CNC M800V/M80V Series

Concept

The Evolution in Smart Manufacturing.

Seven years on, M800/M80 Series ushers in a new dimension.

A variety of innovative control functions help you to machine various ‘things’ with high speed and accuracy.

The industry's first* built-in wireless LAN, which reduces wiring and operators' movement, high‑definition 3D machining simulation, which minimizes trial cutting, and advanced user-friendly and intuitive operations streamline overall manufacturing processes and create 'time' as never before envisioned.

Our new CNC, keeping abreast of manufacturers’ needs and the advancement of the times, will optimize manufacturing in a smarter way from the perspective of ‘things’ and ‘time’.

The all new M800V/M80V CNC Series.

*As of August 2021. According to research by Mitsubishi Electric Corporation.

New control functions

Fast and high-quality machining is nothing special anymore.

New control technologies support your machining.

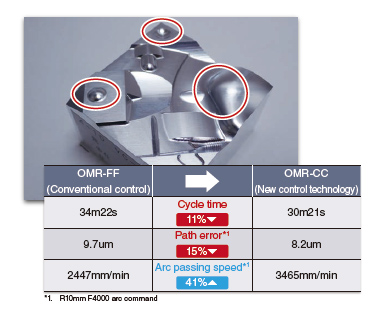

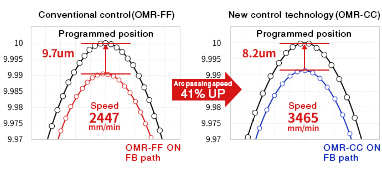

●OMR-CC(Optimum machine response-contour control)

Machining is approximately 11% faster, with no loss of accuracy, compared to the existing M800 and M80 series. This is due to control processing that adjusts to the workpiece shape to correct for programmed/actual position error.

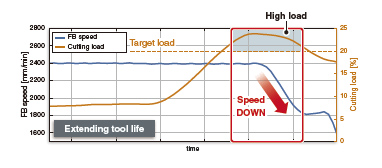

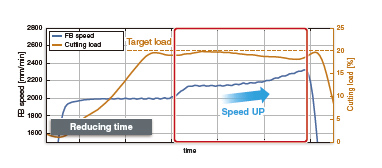

●Cutting load control

Cutting load is automatically controlled, leading to longer tool life and shorter cycle time.

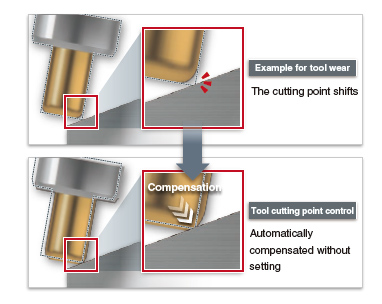

●Tool cutting point control

Tool cutting point control enables optimum machining without modification of the machining program even when the tool shape changes.

*Available for M850VW and M850VS

Built-in wireless LAN

Built-in wireless LAN increases work efficiency.

Our industry-first* NC control unit with built-in wireless LAN frees operation from the constraints of time and space. It can be connected to software tools on a PC to exchange data using wireless communication.

- *As of August 2021. According to research by Mitsubishi Electric Corporation.

- *Available for M800VS and M80V series (Display-integrated control unit)

- *The available legal wireless frequency bands and channels vary from country to country due to varying regulations governing use of radio waves.

Ensure that the country code that matches the country of operation is configured before using the wireless LAN functionality.

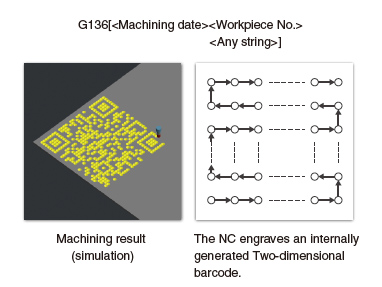

Two-dimensional barcode engraving cycle

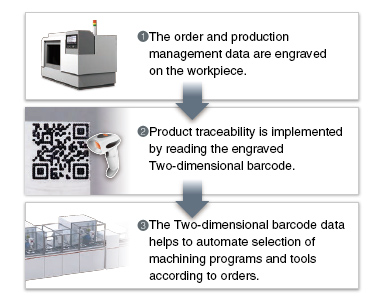

The Two-dimensional barcode engraved directly on the workpiece enables automatic selection of programs and tools as well as easy traceability.

