Inverters-FREQROL-CS Series Application examples

Variety of Functions to Support Various Applications

Spinning

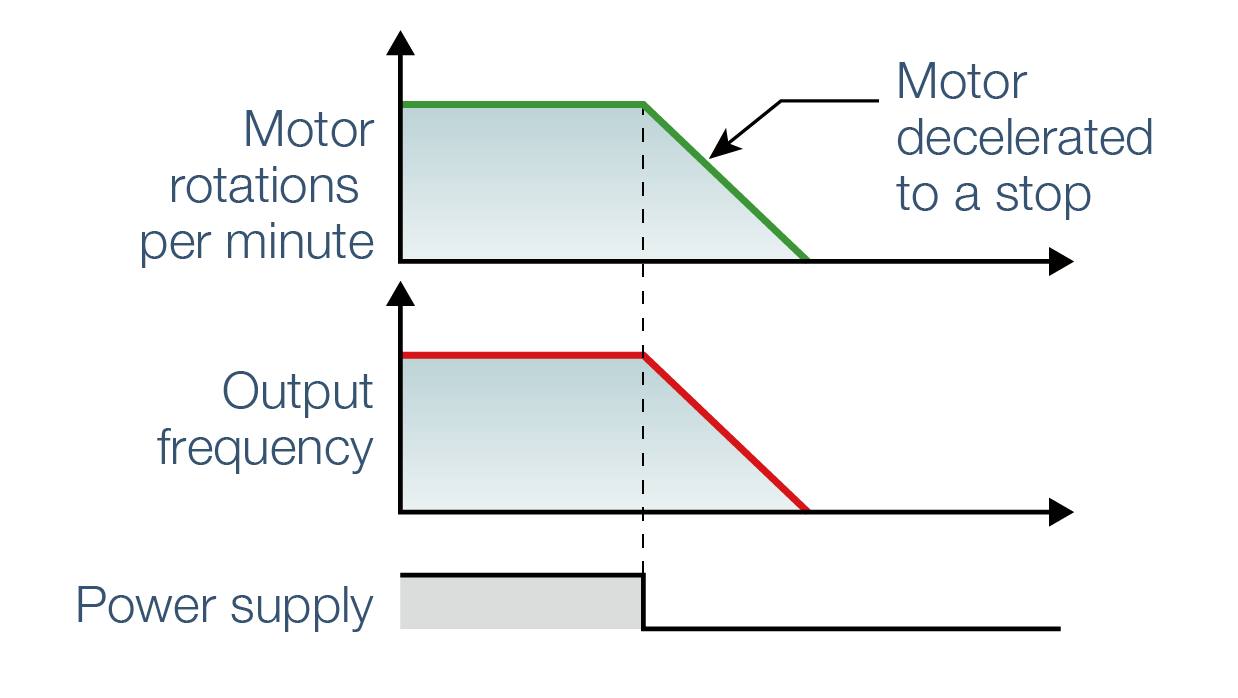

Traverse function

The traverse function, used for the traverse axis of spinning machine, prevents uneven winding or collapsing.

