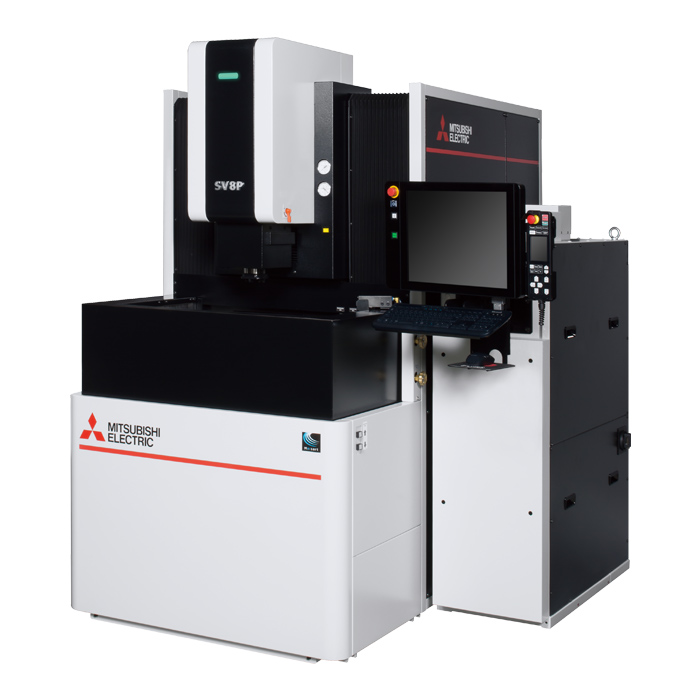

Electrical Discharge MachinesSV8P Features

Basic information

| Model name | SV8P |

| Overview | High precision Die-sinker EDM Next-generation machine incorporating the Mitsubishi Electric's AI technology (Maisart) and control unit (D-CUBES) to pursue both high accur acy and high productivity |

| Sales status | On sale |

Merit

Machining Accuracy

Machining from the fine shape to large size shape can be achieved with high accuracy and high productivity.

* ±3μm pitch accuracy achieved. (The machining accuracy follows the Mitsubishi Electric machining conditions.)

High rigidity construction is realized by structural change of cast.

* Standard function of "Thermal buster"(Mitsubishi Electric original technology).

Temperature change is visualized with "visualization monitor".

* Automatic depth recognition and stable servo control using Maisart make uniform surface finish.

Productivity

Sensing technology (D-CUBES) and AI technology (Maisart) optimize machining in real time.

IDPM3

* Machining speed is up to 50% faster with the combination of highly accelerated (1.6G) jump control and aduptive control "IDPM3".

* Suppresses edge wear enables single electrode machining. Electrode cost, setup and machining time are significantly reduced.

Maisart

* Optimize the jump length according to the machining dimension and shape.

* Automatically recognizes distinct depth of machining to improve stability.

* Plunge machining reduces machining time by up to 30%.

Operability

Excellent performance with "Easy operation", "human error reduction" and "connect ability" supporting productivity improvement for customers.

* Information is displayed on a large 19-inch screen.

* Functions to be viewed or used are called by one touch from the HOME screen.

* The number of operations performed on the Navigation menu from setup to machining is reduced by almost 40%. (as compared to the past)

* Setup performance is improved by a thin hand pendant box with LED.