Controllers MELSEC iQ-R Series Product features -CPU-

Motion CPU module

The motion CPU module is incorporated into the multiple CPU configuration, separating the CPU load efficiently.

High-speed general control and high-accuracy motion control are achieved, thereby contributing to high-speed and high-accuracy machine processing.

Interface

Features<sup>High-response, large-capacity data sharing for flexible adaptation to high-mix production</sup>

- Large-capacity data communication

- G code

- The multi-CPU configuration with a programmable controller CPU and motion CPU enables high-speed, large-capacity shared memory communication

- Large data sets such as cam data can be transferred in a single operation, enabling efficient program creation and modification

- In variable-mix, variable-volume production, product recipes can be instantly reflected in the motor drive according to production instructions from a computer

- Can be used for various applications, such as alignment control coordinated with the vision system and machining using G-code analysis

Visually intuitive, flexible motion control programs

- Flowchart

- Event responsiveness

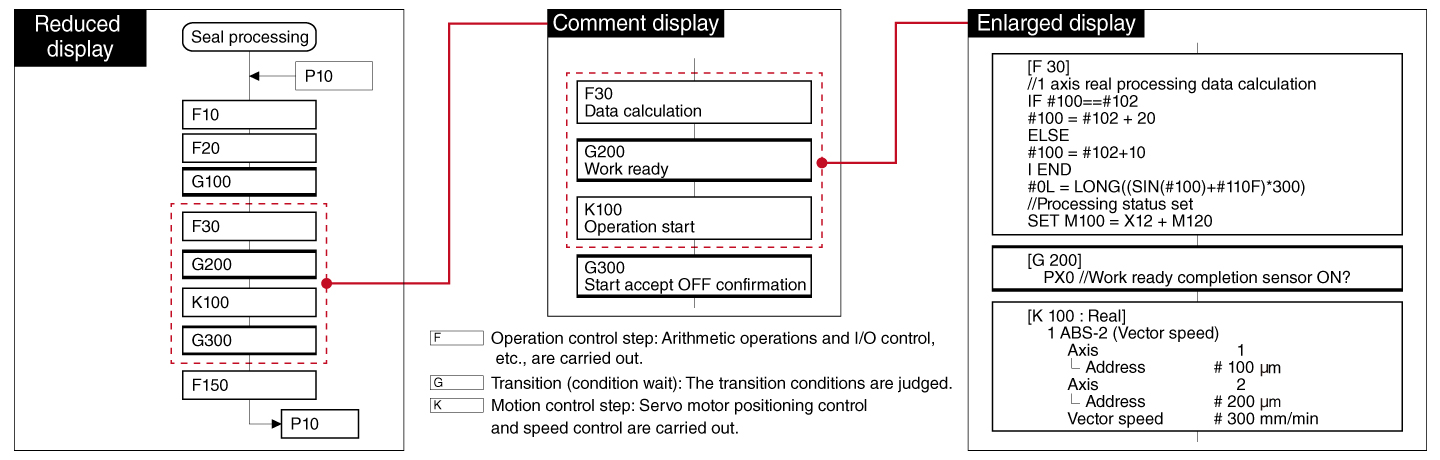

- Motion control programs can be written using flowchart-based motion SFC*1

- This format makes the processing flow easy to understand visually, resulting in high maintainability and flexibility for equipment modifications

- Motion SFC enables high event responsiveness, ensuring stable operation in equipment and line control

- *1.SFC: Sequential Function Chart

Motion SFC Program

Specifications

Motion CPU module specifications

MT SFC : Motion SFCINS : Dedicated instruction

| Item | R16MTCPU | R32MTCPU | R64MTCPU |

|---|---|---|---|

| Max. number of control axes | 16 | 32 (16 axes × 2 lines) | 64 (32 axes × 2 lines) |

| Operation cycle setting (ms) | 0.222, 0.444, 0.888, 1.777, 3.555, 7.111 |

0.222, 0.444, 0.888, 1.777, 3.555, 7.111 |

0.222, 0.444, 0.888, 1.777, 3.555, 7.111 |

| Programming language | MT SFCINS |

MT SFCINS |

MT SFCINS |

| Servo program capacity (step) | 64K | 64K | 64K |

| Number of positioning points | 6400 (positioning data can be designated indirectly) | 6400 (positioning data can be designated indirectly) | 6400 (positioning data can be designated indirectly) |

| Servo amplifier network | SSCNETⅢ/H (1 line) | SSCNETⅢ/H (2 lines) | SSCNETⅢ/H (2 lines) |

| Max. distance between stations (m) | 100 | 100 | 100 |

| Interpolation | |||

| Linear interpolation (axis) | Max. 4 | Max. 4 | Max. 4 |

| Circular interpolation (axis) | 2 | 2 | 2 |

| Helical interpolation (axis) | 3 | 3 | 3 |

| Control mode | |||

| Positioning control | ● | ● | ● |

| Continuous path control | ● | ● | ● |

| Position follow-up control | ● | ● | ● |

| Advanced synchronous control | ● | ● | ● |

| Speed-torque control | ● | ● | ● |

| G-code control*2 | ● | ● | ● |

| Acceleration/deceleration control | |||

| Trapezoidal acceleration/deceleration | ● | ● | ● |

| S-curve acceleration/deceleration | ● | ● | ● |

| Advanced S-curve acceleration/deceleration | ● | ● | ● |

| Interface | |||

| PERIPHERAL I/F | ● | ● | ● |

| SD memory card | ● | ● | ● |

| Function | |||

| Absolute position system*3 | ● | ● | ● |

| Mark detection function | ● | ● | ● |

| Digital oscilloscope function | ● | ● | ● |

| Driver communication function | ● | ● | ● |

- *2.G-code control is available by additionally installing the G-code control add-on library. For more information, please contact your local Mitsubishi Electric sales office or representative.

- *3.Supported when a battery is connected to the servo amplifier. A battery is not required when using a servo motor equipped with a battery-less absolute position encoder.