CNC E80 Series

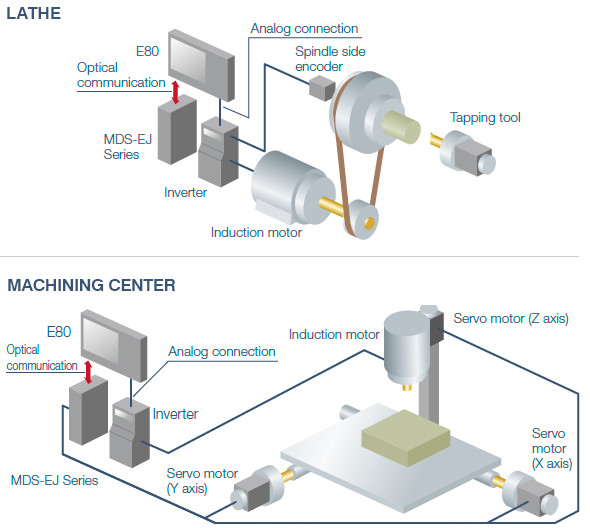

System Configurations

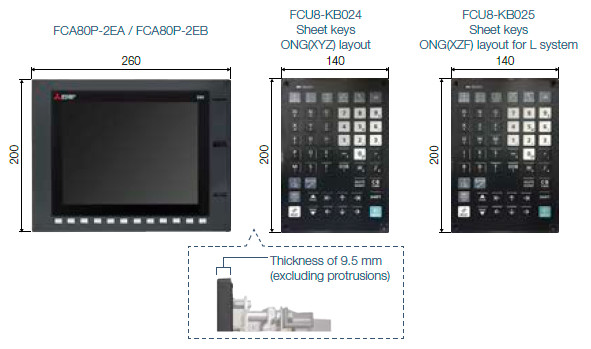

Design

Leading design

Display Units and Keyboards

The E80 Series adopts the M800/M80 Series design. The display unit and keyboard are only 9.5 mm thick, and their flat profile opens up new possibilities for machine design.

There are 2 types of keyboard layouts, one for lathes and the other for milling.

Features

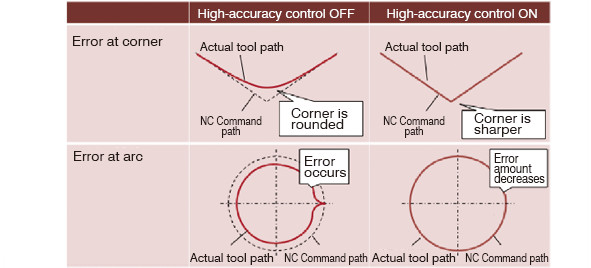

- High-accuracy Control

- Interactive Cycle Insertion

- Tolerance Control

- Multiple-axis Synchronization Control

- CNC-dedicated CPU

- Synchronous Tapping with Analog I/F Spindle

High-accuracy Control

Improved machining accuracy

High-accuracy Control

E80 Series high-accuracy control minimizes deviation of the actual tool path from the command path, improving the accuracy of the machining of corners and arcs.

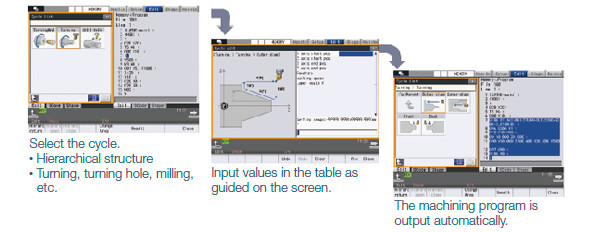

Interactive Cycle Insertion

Easier program creation

Interactive Cycle Insertion

Create a machining program automatically simply by inserting a machining shape in a selected machining cycle.

Interactive cycle insertion enables the user to create programs intuitively while referring to drawings on the screen, reducing the time required for program creation compared with G-code input.

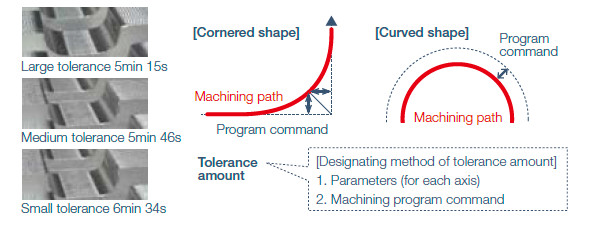

Tolerance Control

Easy operation, high quality

Tolerance Control

This function obtains the optimum clamp speed for corners or curves based on the designated tolerance to perform operations. It also ensures smooth passing in corner sections within the tolerance range, which suppresses machine vibrations. The cycle time is reduced because the clamp speed can be increased to a higher speed than usual.

Simply set the amount of tolerance, and the machine operates at the optimal speed and tool path, making it easy to achieve a high-quality machined surface.

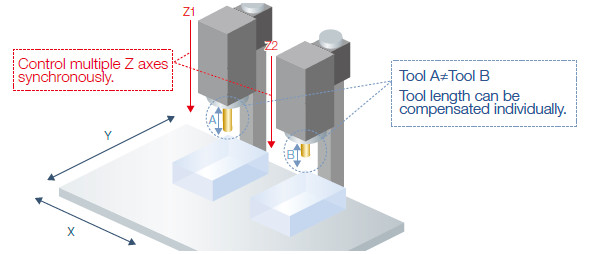

Multiple-axis Synchronization Control

Applicable to a wide array of machine specifications

Multiple-axis Synchronization Control

This function enables the synchronous control of multiple Z axes.

Synchronizing multiple axes enables the controlling of machines that perform the same operation over multiple axes such as multi-head machines.

The tool length for each Z axis can be compensated individually, and it improves machining accuracy.

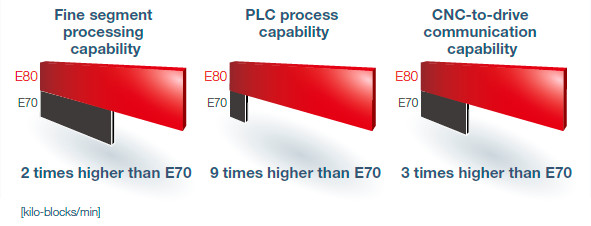

CNC-dedicated CPU

Drastic improvements in performance

CNC-dedicated CPU

With Mitsubishi Electric's high-speed CNC-dedicated CPU, the E80 Series reduces cycle times due to a higher program and PLC processing capability.

Higher optical communication speeds between the CNC and drive acheive higher accuracy in machining.

Synchronous Tapping with Analog I/F Spindle

Applicable to a wide array of machine specifications

Synchronous Tapping with Analog I/F Spindle

Synchronous tapping can be performed with an analog-connected spindle such as an inverter without using a dedicated tool holder. The applicability to a wide array of machine specifications allows for more efficient machining.