Inverters-FREQROL-CS Series Feature

World's smallest class compact body

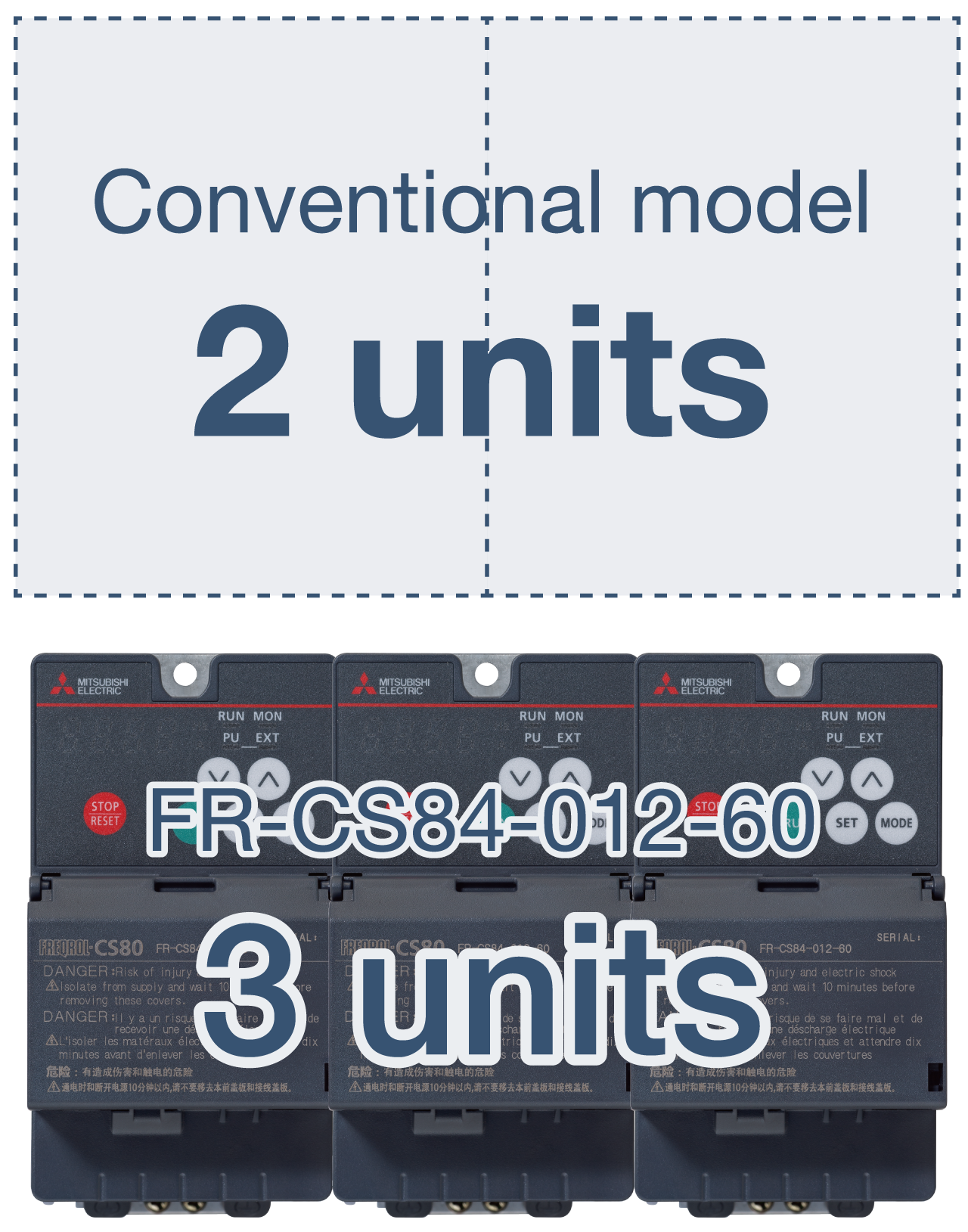

Space saving by the side-by-side installation

Side-by-side installation is possible*. Three FR-CS84-012-60 inverters can be installed in space for two conventional models to save space.

