Events & Seminars / ShowroomHVAC Redundancy Control System

HVAC Redundancy Control System

HVAC Redundancy Control System

Supported by MELSEC iQ-R Process Control

The simulation of this Redundancy Control System is named "HVAC Redundancy Control System" supported by the MELSEC iQ-R Process Control. The MELSEC iQ-R Series enables a process control system through its range of CPU modules (up to 1200K steps) integrating advanced PID and general control into one module providing excellent system scalability (from small to large) for a best-fit solution. When paired with a redundant function module, it realizes a redundant control system ideal for applications that require highly reliable control. Various network modules with redundant functionality embedded are also available, further improving reliability.

Through its interconnectivity with supervisory control and data acquisition (SCADA) software GENESIS64™, GT SoftGOT2000, GOT2000, extensive plant-wide monitoring and control can be realized.

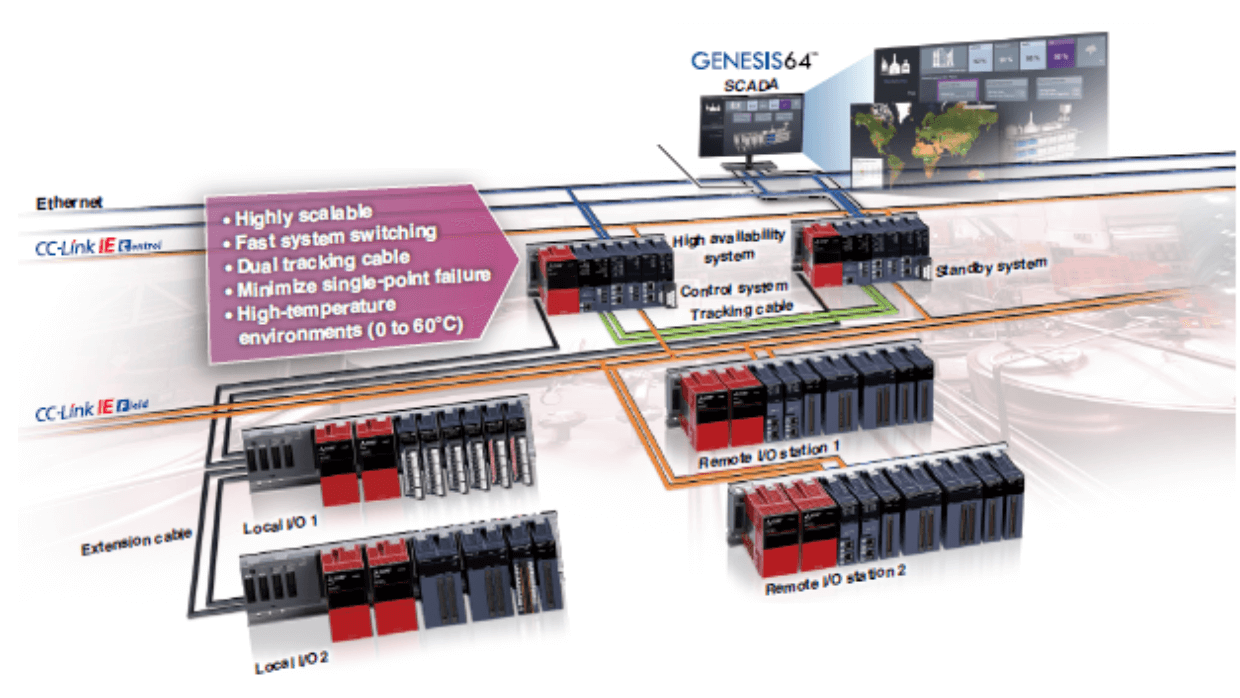

The MELSEC iQ-R Series redundant system enables high availability at multiple levels in the control system hierarchy, from visualization (SCADA) and control to networks, thereby improving system reliability

Benefit of MELSEC iQ-R Process Control

A. High-Available Process Control in a Scalable Automation Solution

MELSEC iQ-R Series process CPU modules are designed to cover wide-ranging process control applications, from small- to large-scale. All models provide high-speed performance coupled with the ability to handle large PID loops utilizing embedded PID control algorithms; integrating both general and process control into one module. When paired with a redundant function module, a redundant control system ideal for applications that require highly reliable control can be easily realized at a low cost.

Highly reliable control systems can be easily realized minimizing the possibility of single-point failure at the visualization (SCADA), control, network, and extension cable levels, thereby avoiding system downtime and ensuring continuous control and operation of critical systems.

B. Highly Scalable Process Control Visualization

SCADA Software GENESIS64™, GOT2000, and GT SoftGOT2000 provide extensive visualization with their enhanced interconnectivity with the MELSEC iQ-R Series. Advanced features such as energy management, scheduling, alarm and event management, trending, reporting, historian, and Geo-SCADA monitoring realize intuitive factory-wide control.

