Initiatives that contribute to addressing social challenges

Building Systems Group

Message from the Group President

Making the Most of the Mitsubishi Electric Group’s Advanced and Environmental Technologies to Provide Solutions that Satisfy Customers in All Aspects of Safety, Comfort, Efficiency and the Environment

Iwao Oda

Senior Executive Officer,

Group President, Building Systems

As of July 2023

The Building Systems Group manufactures building management systems and elevators and escalators that provide vertical transportation within buildings. As part of our mission to deliver products and systems and the subsequent maintenance thereof, we believe it is important to give priority to the safety and security of our customers throughout the product lifecycle. In doing so, we help to create a comfortable, sustainable society through our products and services. Maintaining this promise, the Building Systems Group is focused on the following initiatives:

- Pursuing user-friendly, eco-conscious products

- Promoting the development of high-efficiency, energy-saving products and technologies, and saving resources by designing products and systems that are safe and easy to use for everybody.

- Promoting the renewal of existing equipment and facilities in order to reduce power consumption and improve safety and convenience, and minimizing waste emissions by reusing parts whenever possible.

- Offering one-stop ZEB*1 solutions

- As a registered ZEB planner*2, Mitsubishi Electric offers one-stop solutions, from support for the design of ZEBs to services that contribute to customers’ energy-saving efforts after the start of operations. We also support initiatives to improve the added value of buildings beyond a higher level of energy efficiency.

- *1 A building where the net consumption of fossil fuel energy is zero or roughly zero, offset by energy savings and the utilization of renewable energy resources.

- *2 A registration system introduced by the Ministry of Economy, Trade and Industry in 2017 for the dissemination of ZEB.

- Contributing to smart buildings*3 and smart cities*4

- Mitsubishi Electric contributes to the construction of smart buildings and smart cities by providing building operation support services via our IoT platform.

- *3 Buildings where people feel safe and comfortable and can work efficiently that also solve social challenges through energy and labor savings achieved with in-building data collected using IoT technology.

- *4 Cities with optimized urban infrastructure and facility management operations as well as increased convenience and comfort for businesses and consumers. AI is used to analyze big data generated from facilities, the environment, and consumer behavior data in order to remotely control facilities and equipment.

| Major social challenges for which risks and opportunities have been recognized and evaluated | Priority SDG initiatives |

|---|---|

|

|

Initiatives that contribute to addressing social challenges

Pursuing Comfortable, Safe and Secure Elevator Transport and Contributing to Smart Buildings

・AXIEZ-LINKs Series: Standardized Elevators for the Japanese Market

AXIEZ-LINKs, the Japanese market standard model elevator launched in October 2020, is newly equipped with a "connect with people function" that increases operational efficiency and comfort, a "connect with buildings function" that connects elevators to building facilities, and a "connect with city" function that collectively manages the elevators in multiple buildings. Together, these functions contribute to the realization of smart buildings.

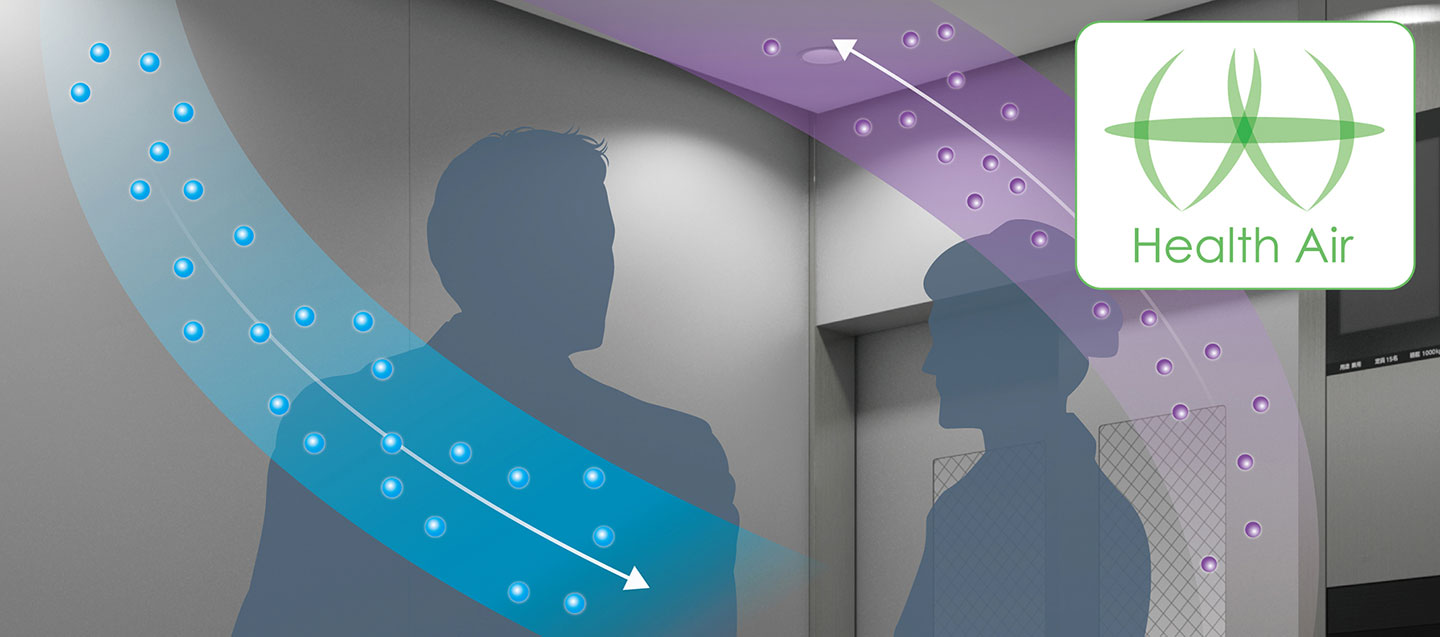

The "connect with people" function can optimize the operation of multiple elevators according to the flow of people into buildings as predicted by Mitsubishi Electric’s AI technology. The elevators are standard-equipped with circulation fans featuring Mitsubishi Electric’s trademark Health Air® function*1 that controls airborne substances, buttons with anti-viral properties, buttons that can be actuated without contact, and a smartphone service*2 that allows users to operate elevators without touching surfaces for a clean, comfortable ride. The elevator system also provides announcements in four languages even in emergencies, offering overseas visitors peace of mind.

