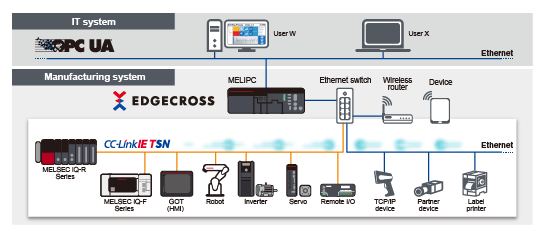

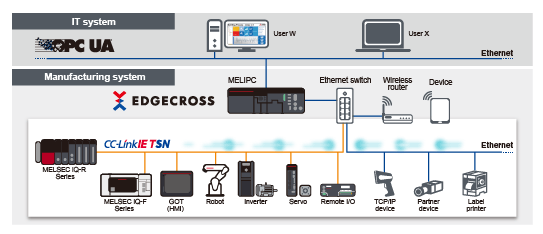

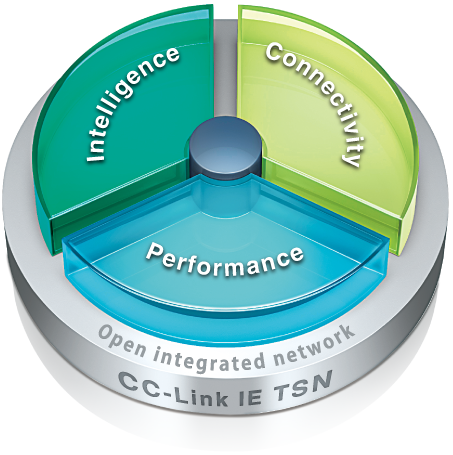

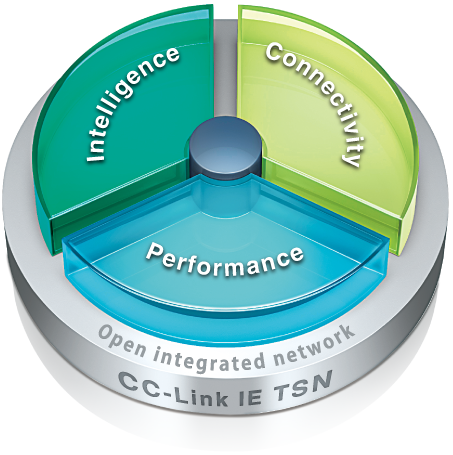

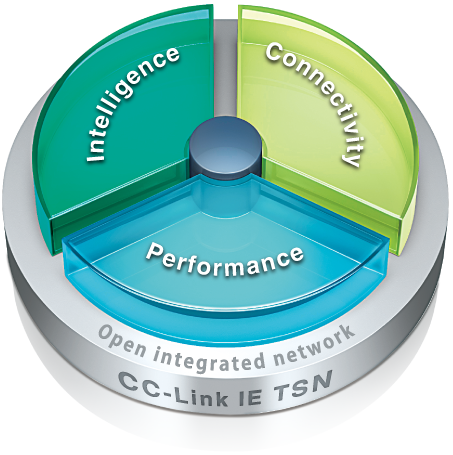

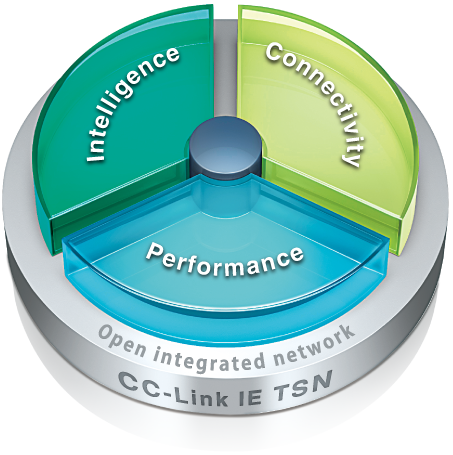

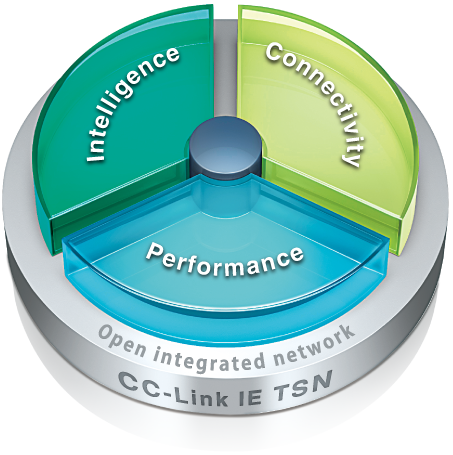

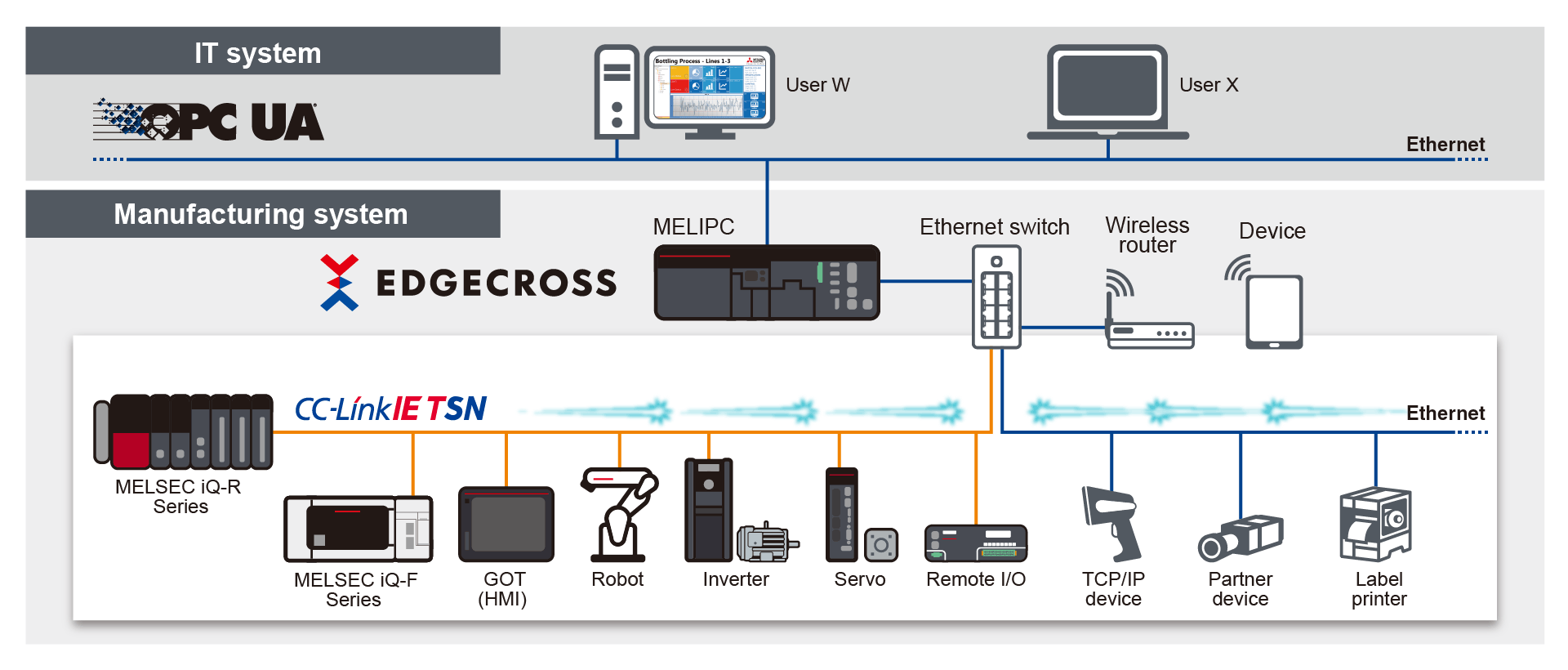

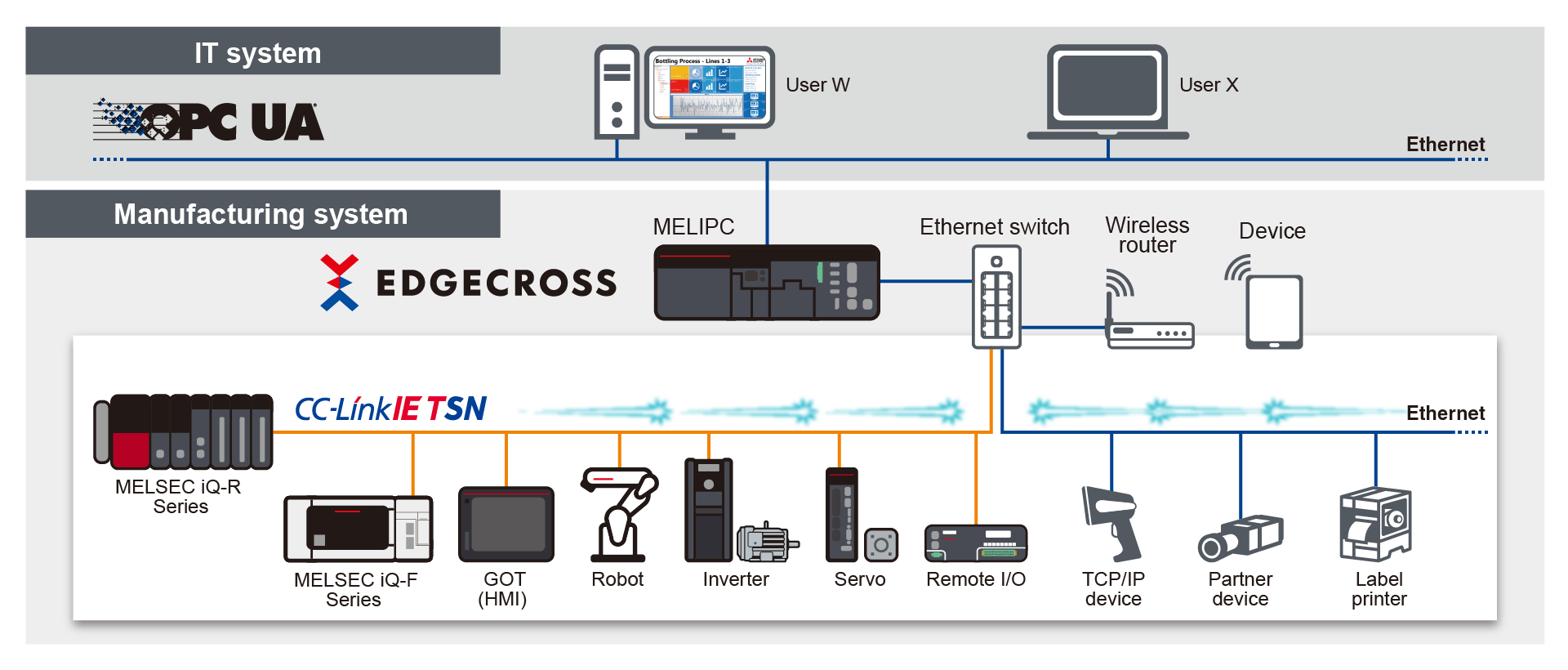

Open integrated networking across the manufacturing enterprise

Leveraging an integrated and open network utilizing TSN technology realizes real-time data collection from the shop floor to IT systems