A DIN rail installation attachment (FR-UDA[][]) option can be used. (excluding inverters FR-CS84-120 to 295)

* Keep the surrounding air temperature of the inverter at 40 ℃ maximum.

High performance

Compact yet high performance

General-purpose magnetic flux vector control

General-purpose magnetic flux vector control and auto tuning functions are available. These functions ensure the applications that require high starting torque, such as washing machines, agitators, and transfer machines including conveyors, hoists, and elevators.

- High torque of 150% / 1 Hz is realized (when the slip compensation function is valid).

- Auto tuning

With our "non-rotation" auto tuning function the motor constant (R1) can be automatically calculated.

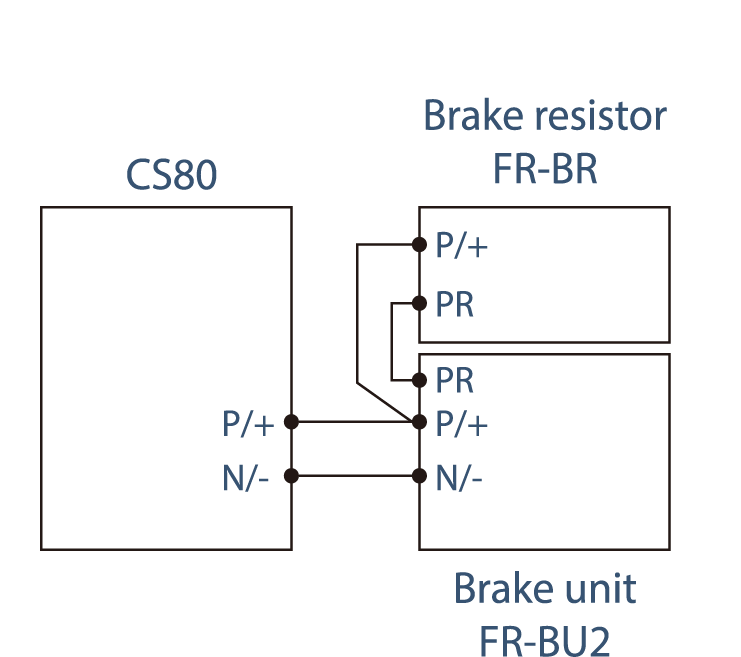

Brake unit connectionOption

Brake unit can be connected using terminal P/+ and terminal N/-. It is useful for applications require regenerative braking torque during deceleration, such as transfer machines and food machines.

When using the inverter with the brake unit, use the FR-CS84-050-60 or higher capacity inverter.

Optimum excitation control

The excitation current is constantly adjusted to its optimum value to drive the motor most efficiently. With a small load torque, a substantial energy saving can be achieved.

Easy to use

Easy-to-read operation panel

Operation panel FR-LU08Option

An optional LCD operation panel (FR-LU08) is also available.

