FR-A800 Plus Series

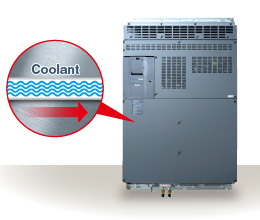

FR-A800 Plus Liquid cooled type

Coolant is used for cooling the inside of the inverter. Liquid cooling enables new applications in the environments where heat is difficult to be dissipated.

Features

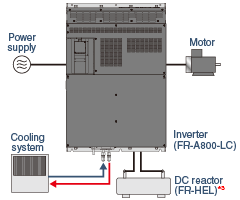

A smaller enclosure can be used since the quantity of the heat dissipated in the enclosure is reduced.

A sensor (flow switch) is attached at the inlet of coolant to send a signal to the inverter. When the coolant flow rate decreases, a warning is output, enabling quick, direct detection of system faults.

The power supply voltage of 690 VAC is supported. A wider range of power supply voltage is covered.

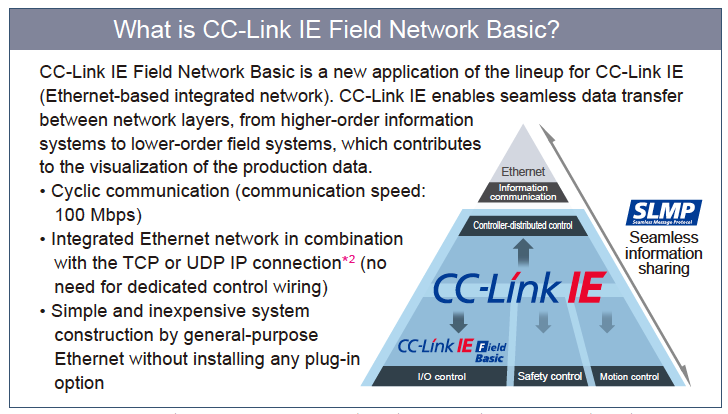

- ● CC-Link IE Field Network Basic

- ● MELSOFT / FA product connection

- ● SLMP*1

- ● MODBUS/TCP

- *1:SLMP is a common protocol for seamless communication between applications. Users do not have to be concerned with network layers or boundaries.

- *2:MELSOFT / FA product connection, SLMP, etc.

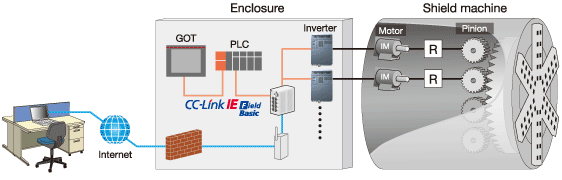

The FR-A800-E-LC inverter can be remotely operated via Ethernet using FR Configurator2, which will be upgraded soon. Parameter setting, monitoring, and maintenance (for example, parts lifespan diagnosis) of the FR-A800-E-LC inverter is possible through network. Adjustment time and downtime of the inverter can be reduced.

Application examples

System configuration example

- *3: Always connect a DC reactor appropriate to the applied motor capacity.

Model

■Inverter

■DC reactor

- *4: For the CA type, the monitor output terminal FM/CA operates as terminal CA (analog current output: 0 to 20 mADC), not as terminal FM (pulse train output