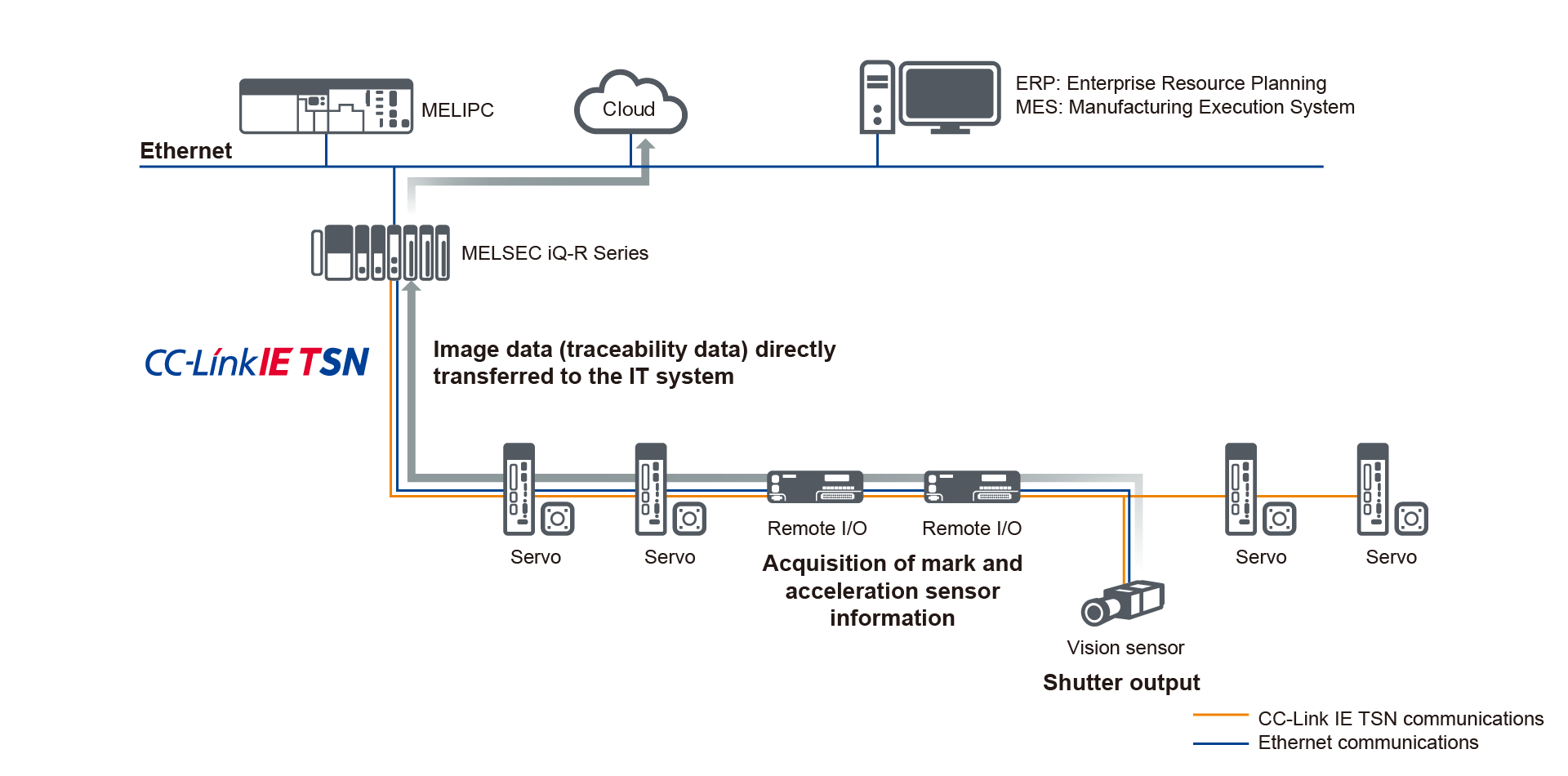

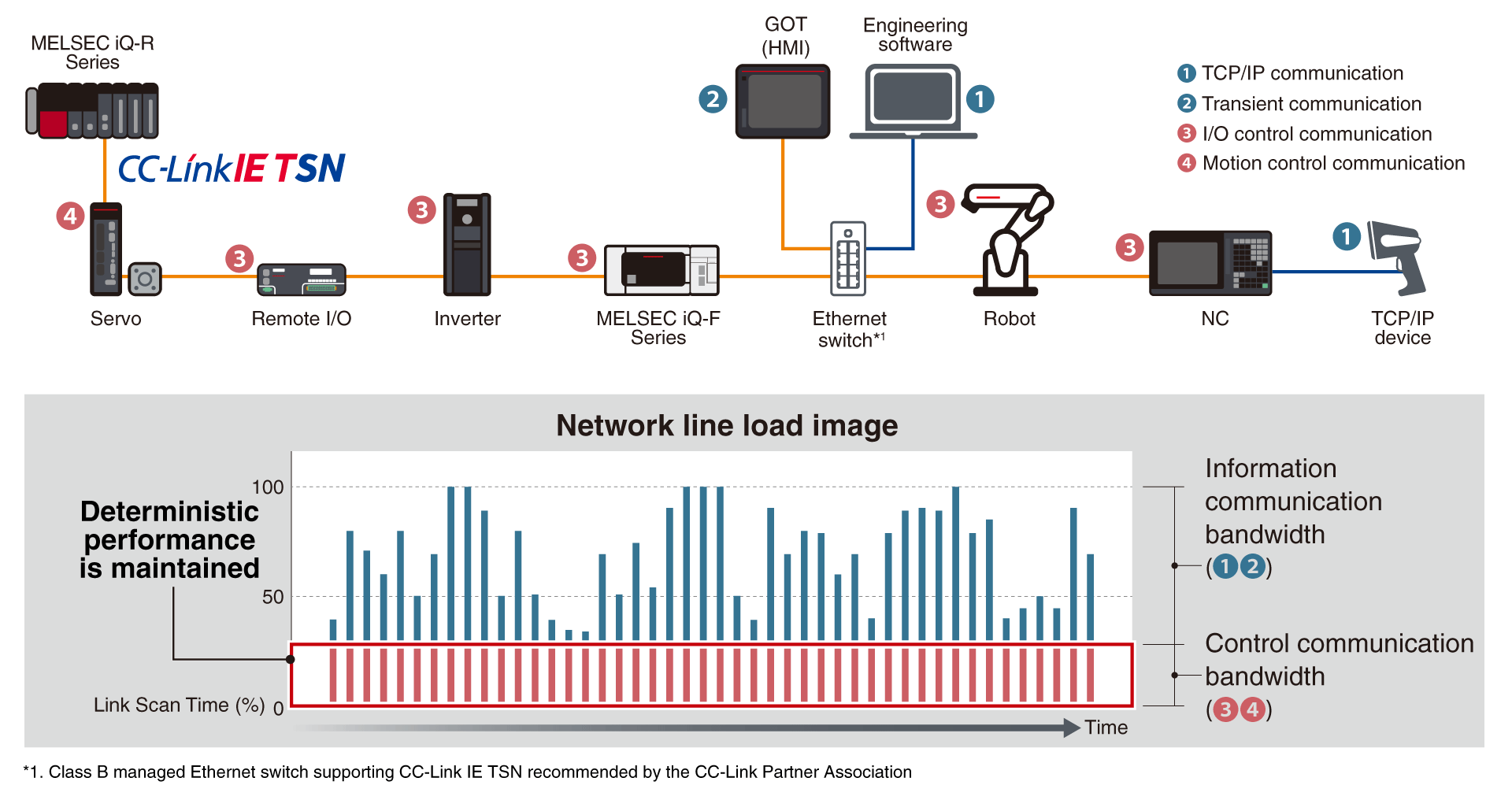

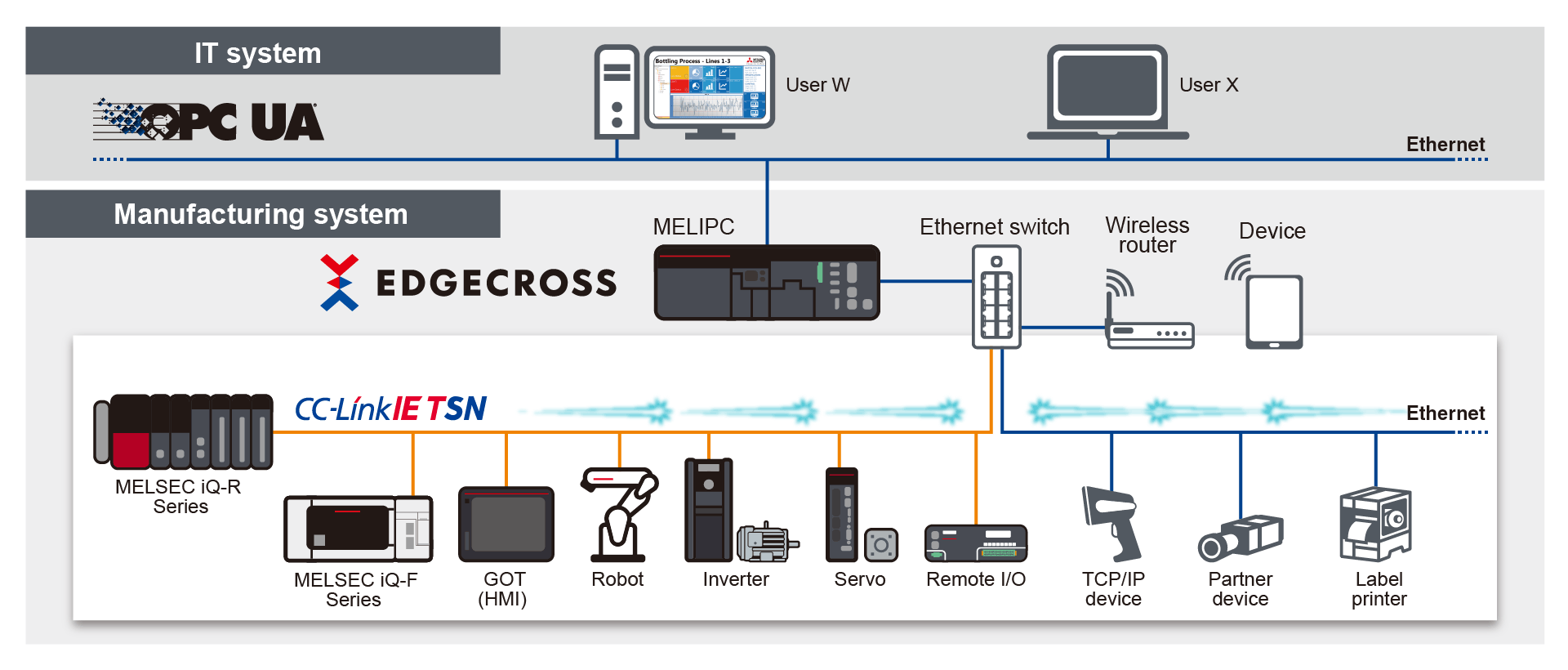

CC-Link IE TSN supports TCP/IP communications and applies it to industrial architectures through its support of TSN enabling real-time communications. With its flexible system architecture and extensive setup and troubleshooting features make CC-Link IE TSN ideal for building an IIoT infrastructure across the entire manufacturing enterprise.

- *TSN: Time Sensitive Networking

- *IIoT: Industrial Internet of Things

High-speed and large bandwidth ideal for systems requiring deterministic control

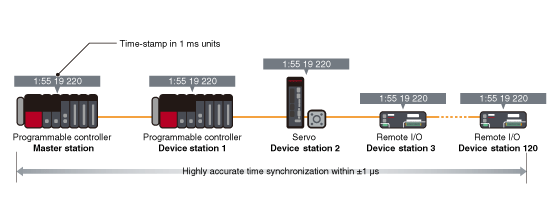

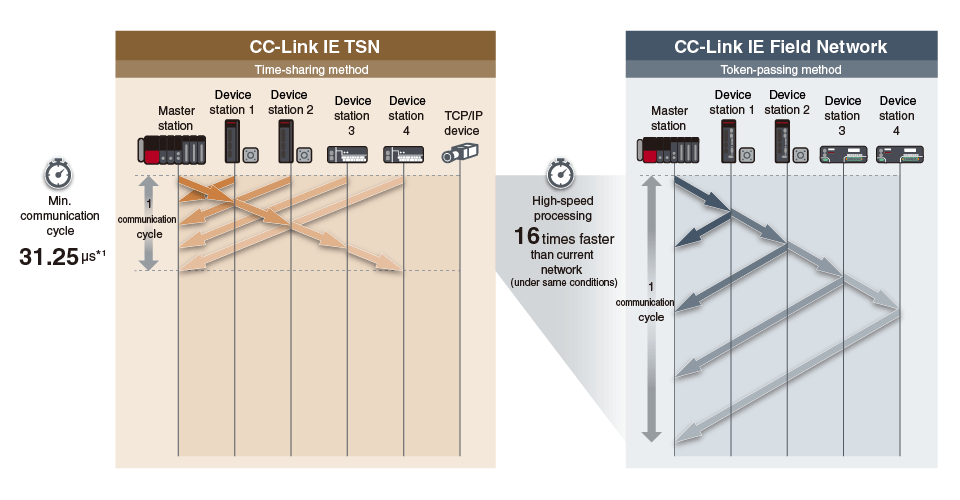

Current manufacturing trends are utilizing AI and predictive maintenance to ensure high productivity and quality are achieved simultaneously. This requires high-speed communication and deterministic control of large volumes of data to IT systems. The innovative communication technology of CC-Link IE TSN increases communication performance, enables highly accurate motion control and high-speed I/O control without adversely affecting operating performance.