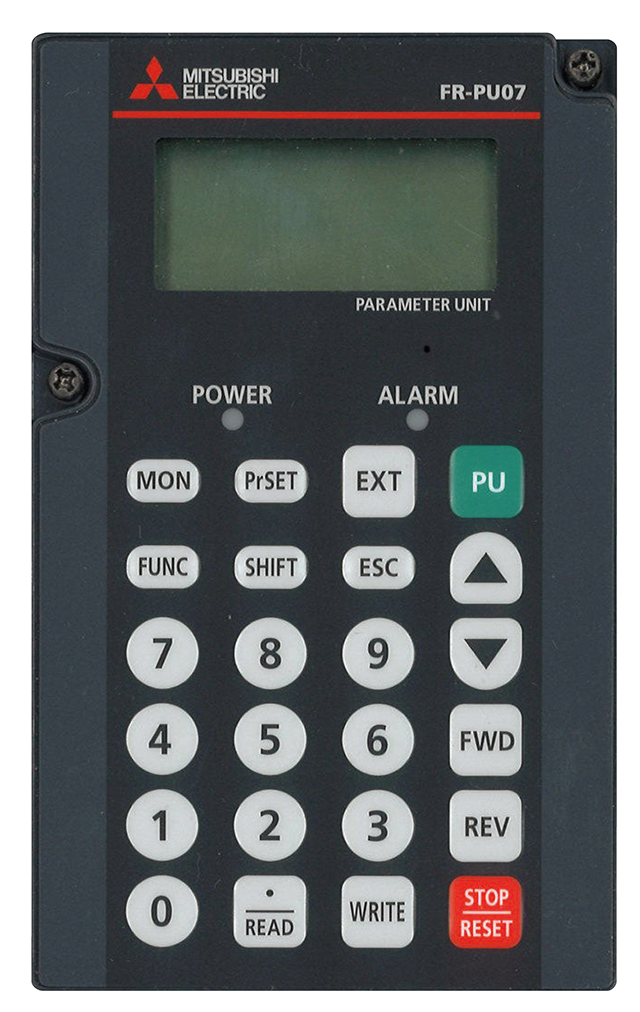

Parameter unit FR-PU07Option

The parameter unit features helpful settings such as direct input with ten-key pad, operating status display, and help function.

Eight languages are supported.

Parameter settings for up to three units can be saved.

Enclosure surface operation panel FR-PA07Option

The operation panel enables inverter operation and monitoring of frequency setting from the enclosure surface.

The operation panel cannot be removed from the inverter. The separate parameter unit connection cable (FR-CB20[]) is required.

To connect the FR-LU08, the operation panel connection connector (FR-ADP) is also required.

Shorter startup time with easy setup

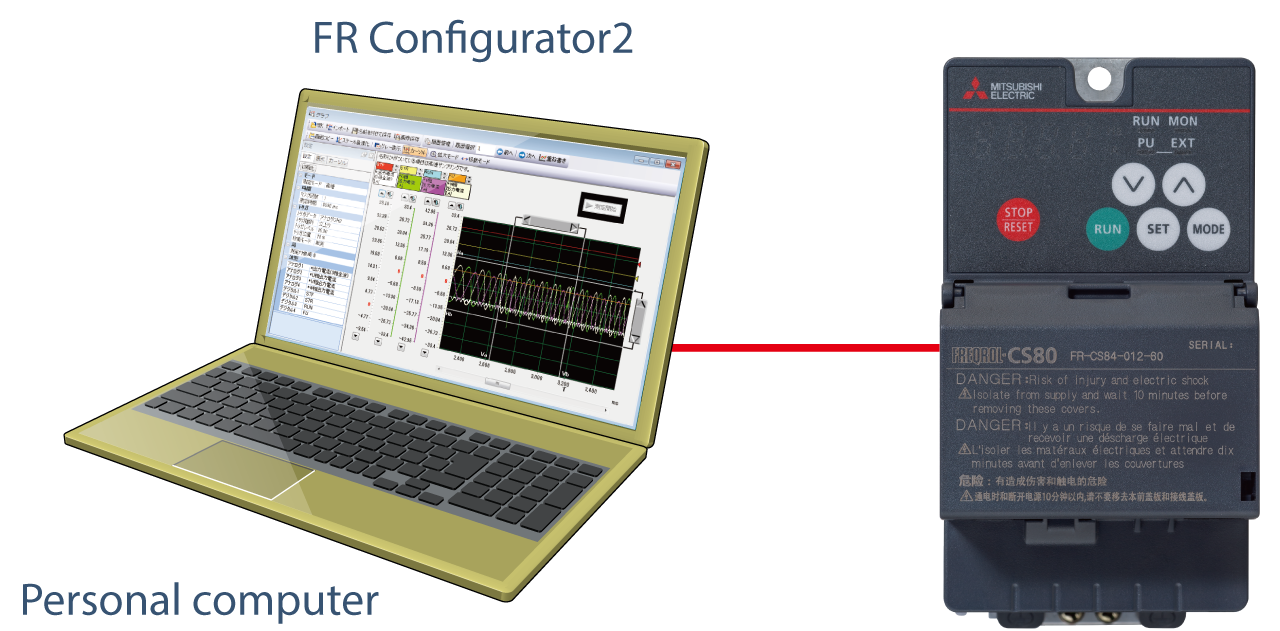

Inverter setup software FR Configurator2Option

The software is easy to use and has unity as Mitsubishi Electric FA products with MELSOFT common design and good operability.