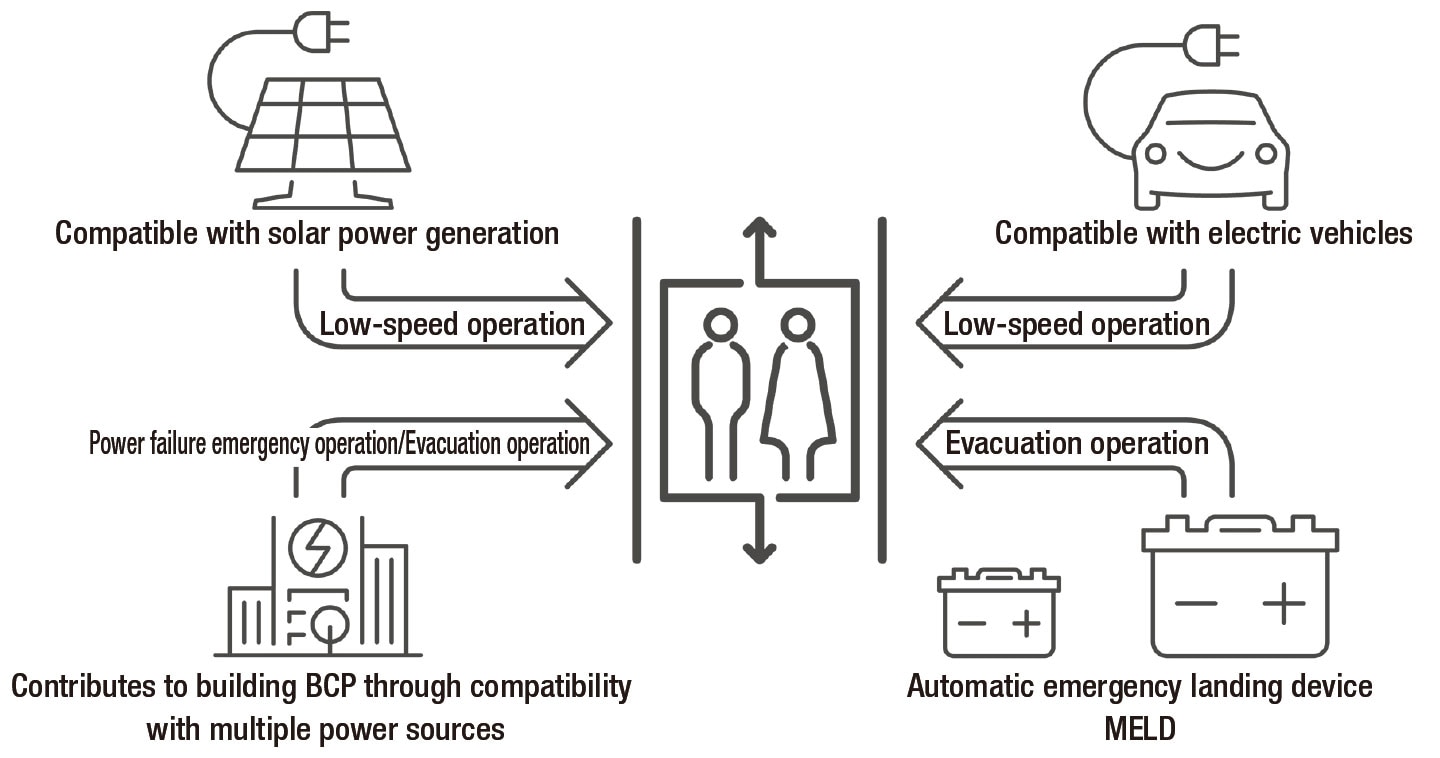

The "connect with buildings" function contributes to BCP*3 through its multiple power source function that enables the elevators to receive power from solar power generation systems and electric vehicles. The elevators can connect to service robots that perform security, cleaning and transport services via Mitsubishi Electric’s IoT platform "Ville-feuille®"*4 to achieve manpower savings and to prevent congestion.

The "connect with the city" function achieves integrated management of elevators and building facilities across multiple buildings by connecting with the building integration solution "BuilUnity"*5. We also have debuted a larger seven-person elevator size that can comfortably transport a wheelchair to support barrier-free access.

- *1 Mitsubishi Electric’s proprietary technology for controlling airborne substances by creating an electric field and discharging space in the area.

- *2 Separately requires a maintenance contract with Mitsubishi Electric Building Solutions Corporation.

- *3 BCP: Business Continuity Plan

- *4 Mitsubishi Electric’s IoT open platform that can gather and accumulate data generated within a building for use as needed.

- *5 A building integration solution that manages building security, including facility monitoring as well as facility control, access control, and video monitoring.

Circulating fan equipped with the Health Air® function: The elevator car is kept comfortable continuously with the Health Air® function, which creates a curtain-like electric field and discharge space to control various airborne substances, and a deodorizing filter.

-

Contactless elevator buttons:

Register the elevator call by raising your hand to the button without contact -

Anti-viral, anti-bacterial:

The buttons in the elevator car and hall now have anti-viral, anti-bacterial properties. You can use the elevators with greater peace of mind knowing that all parts you may touch are anti-viral and anti-bacterial.

Smartphone service:

Using a dedicated smartphone app, you can now automatically call for an elevator without using your hands and automatically register the floor you are headed to. Smartphone linkage makes our elevators more convenient and comfortable than ever before.