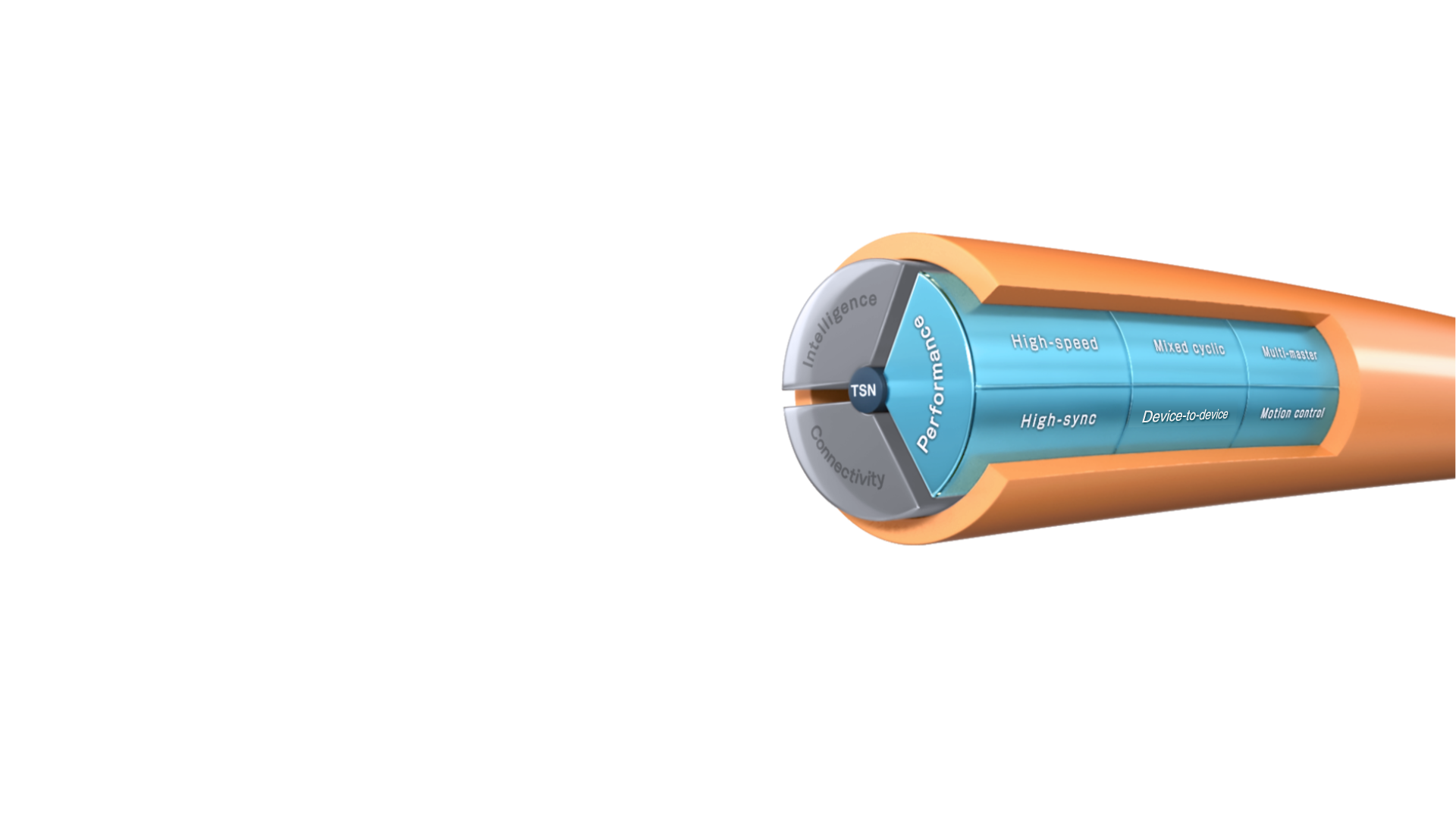

Performance

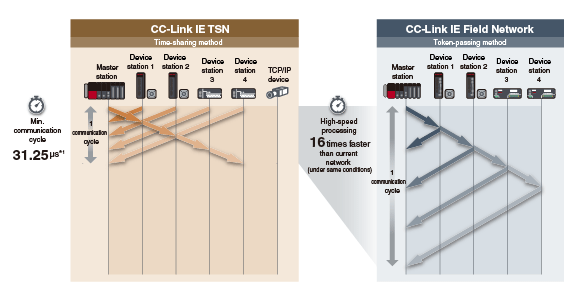

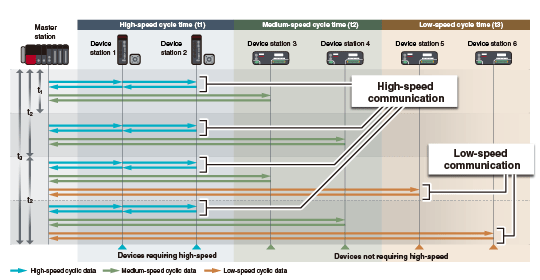

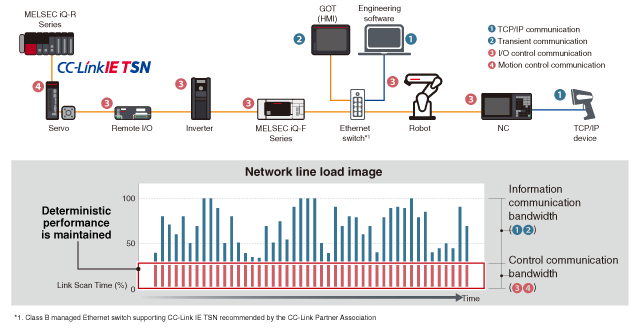

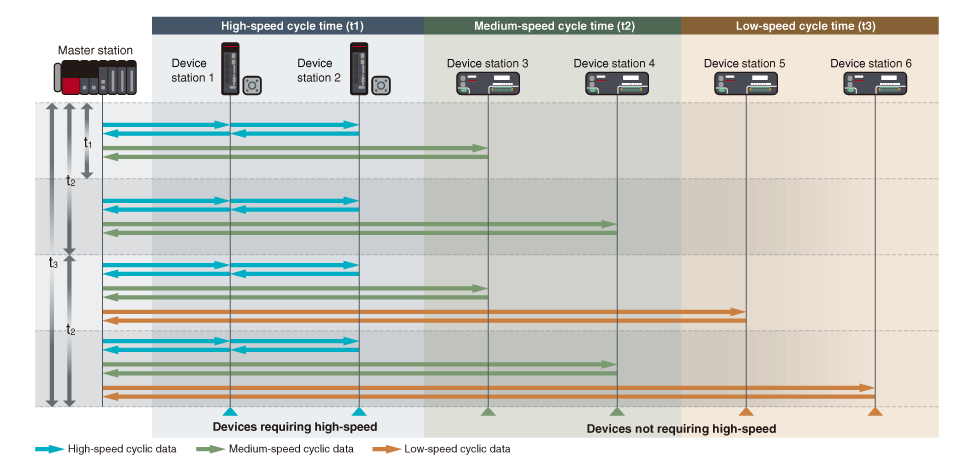

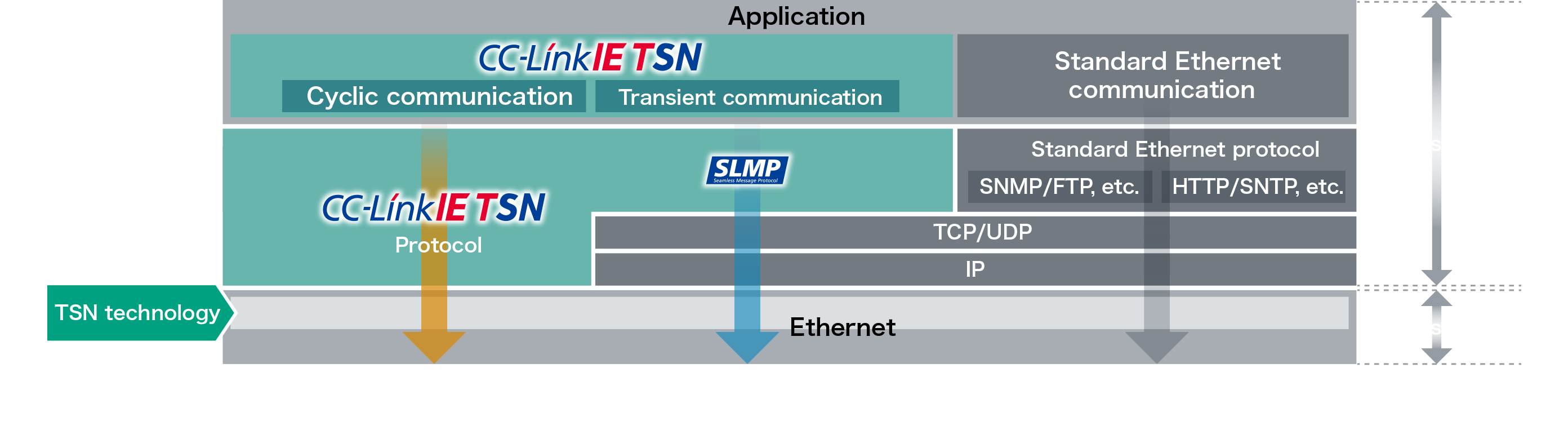

Gigabit Ethernet meets TSN technology CC-Link IE TSN combines protocols to high-speed cyclic communication and TSN technology. Current manufacturing trends require high-speed communication, deterministic cycle times and the management of large amounts of data. TSN technology allows TCP/IP communication to be added to the network without compromising the control communication necessary for device operation. The protocol also realizes the high-speed transfer of large-capacity data, thereby shortening cycle times and improving productivity.

- ・Real-time deterministic control using standard Ethernet

- ・Allocation of control communication bandwidth over IT

- ・Supports multiple protocols on same network line

- ・Fast cycle time using time-sharing method and bidirectional communications

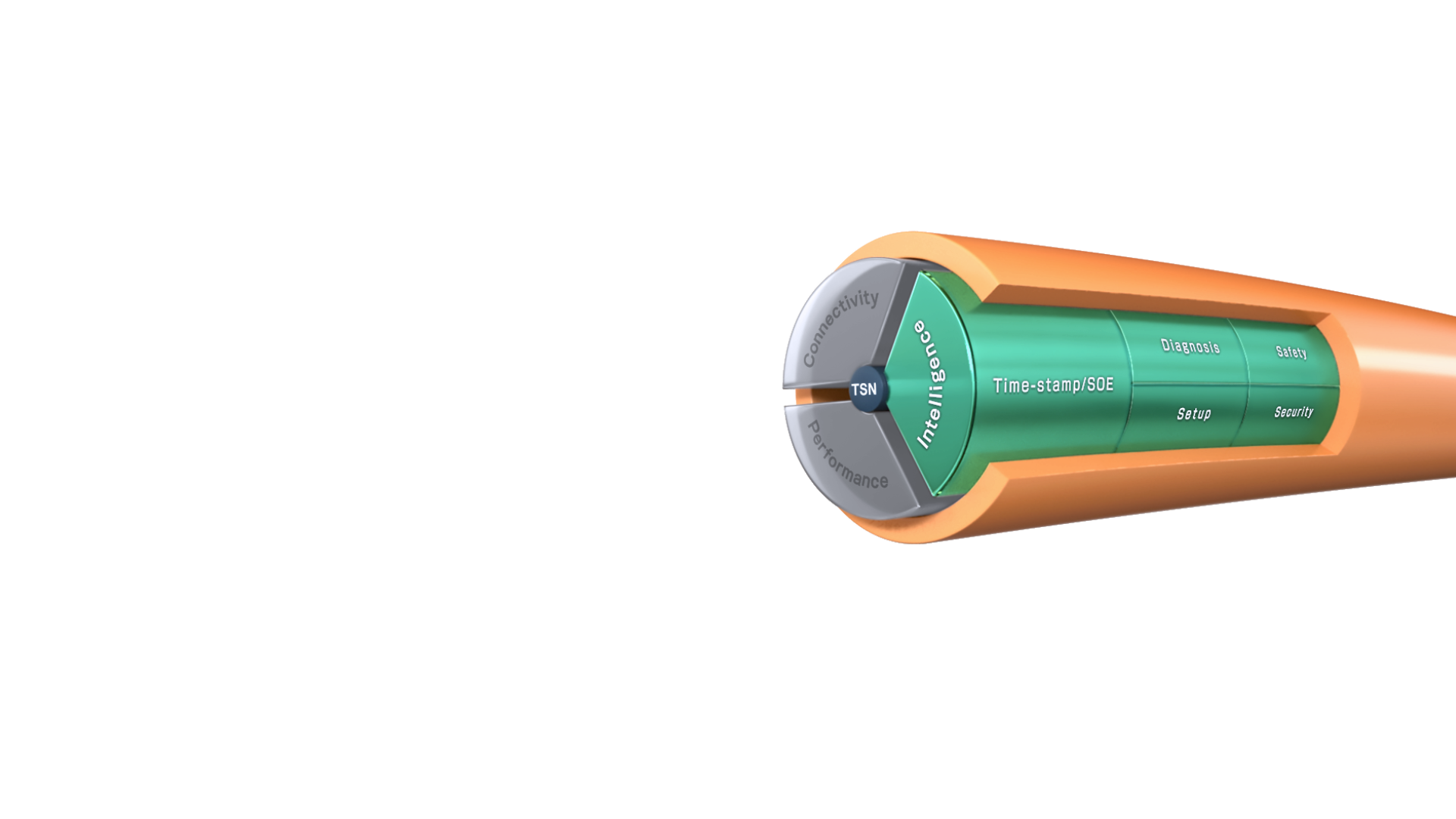

Extensive network technology supporting reduced downtime and easier system implementation

