Initiatives that contribute to addressing social challenges

Public Utility Systems Group

Message from the Group President

Contributing to Creation of a Sustainable, Safe, Secure, Comfortable and Affluent Society by Providing Products, Systems and Services for the Social Infrastructure that Underpins Our Lives

Hideto Negoro

Executive Officer,

Group President,

Public Utility Systems

As of July 2023

The Public Utility Systems Group provides a host of products, systems and services used in social infrastructure in the areas of water environment, rivers, railways, roads, aviation, and communication. Integrating the wide range of technologies we have accumulated over the years, we provide solutions to address various social challenges in order to contribute to a safe, secure, comfortable and affluent society.

1. Realizing a society with rich water cycle

The world has been facing a number of problems related to water use—the number of water pollution sources has been increasing due to concentration of population and industry; demand for water has been growing due to industrial development and population growth; and distribution of water resources is becoming more uneven due to climate change. With this in mind, we will continue to reduce environmental burdens and realize a society with rich water cycle by advancing water and sewage systems using IoT technology and introducing highly efficient water recycling systems that make use of ozone.

2. Contributing to the achievement of carbon neutrality

We are also contributing to the development of railways, which are an energy efficient and environmentally friendly transportation network. We produce highly reliable, energy efficient electrical components for rolling stock and develop information processing systems that provide a variety of services to railway operators and users. We will continue to contribute to the further development of the railway business and the achievement of carbon neutrality by providing maintenance solutions that improve the efficiency of troubleshooting and maintenance management as well as platforms that promote data utilization.

3. Creating safe, secure and comfortable cities

Mitsubishi Electric is also developing disaster prevention and mitigation systems in response to increasingly severe natural disasters as well as services that enhance maintenance and management of aging social infrastructure such as tunnels to create safe, secure cities. In addition, we also aim to create even more comfortable cities by providing video analysis solutions for realizing new services, such as analyzing the movement and flow of people to prevent congestion, in addition to high-speed, large-capacity communication systems that support the development of an IoT society.

| Major social challenges for which risks and opportunities have been recognized and evaluated | Priority SDG initiatives |

|---|---|

|

|

Initiatives that contribute to addressing social challenges

Realizing a Society with Rich Water Cycle

Ozone Generator

Ozone generator

Ozone generators are used in advanced water treatment processes and paper pulp bleaching due to their superior oxidizing power and ability to eliminate bacteria, odors, and colors. By developing a technology that places electrodes closer together in the generator's oxygen source and applying it to the air source as well, we have achieved a more compact, more efficient design. As a result, overall system power consumption has been reduced by 15%.