Free trial version, which contains start-up functions, is available. It can be downloaded at Mitsubishi Electric FA Global Website.

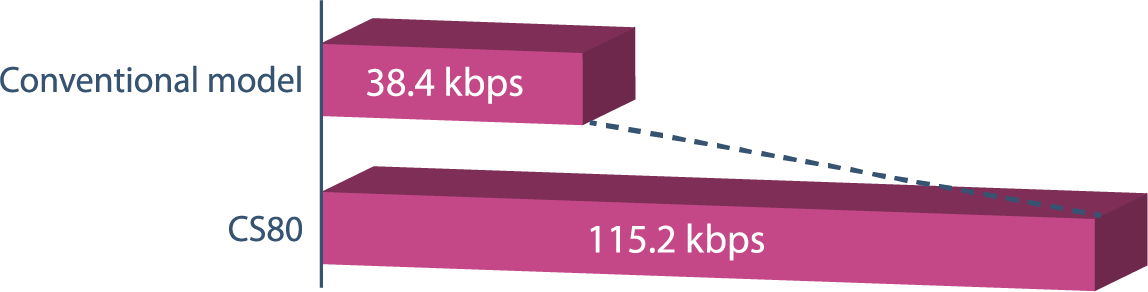

Supporting high-speed communication

RS-485 communication

Using a controller, the inverter can be controlled and monitored via network. The standard model with an RS-485 interface (Mitsubishi inverter protocol, MODBUS RTU protocol) enables communication with the speed of up to 115.2 kbps.

Easy-to-follow display improves the operability

Easy connection with GOT

When the automatic connection is enabled, the inverter can communicate with the GOT2000 series simply by connecting the GOT.

