Events & Seminars / ShowroomDigitalization of Smart Manufacturing for Production Line

Digitalization of Smart Manufacturing for Production Line

In enhancing operational efficiency, flexibility, and visibility, we introduce a revolutionary concept featuring a Smart Manufacturing simulation called "Digitalization of Smart Manufacturing for Production Line“.

This system show full automation production, start from ordering process by incorporating using digital technology with Industrial Robots and Programmable Controllers MELSEC, until serve e-Money card gift, as a finished goods.

Visualization system also shown in this Digitalization of Smart Manufacturing for Production Line, such as OEE data machine, Smart Maintenance Monitoring, Andon System, Energy Monitoring, Data Traceability System for queuing order process, through SCADA .

There are two types of Industrial Robots used in this simulation: Vertical type and Horizontal type.

The Industrial Robot not only emphasizes high levels of automation but is also capable of a wide range of applications, including the assembly of small parts, heavy load handling, and packing, It is also fit for futuristic variable products and variable production. Meanwhile, Programmable Controllers MELSEC handling all controls in this simulation.

In this system, we introduce cutting-edge technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) to optimize production limitlessly, also enable Remote Monitoring.

In addition to implementing Smart Manufacturing, this simulation reflects the "Automating the World" slogan namely "Let’s manufacture what matters to you," "Digitally multiplying the potential of manufacturing," and "Manufacturing made sustainable." This simulation aimed at creating intelligent, responsive production in alignment with the vision of "Automating the World.“.

This Digitalization Production Line comprises 3 processes :

1. Order Process: Customers can register through “QR Code for registration”. After registration, the system automatically generates a QR Code in the "Thank You Message" for the retrieval of the e-Money card gift. Please scan the those QR Code into the Barcode Reader in the "Order Process" area. Customers can choose the design from 3 visual illustrations of the "Automating the World" slogan for the available e-Money card gift on the Human Machine Interfaces-GOT device.

e-Money Design Options based on visual illustrations of the "Automating the World" slogan :

2. Printing Process: Customers can personalize the e-money cards by entering their name into the system, which will then automatically apply their custom name to the e-money design, creating a unique and personalized product.

Example of e-Money personalization :

3. Pick Up Process: In the "Pick Up Process" area, customers can retrieve their selected design and have the opportunity to confirm the accuracy and appearance base on their personalization on the Human Machine Interfaces (HMI) GOT device, ensuring that the customized details meet their expectations before finalizing the process.

Mitsubishi Electric Industrial Robot

Armed for productivity

MITSUBISHI MELFA Industrial Robot fits for cell manufacturing with high speed and high precision performance and combining intelligent technology and MELFA Smart Plus, it has easy connectivity with Mitsubishi's PLCs and FA equipments.

Vertical, multiple-joint type robots

- Optimized arm length and 6 joints for a broader range of movement support complex assembly and process operations.

- Compact body and slender arms capable of covering a large work area and large load capacity.

- Suitable for a broad range of layouts, from transporting machine parts to assembling electrical components.

- Designed to withstand environmental conditions, making it ideal for a wide range of applications without having to worry about the installation environment.

Horizontal, multiple-joint type robots

- With a wealth of operating areas and variations, it is the perfect fit for a variety of applications.

- Highly rigid arms and cutting-edge servo controls provide superb precision and speed. Ideal for a wide range of fields, from high-volume production of foodstuffs and pharmaceuticals that demands fast operation, through to assembly work where high levels of precision are required.

This Application is Suitable for Industry :

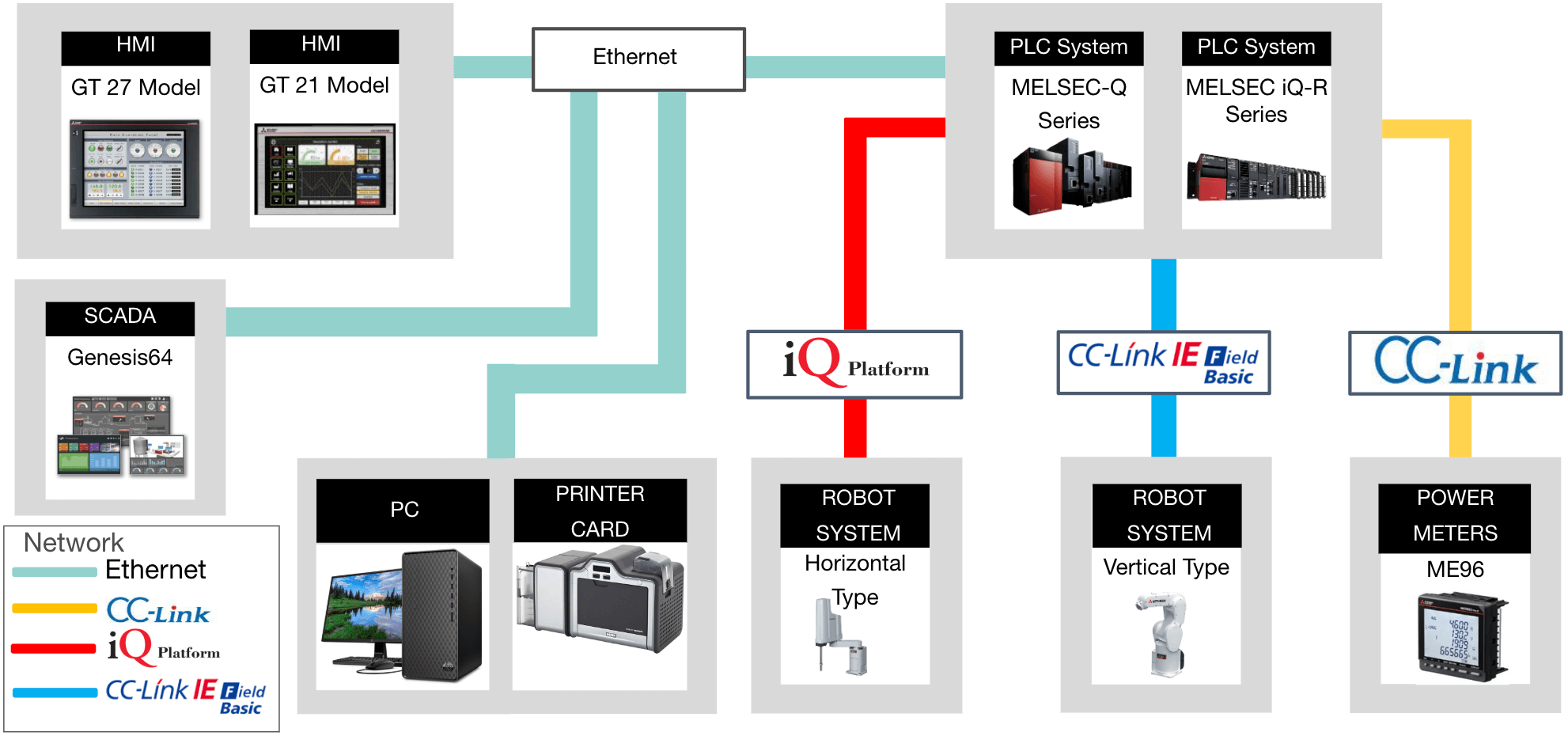

System Configuration

Product Used and Features