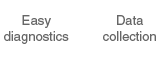

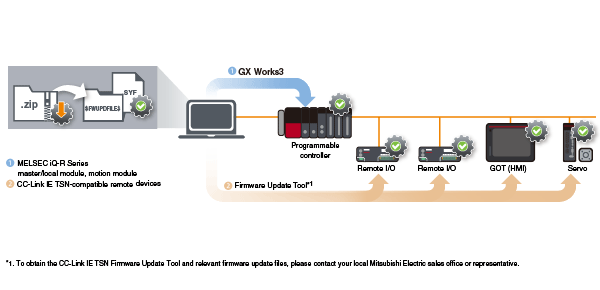

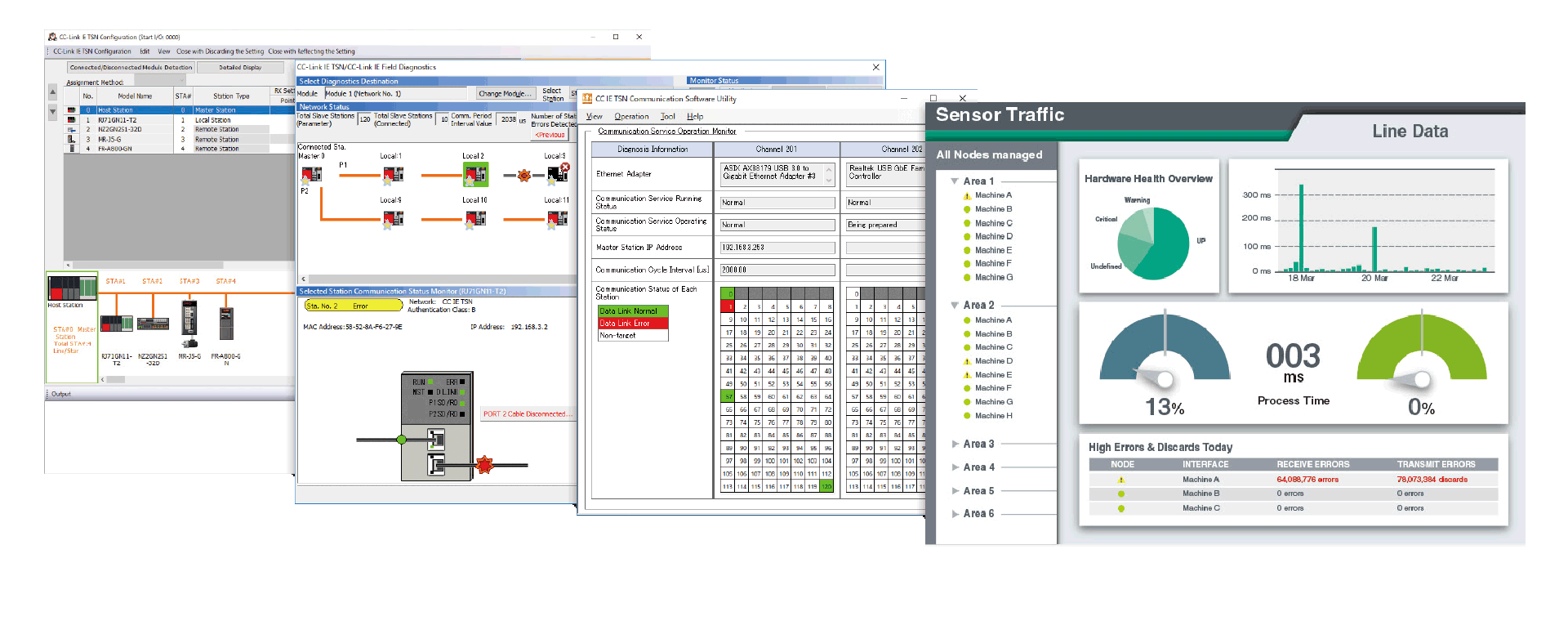

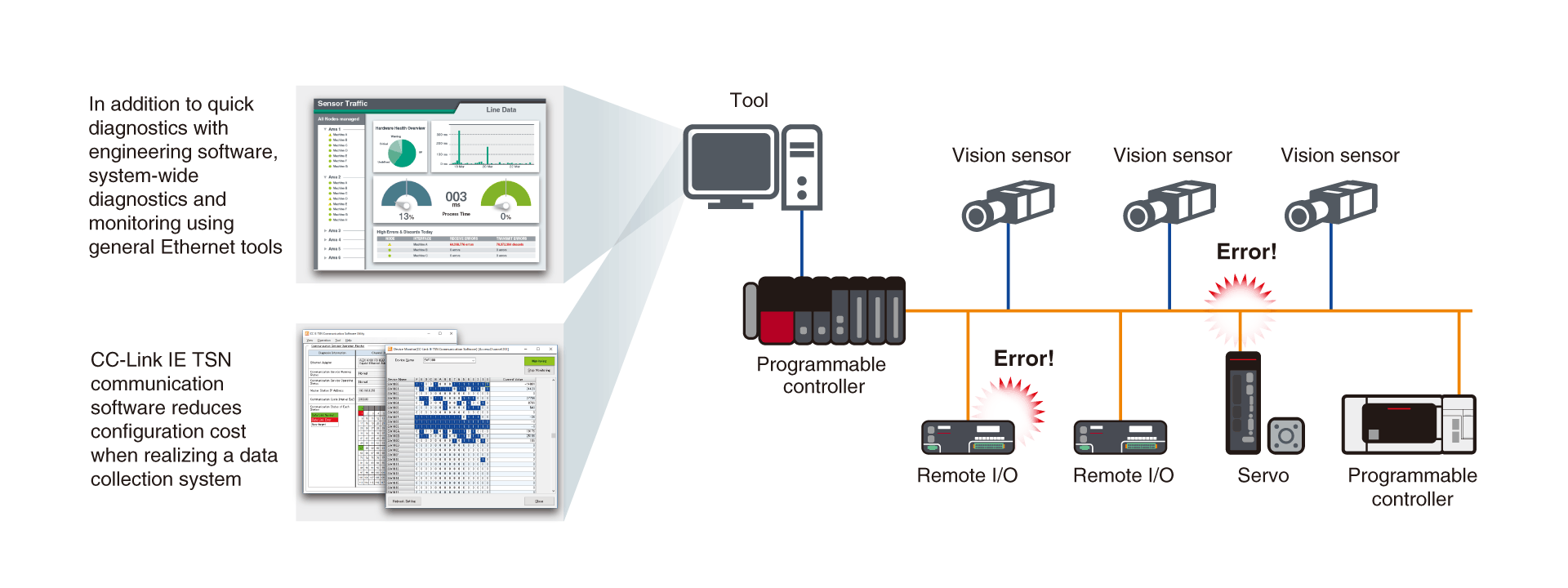

Intelligent networks that support industrial communications to realize easy device setup and preventive maintenance are essential for efficient operations. CC-Link IE TSN supports third-party diagnostic software, enabling troubleshooting of network devices (including standard Ethernet). Network event errors are time-stamped, enabling the actual cause of error to be easily evaluated. In addition, automatic generation of network system architectures and parameters simplifies commissioning.

Intelligence

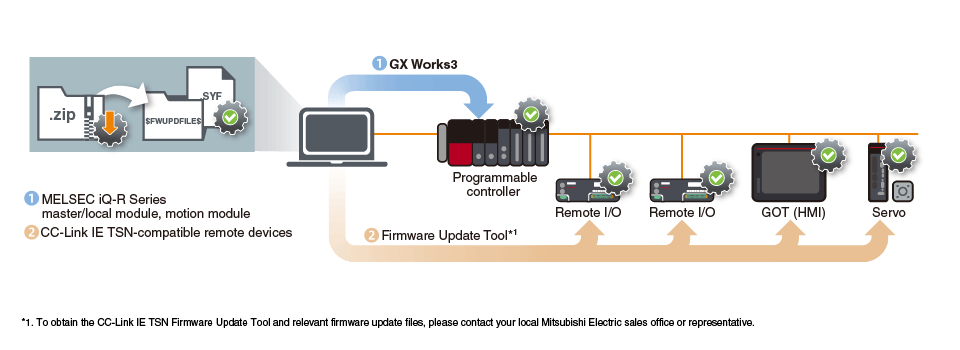

Multiple features enabling a robust and easy-to-use communications network CC-Link IE TSN can utilize extensive troubleshooting tools through its support of GX Works3 and third-party monitoring and diagnostic software based on the SNMP protocol. In addition, parameters are distributed automatically, making it easy to setup remote devices and simplifying the commissioning process.

- ・Extensive maintenance and easy setup of network devices

- ・Supports third-party monitoring tools based on SNMP

- ・Automatic registration of remote device parameters

- ・Event history based on time stamp simplifies diagnostics and troubleshooting

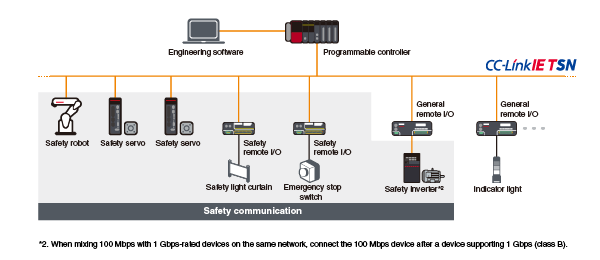

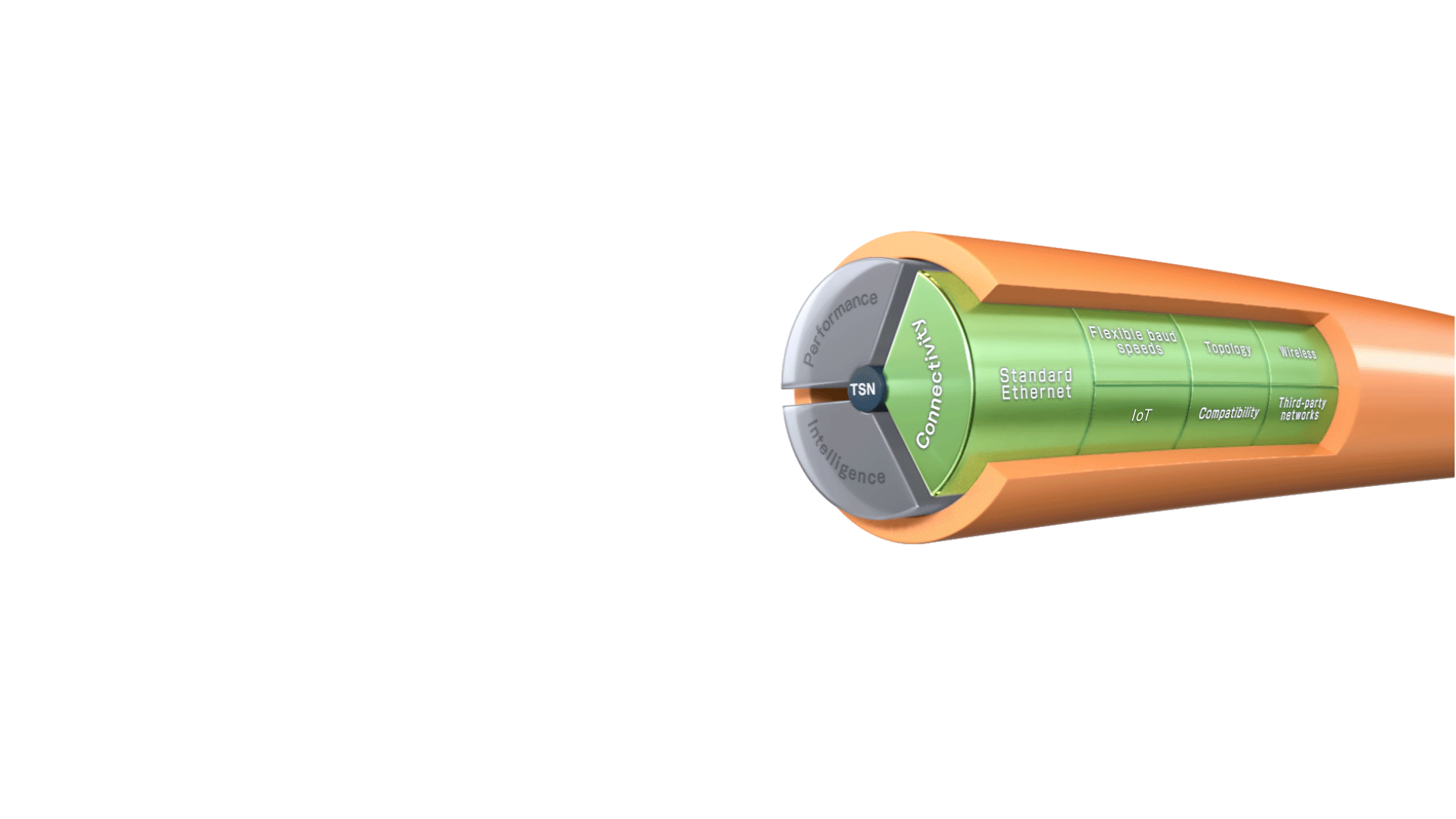

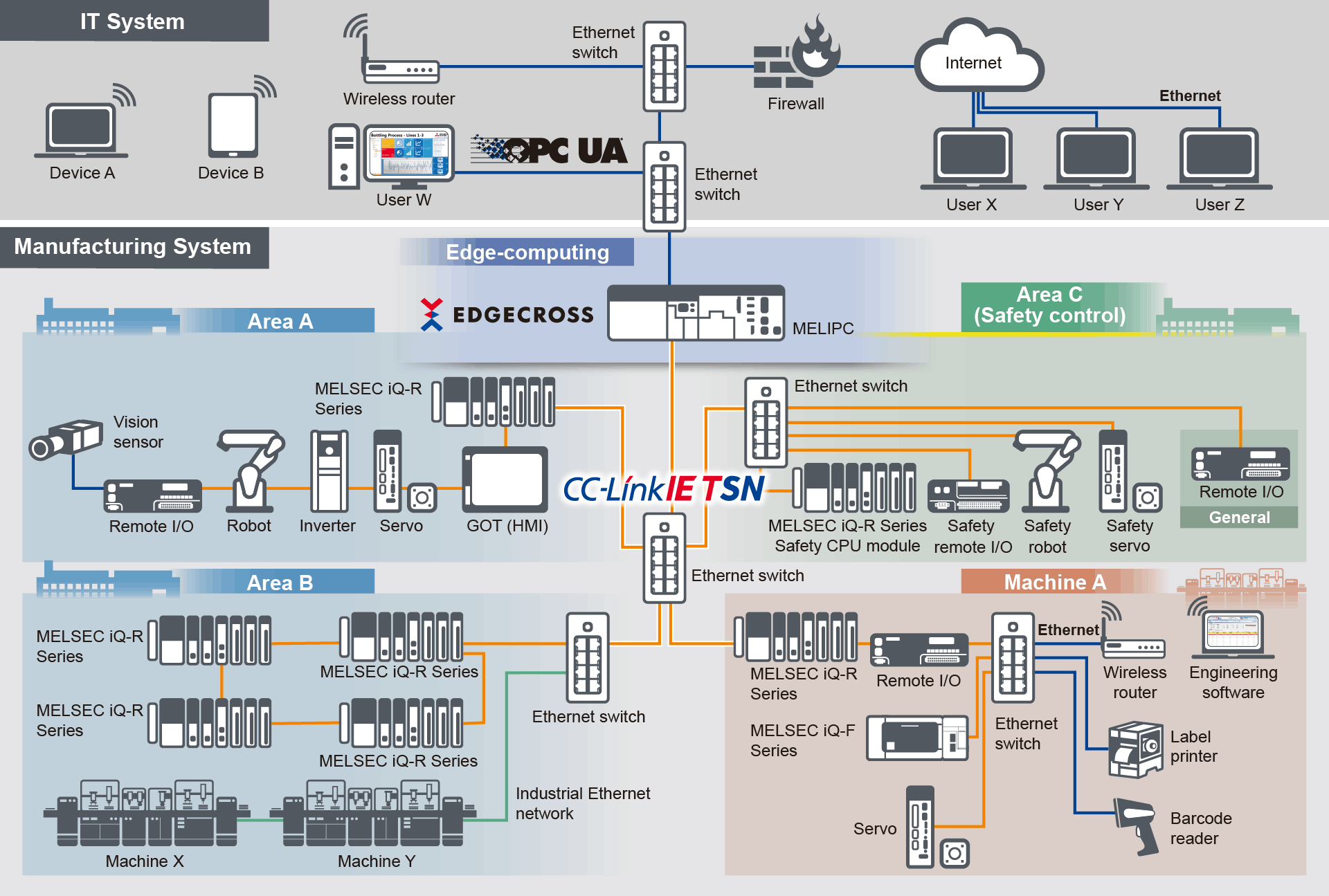

Optimal system with a highly flexible and integrated (general, motion and safety) network