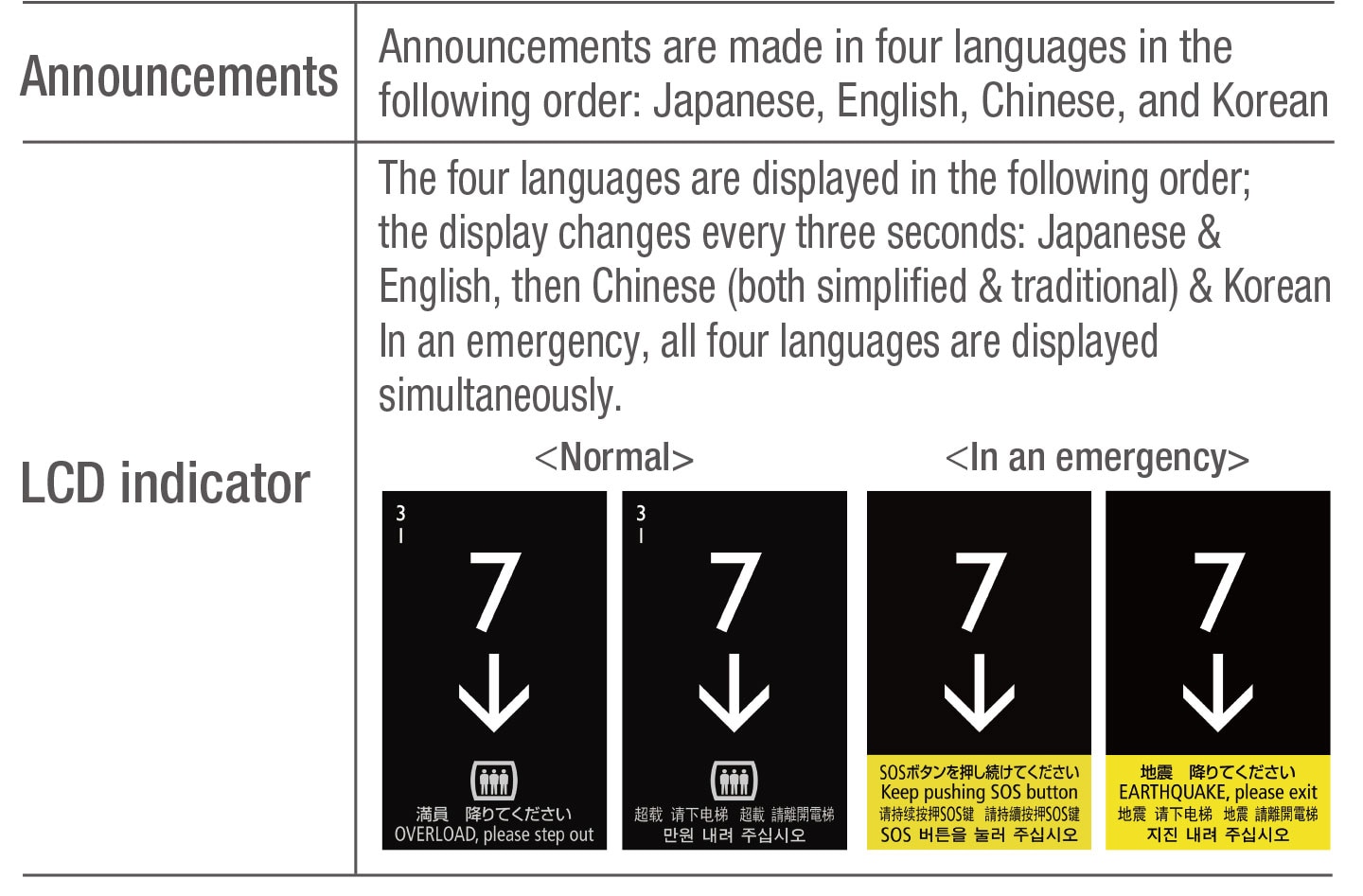

Provides service in multiple languages:

To offer a sense of security to non-Japanese speaking users, announcements and indicators come in multiple languages. Emergency indicators are available in four languages, namely Japanese, English, Chinese, and Korean, and in two languages during ordinary times.

Adaptable to multiple power sources:

The system is compatible with various power sources even if power supply is interrupted in an emergency. In addition to use of the included battery, the elevator can be operated at lower speed using power from solar power generation systems and electric vehicles (V2H).

・Standardized Elevators for International Markets

Elevator for India

NEXIEZ-LITE

The NEXIEZ Series, a line of standardized elevators for international markets use a gearless traction machine equipped with a permanent magnet motor. This results in a more compact, lightweight design and a 20% reduction in power consumption compared to conventional models. Further reductions in power consumption can be achieved by installing LED interior lighting and a converter system that stores and uses electricity generated during braking. For Europe, where people are very environmentally conscious, we have introduced MOVE, which saves space and reduces the burden on the environment for low- to medium-rise office buildings and condominiums. NEXIEZ-LITE for India, where power outages occur often, we provide a function that automatically checks the elevator conditions and swiftly lands the elevator car at the nearest floor using a battery in the event passengers are confined in the car due to a power outage as a standard function to support the needs of local users.

