News Release Archives

Note that the releases are accurate at the time of publication but may be subject to change without notice.

FOR IMMEDIATE RELEASE No.2819

Mitsubishi Electric Develops Micro Glass-processing Technology Incorporating Pulsed CO2 Laser

Achieves world's smallest holes with diameters of just 25 microns

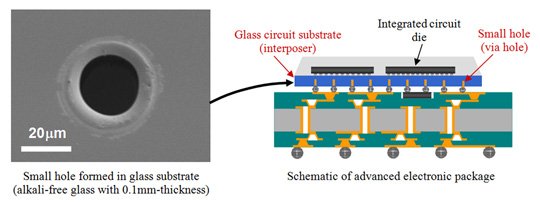

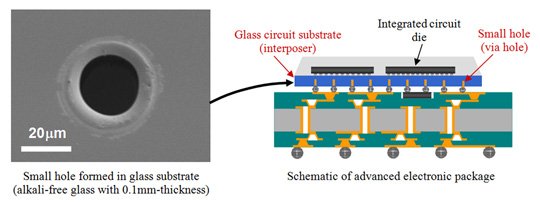

TOKYO, February 13, 2014- Mitsubishi Electric Corporation (TOKYO: 6503) announced today it has developed micro glass-processing technologies that use a pulsed CO2 laser to drill the world's smallest holes measuring just 25 microns in diameter (1 micron equals 1/1,000 millimeter) in glass substrate. The technology is expected to enhance the use of glass circuit substrates for the improved performance of electronic devices.

A far-infrared CO2 laser with a wavelength of about 10 microns is used to drill transparent glass. Short laser pulses lasting 1/1,000,000th of a second can reduce heating of the glass substrate during the drilling. Surface treatment technology is applied to suppress the over-enlargement of drilled holes. Some 200 holes per second can be drilled using a high precision, high-speed galvano mirror to scan the laser beam. CO2 lasers, which can easily be geared to high-power, are used widely in industry and offer vastly improved productivity compared to conventional ultraviolet laser oscillators characterized by high cost and limited light-harvesting properties.

Patents

Pending patents for the technology announced in this news release number three in Japan.

Patents

Pending patents for the technology announced in this news release number three in Japan.

Inquiry

Customer Inquiries

Mitsubishi Electric Corporation