Inverters-FREQROL FR-A800 Series SYSTEM SUPPORT (NETWORK)

SYSTEM SUPPORT

(NETWORK)

A seamless data interface is offered.

Ethernet communication function integrated

Inverter with communication function NEW

FR-A800-GN

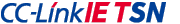

With the CC-Link IE TSN (Time Sensitive Networking) communication function, data can be transmitted to IT systems while performing real-time cyclic communication control. This will contribute to startup time reduction and maintainability improvement.

Startup time reduction

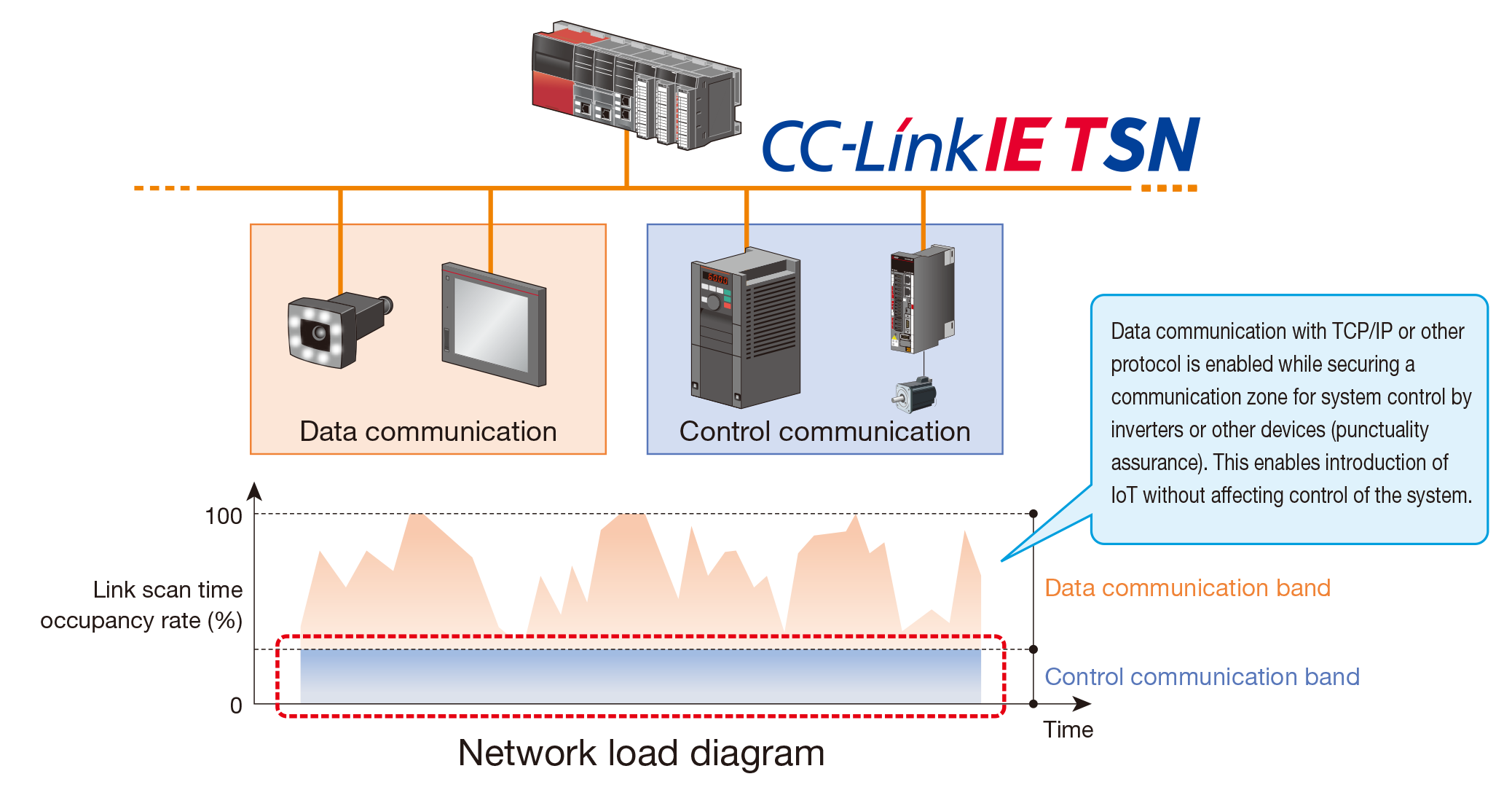

Station numbers are easily set with rotary switches.

Automatic detection of the network configuration by the engineering software (GX Works3) reduces the startup time.

Problems at startup such as line faults can be discovered at a glance with the diagnostic function.

Improved maintainability

Time synchronization allows for real-time monitoring.

This enables trouble analysis to be performed right after an error has occurred.

