Industrial robot MELFA Discontinued Products

*Production discontinuation: Mar 31,2024

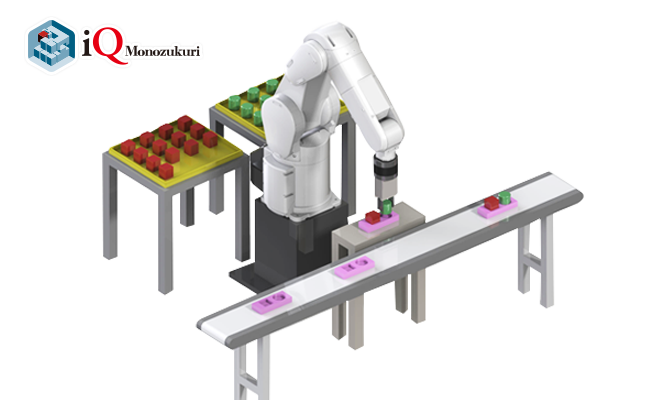

FA Application package

Devices, application programs, and useful startup tools required for automation system configuration and startup are all included in this package.(Supported robots: RV-F series)

- Since essential components are included in a package, burden for system consideration can be reduced.

- Anyone can connect various devices using ready-to-operate robots, easy wiring, and piping.

- Systems can be easily configuredusing dedicated application programs and startup tools.

Processing Machine Loading Application

This application facilitates the configuration of a loading/unloading system for processing machines in which a Mitsubishi CNC numerical control devices has been installed. (Supported robots: RV-F series)

*Production discontinuation: Mar 31,2024

- No need to create robot programs.

- User-friendly wizard screens shorten the startup time by 80%.

- The system operation can be started smoothly with the various screens pre-installedon the operation box.

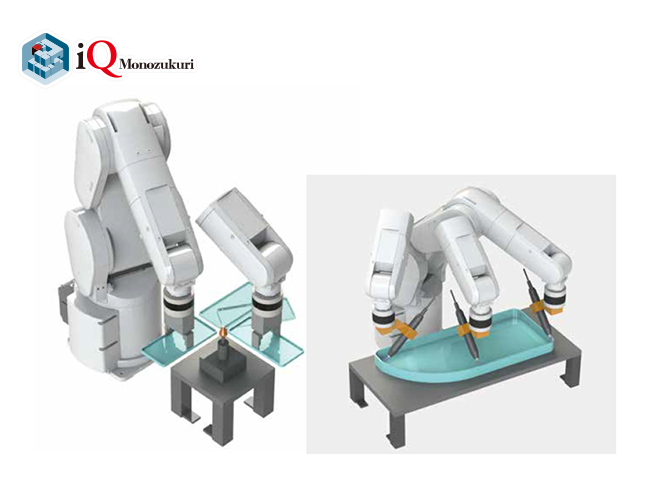

Force sense Application

Techniques and know-how are added to MELFA robots to achieve the automation of force-sense operations such as assembly, insertion, and inspection. (Supported robots: RV-F series)

*Production discontinuation: Mar 31,2024

- No need to create force-sense programs.

- The startup time of force-sense operation can be reduced 80%.

- Operation including force sensor settings and force-sense application operations can be easily configured with dedicated tools.

Deburring / Polishing Application

Easily creates a machining path of deburring/polishing and performs machining.

On-site operators can automate their teaching process with rough teaching using a master workpiece and tools. (Supported robots: RV-F series)

*Production discontinuation: Mar 31,2024

- On-site operators can create a machining path at their sites.

- Teaching can be easily performed wiht the simple configuration.

- Compared with the offline teaching that uses an actual workpiece, the statup time has decreased by 80%.