- f0: set frequency

- f1: amplitude amount from the set frequency

- f2: compensation amount at transition from acceleration to deceleration

- f3: compensation amount at transition from deceleration to acceleration

- t1: time for acceleration during traverse operation

- t2: time for deceleration during traverse operation

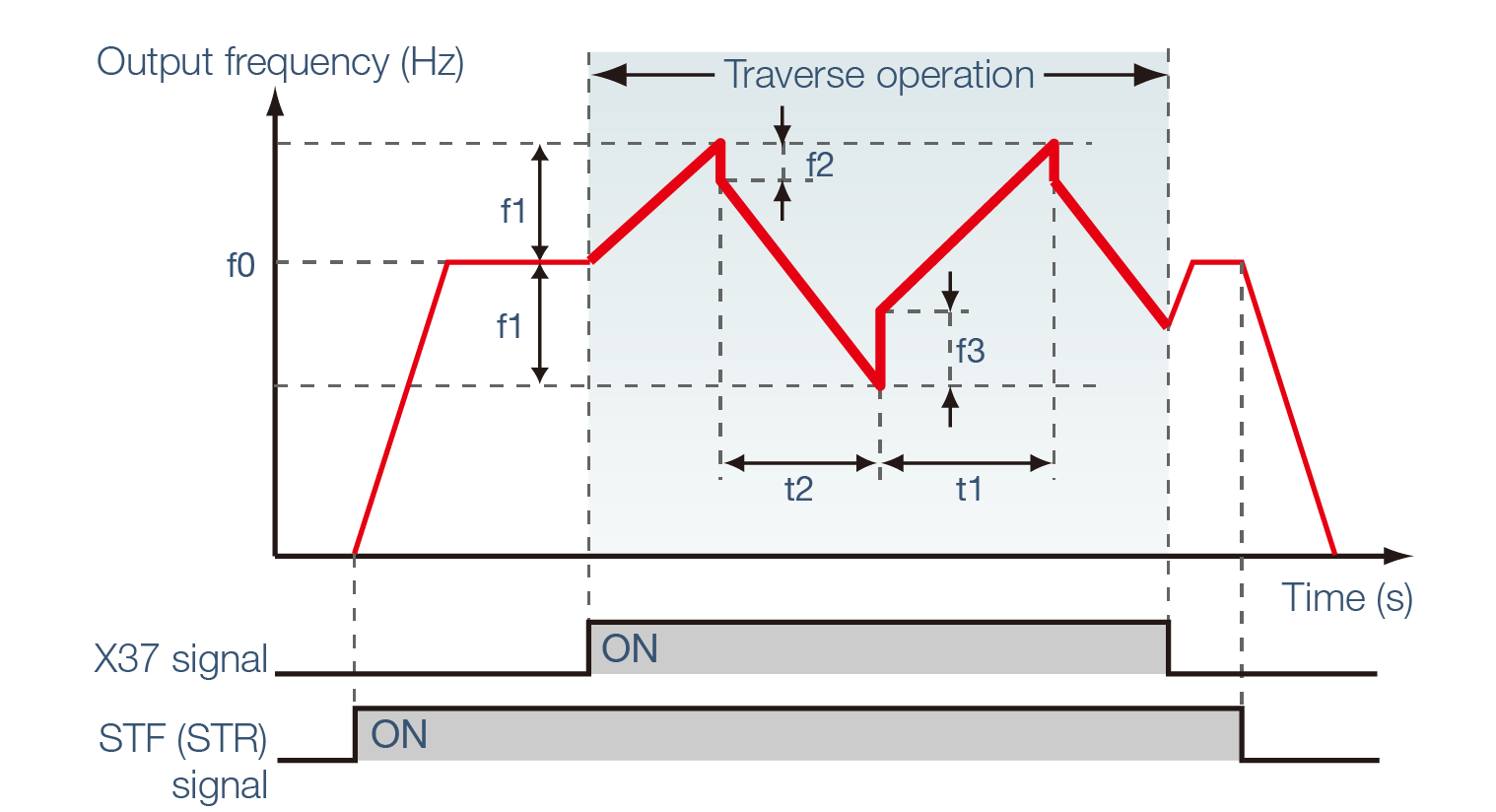

Power failure time deceleration-to-stop function

The motor decelerates to a stop without coasting when power failure or undervoltage occurs. Slack in the thread can be controlled even if there is a power failure.

