Products

MELFA-3D Vision

MELFA-3D Vision

This 3D vision sensor for small robots is small and performs high-speed and high-accuracy measurements.

This sensor is optimal as a replacement for a parts feeder.Its unique model-less recognition processing enables high-speed picking.

Lightweight and Compact

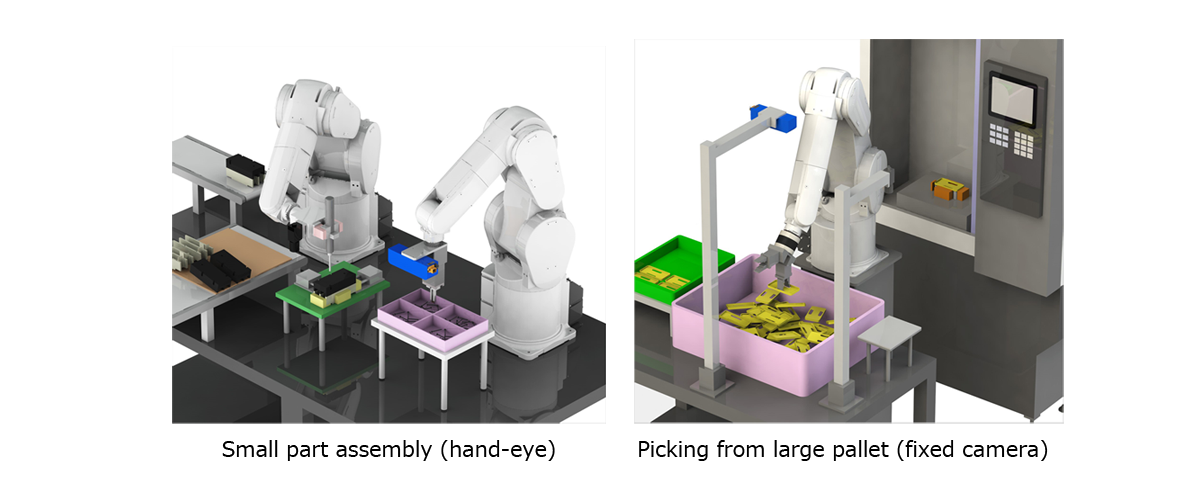

Smaller and more lightweight, equipped with ENSENSO camera head. Both hand-eye and fixed installation are available.

Additionally, the camera itself supports oil mist environments (IP65/IP67), and increased workpiece distance and visual field allow for broader application.

It flexibly supports everything from precision assembly of small parts to bulk picking from large pallets.

High-speed Picking

High-speed recognition technology reduces the time required for image recognition.

Choose between modelless recognition for high-speed picking and model matching recognition for accurate recognition of workpiece position and orientation according to application.

Model matching recognition

A method of recognizing workpiece grip by registering the shape of the hand tip and suction pad and looking for a space to insert the tip or where the pad can stick.

The shape of the workpiece does not need to be registered.

Modelless recognition

A method of recognizing workpiece grip by registering the shape of the workpiece using a 3D CAD model and looking for workpieces matching that model.

This allows the grip location and orientation of the workpiece to be specified.

