, directions for use, etc.

* Refer to the operation manual for the table for distinction.