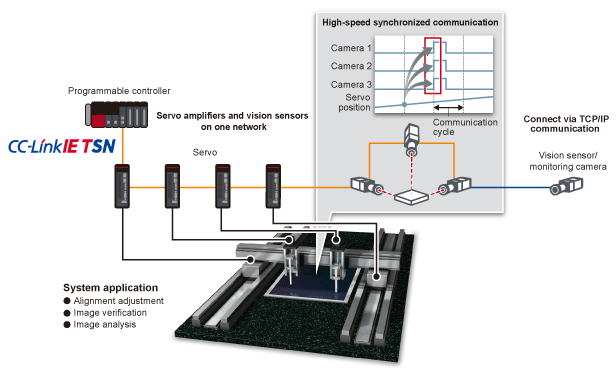

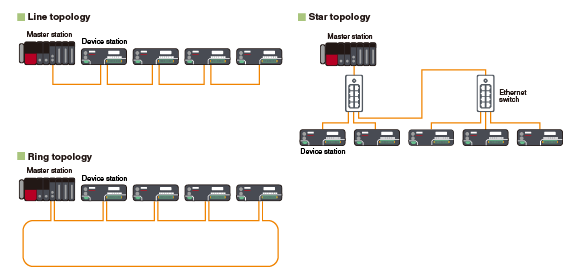

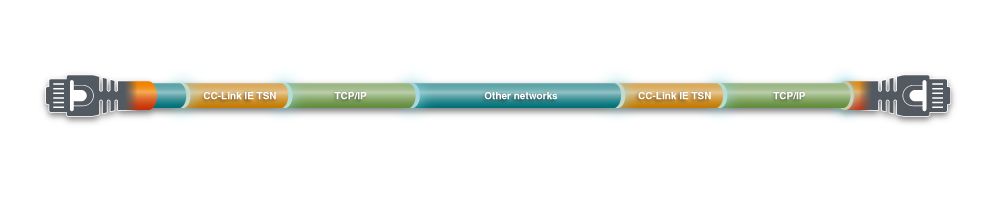

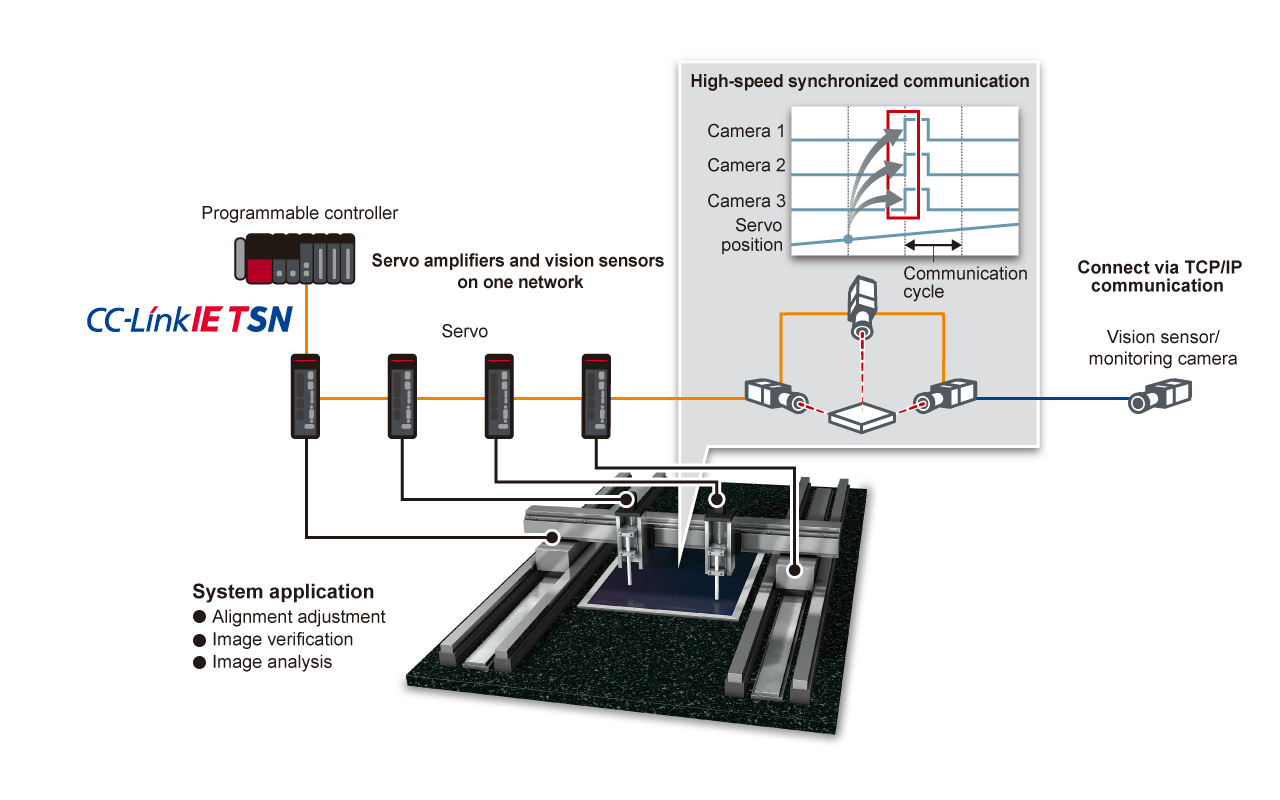

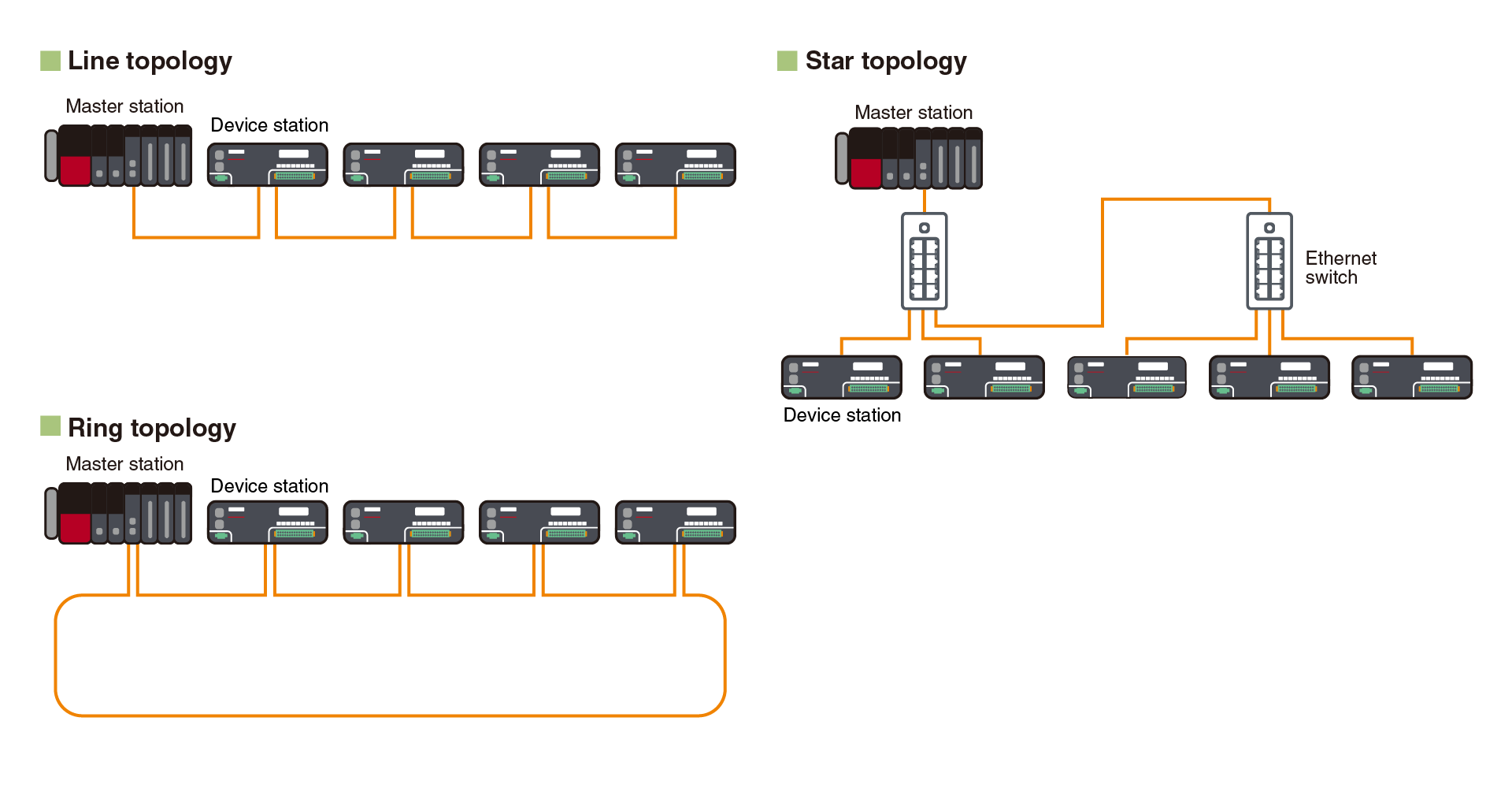

CC-Link IE TSN is the key to realizing real-time communication in manufacturing systems utilizing TCP/IP-compatible Ethernet-based networks. It also enables third-party networks and standard Ethernet devices such as vision sensors and wireless routers to be integrated, and has multiple topology possibilities in support of highly scalable and flexible system architectures.

Connectivity

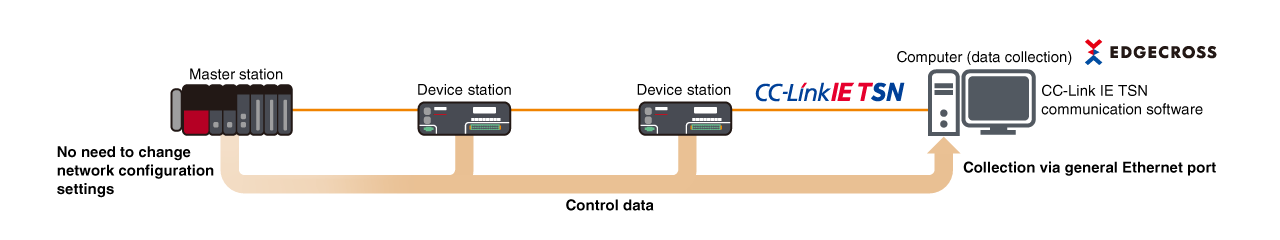

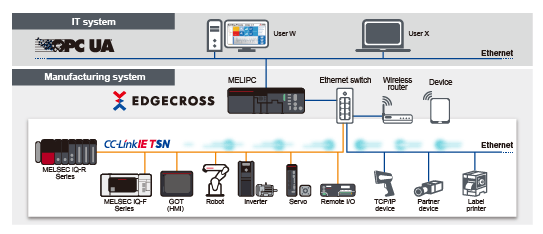

Seamless communication across entire network Integrating TCP/IP communication and CC-Link IE TSN for IT data and control data, respectively, realizes seamless communication throughout the entire network. Large amounts of data, such as images from vision sensors communicating via Ethernet, can be processed by other control devices elsewhere in the line without affecting the control data cycle time. Data from various machine processes can also be logged continuously and fed into edge-computing devices, which is essential for predictive maintenance that uses AI algorithms.

- ・Flexible configurations enable utilization of best-in-class devices

- ・Multiple topologies supported, line, star and ring

- ・Supports various TSN-compatible open networks

- ・Utilizes standard TCP/IP devices

Seamless communication between various factory automation products and IT systems,

realizing an IIoT‑enabled network.