Easy maintenance

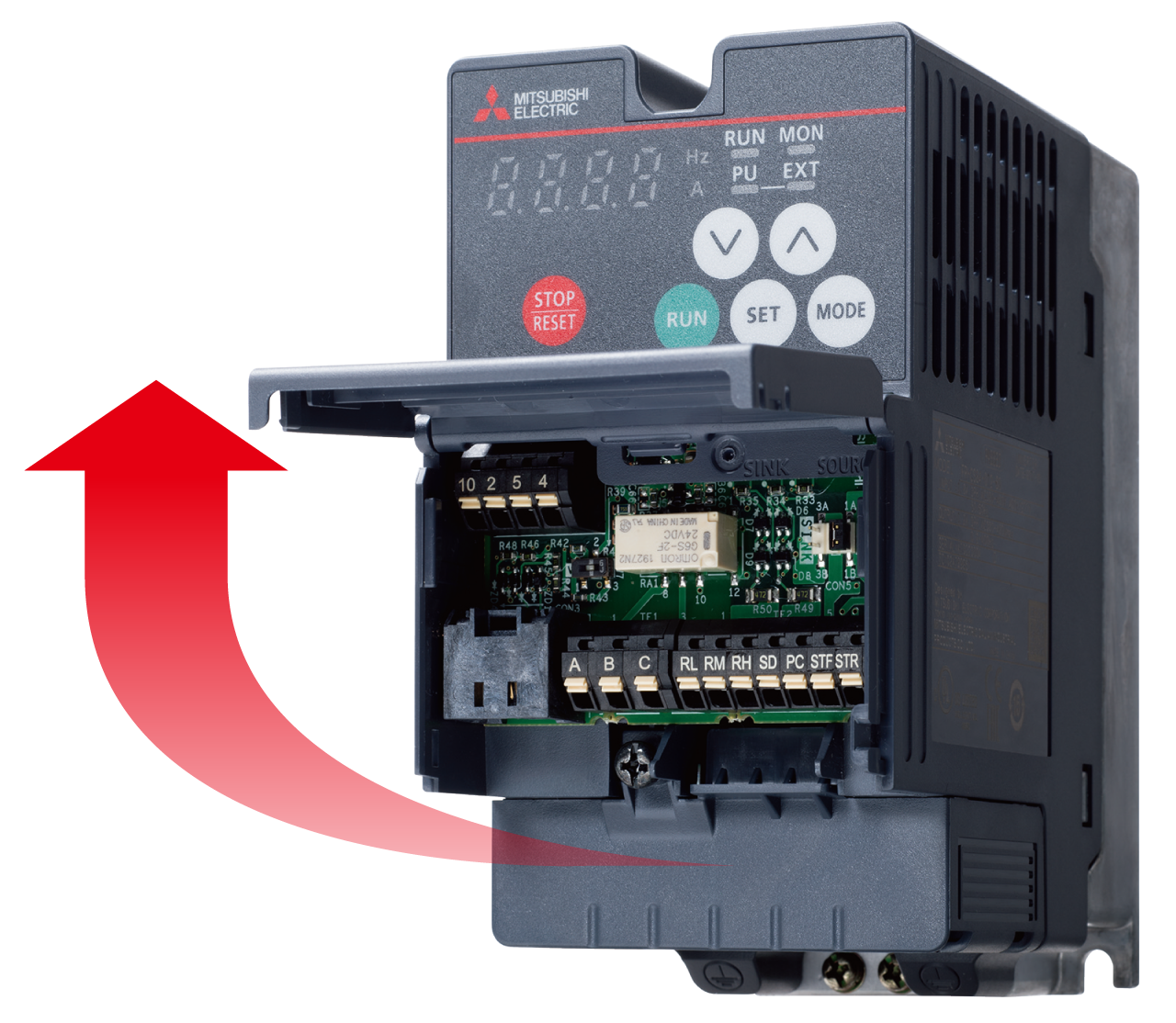

Reduced wiring check time

The wiring can be checked only by lifting the control terminal cover, which makes maintenance work easier.

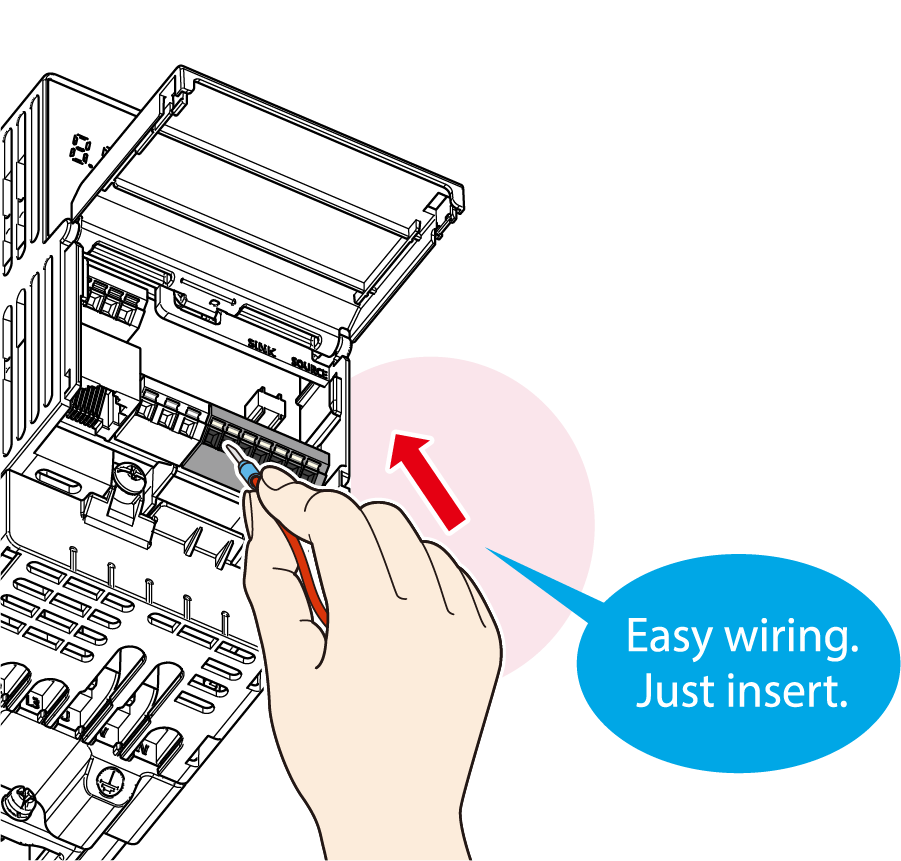

Easy wiring to the control circuit

Spring clamp terminals (control circuit terminals)