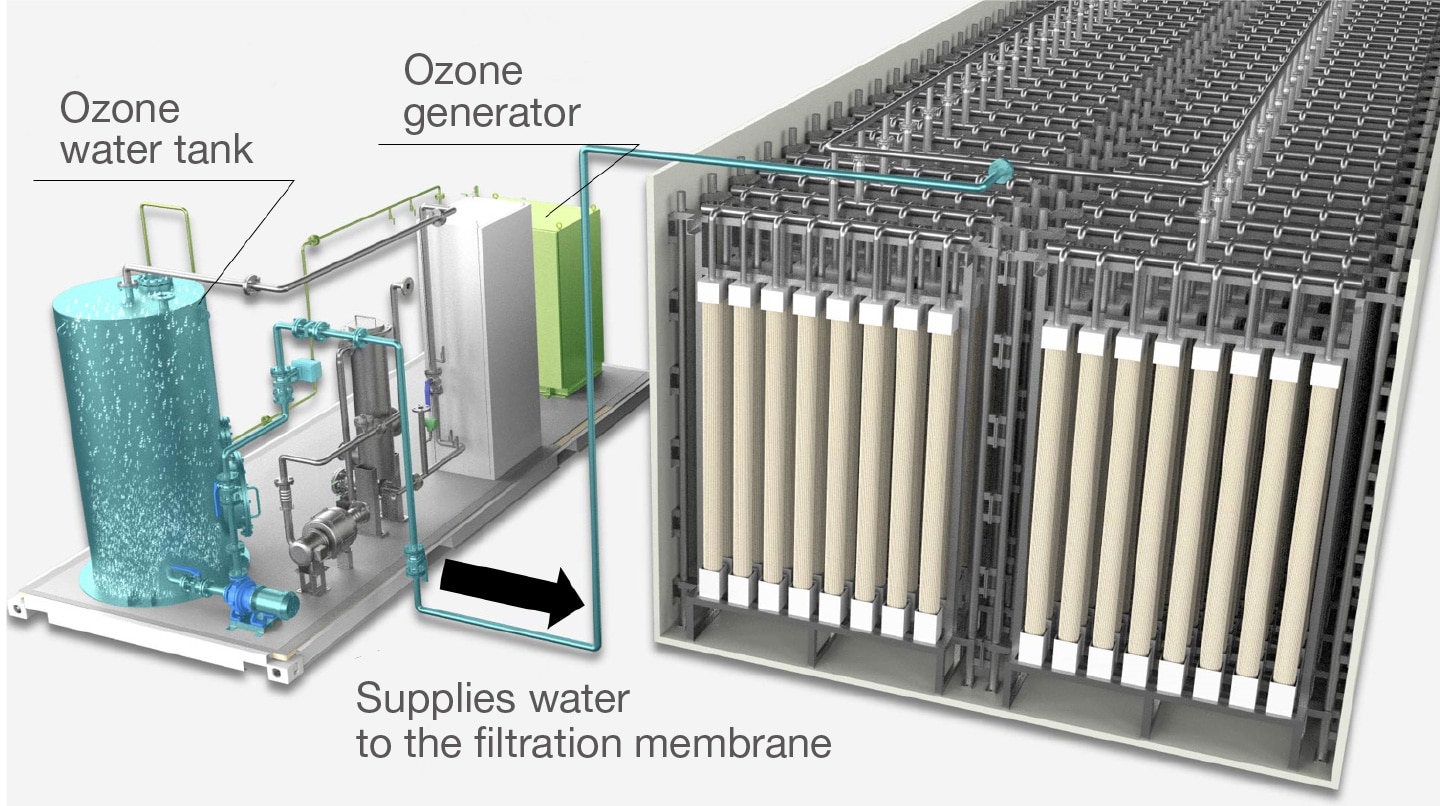

Eco Membrane BioReactor (EcoMBR™*1)

We have developed a compact membrane bioreactor (EcoMBR™), which cleans with ozonized water the membrane filters for treating and recycling municipal and industrial wastewater. The compact, energy-efficient EcoMBR™ system is capable of high-speed filtration, which enables the device to treat twice as much water per membrane filter surface area compared to conventional methods.

- *1 Eco Membrane BioReactor

Eco Membrane BioReactor (EcoMBR™)

Contributing to a Decarbonized Society

Inverters Equipped with All-SiC Power Modules*2 for Use in Rolling Stock

Inverter for rolling stock

We produced an inverter equipped with all-SiC power modules for use in rolling stock for the first time in the world and launched it at the end of fiscal 2015. It enables energy savings of approximately 40% compared to conventional vehicles. This product is now being used by many customers in and out of Japan.

- *2 Part of the development of this power module was commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

