About Mitsubishi Electric Factory AutomationThe Road to Automating the WorldInterviews with People Involved in the Factory Automation Systems Business

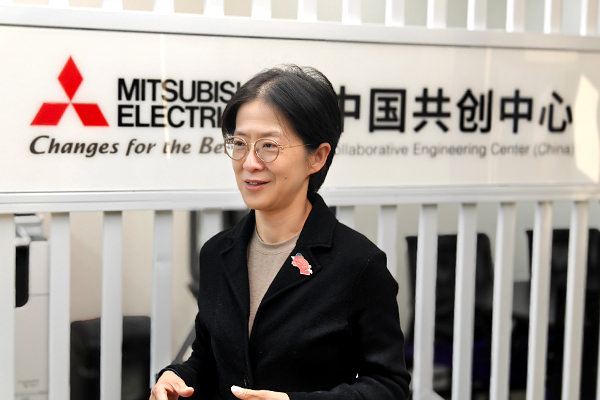

Creating the Future of Factory Automation Through Product DevelopmentRong Gang,

Deputy Director of China Co-creation Center,

joined Mitsubishi Electric Automation (CHINA) Ltd in 1998.

2025-03

Mitsubishi Electric’s FA systems business aims to enable employees to fully demonstrate their ideas, technologies, and beliefs to achieve the common goal of “Automating the World.”

Through the “Road to Automating the World” series, we share their authentic voices from around the world.

In this article, we interviewed Ms. Rong Gang, Deputy Director of the China Co-creation Center, which was launched in March 2022

I Was Confident That This Was Where I Could Fulfill My Ambition

── What did you study at university?

Rong:China had national goals known as the “Four Modernizations,” which were to be achieved by the end of the 20th century. One of the targeted areas was industry. My father told me that if I studied science and mathematics, I would have opportunities anywhere in the world. That partly inspired me to become an engineer. I majored in industrial automation and minored in technology economics. After graduating from university, I earned an MBA while working.

── How did you come to join Mitsubishi Electric?

Rong:As I gained experience in my previous job, I began to have doubts about my career path and considered changing jobs. At that precise moment, I heard that Mitsubishi Electric was hiring staff to expand its factory automation (FA) business. Mitsubishi Electric is a globally recognized company, and I was eager to work for them. That’s how I joined the company.

── What responsibilities did you take on after joining?

Rong:I joined in 1998, at the same time as the establishment of the FA Division at Mitsubishi Electric & Electronics (Shanghai) Co., Ltd., which later became Mitsubishi Electric Automation (China) Ltd. Since then, I have taken on various technical roles, including engineering projects, customer training, technical support, troubleshooting, and product repairs. Later, I became a manager of a service technology team. A few years after that, I was involved in launching the e-F@ctory business and received several internal recognitions. It is safe to say that I grew with the company.

── Could you tell us about your current job and responsibilities?

Rong:I am currently the Deputy Director of the China Co-creation Center, launched in 2022, and oversee the planning and development departments. Working closely with my colleagues at the Center, I develop applications for FA products. At the same time, I focus on collaboration with other Co-creation Centers in the U.S., Europe, and India, as well as with other organizations.

I Take Great Pride in Our Technological Achievements

── What do you care about most when performing your job?

Rong:I take great pride in our technologies. When we conducted an acceptance inspection of processing equipment installed on an exhibition production line alongside a technician from Japan, we discovered a processing defect resembling ripples on the polished surface of a component. We eventually had it rectified by the equipment manufacturer, but I initially questioned whether such a high level of precision was necessary for a production line that was only for demonstration purposes. However, the technician explained that this level of precision was a hallmark of Mitsubishi Electric’s brand, and even an exhibition production line had to produce the same quality as an actual one. That experience made me realize the importance of pursuing the highest quality, and I continue to uphold this principle in my work.

── Could you share some challenges you have faced and how you overcame them?

Rong:At the China Co-creation Center, we develop applications for FA products. To create customized applications tailored to each customer’s requirements, we collaborate with other organizations, such as Nagoya Works in Japan. This requires extensive coordination, including aligning a sales company’s business needs with R&D rules in Japan while developing new task models. In the early days, cultural differences between China and Japan often led to conflicts. However, we were united by a shared commitment to providing better solutions for our customers. To overcome these challenges, we built a new division from the ground up, including hiring new staff. After three years of hard work, we established a smooth workflow. As a result, we can now offer solutions that satisfy many customers, leading to increased revenue.

── What would you like to create in the future?

Rong:The applications we currently develop mainly target niche markets that existing products do not cover. In China, there are numerous opportunities to apply advanced industrial technologies. I hope to continue increasing the added value of our products by developing innovative applications, ultimately strengthening the competitiveness of our offerings.

── Finally, please share your thoughts on “monozukuri” (manufacturing).

Rong:FA products have evolved significantly, progressing from relays to programmable controllers, from motion controllers to robots, and further into network construction and cloud computing. More recently, cutting-edge technologies such as real-time virtual technology, industrial 5G/6G communications, and generative AI have been successfully demonstrated, opening a new chapter for the automation industry. By keeping up with these trends, I aim to develop FA products that anticipate and shape the future. These products should be more convenient, more efficient, and greener.

*This article is based on interviews conducted in February 2025.