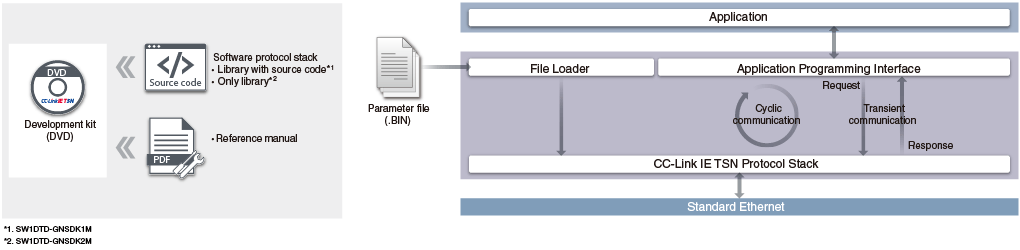

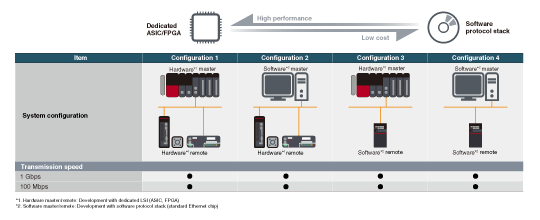

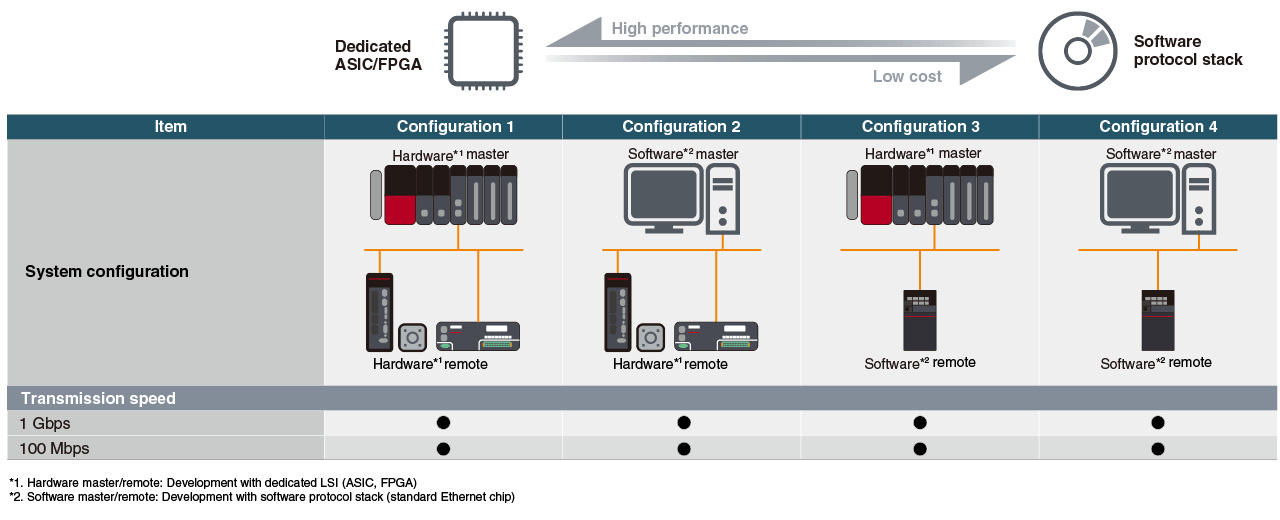

Development kit/tool

・High-speed and large data capacity

・High-accuracy motion control

・High performance even with various cyclic speeds

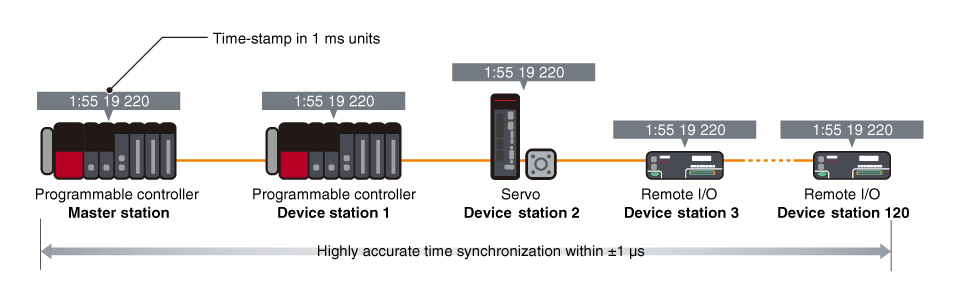

・System-wide synchronization responding to errors

・Easier troubleshooting supporting third-party diagnostic tools

・Flexible system structure utilizing standard Ethernet technology

・Realize IIoT through seamless data across multiple layers

・Both control and information communications on the same line

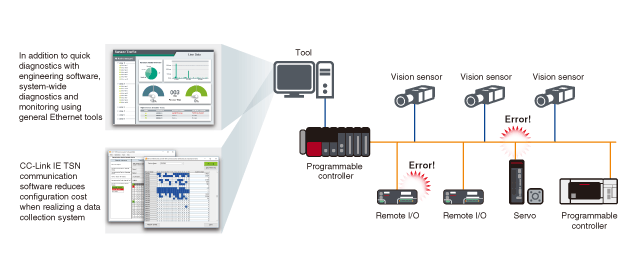

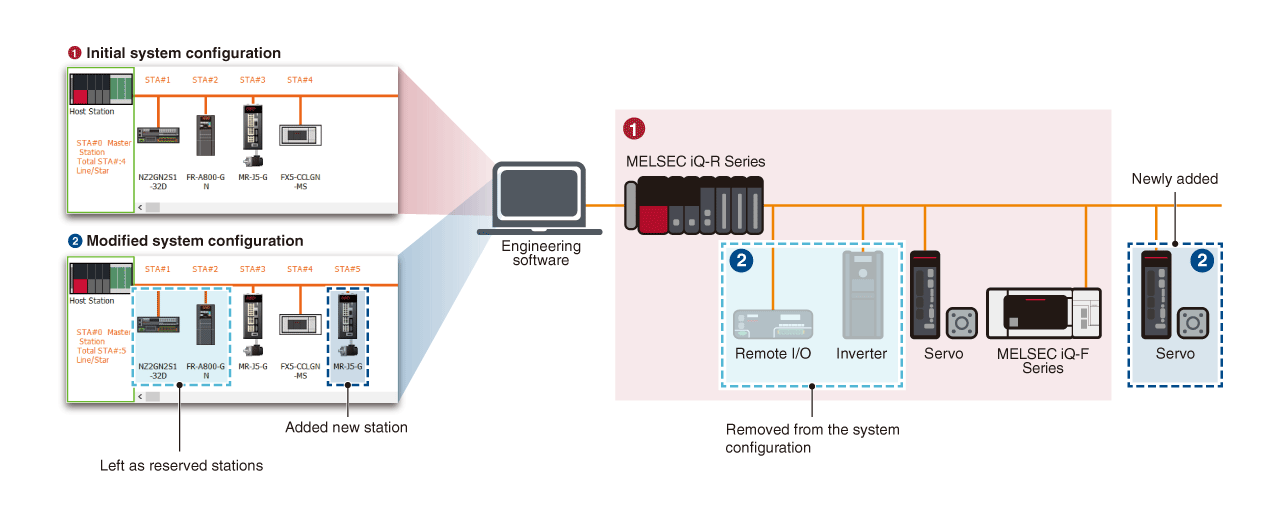

・Reduce engineering cost with easy system changes

・Multiple topologies supported, realizing easy configuration

・Easier integration supporting multiple protocols on one network

・Highly scalable system utilizing best-in-class devices

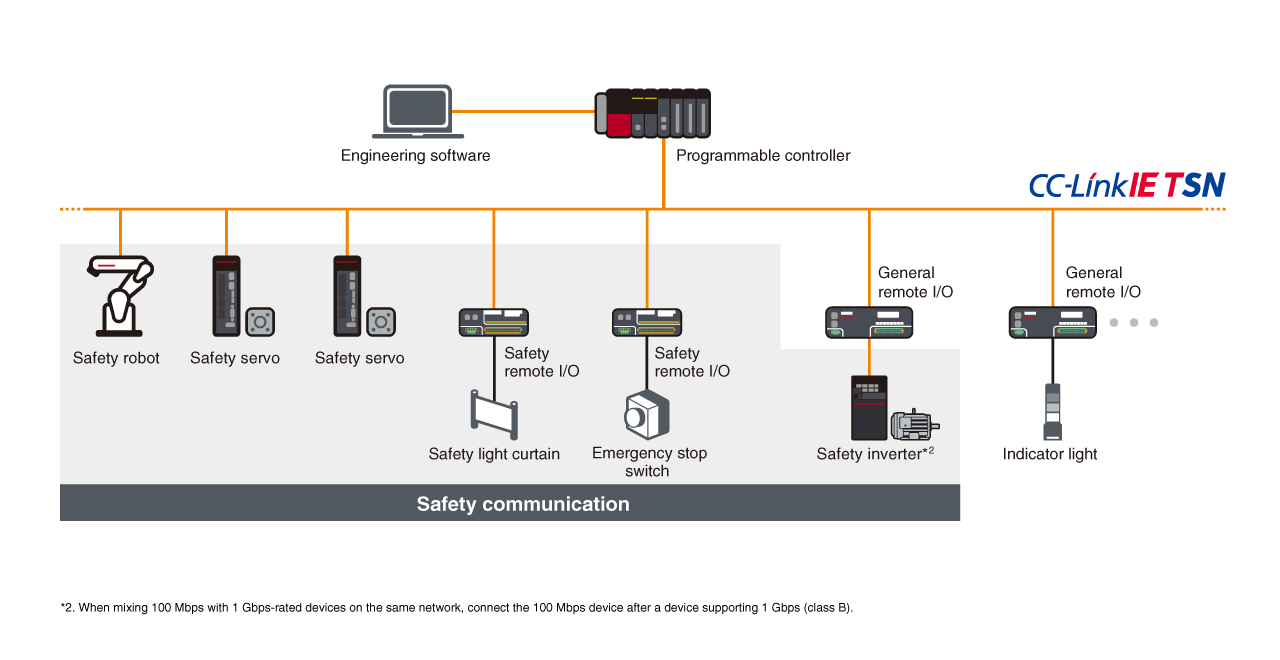

・Integration of safety and general control into one network

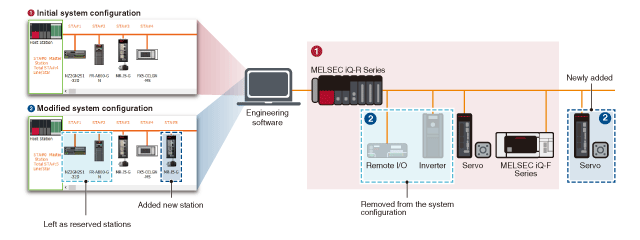

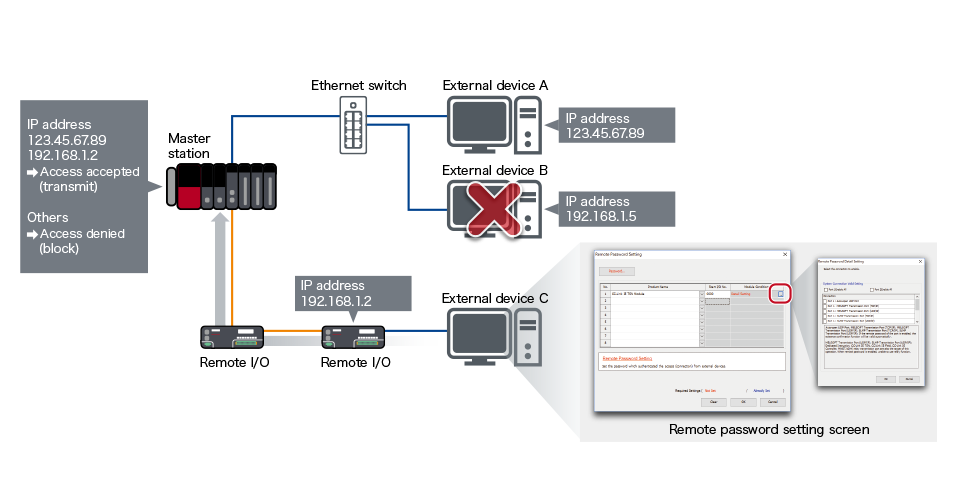

・Multi-level security protecting plant data

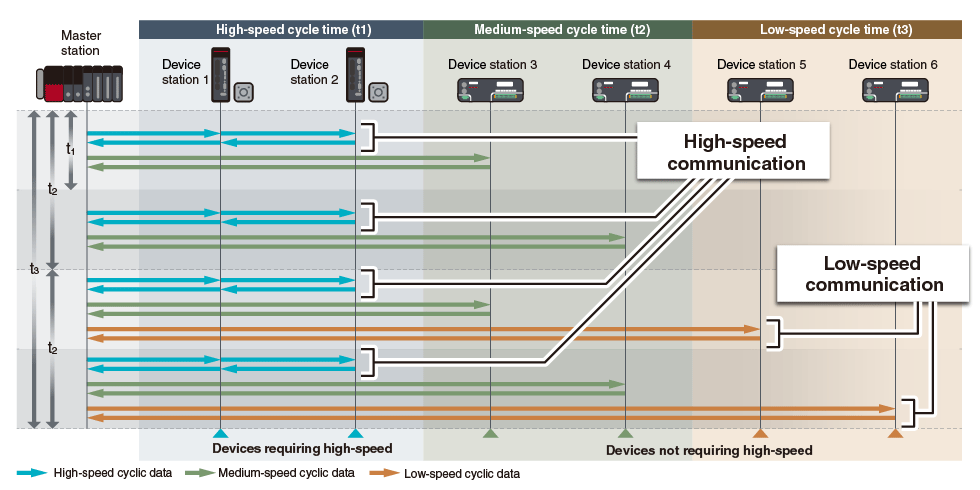

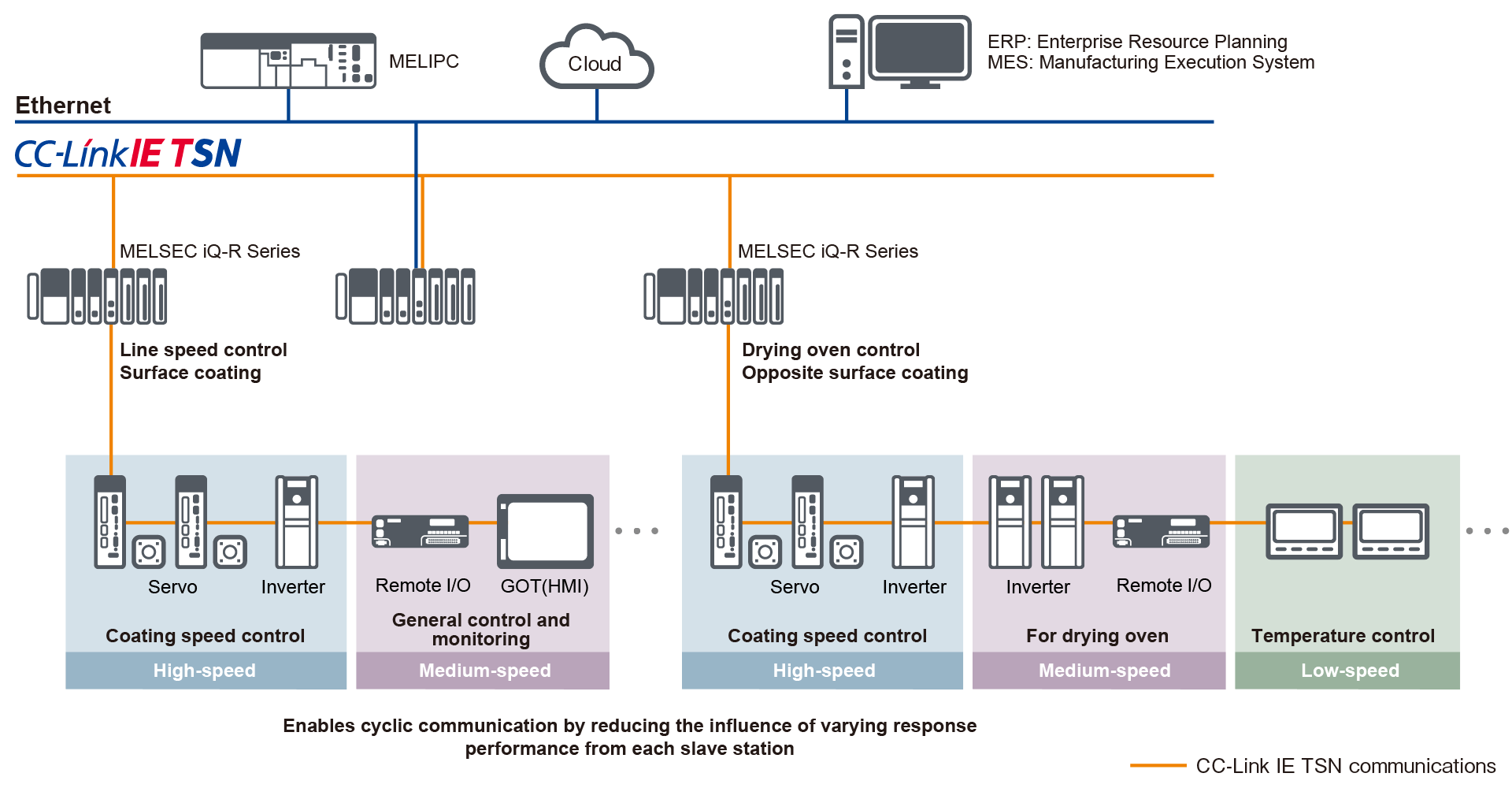

Lithium-ion battery production requires a large-scale production line that includes electrode formation, stacking, inspection, packaging, and shipping processes. Utilizing various Mitsubishi Electric factory automation technologies and products, such as tension control, motion control, synchronization control, robots and IT system coordination (e-F@ctory) in each process enables efficient production of high-quality lithium-ion batteries. Incorporating CC-Link IE TSN enables the mixing of high-speed cyclic control and slower response time control, thereby ensuring maximum performance of each device. Large-scale production lines can be configured, contributing to high-speed, highly accurate motion control, enhanced operation management and quality control throughout the entire factory.