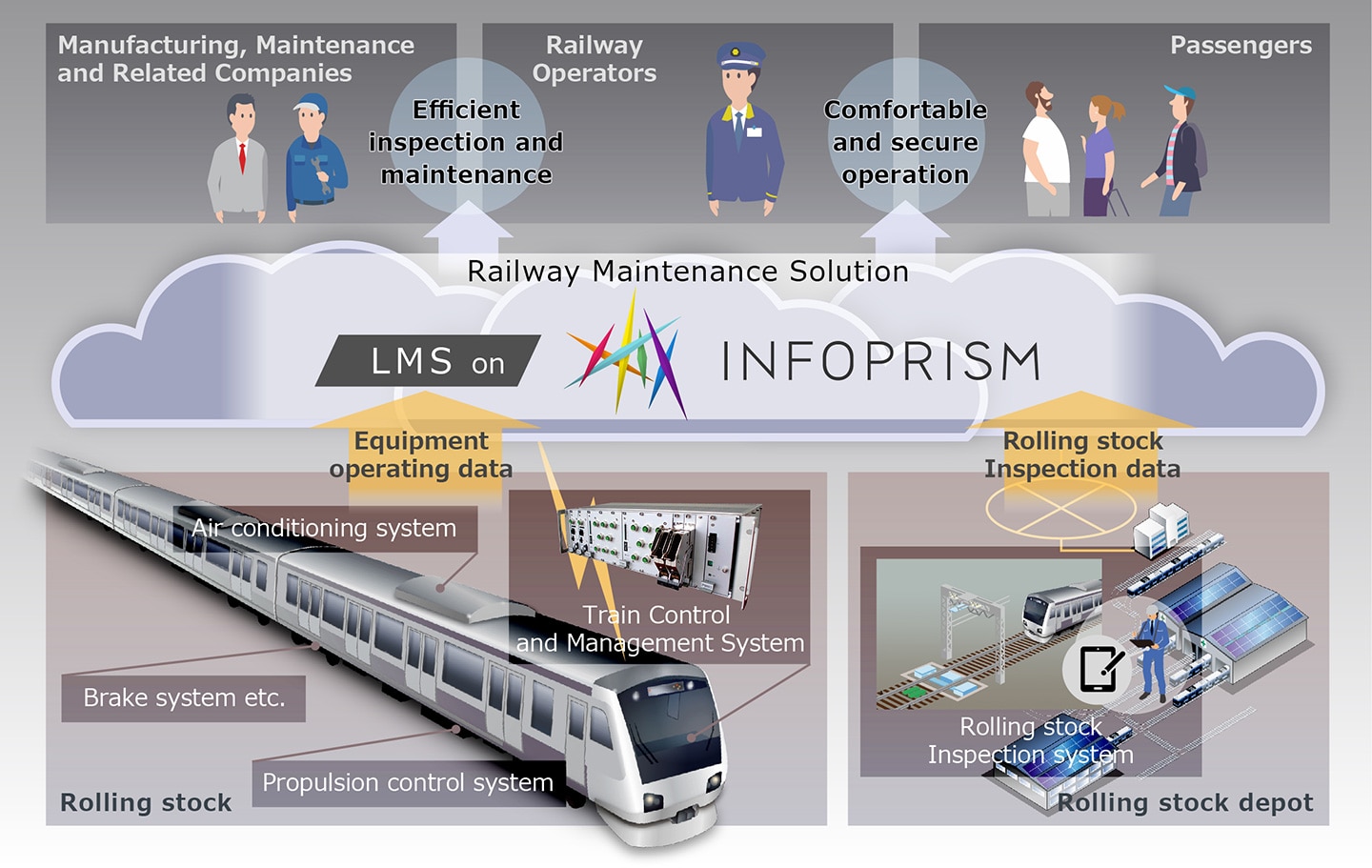

Railway maintenance solution "LMS*3 on INFOPRISM"

Using our IoT platform INFOPRISM, which leverages our AI technology Maisart®, we collect and analyze data on rolling stock in real time in order to increase the maintenance efficiency of rolling stock inspection, testing and repair, and support data sharing and use among railway operators. Going forward, we will seek to solve social challenges related to railways and increase added value by combining the information held by not only railway operators but also railway users.

- *3 LMS is a full Lifecycle Management Solution for rolling stock.

Railway LMS on INFOPRISM

Creating Safe, Secure and Comfortable Cities

Helicopter Satellite Communication System (HSA)

Helicopter Satellite Communication System (HSA)

In the event of large-scale disasters such as earthquakes and fires, Helicopter Satellite Communication System transmits real-time aerial images of the affected areas from a helicopter to the authorities in charge of disaster response. By providing accurate information on the affected areas, this system contributes to appropriate and prompt actions onsite, including emergency services.

Mitsubishi Infrastructure Monitoring System MMSD®*4

Mitsubishi Multi-dimensional Data Management for Diagnosis MDMD®*5

Mitsubishi Infrastructure Monitoring System (MMSD®) measuring vehicle

Inspections, repairs, and replacements for proper maintenance and management of civil engineering and road structures have long been a significant burden for operators. The Mitsubishi Infrastructure Monitoring System (MMSD®), which is equipped with a high-density 3D laser and a high-resolution line camera, can measure and analyze roads, railways and tunnels accurately. The Mitsubishi Multi-dimensional Data Management for Diagnosis (MDMD®) reproduces road and railway conditions in a 3D virtual space using acquired data, thereby helping to reduce onsite work and to share information. Through these technologies, we contribute to reducing the burden of social infrastructure maintenance and management work.

- *4 Mitsubishi MMS for Diagnosis

- *5 Mitsubishi Multi-dimensional Data Management for Diagnosis

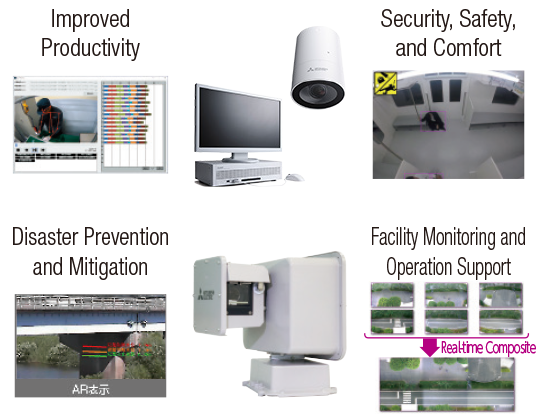

Network camera systems

Network camera system

Network camera systems are not only capable of image recording and monitoring, but also expanding their applications with image analysis technology, including crime prevention by detecting suspicious objects, creation of a comfortable space by detecting congestion levels and traffic flows, and prevention and mitigation of disasters. We manufacture products such as the MELOOK series, which meets diverse requirements, and other products that are ideal for the surveillance of broad areas such as public facilities, and thereby promote the development of safe and secure cities.

Optical access system 10G-EPON

Subscriber equipment

The optical access system 10G-EPON subscriber equipment uses a passive optical network (PON) that enables optical fibers to be shared among many users and realizes wide-band communications. It also achieves a 96% reduction in power consumption per traffic and 96% reduction in material usage compared to conventional equipment as a result of using parts that consume less power and reducing the number of parts in the equipment.

- Sustainability

- Management message

- Sustainability management

- Environment

- Social

- Philanthropic activities

- Governance

- Policy on sustainability information disclosure

- Guideline comparison tables

- Reports