Spring clamp terminals*1 provide high reliability and easy wiring.

*1The main circuit terminals are screw terminals.

- Easy wiring

Wiring is completed only by inserting the dedicated blade terminal of each cable.

Without using the blade terminal, the loose wires can also be connected using a flathead screwdriver.

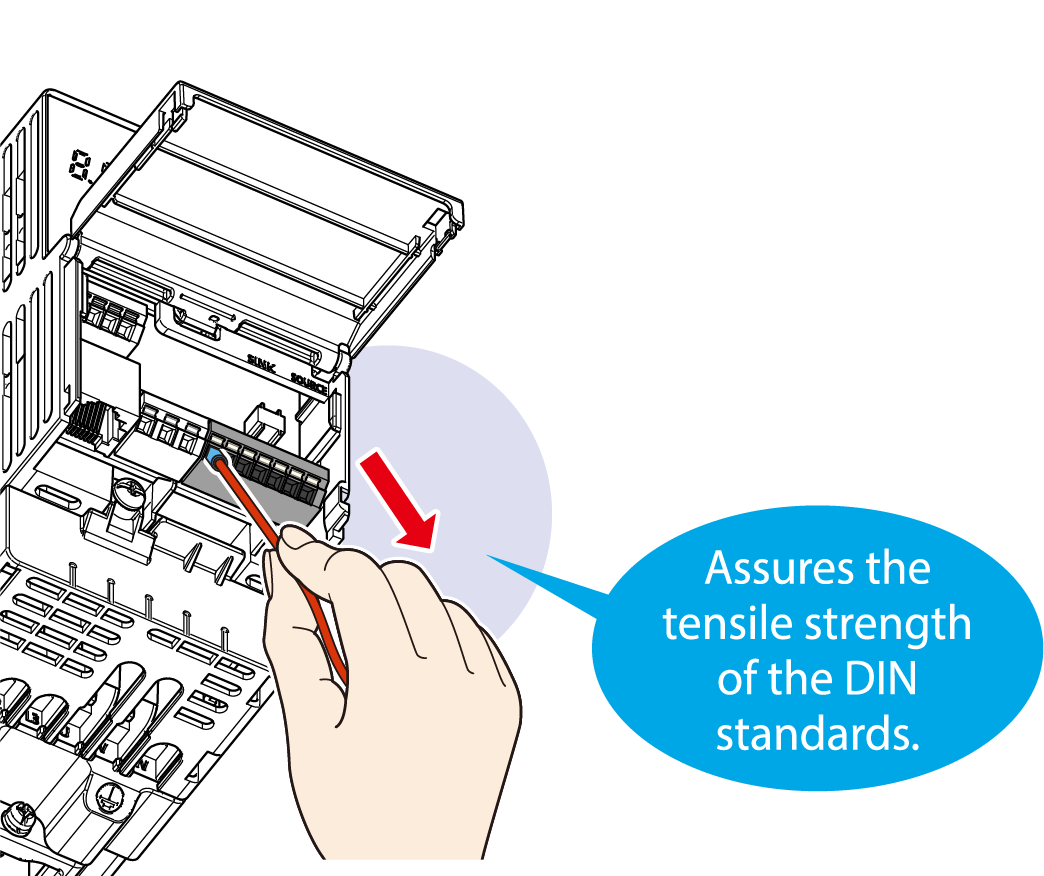

- High reliability

Internal terminal contacts are spring-type.

Therefore, wires can be protected against loosening or contact faults due to vibrations during operation on a bogie or during transport. - Maintenance-free

No additional screw tightening is required.