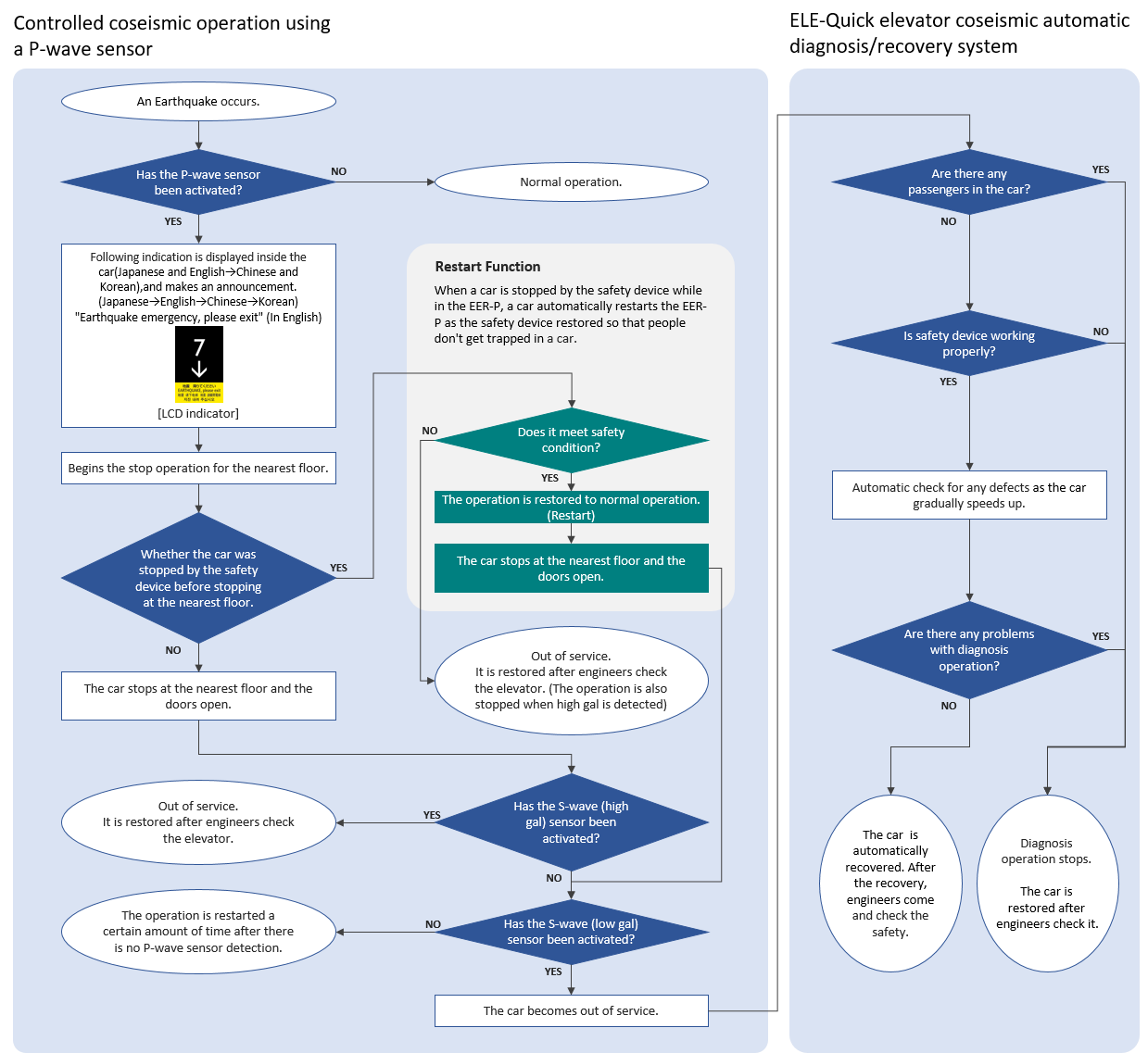

・Disaster Prevention Functions

Mitsubishi Electric’s elevators have built-in disaster prevention functions in case of various disasters, including earthquakes, fires and flooding due to heavy rain. For example, in the event of an earthquake, when a sensor detects the first tremor (P-waves) or when a large quake is forecast based on earthquake early warnings distributed by the Japan Meteorological Agency, the cars will park at the nearest floor to reduce the risk of passengers becoming trapped inside. Additionally, ELE-Quick is included in the elevator maintenance menu. This diagnosis/recovery system enables an elevator to automatically determine whether or not there is any anomaly after it is stopped by the earthquake emergency operation system. When it is determined that operation is safe, elevator service resumes, and elevators are put back in use quicker than conventional systems.