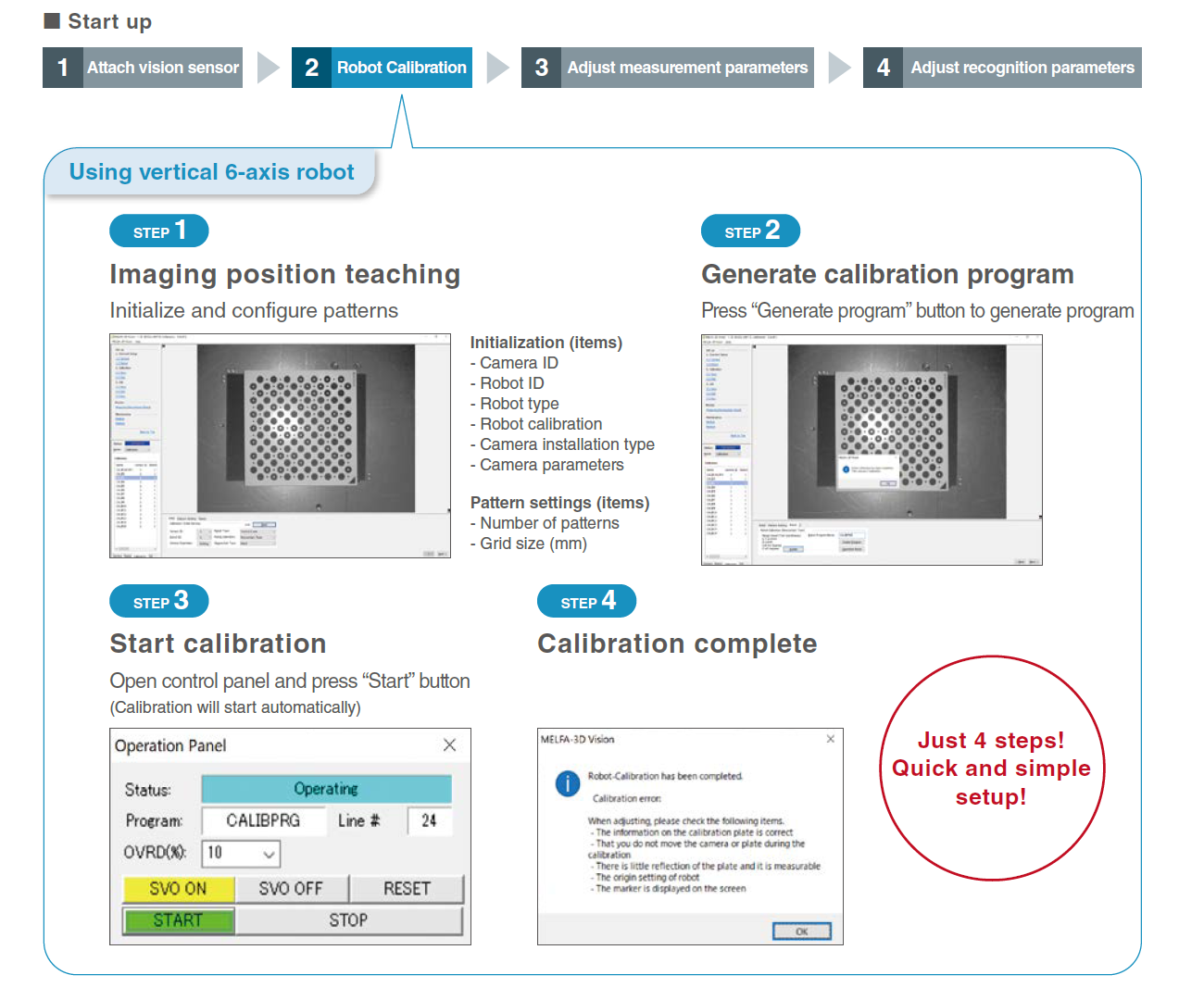

Auto Calibration Function

Equipped with an auto calibration function to automatically align the robot and vision sensor. This simplifies adjustment work.