Highly accurate motion control of multiple axes

- ・Devices normally connected to SSCNET and CC-Link IE can be integrated into one network

- ・Highly accurate synchronous control of multiple axes even when mixed with servos and inverters

Mixing of multiple cyclic communication cycles

- ・High-speed cycle time control (such as servos) and slower response time control (such as inverters and temperature control) can be combined

- ・Ensures maximum device performance and reduces hardware cost by enabling optimal device selection for applications

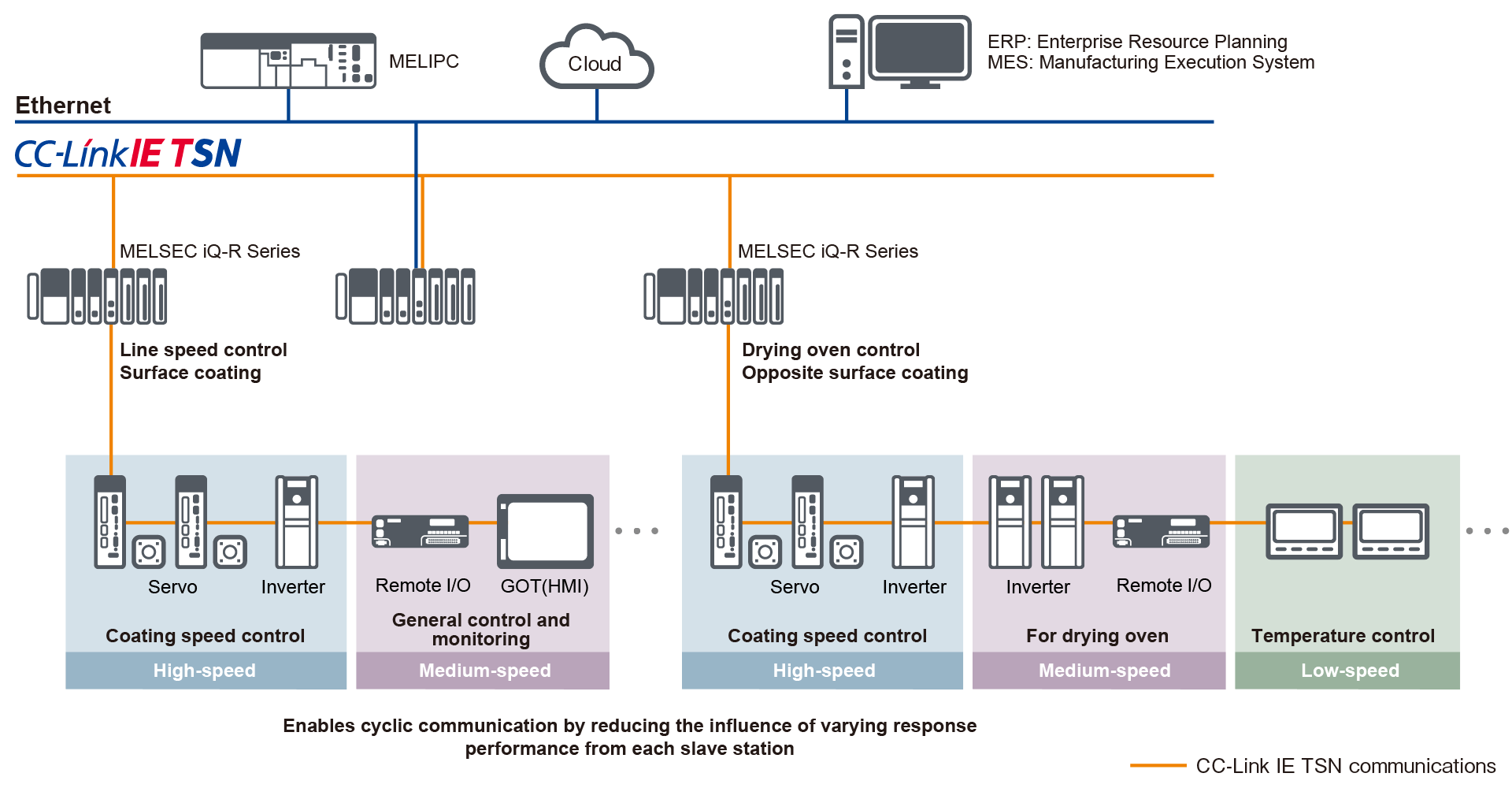

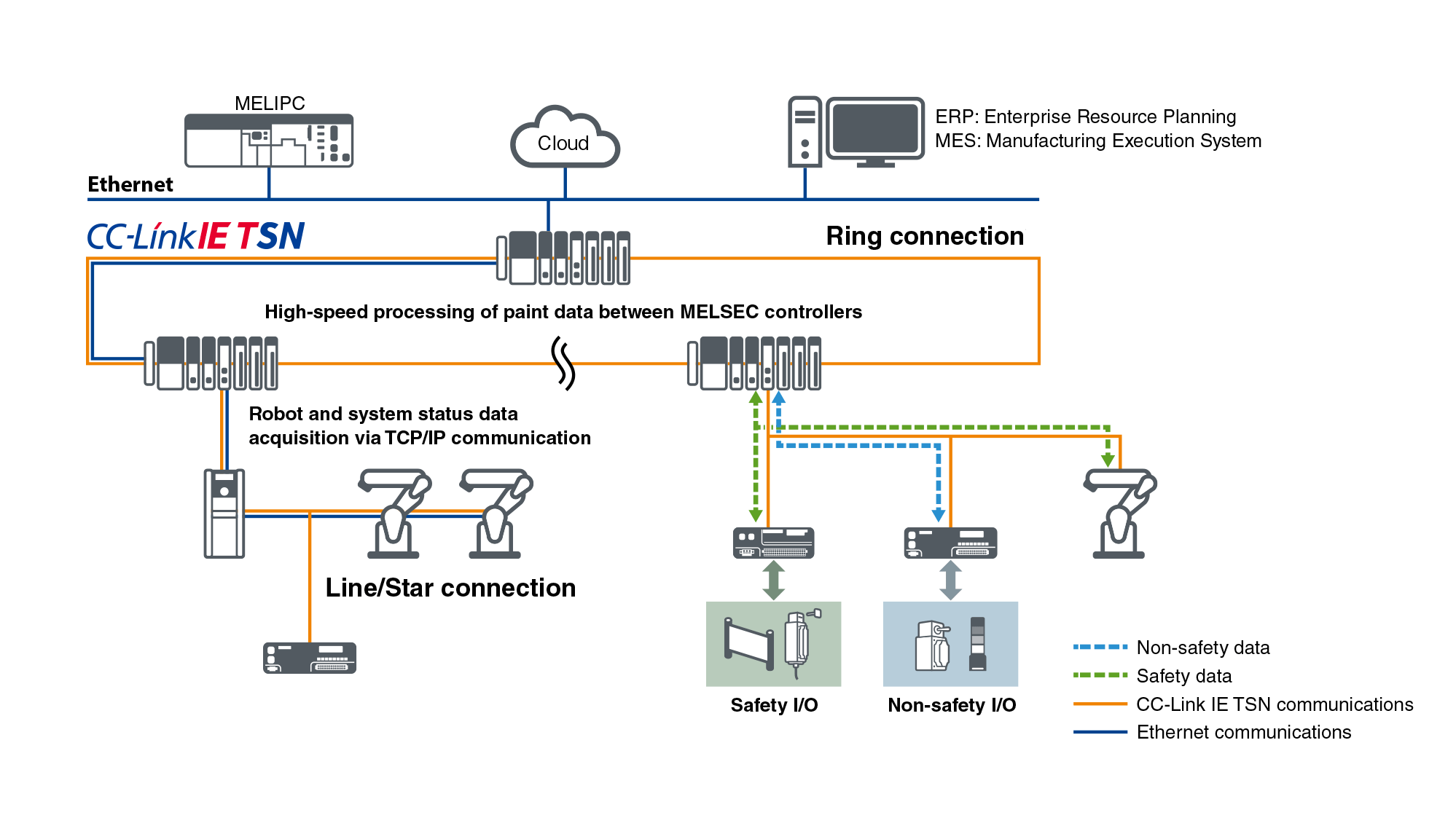

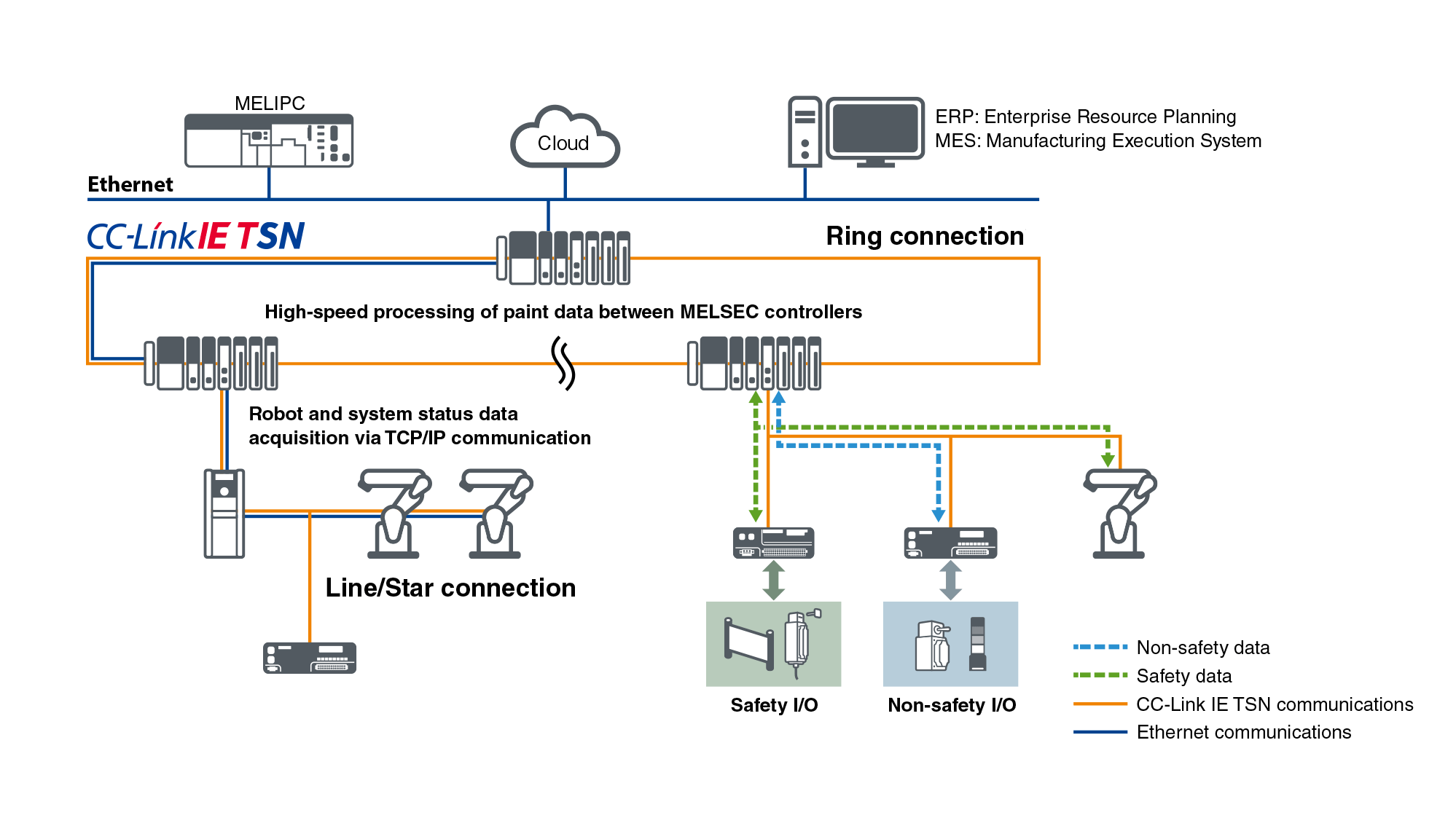

Automotive manufacturing was the birth of line assembly where continuously moving production lines are common. With the automated manufacturing boom in the 1970s and introduction of lean manufacturing, the call to reduce inventory and waste and speed up cycle times has dominated the industry. With the onset of digitalization, Industry 4.0, device interconnectivity and large-capacity data, real-time networks that have seamless communication with multiple devices and open networks have become even more essential. With CC-Link IE TSN, the entire supply chain, from IT services and machine/OEM manufacturers to the end user, can utilize its distinct features to realize a smart factory with optimal automotive manufacturing performance.