(Example: transport of the inverters)

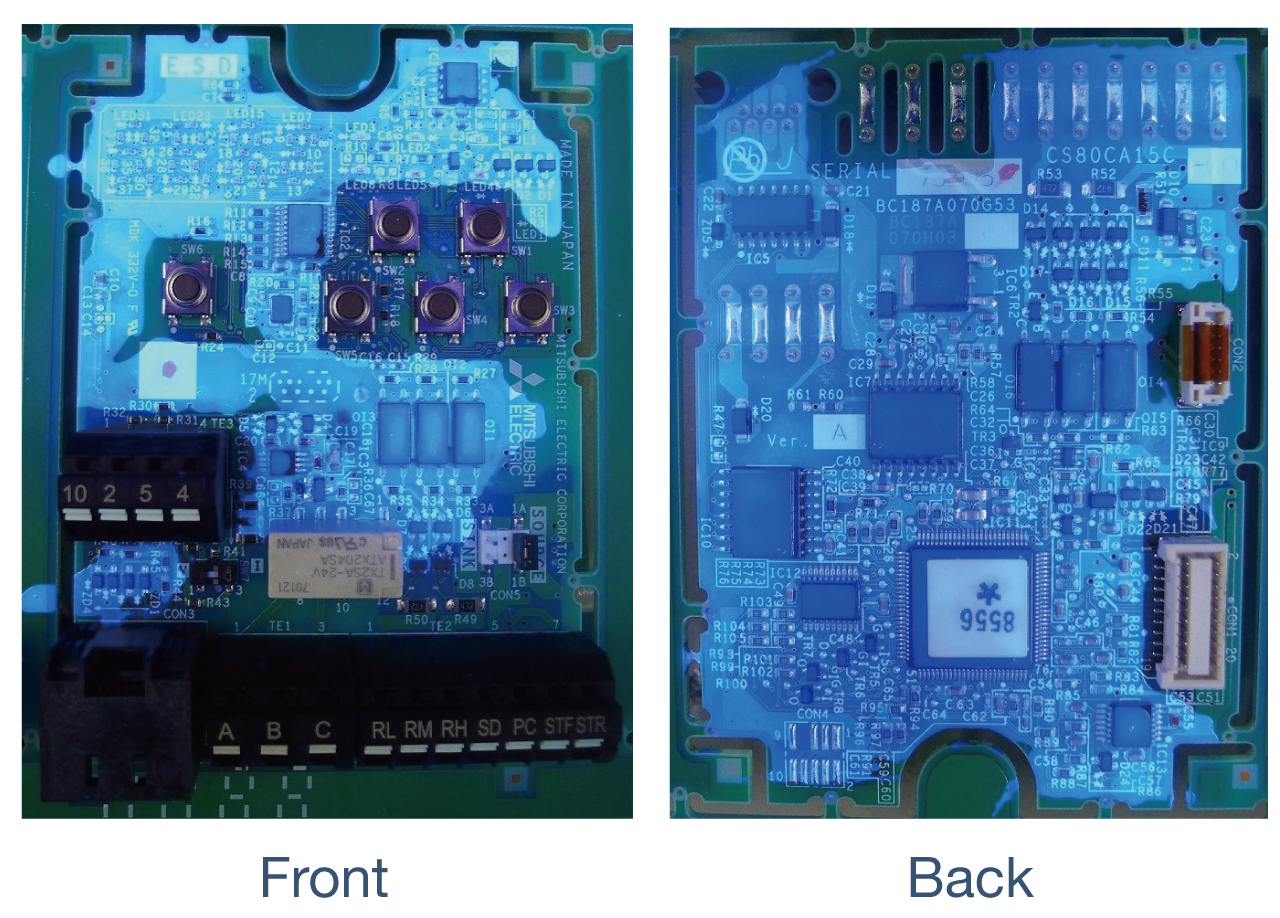

Protected in hazardous environments

The circuit board coating conforms to IEC 60721-3-3 3C2/3S2 for improved environmental resistance.