FA Application Package Tool Wear Diagnosis for Machine Tools

We Provide Various Functions to Support the Realization of Digital Transformation

Set the parameters for connection and data collection according to the target device and then perform data collection.

Set the parameters for connection and data collection according to the target device and then perform data collection.

Settings during installation

System settings

Configure the common settings for the diagnosis system (diagnosis system ID and password settings).

Common settings screen

Machine settings

The machine tool communication method and data cleansing conditions can be set for each machine to enable the collection of machining status data.

Machine settings screen

Model settings

Register the diagnosis model for each machining condition.

The automatic model registration function allows you to automatically register models according to the received machining conditions.

Model settings screen

Collection of machining data

Collect machining data of each machine tools in real-time for storage or comparison purposes. (compare differences between deteriorated tools and new tools)

Machining data collection screen

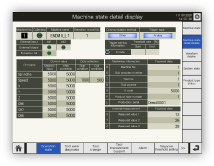

Machine status monitoring

On the Machine state detail display, the data received from the CNC and the collected data are displayed in real time.

Machine details status screen

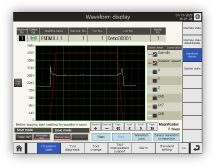

Waveform and trend display function

The Advanced Data Science Tool allows you to display stored waveform and trend data over a specified selection data. This allows you to check the wear state of the tool.

Machining data collection screen

Data transfer

Advanced Data Science Tool

The set threshold is automatically calculated from the collected data, and the optimized diagnosis threshold is then set in the system.

The set threshold is automatically calculated from the collected data, and the optimized diagnosis threshold is then set in the system.

Diagnosis threshold setting

Advanced Data Science Tool

Section extraction setting

While checking the cutting torque waveform, it is possible to set the selection extraction conditions from the collected waveform data.

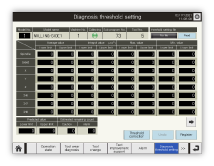

Diagnosis threshold setting

The statistical analysis function automatically calculates recommended thresholds from trends in the feature values.

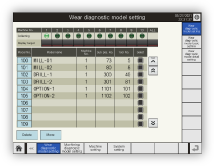

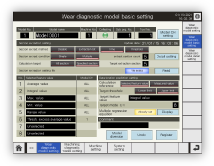

Model detail setting

It is possible to set the data cleansing conditions, data processing conditions, and diagnostic feature values for the model according to your diagnostic requirements.

Model detail setting screen

Diagnosis threshold setting

It is possible to use the values calculated by the Advanced Data Science Tool or custom values from the user.

Diagnosis threshold setting screen

Tool wear diagnosis

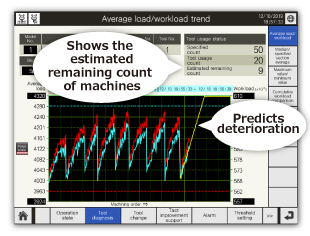

Analyze Management of Trend Data for Various Feature Values

Various feature values are automatically calculated, and their trend data is displayed. The threshold deviation is then determined according to the calculation results.

Analyze management of trend data for various feature values

Tool wear diagnosis

The system can predict the tool service life according to the state of wear and notify the user of the estimated remaining count of machines of the tool.

Visualization of tool wear

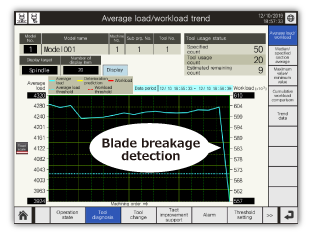

Machining abnormality diagnosis

In the case of a tool or machining abnormality, a threshold deviation judgment is made and an alert is issued.

Visualization of tool abnormalities

Machine learning algorithms are applied to inspection and machining data to enable the prediction of machining quality.

Machine learning algorithms are applied to inspection and machining data to enable the prediction of machining quality.

Quality prediction

Transmission of internal measurement values from machine

Dimension data measured by a CNC device can be transmitted to the Advanced Data Science Tool

Internal measurement value transmission screen

Data transfer

Advanced Data Science Tool

Analysis of the relationship between inspection and machining data

n the Advanced Data Science Tool, the machining and measurement data (machining quality) are linked according to the production serial number information.

Model creation and evaluation

From the results of correlation analysis between the machining quality and the collected machining data, the feature values of the optimum target for learning are automatically selected, and a predictive model is automatically created by machine learning.

Predictive model and diagnosis threshold settings

The Advanced Data Science Tool allows you to set the calculated predictive model and the diagnosis threshold calculated from feature value trends.

Advanced Data Science Tool

Predictive model

Wear diagnosis model settings screen

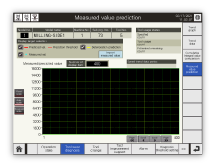

Measured value prediction

Immediately after machining, the predicted measured value (quality indicator) is calculated from the predictive model. The system then calculates the threshold deviation and the estimated remaining count of machines.

Measured value prediction screen

Provides support for tool replacement that utilizes tools up to the end of their service life

Provides support for tool replacement that utilizes tools up to the end of their service life

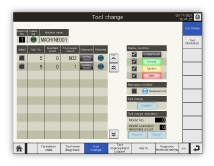

Tool replacement information

The system is able to display the tool usage status.(To help with the tool change process, the system can trigger an alarm when it is time to change the tool.)

Tool replacement information screen

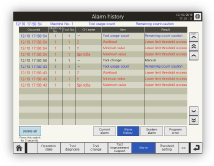

Alarm history

The system is able to display tool error messages and tool change alarms.

Alarm history screen

Improvement of cycle time and tool life through optimization of machining conditions

Improvement of cycle time and tool life through optimization of machining conditions

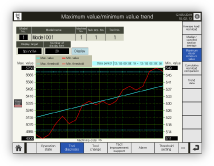

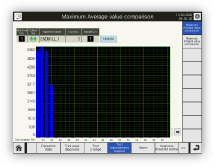

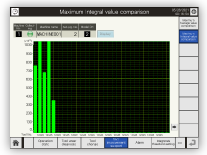

Maximum Average Load Comparison, Maximum Integral Value Comparison

By comparing machining condition for the same tool between machining programs, optimizes machining conditions such as cutting speed, feed amount, cutting depth, etc. to support improvement of cycle time.

Maximum average load comparison screen

Maximum integral value comparison screen

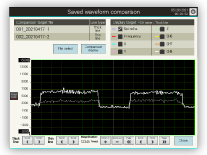

Waveform Comparison

Optimal machining conditions can be confirmed by comparison of changes in time load is placed on tool.

Waveform comparison screen