Integrate general, safety, and TCP/IP communications onto one network

- ・Manage general and safety communications on one network, ensuring control of paint robots and conveyors

- ・Integrate Ethernet communications on the same network without requiring dedicated couplers

Flexible topologies ensure easier system changes and integration into existing lines

- ・Star, line, and ring topologies are supported, simplifying system layouts and ensuring easier upgrade paths

- ・Using a TSN-supported switch enables simple integration into existing systems with other networks and factory automation products

- ・Ring topology ensures data communication integrity when an error occurs using the loop-back function

High-speed, large-capacity data communication ensures high-speed processing and easier maintenance

- ・High-speed processing of paint data utilizing MELSEC iQ-R CPU and fast network performance of

CC-Link IE TSN - ・Various data from different processes can be transferred to the main controller and IT system utilizing edge devices such as MELIPC

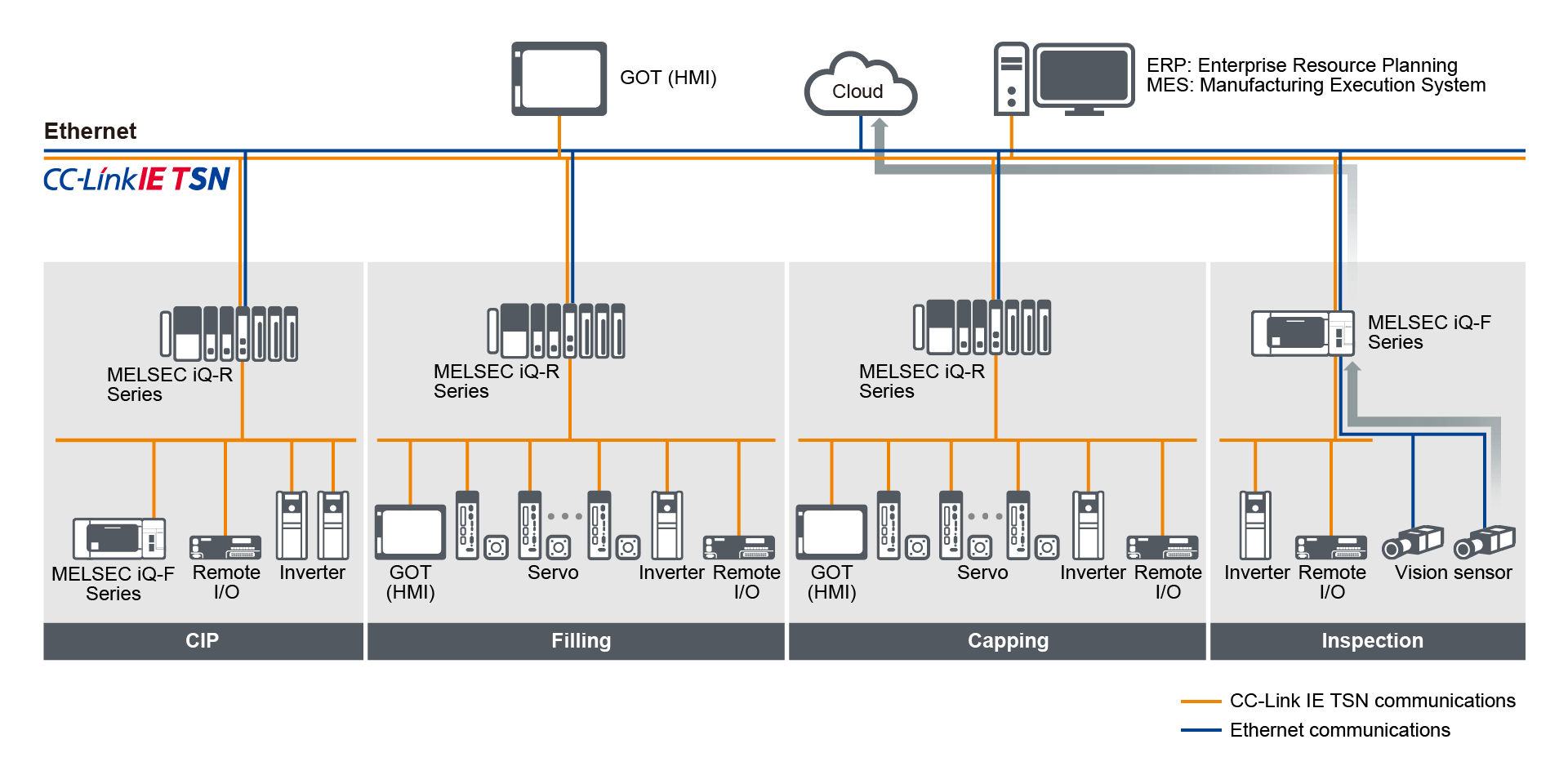

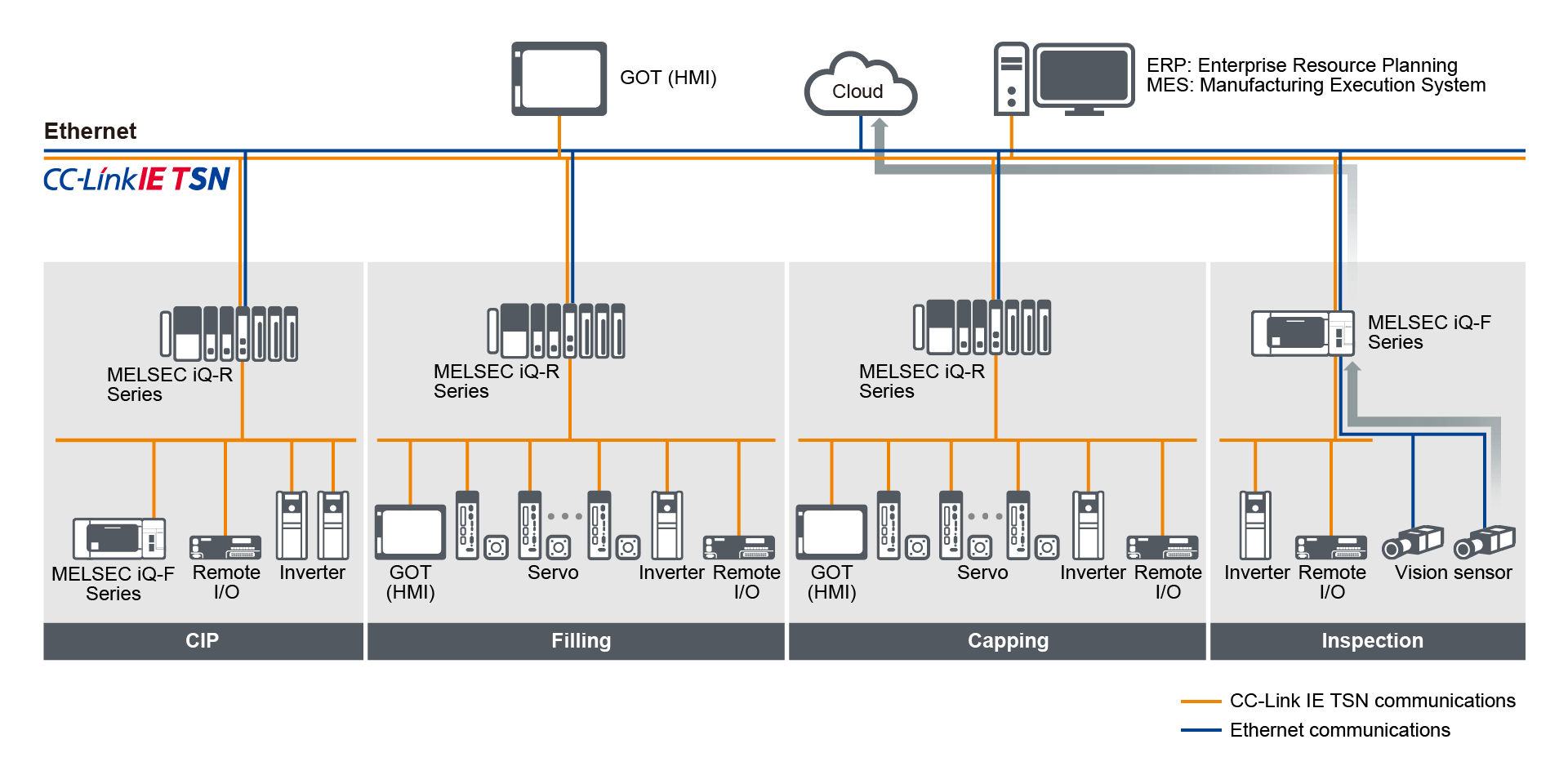

Eliminating defects, reducing downtime, and maintaining high productivity are basic requirements within the food and beverage industry; especially where consumers expect high product quality. In the packaging process, ensuring accurate and quick filling/sealing of products are required to avoid unnecessary product wastage and longer manufacturing cycles. In addition, with consumer product quality requirements normally being stringent, a robust, high-speed network that can handle large-capacity data communications is required to collect and process traceability data, which can be used to analyze the root cause of defective products in manufacturing processes.

Integrating advanced motion control enables faster machine cycle times and highly accurate processing

- ・Advanced communication protocol enhances motion performance, realizing high-speed, highly accurate motion control

- ・Realize synchronous control with direct data communication between servos*1

*1. Future release

Real-time collection and analysis of quality data from the shop floor

- ・Time-stamping traceability information and product filling data enables highly accurate data analysis, improving product quality management

Integrate CC-Link IE TSN and Ethernet devices

- ・Mixing with TCP/IP communication allows utilization of best-in-class Ethernet devices on the same network

- ・TCP/IP communication is possible without affecting overall machine performance

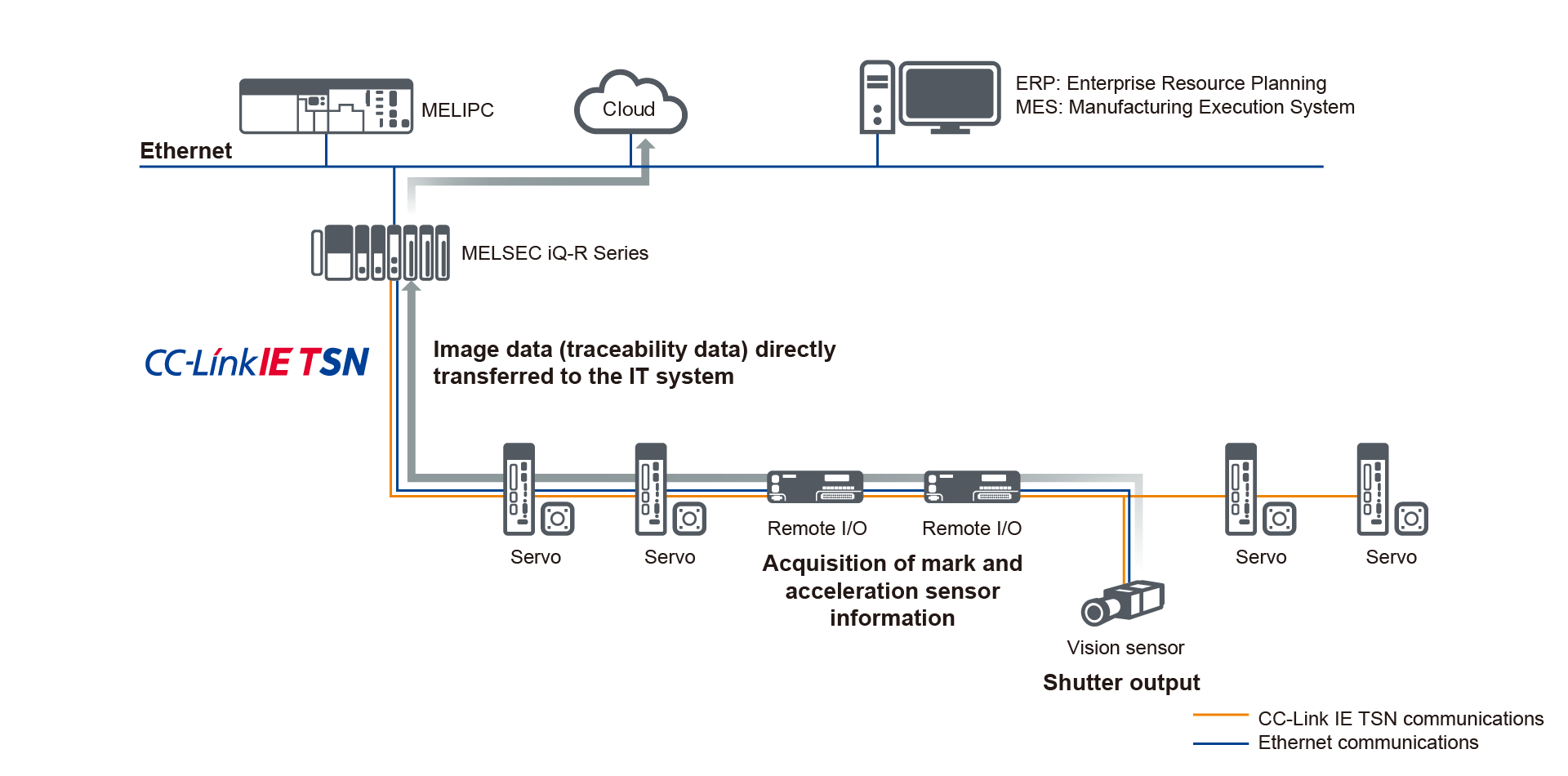

With the shift to digital media, the printing industry has also experienced a shift from mass continuous printing of small diversified contents for multiple readers to flexible printing where a large variety of contents is printed in small quantity. As the result, printing machines now require multiple functionality that enables efficient production of printed media in various runs, shapes and colors while maintaining high-quality print and productivity. CC-Link IE TSN enables highly accurate synchronization of multiple axes between various printing processes such as converting (paper infeed/outfeed), printing, processing, binding, and sorting. Together with the integration of various sensors and I/Os, highly scalable printing systems can be realized.

High-speed, highly accurate motion control system

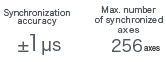

- ・Large-scale systems utilizing highly accurate synchronous control of up to 256 axes with a single network master

Synergy with vision sensors

- ・Time synchronization between the servo and vision sensors enables highly accurate positioning by detecting moving workpieces relative to the printing position and compensating any deviation, thereby reducing the overall operating cycle time

MENU