MELSERVO-J4 Series Linear Servo Motor Features

- Sophisticated Performance

- Achieving High-performance Machine

- Ideal for Multi-Head Systems

- LM-H3 Series

- LM-F Series

- LM-K2 Series

- LM-U2 Series

- Related Link

Sophisticated Performance

- Maximum speed: 3 m/s (LM-H3 series)

- Maximum thrust range: 150 N to 18000 N

Small size and high thrust are achieved by the increased winding density and the optimized core and magnet geometries as a result of electromagnetic field analysis. - Four series are available: core, liquid-cooling core, magnetic attraction counter-force core, and coreless types.

- The linear servo motors are compatible with a variety of serial interface linear encoders including A/B/Z-phase differential output type linear encoders*. The linear encoder resolution ranges from 1 nm and up.

* A/B/Z-phase differential output type linear encoder is compatible with MR-J4-GF-RJ/MR-J4-B-RJ/MR-J4-A-RJ servo amplifier. - High-performance systems such as high-accuracy tandem synchronous control are achieved using MR-J4 series servo amplifier with CC-Link IE Field Network or SSCNET III/H compatible controller.

Achieving High-Performance Machine

For higher machine performance

- Improved productivity due to high-speed driving part.

- High-accuracy positioning by fully closed loop control system.

For easier use

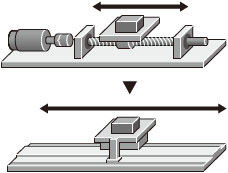

- The linear servo motor enables simple and compact machine with high rigidity.

- Smooth operation and clean system are achieved.

For flexible machine configurations

- Multi-head and tandem systems are easily configured.

- The linear servo motor is suitable for long-stroke applications.

[Offers more advantage than conventional ball screw driving systems]

Ideal for Multi-Head Systems

- The linear servo motors configured in tandem are suitable for large systems that require highly accurate synchronous operation between two axes.

- Multi-head systems enable control of two motor coils independently, thereby simplifying machine mechanisms. This system is suitable for machines that require a short cycle time.

LM-H3 Series

LM-H3 Series Structure

- The motor primary side consists of laminated core and motor coil. The coil is inserted into the slots on the core. The entire section is molded with resin.

- The secondary side consists of permanent magnets and a mounting plate. The permanent magnets are precisely positioned and fixed on the mounting plate, and then covered with stainless steel plate.

LM-F Series

LM-F Series Structure

- The basic structure is the same as the LM-H3 series. However, this series has a liquid-cooling pipe in the primary side to suppress heat generation.

LM-K2 Series

LM-K2 Series Structure

- The motor primary side consists of laminated core and motor coil. The coil is inserted into the slots on the core. The entire section is molded with resin.

- The secondary side consists of permanent magnets and mounting plates. The permanent magnets are precisely positioned and fixed on the mounting plates, which are located on both sides of the primary side, and then covered with stainless steel plate.

LM-U2 Series

LM-U2 Series Structure

- The motor primary side consists of motor coil and no laminated core. The coil is precisely positioned on the base, and molded with resin.

- The secondary side consists of permanent magnets and a mounting plate. The permanent magnets are precisely positioned and fixed to face each other on a U-shaped mounting plate.