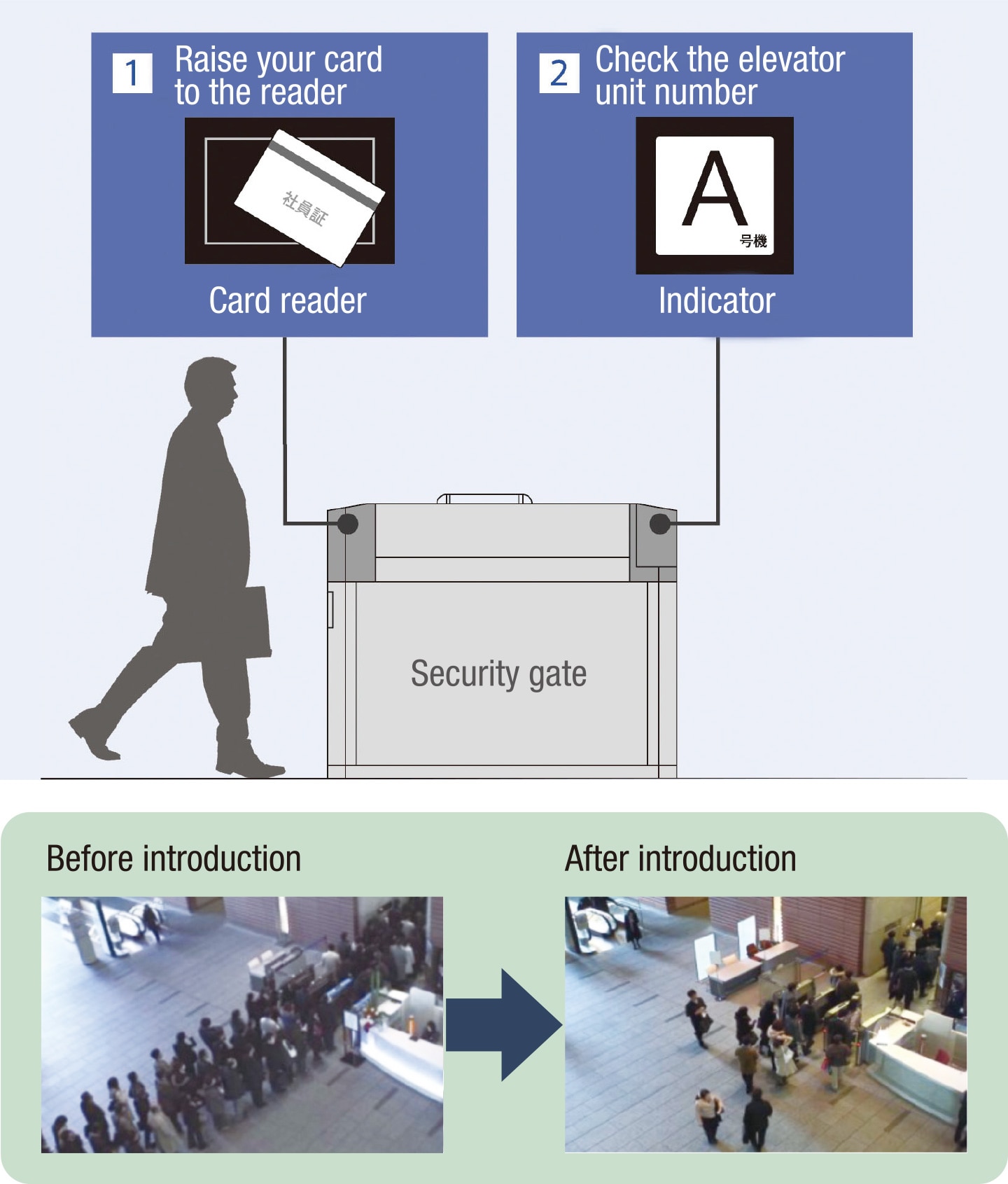

・ELE NAVI Security-linked Elevator Destination Forecast System

When elevator passengers pass through a security gate, their destination floors are automatically registered in the system based on security information stored in their ID card, such as an employee card. Furthermore, passengers are advised as to which elevator to board on a display at the security gate. This eliminates the need to press buttons in the elevator hall or inside the elevator car. It also minimizes stops by assembling passengers into a single car according to their destination floors. Boarding times can be shortened during rush hours, such as the beginning of office hours, and transport efficiency is improved. As a result, congestion in the elevator hall is eased.

Supporting Safe and Comfortable Use of Elevators and Escalators with Maintenance Services

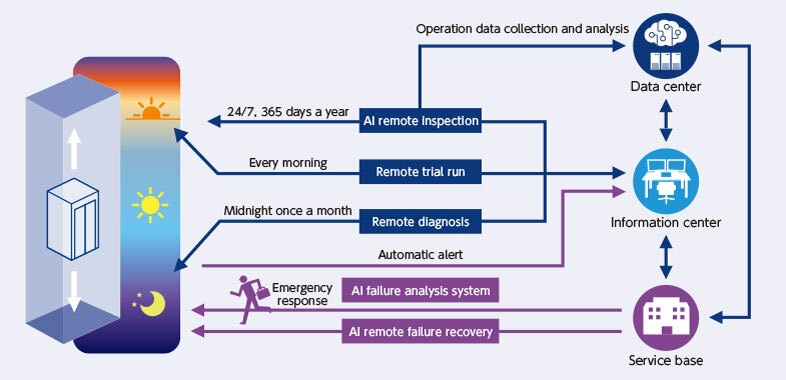

・ELE FIRST - smart Remote Maintenance Service

ELE FIRST - smart (compatible with AXIEZ-LINKs Mitsubishi machine-room-less elevator) accumulates daily elevator operation data and predicts the aging of equipment through machine learning to allow for maintenance to be performed at optimal timing. It also further promotes the prompt rescue of passengers trapped in an elevator car, and early recovery in the event of an earthquake based on the automatic diagnosis function, along with other benefits. Its services provide optimal information and functions to improve convenience for the elevator owner in maintenance and management, as well as convenience for elevator users (through smartphone services, etc.). These services realize an elevator that will not stop or be stopped and an elevator that can be connected to at any time.

In the event of one or more passengers being trapped in an elevator car, the system’s service for the remote rescue of trapped passengers automatically alerts the information center and analyzes the status of the elevator. If remote rescue is deemed to be possible, the staff members confirm the situation by communicating with passengers via an intercom transceiver and camera mounted inside the elevator car. A rescue attempt is then made via remote access.

The ELE-Quick diagnosis/recovery system allows for the elevator to automatically determine whether or not there are any anomalies after the earthquake emergency operation system stops it. Once it is determined that operation is safe, elevator service resumes, meaning that elevators can go back into use quicker than conventional systems.

Furthermore, the smartphone service allows users to set their destination floor via a dedicated app in advance so that they can operate the elevator without touching the buttons in the waiting area or inside the elevator car.

- * Using this service requires a contract with Mitsubishi Electric Building Solutions Corporation.