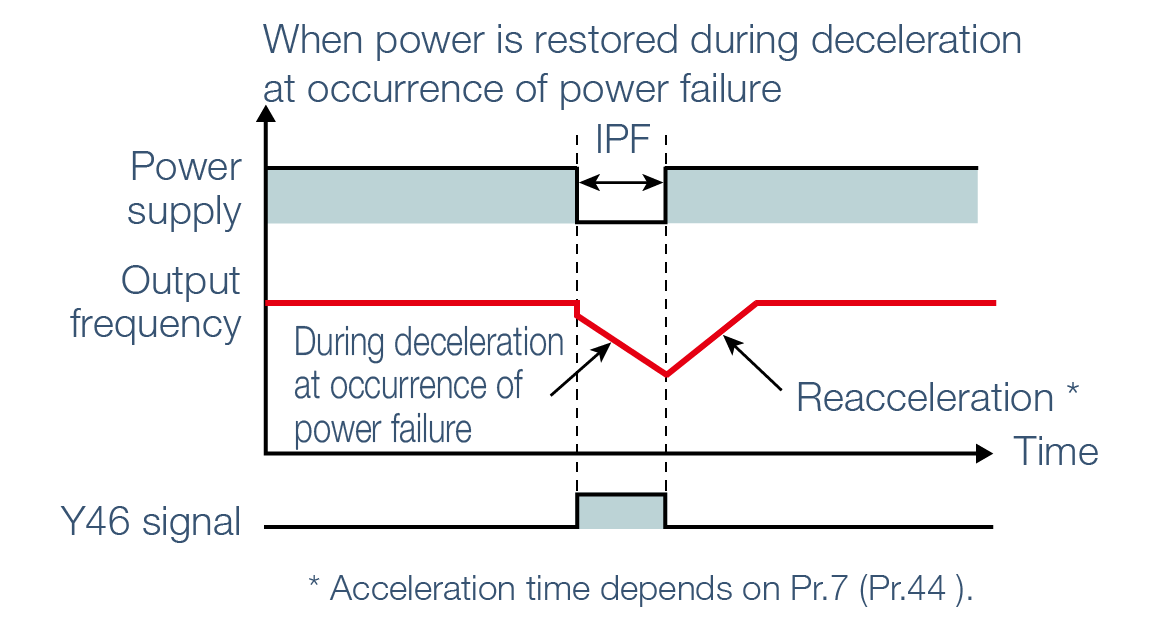

Continuous operation function at instantaneous power failure

Even in the event of an instantaneous power failure, motor operation continues without coasting and production is maintained.

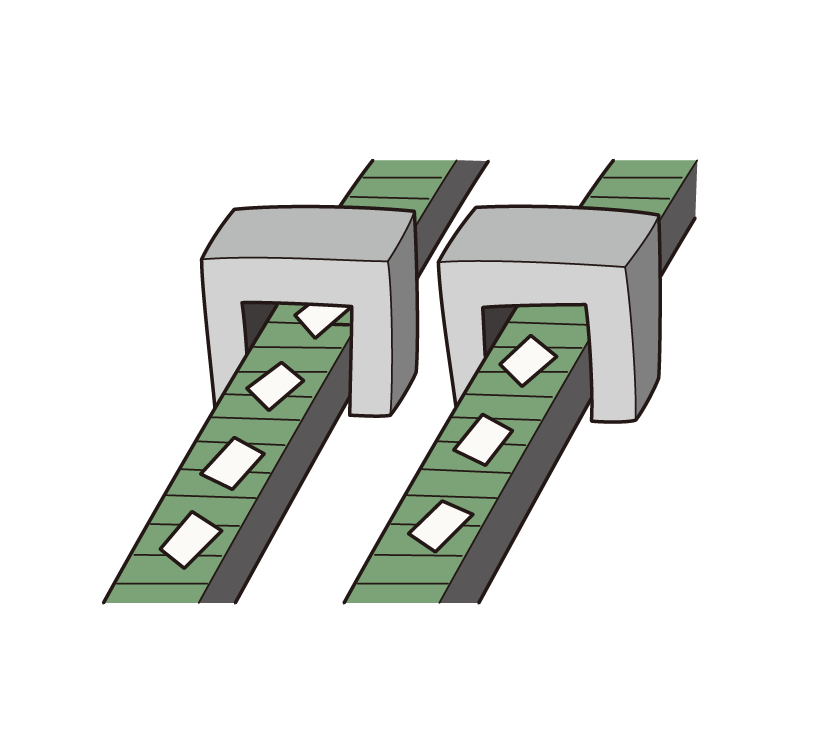

Conveyor

Increased excitation deceleration

The deceleration time can be reduced without using a brake resistor.

The tact time can be reduced for a transfer line or the like.

Communication operation (RS-485 communication)

Conveyor belts can be controlled individually by using multiple inverters.

Automatic operation is possible by collectively managing multiple inverters.

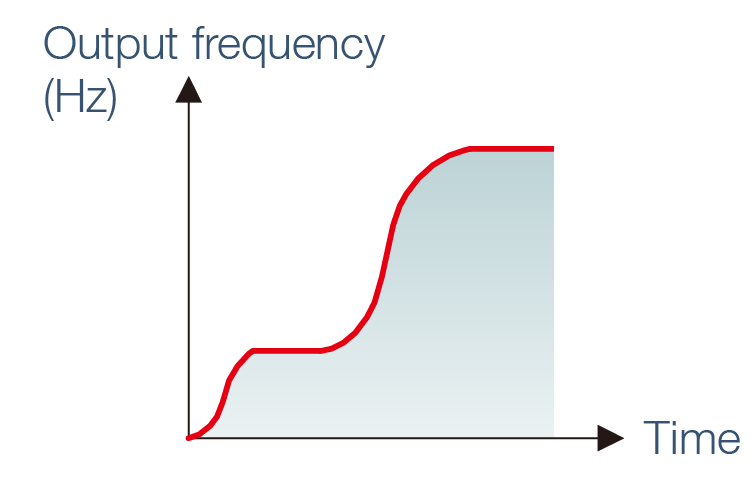

S-pattern acceleration/deceleration

An S-pattern is maintained from the present frequency to the target frequency; therefore it is possible to reduce shock during acceleration/deceleration and prevent load shifts.