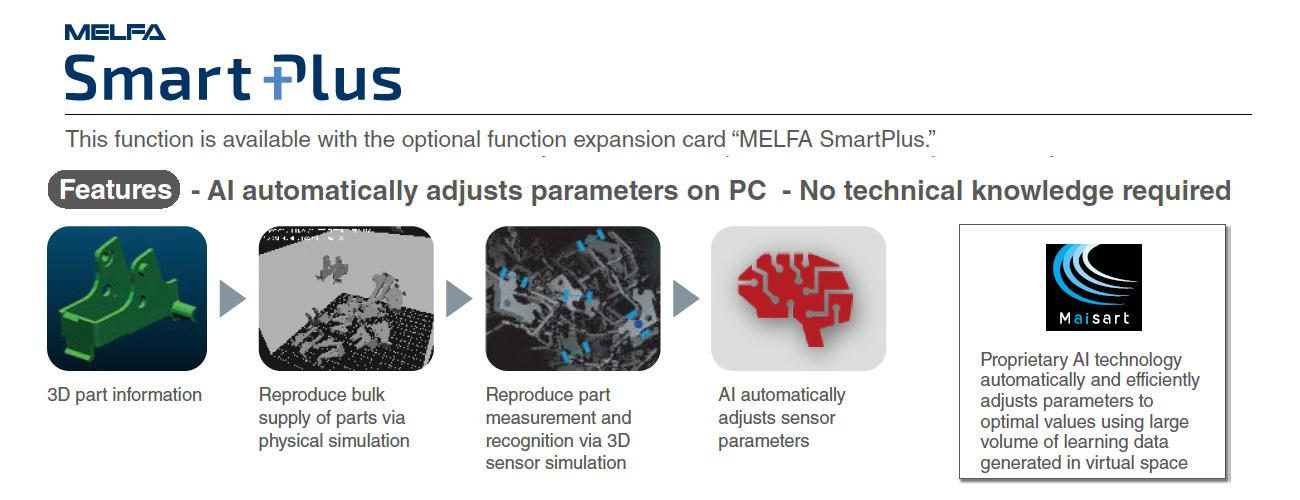

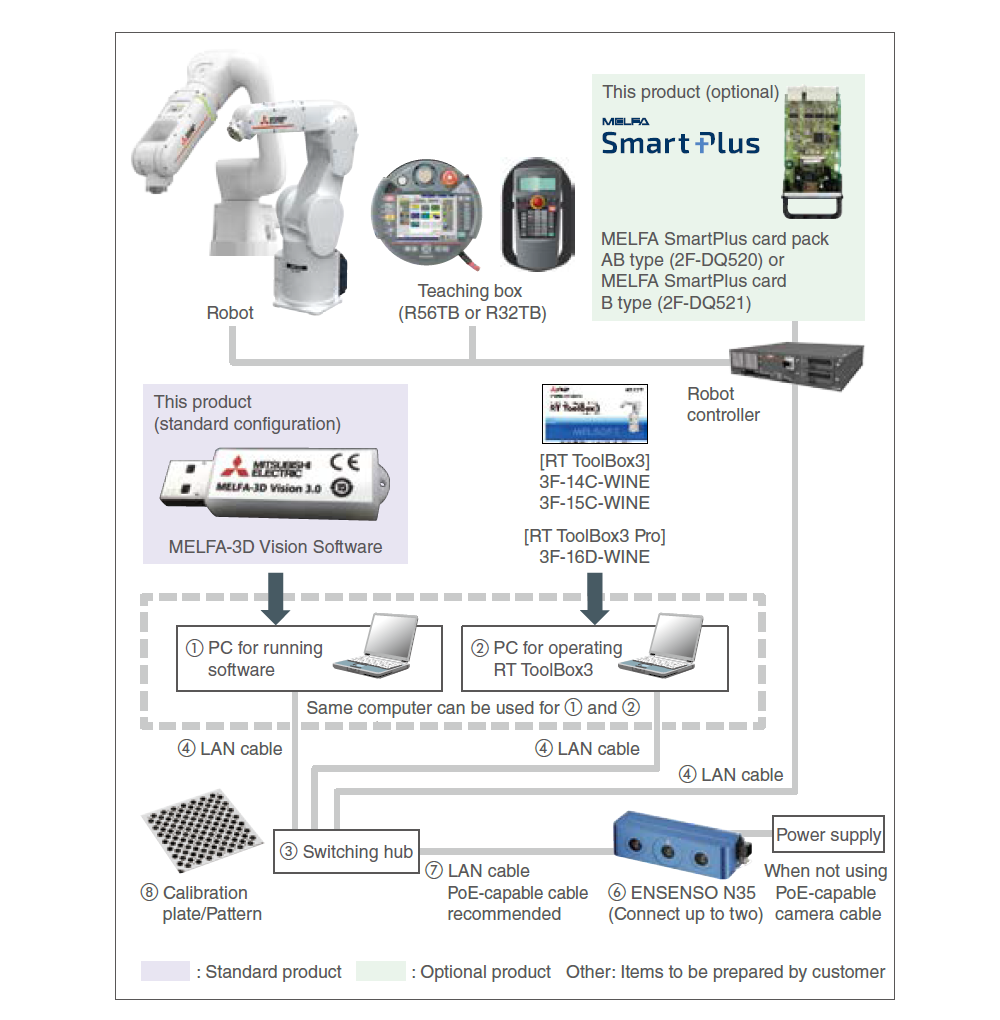

MELFA Smart Plus

This function is available with the optional function expansion card “MELFA SmartPlus.”

*Models supporting vision sensors: N35-804-16-IR, N35-806-16-IR, N35-808-16-IR

Recognized parameter auto adjusting AI

AI automatically adjusts the 3D sensor parameters (image processing parameters, grip position recognition parameters) to the optimal values in the virtual space.

Easy adjustment of complex parameters using 3D CAD data without a camera head.

Substantially reduce the time required for vision sensor parameter adjustments.

Show details of MELFA Smart Plus MELFA-3D Vision enhancement function

Product Components

Cataloges

Please refer to the catalogs for details

Manufacturer website

You can select the optimal camera for the workpiece distance and measuring range of IDS Imaging Development Systems GmbH website. (Camera selection tool)

Check with IDS Imaging Development Systems GmbH for details.