Industrial robot MELFA For semiconductor manufacturing processes

How about automating your semiconductor manufacturing process with MELFA?

Are you facing challenges in automating your semiconductor manufacturing process?

Our company provides the possibility of solving various concerns by introducing industrial robots.

We will expand your automation and labor-saving potential with the following features!

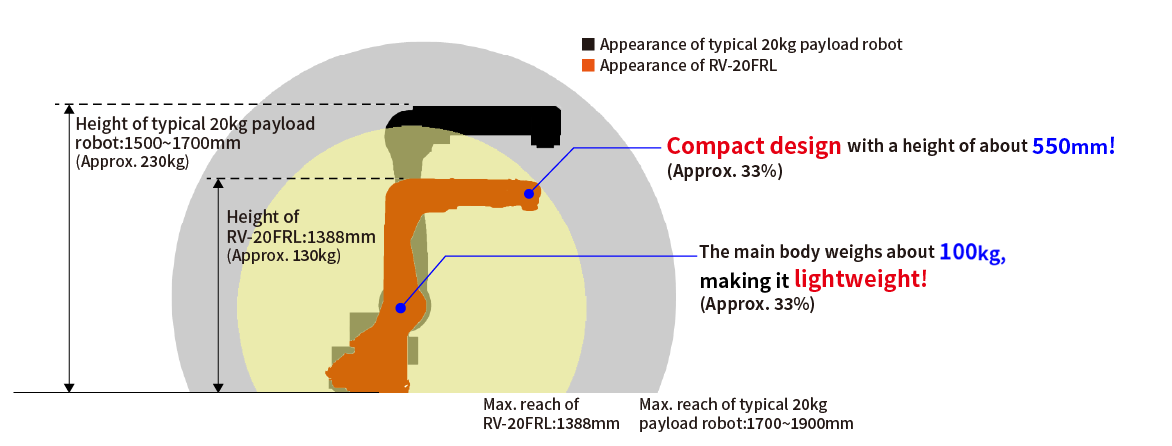

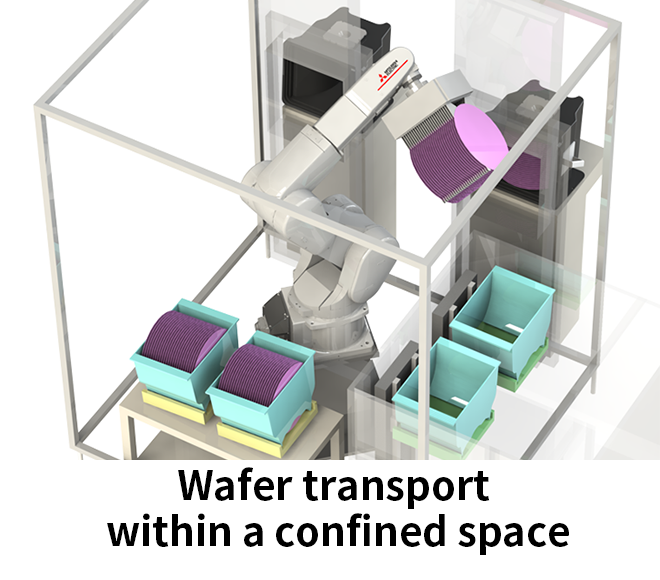

I’m looking for a transport robot that can operate in tight spaces between devices and processes...

◆The RV-20FRL is one of the smallest 20kg payload robots in the industry, and it can be integrated into narrow devices and processes with limited operating ranges.

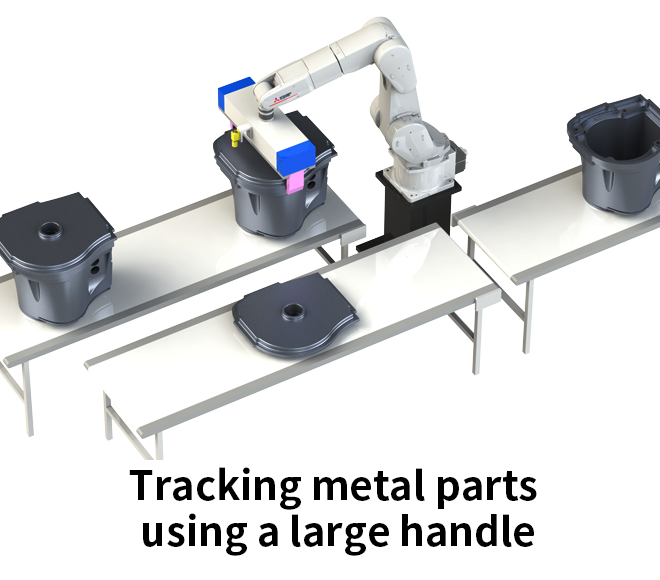

Enhance the allowable moment and inertia

◆We can significantly enhance the allowable moment and inertia compared to the RV-13FRL, effectively reducing vibrations when a large handle is attached.

Allowable moment [N・m]

| Axis | RV-13FRL | RV-20FRL |

| J4 | 19.3 | 49 |

| J5 | 19.3 | 49 |

| J6 | 11 | 11 |

Allowable inertia [kgm2]

| Axis | RV-13FRL | RV-20FRL |

| J4 | 0.47 | 1.4 |

| J5 | 0.47 | 1.4 |

| J6 | 0.14 | 0.86 |

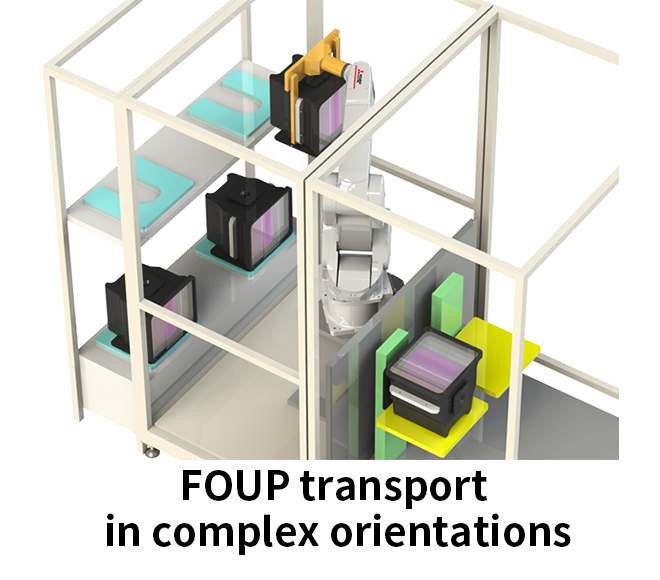

A semiconductor-specific robot cannot perform three-dimensional movement...

◆A vertical multi-joint can perform vertical transportation and make precise adjustments to position and posture!

MELFA High Drive

◆Thanks to MELFA High Drive (Mitsubishi Electric’s new control system), we achieve industry-leading vibration performance.

(Applicable only to models compatible with MELFA High Drive)

I want to use it in special environments such as clean rooms...

◆All of our cleanroom robots undergo dust level checks using particle counters to ensure compliance with ISO Class 3, and they are shipped only after confirming that dust levels are below the standard.

◆We also provide models suitable for use in oil mist and dust environments, allowing for safe operation in various conditions.