Fan and pump

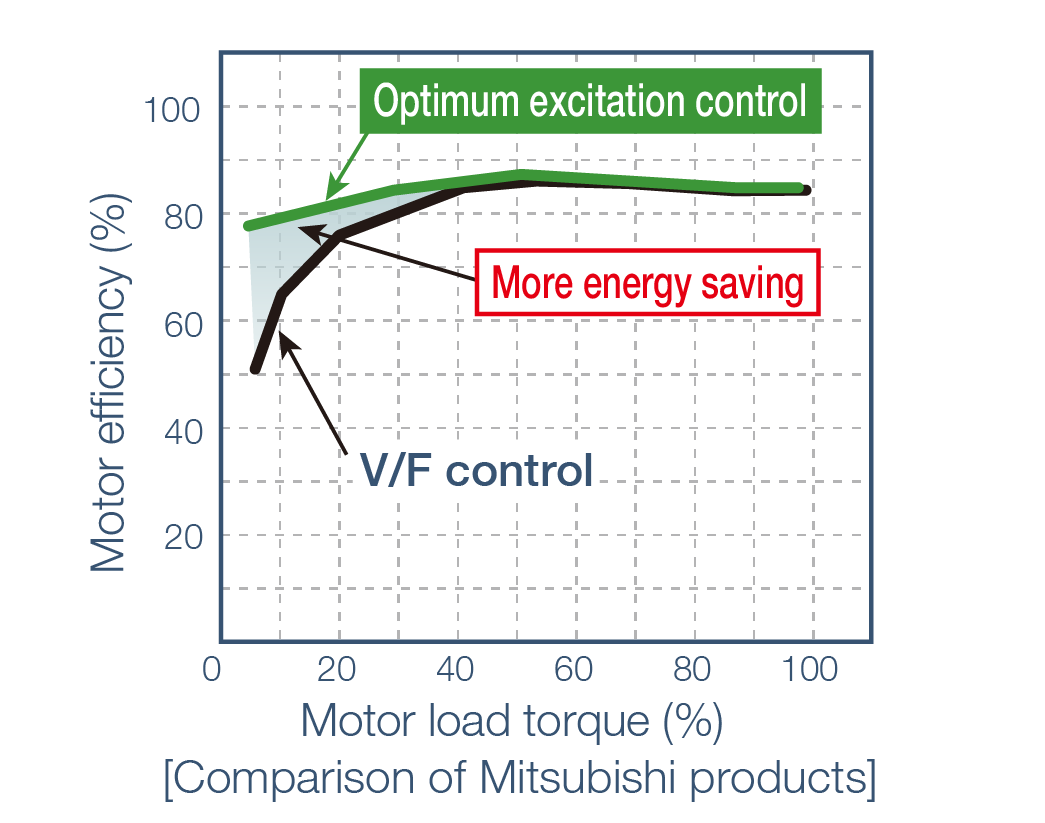

Optimum excitation control

This control enables the motor efficiency to its optimum. More energy saving is possible in applications with variable load torque characteristic such as fan and pump.

PID control

Flow rate and air volume is controlled by an inverter. It is possible to regulate flow rate and air volume so that they stay at a pre-set level.

Adjustable 3 points V/F

The optimal V/F pattern matching the torque characteristics of the facility can be set.