You can create a program for engraving a Two-dimensional barcode easily using a fixed cycle.

The Two-dimensional barcode engraved on the workpiece helps automation of high-mix low-volume production and traceability of workpieces.

Intuitive operation

Streamline your work through intuitive operation not requiring expertise or know-how.

●Multi-touch operation

The usability of previous M800/M80 Series has further evolved! Four-point multi-touch makes operation easy and efficient.

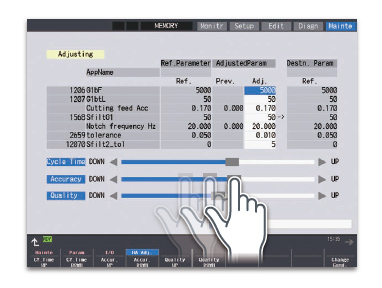

●Parameter adjustment screen for high-accuracy control

Parameter setting guidance on the dedicated screen makes it easy for anyone to improve machining quality.

Customization of screens

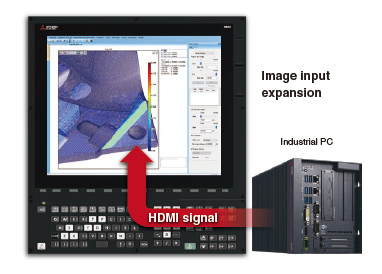

Image input interface allows for flexible customization of NC screens and applications, helping you to differentiate machine tools and create added value.

The applications on the industrial PC can be operated from the NC screen.

The NC screen can display camera images such as the inside of the machine by connecting an external camera.

*Available for M800VS and M80V series (Display-integrated control unit)

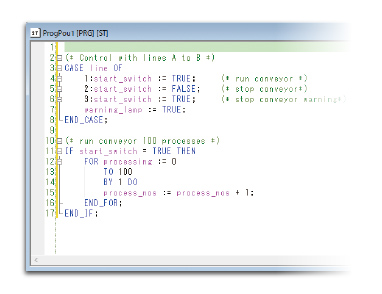

Support of ST language

ST language is supported in addition to the ladder language.

This allows you to create and edit PLC programs efficiently using the syntax resembling that of conventional programming languages.

Unlike the ladder language, ST language allows for flexible text-based programming and compact operation processing.

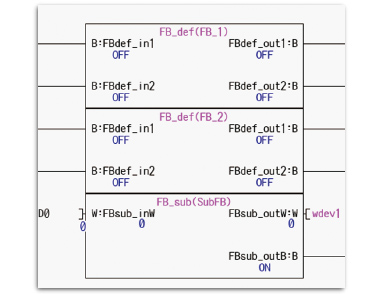

MELSEC development tool (GX Works2)

You can convert a program into function blocks (FBs) and use them in a similar way to function call in C language and Basic.

MELSEC development tool (GX Works2)

Support for sustainability

M800V/M80V Series contributes to your company’s sustainability by reducing waste caused by trial machining and defective machining.

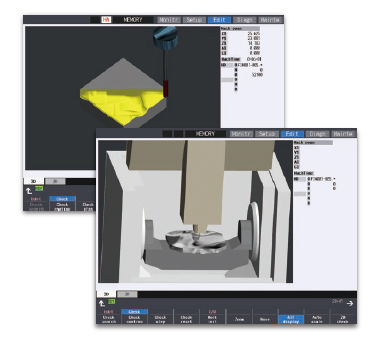

3D machining simulation

Machine interference and machining quality can be checked before machining, which reduces workpieces discarded because of trial cutting and defective machining.

*Available for M800VW series