Process tag labels (variables) can be shared between GX Works3, SCADA software GENESIS64™, GT SoftGOT2000, and GOT2000, realizing an efficient engineering environment that makes screen creation easier. In addition, a scalable SCADA control system can be realized combining these products.

The Key Features of MELSEC iQ-R Redundant Process Control

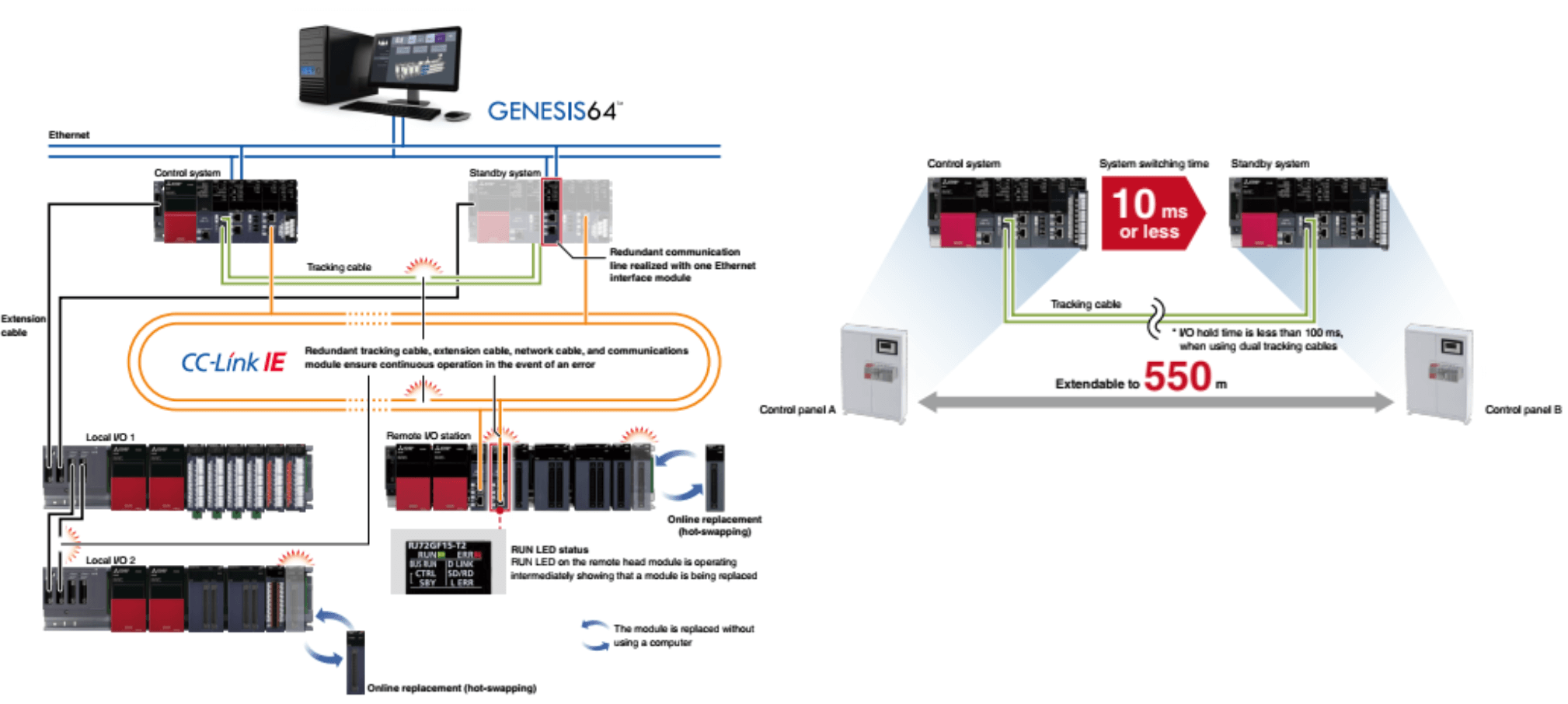

High-Speed Switching Optical-fiber tracking cables enable the standby system to be installed in a remote location up to 550 m from the control (primary) system. The tracking cables are immune to noise interference and support fast data transfer rates. System switching speed from the control system to the standby system has also been improved to speeds of 10 ms or less, further improving system reliability.

Efficient Engineering Software An efficient and highly-scalable engineering environment can be realized by the extensive compatibility between GX Works3 together with SCADA software (GENESIS64™), monitoring software GT SoftGOT2000 and GT Works3 [GOT (HMI)].

Reduced Single-Point Failure A multi-level redundant system can be realized by installing dual control systems consisting of the control (primary) and standby CPUs. Combined with a dual extension cable topology for both the redundant extension base units and network cabling of the CC-Link IE Field networks together with dual remote stations, minimizes the risk of singe-point failure. Online replacement of cables and modules (hot-swapping) is possible without stopping the operating control system when an error occurs.

System Configuration