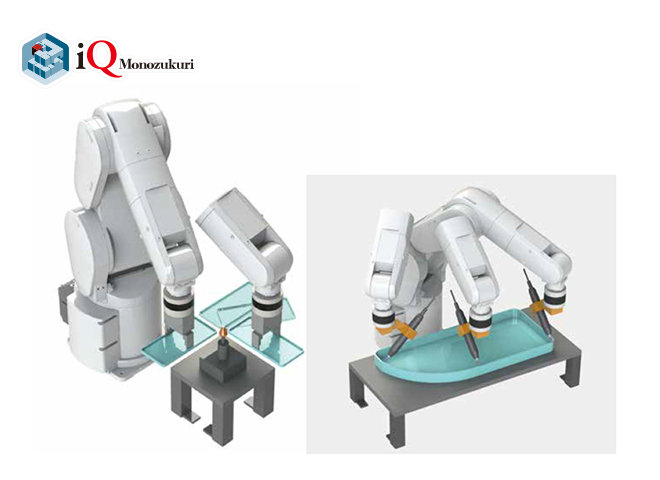

FA Application Package iQ Monozukuri Deburring / Polishing Application

Introduction

Easily creates a machining path of deburring/polishing and performs machining.

On-site operators can automate their teaching process with rough teaching using a master workpiece and tools. (Supported robots: RV-F series)

*Mar 31, 2024 to be discontinued.

Advantages

- On-site operators can create a machining path at their sites.

- Teaching can be easily performed wiht the simple configuration.

- Compared with the offline teaching that uses an actual workpiece, the statup time has decreased by 80%.