Product Features

Product Features

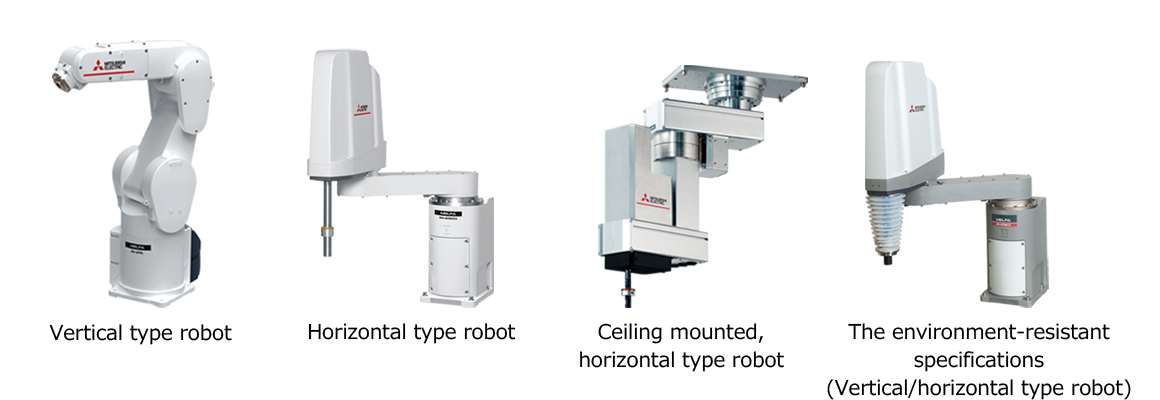

Industrial Robots

- With a wealth of operating areas and variations, it is the perfect fit for a variety of applications.

- Ideal for a wide range of fields, from high-volume production of foodstuffs and pharmaceuticals that demands fast operation, through to assembling components where high levels of precision are required.

- Designed to withstand environmental conditions, making it ideal for a wide range of applications without having to worry about the installation environment.

Show details of Industrial Robots

Cataloges

Please refer to the catalogs for details