Geared Motors Product Features Examples

Examples of S-PM uses

No. 1: Panel-coating device

Benefits of going sensorless

- Synchronizes each axis

- Reduces rotation unevenness

- Simplifies wiring

Configuration and objectives for former devices

Driven by a single belt-equipped unit, this product reduces the amount of abrasion powder, contributing to maintenance-free operation (which is also affected by slippage in asynchronous motors).

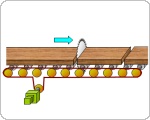

No.2: Automatic cutting machine

Benefits of going sensorless

- Enables maintenance-free operation

- Makes drive section more compact

- Improves frequency

Configuration and objectives for former devices

Clutch brake-equipped geared motors drive provides reduced costs and improved cutting rates.

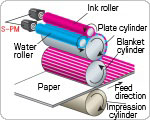

No.3: Offset printing press

Benefits of going sensorless

- duction of speed variance rate

- Synchronizes each axis

- Reduces rotation unevenness

Configuration and objectives for former devices

Provides more stable speed (and less printing unevenness) than brushless DC motor operation, and improves reliability.

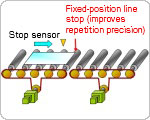

No.4: Panel deposition device

Benefits of going sensorless

- No induction motor slippage effects

- Improves repetition precision

- Makes compact

Configuration and objectives for former devices

Combination of geared motors, inverter control, and positioning sensor keeps variance under control in stop position.

No.5: Noodle-making machine

Benefits of going sensorless

- Reduction of speed variance rate

- Simplifies equipment

- Uses positioning sensor to improve waterproofing properties

Configuration and objectives for former devices

The configuration combining an encoder with geared motors provides for improved waterproofing properties, more constant speeds, and more streamlined operation.

Examples of Geared Motors uses

No.1: General-purpose conveyor

Geared motors are commonly used in general-purpose conveyor applications, because they can be applied variously to carry lightweight products or heavy goods such as earth and sand.

You can choose geared motors ranging from 25 W to 55 kW depending on conveyance speed desired and load mass.

No.2: Mixing machine

Geared motors can also be used for direct-drive applications of flanged and vertical geared motors used for mixing and stirring viscous substances.

Care must be taken when selecting geared motors to accmodate such factors as changes in viscosity when stirring.

No.3: Food machinery

Geared motors have a broad range of applications such as wrapping foodstuffs or cleaning.

We also offer waterproof models such as the IP67 and IP65.

No.4: Multilevel parking garage use

We offers reduced-noise models for keeping ambient noise down to a minimum when used with equipment for multistory parking garages located in apartment buildings or aboveground parking lots.

Also maintains waterproof properties.

No.5: Semiconductor fabrication equipment

Waterproof models that suppress dust are available, optimized for clean environments.

Fanless S-PM of up to 0.75 kW are also available.

No.6: Woodworking machines

Geared motors can be used for powder dust environments and outdoor specifications, as well as applications that generate impulse loads.