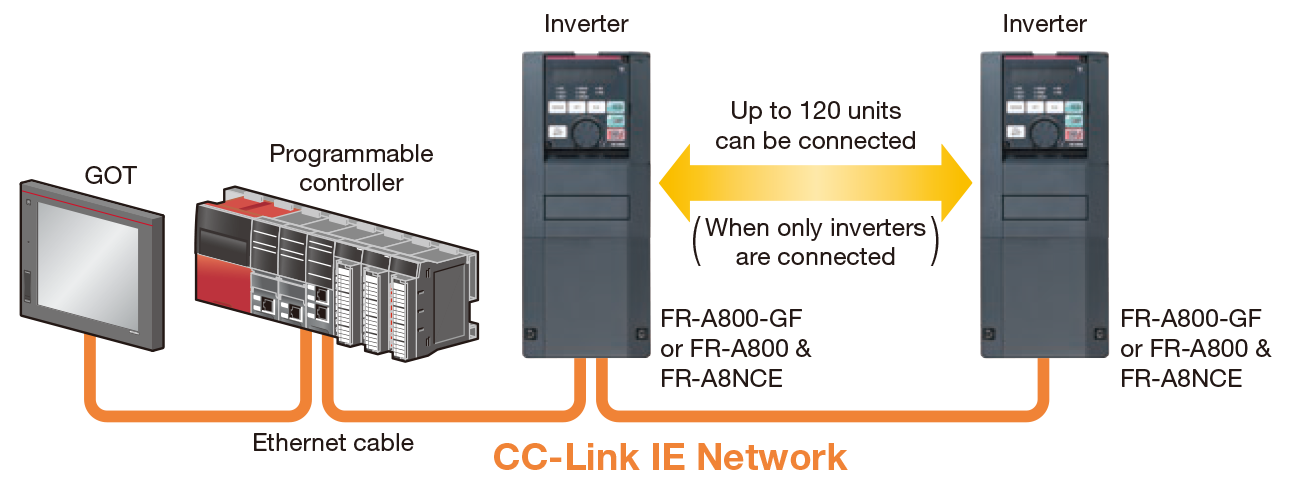

FR Configurator2 can be connected via Ethernet, which makes maintenance work easier.

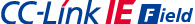

FR-A800-GF

The inverter has the CC-Link IE Field Network communication function, which enables immediate operation via the CC-Link IE Field Network.

FR-A800-E

The CC-Link IE Field Network Basic is supported, so the network can be created easily. The inverter's status can be monitored and the parameters can be set via Internet. (MODBUS/TCP is also supported.)

CC-Link family compatible with the FR-A800 series inverters

| Item |  |

|

|

|

|

|---|---|---|---|---|---|

| Compatible inverter | FR-A800-GN、 FR-A800+FR-A8NCG |

FR-A800-GF、 FR-A800+FR-A8NCE |

FR-A800-E | FR-A800+FR-A8NC | |

| Communication speed | 1Gbps | 1Gbps | 100Mbps | 10Mbps | |

| Cable | Ethernet category 5e or higher | Ethernet category 5e or higher | Ethernet category 5 or higher | Dedicated cable | |

| Number of connectable inverters | 121 (sum of master and slave stations) | 64 | 64 (open specification)*1 | 42 (maximum) | |

| Cyclic communication | Compatible | Compatible | Compatible | Compatible | |

| Number of links*2 | RX | 64 | 64 | 64 | 64 |

| RY | 64 | 64 | 64 | 64 | |

| RWr | 128 (256 bytes) | 128 (256 bytes) | 32 (64 bytes) | 32 (64 bytes) | |

| RWw | 128 (256 bytes) | 128 (256 bytes) | 32 (64 bytes) | 32 (64 bytes) | |

| Combination with TCP/IP | Supported | Not supported | Supported | Not supported | |

| Topology | Line, star, ring*3, line-star |

Line, star, ring, line-star |

Star | Bus | |

- *1The actual number of connectable inverters differs according to the setting of the master.

- *2The numbers of inverter's remote I/O devices and the addresses of inverter's remote registers are common between CC-Link and CC-Link IE Field Network Basic.

- *3Ring topology will be supported later.

Other network communication

Communication option

- CC-Link, SSCNET III (/H), DeviceNet™, PROFIBUS-DPV0 are supported using a compatible communication option. Other Ethernet-based communication such as the CC-Link IE Field Network communication and the FL remote communication can be also supported.

- A function block (FB) programming for CC-Link communication is available for the MELSEC-Q/L series to create the inverter control sequence programs easily. (The FB library (collection of FB elements) can be downloaded from the Mitsubishi Electric FA Global Website.)

- The standard model with an RS-485 interface (Mitsubishi inverter protocol, MODBUS® RTU protocol) enables communication with other devices without using a communication option.