Factory Automation

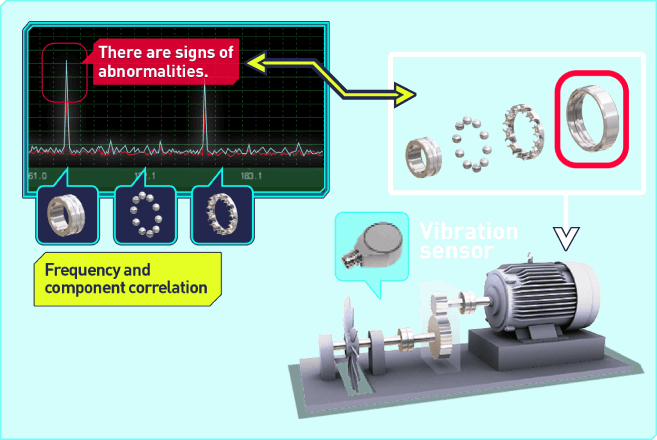

by understanding the presence of abnormalities within rotating machines

without the need to stop the equipment.

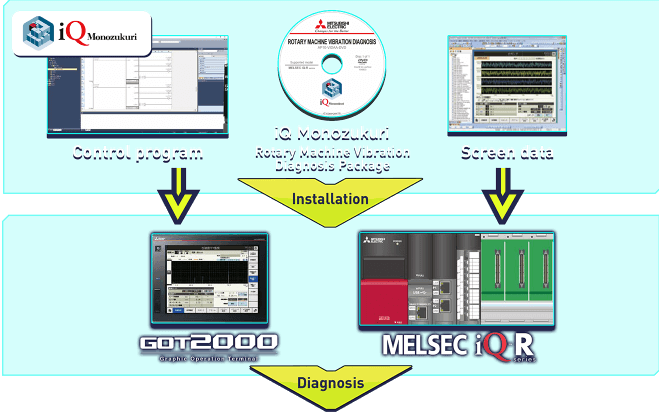

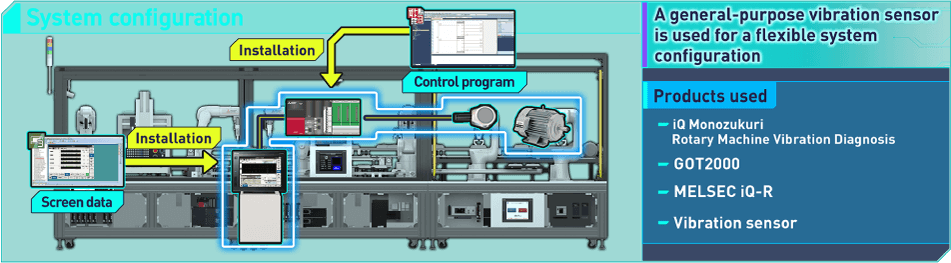

Easy installation; one package with ready to use facility

diagnosis

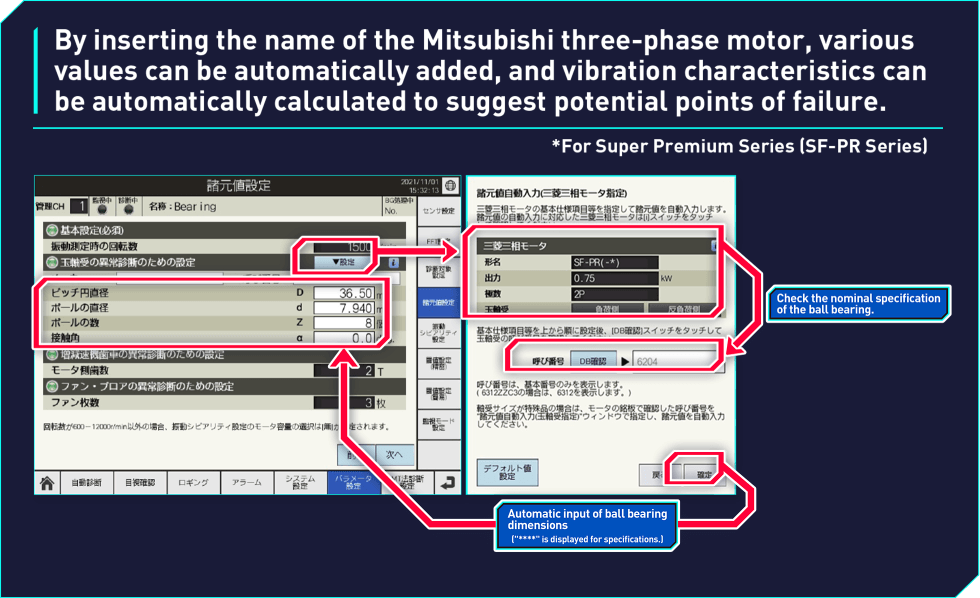

Vibration characteristics can be automatically calculated by simply inputting component values. This can then be used to suggest potential points of failure.

*Equipment subject to diagnosis:Equipment that continues rotating in the same direction at a constant speed and load for a fixed period of time. Equipment that generates shocks and vibrations (ex. presses) and equipment that generates vibration due to self-propulsion (ex. AGVs) are excluded.

Examples of target equipment: motors, ventilation (fan, blower), compressors, pumps, gearboxes, stirrers, conveyors, converting machines, etc.

Learn More

Related Content

Advanced technology exhibition of cutting-edge technologies for automation and measurement

The Mitsubishi Electric Group is exhibiting a number of cutting-edge FA solutions and the latest FA equipment at IIFES 2020, which is being held under the theme of “The digital transformation (DX) of the production site, ready to meet the ‘new manufacturing era’.” The details of the exhibits are also available on the Mitsubishi Electric IIFES special website.