-

ELE FIRST - smart

-

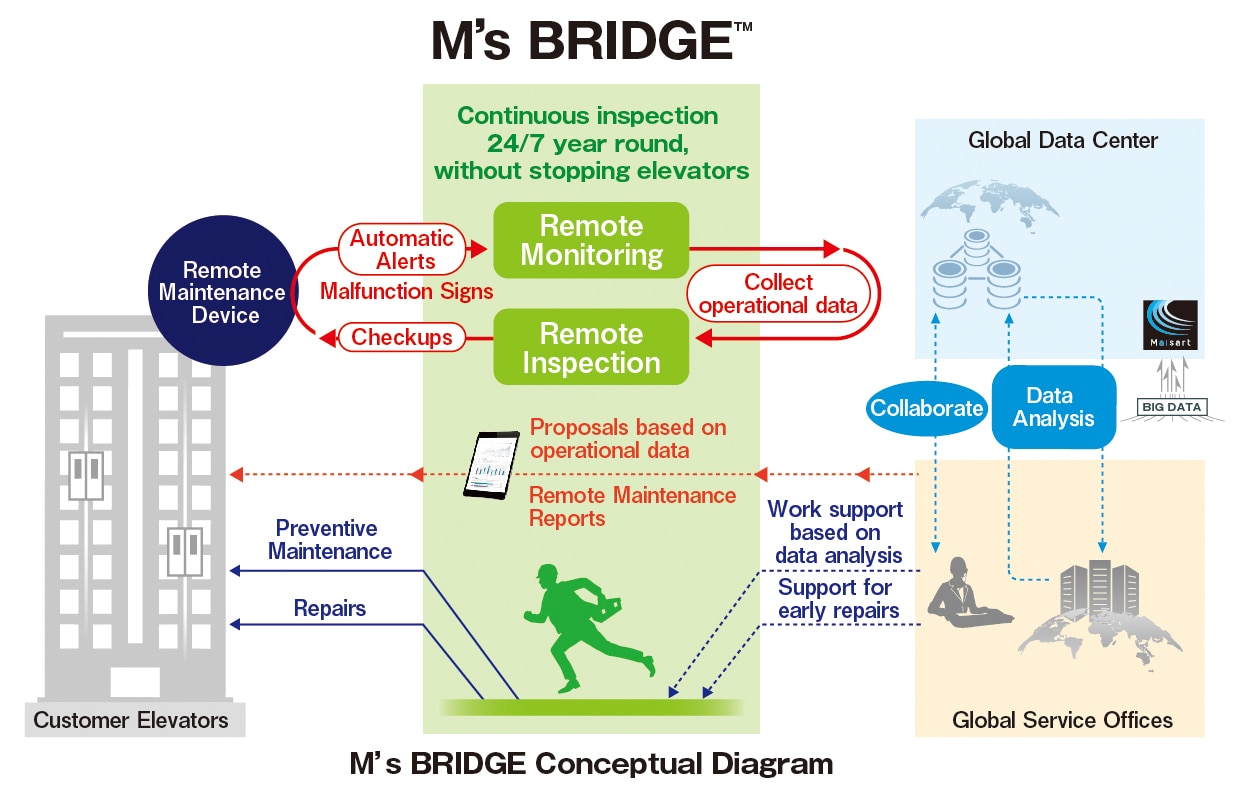

・M's BRIDGE™ Global Remote Maintenance Service for Elevators

In the growing global elevator market, the need for user convenience and comfort as well as safety is increasing, and the importance of maintenance services supporting such needs are attracting attention. M's BRIDGE uses Mitsubishi Electric's unique IoT platform to automatically detect a failure remotely and analyze and investigate the cause based on collected failure data remotely. By restoring the elevator service as soon as possible, M's BRIDGE contributes to improved user safety, security, and convenience. In addition, this service uses data collected through remote inspection to prevent elevators from failing and provides quality and efficient maintenance services.

Conceptual diagram of M's BRIDGE

Further Improving Safety, Comfort, and Functionality Through Elevator and Escalator Renewal

・Elemotion+ Elevator Renewal Menu

![photo: Elemotion+ [ZERO]](/en/sustainability/management/social_contributions/building/images/img_07.jpg)

Elemotion+ [ZERO]

To maintain the safety, security and comfort of elevators, renewal at appropriate times*1 is essential. The Elemotion+ menu facilitates the renewal of existing rope-type elevators to the latest model equipped with an inverter-controlled system, a gearless traction machine and permanent magnet motor. With the adoption of a system to protect elevators from moving with the door opened*2 and devices in accordance with the latest seismic criteria, this menu provides safe, secure, smooth and comfortable rides. Moreover, Elemotion+ offers a variety of replacement equipment, enabling customers to make decisions based on budget, preferred installation time, and the ability to reduce waste.

The addition of Elemotion+ [ZERO] has made it possible to conduct renewal work with zero days of consecutive elevator stoppage. We are promoting elevator renewals by making it easy for customers to plan renewal work.

- *1 25 years after completion of a building is regarded as an indication for renewal.

- *2 A system to prevent elevators from traveling with the door open even in the event of abnormalities in the control circuit or brake.

