Human-Machine Interfaces (HMIs)-GOT FA Application Package iQ Monozukuri

Easily collect and visualize information of multiple devices on a production line Introduction

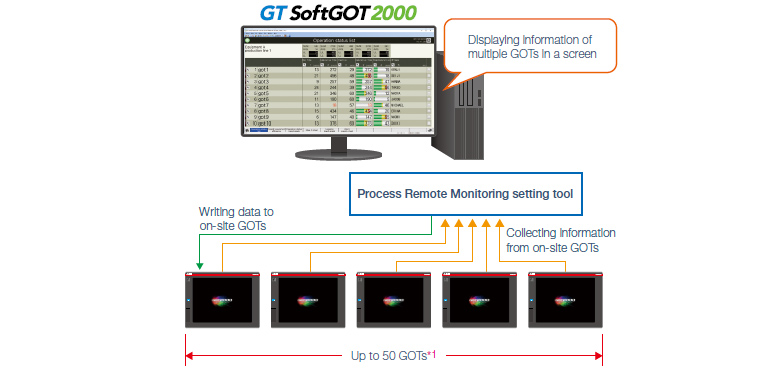

Easy data collection from multiple devices

In an iQ Monozukuri Process Remote Monitoring system, information of up to 50 GOTs installed in a facility can be managed by collecting data with a dedicated tool (Process

Remote Monitoring setting tool).*1

The collected facility information can be displayed and checked in the display screen of a personal computer.

- *1Up to five GOTs can be managed for each license. To manage information of 50 GOTs, purchase the product including 10 licenses.

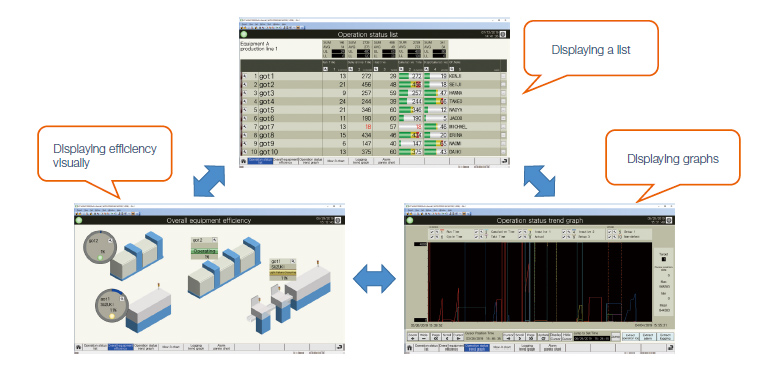

Displaying operation status obviously in a "visualize" template screen

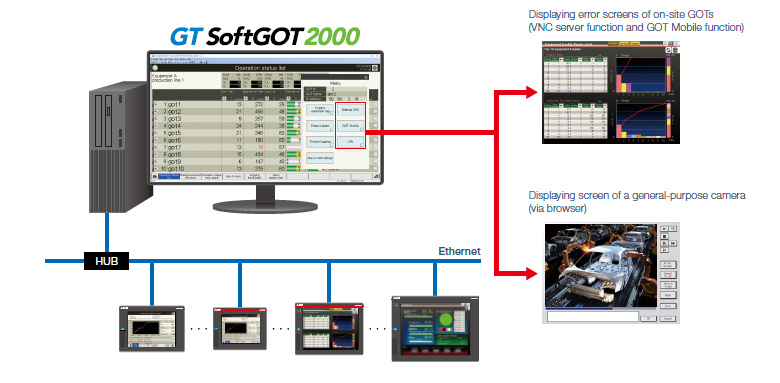

This package includes template screens for Process Remote Monitoring to display collected data in GT SoftGOT2000.

Product lines can be visualized by displaying operation statuses in a list or on trend graphs.

Whether loss is occurring in facilities can be checked in the overall equipment efficiency screen so that the loss time decreases and early detection of error locations improves the effectiveness.

More detailed remote monitoring with GOT Mobile function and a general-purpose camera

By starting other applications from GT SoftGOT2000 in a personal computer, the screens of on-site GOTs can be checked on a personal computer apart from the on-site GOTs with remote connection (VNC server function, GOT Mobile function) and images of network cameras installed in the shop floor can be checked with a browser; therefore, the situation can be monitored without going to the shop floor.

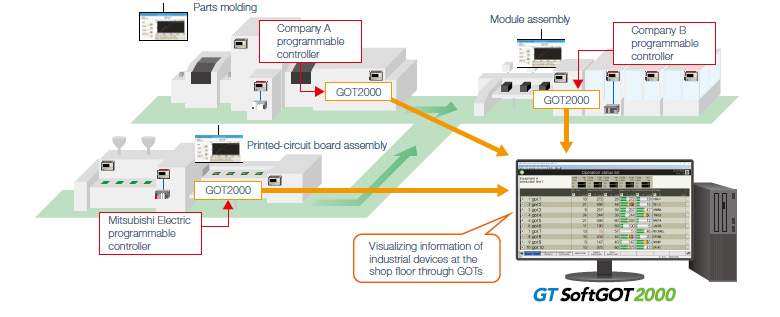

Monitoring wide variety of targets with various kinds of equipment connectable to on-site GOT

GOT acts as a gateway to collect information of industrial devices that are connected in various connection types (Ethernet, serial, etc.)

and iQ Monozukuri Process Remote Monitoring aggregates the information.

GOTs can be connected to a wide variety of industrial devices because various types of communication drivers are supported.

Any types of equipment that can be connected to GOTs can be monitored with iQ Monozukuri Process Remote Monitoring so that each

equipment can be visualized and monitored collectively.