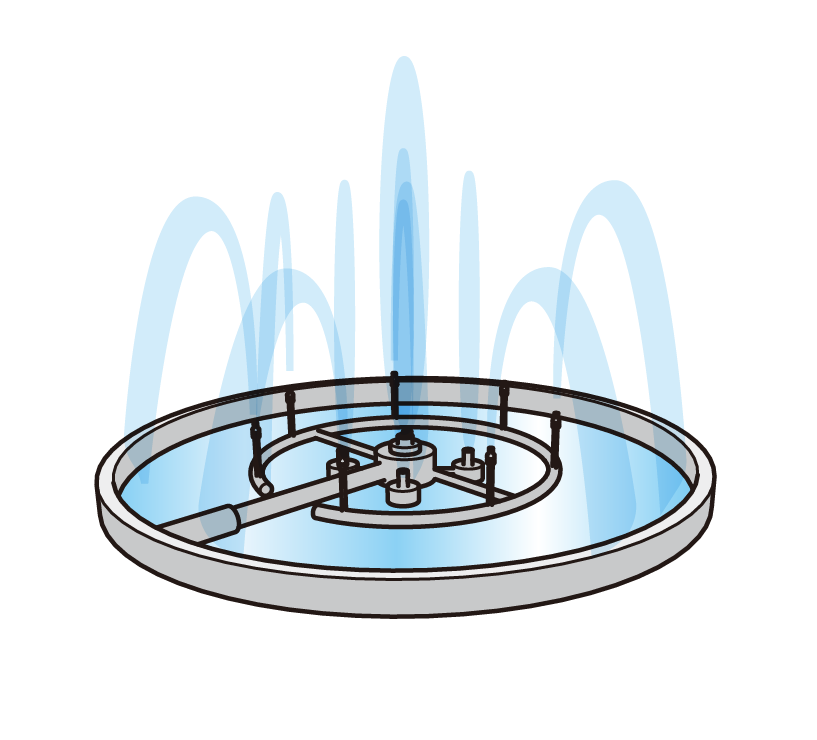

Fountain

General-purpose magnetic flux vector control

Brake unit connection

A variety of fountain displays are possible by connecting a brake unit which allows high starting torque and improved braking efficiency during deceleration under General-purpose magnetic flux vector control.

Continuous operation function at instantaneous power failure

Even in the event of an instantaneous power failure, motor operation continues without coasting and the fountain's operations are undisturbed.

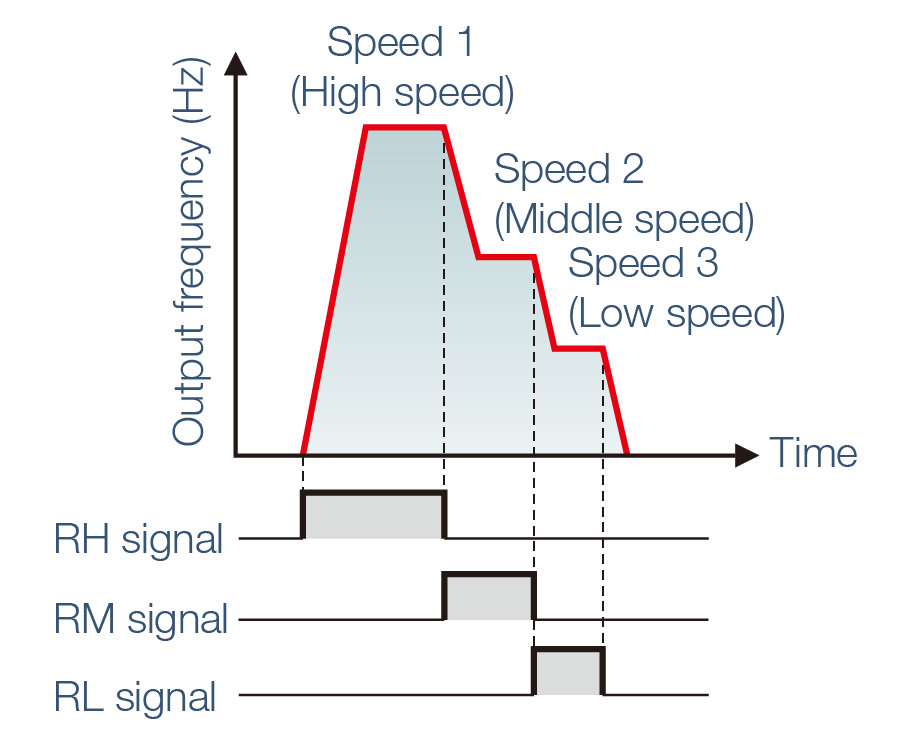

Multi-speed function (Up to 15-speed switching operation)

Operation speeds can be pre-set via parameters. Motor speed to meet the height requirements of the fountain can be set and easily changed.

Wood processing machine

Continuous operation function at instantaneous power failure

Even in the event of an instantaneous power failure, motor operation continues without coasting and production is maintained.

Power failure time deceleration-to-stop function

The motor decelerates to a stop without coasting when power failure or undervoltage occurs. This function is useful for stopping the motor at power failure to prevent danger.

Multi-speed function (Up to 15-speed switching operation)

Operation speeds can be pre-set via parameters. Operation speed suitable for the ingredients being used can be set and easily changed.

Food machinery

General-purpose magnetic flux vector control

Depending on the type of ingredients, with the right amount of low speed torque it is possible to regulate a suitable speed for food production.

Fast-response current limit

Operation continues and the overcurrent alarm is not activated even if there is a sudden change in load during the cutting of food.

Power failure time deceleration-to-stop function

The motor decelerates to a stop without coasting when power failure or undervoltage occurs. This function is useful for stopping the motor at power failure to prevent danger.