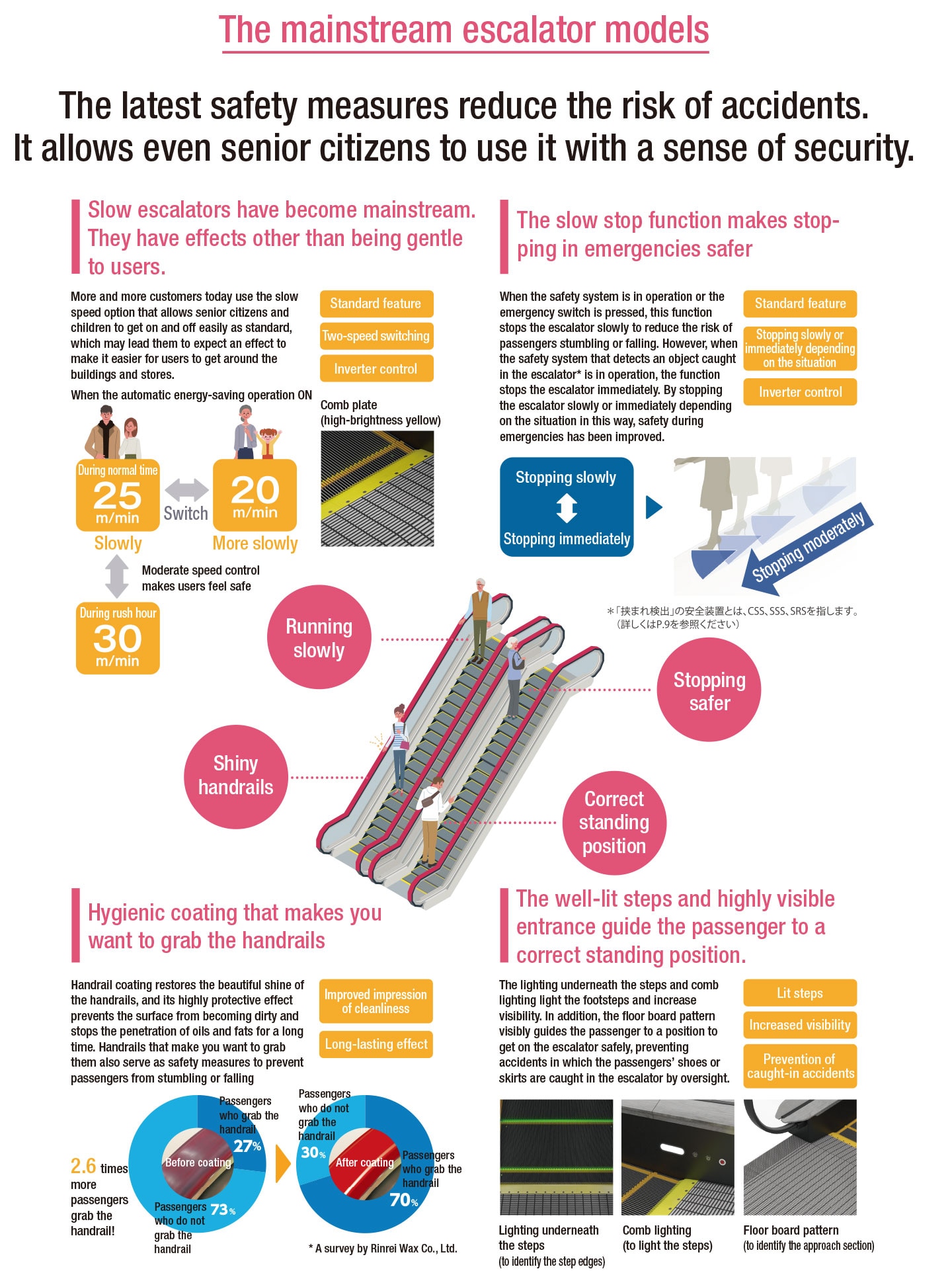

・Esmotion+ Escalator Renewal Menu

To maintain the safety and security of escalators as well, renewal at appropriate times* is necessary. A renewal of escalators to a model with an inverter system facilitated by the Esmotion+ menu provides them with the latest safety measures that allow the escalators to be used with a sense of security. When the safety system is in operation or the emergency switch is pressed, the escalator stops slowly to reduce the risk of passengers stumbling or falling. However, when the escalator detects an object caught in the escalator, it stops the escalator immediately. By stopping the escalator slowly or immediately depending on the situation in this way, safety during emergencies has been improved. The inverter system, which enables the speed to be switched to a slow speed for senior citizens and children to get on and off easily, also considers the safety of users.

- * 25 years after completion of a building is regarded as an indication for renewal.

Safety advantages of the Esmotion+ escalator renewal menu

Safety and Security in Building Security focused on Entrance/Exit Management Systems

・MELSAFETY Integrated Building Security System

MELSAFETY

MELSAFETY meets the security needs of all types of buildings, from small-size to medium and large-scale buildings, as well as offices, hospitals, and factories to solve various issues, including stringent compliance and confidential information management, work-style reform, and BCP* measures.

Furthermore, by linking with attendance management systems, attendance records can be tracked more accurately and efficiently, and by linking with visitor reception systems, labor savings can be achieved in reception work as well. Multiple business site management systems can help improve efficiency and reduce labor.

- * BCP: Business Continuity Plan

Supporting Energy Savings and Comfort for Small-to-Medium-sized Buildings Through Central Management of Various Building Facilities

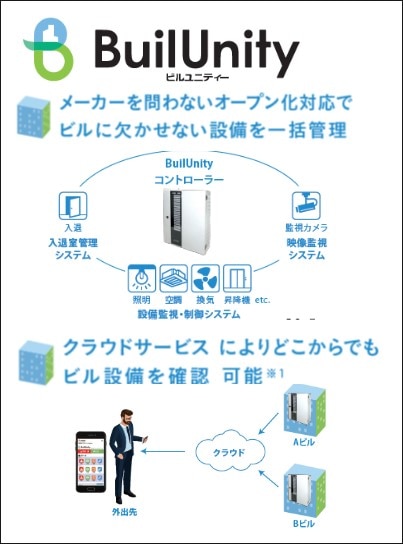

・BuilUnity Building Total Solution

Building total solution BuilUnity

BuilUnity is a packaged system that integrates a central monitoring system with the functions of an access control system. Using room entrance history and ID information of people in the room, the system enables linked control of building facilities, such as air conditioners and lighting, in accordance with the occupancy status of the rooms, thereby saving energy and improving comfort. Additionally, a cloud service contract enables monitoring and control of facility status, from a single building to multiple structures, wherever you are as long as you have a smartphone or tablet. The system thus contributes to increasing efficiency in building management operations.

・Facima Building Automation System – Building Facilities Planning and Operations System

Facima Building Automation System – Building Facilities Planning and Operations System

Facima is a centralized system for monitoring and controlling systems such as air conditioning and lighting facilities in medium- and large-sized buildings. It optimizes demand control by monitoring peak energy demand and stopping the operation of air-conditioning and lighting facilities as required based on a priority order previously set by the building manager. Combining these features with air-conditioning rotation control, the system automatically controls various building facilities, achieving sensible energy conservation with user comfort and convenience in mind. Additionally, when used in combination with our support service, Facima collects and analyzes data on building facilities operation, visualizes energy use conditions, and proposes energy-saving and cost-reducing options for the entire building.

