Process Control/Redundant Application examples

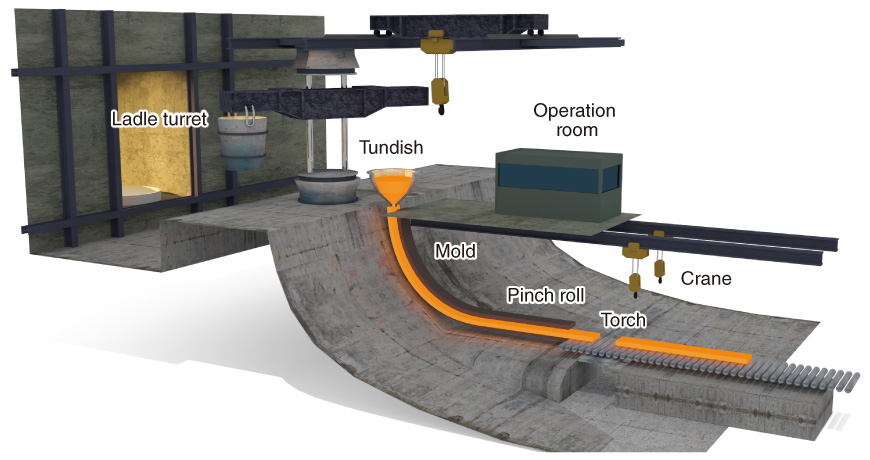

Steel industry

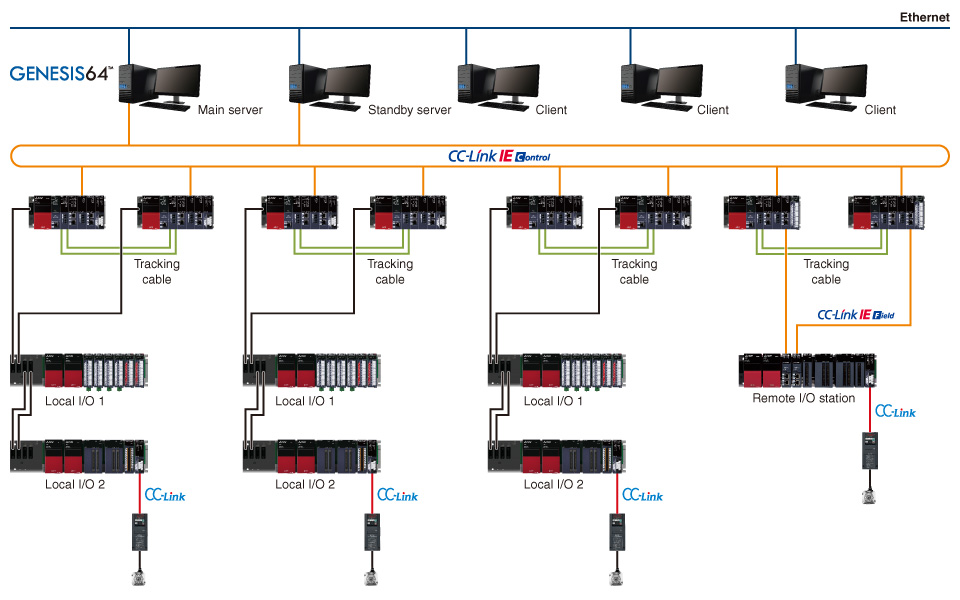

Mitsubishi Electric offers the MELSEC iQ-R Series, GENESIS64™, and HMI (GOT) for monitoring control of the processes and utilities at steel plants. A highly reliable system can be built with redundant CPUs, networks, and SCADA servers. A system with a hierarchical network can be built by integrated connection of programmable controllers via CC-Link IE Controller Network and distributed connection of I/Os via CC-Link IE Field Network.

- Electrical control and process control are combined into one CPU, instead of using separate controllers for loop control (controller) and for electrical control (programmable controller). This results in a cost-effective system that takes up less space and offers high-speed controllability

- High-speed controllability delivers high-resolution PID pulse-width control. Increased accuracy and responsiveness of stopper position control significantly improves level controllability

System configuration