Realizing Comfortable Buildings with Reduced Energy Use to Contribute to a Carbon Neutral Society

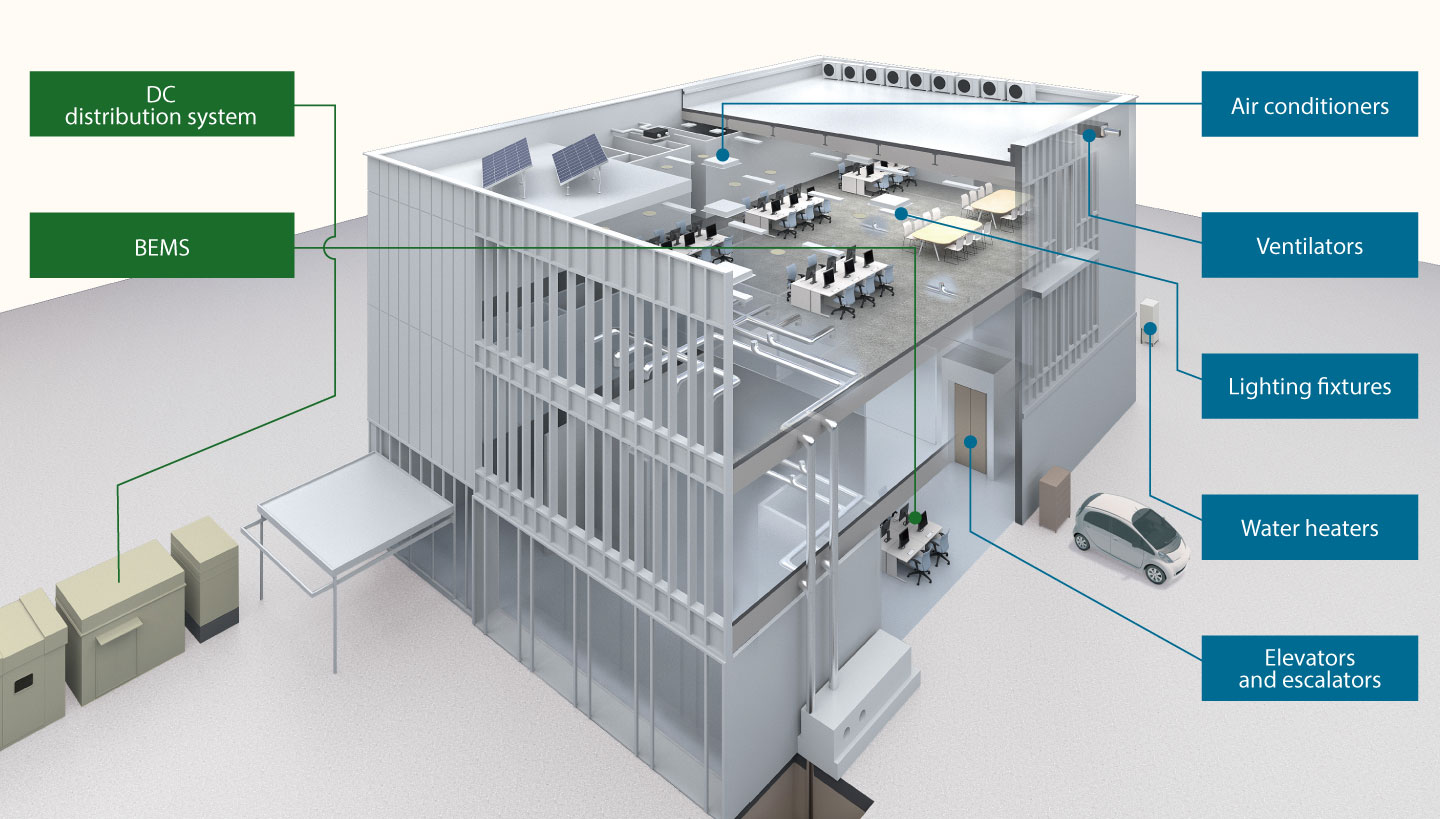

・ZEB Solution

ZEB Planner logo

We provides all services required for ZEB: from the selection and delivery of vital facilities (air conditioning, ventilation, lighting, hot water supply, and vertical transport (elevators/escalators), BEMS, etc.) to services to help customers save energy once the ZEB is operational. As an experienced ZEB planner, Mitsubishi Electric helps customers nationwide achieve ZEB.

Example ZEB Layout

Contributing to the Achievement of a Smart Building by Supporting Robot Mobility within the Building and Supporting ZEB Operations

・Services to Support Building Operation Using the Smart City/Building IoT Platform Ville-feuille®

In recent years, smart buildings that provide a space where people can work efficiently in a secure environment while achieving energy efficiency and labor savings are gaining traction. To realize smart buildings, Mitsubishi Electric has developed the smart city/building IoT platform Ville-feuille®, which uses building facility data gathered and stored in the cloud to provide various services to support building operation.

The robot mobility support service helps service robots contribute to labor savings in building management by providing delivery, security and cleaning services, which are key to solving labor shortages. Mobility support features an elevator collaboration function that enables robots to move vertically and an entrance/exit management system collaboration function, while ensuring people’s safety.

The energy management service centrally manages building facility operation data in the cloud and enables the facility operation status to be checked and controlled remotely to save labor in facility management, while also helping to improve building operation efficiency.

Conceptual diagram of the Smart City/Building IoT Platform Ville-feuille®

Supporting Seamless Travel within the Facility by the Guide System Using Animation Lighting

・TERASU GUIDE Building Total Solution

As traveling within facilities has become complex recently due to an increase in large-scale complexes, the importance of accurately communicating information to visitors, especially foreigners, senior citizens, and people using wheelchairs, is increasing. TERASU GUIDE® projects light animations onto the floor to help facility users understand guidance and cautions intuitively as well as move around smoothly. This enables sign displays to be changed easily according to the time and situation, which also contributes to streamlining guidance operations, reducing the labor involved in building management operations, and reducing the cost of creating sign boards.

-

Sign display example

-

TERASU GUIDE logo

- Sustainability

- Management message

- Sustainability management

- Environment

- Social

- Philanthropic activities

- Governance

- Policy on sustainability information disclosure

- Guideline comparison tables

- Reports