Update : 2023/07/05

AUTOMATION CONTROL SYSTEM GROUP CO., LTD.

Innovation Sensor and Absolute Encoder for high precision, Safety Device, Robotic Accessories and Robot Arm Tooling (Automatic Tool Changer, Multi-Axis Force/Torque Sensing Systems, Material Removal Tools, Clamp, Gripper)

Address

8 Soil Srinakarin 63 , Srinakarin Road, Nongbon, Pravet, Bangkok, Thailand 10250

Tel: +662 185 6381-9

Email: sales@automationcontrolsystem.com

Website

MICRO-EPSILON - Precise measurement of distance, thickness, color, 3D geometry & surface.

Sensors from Micro-Epsilon are extremely compact, smart and profitable. We offer you a wide range of innovative sensor solutions from laser sensors and scanners to robust eddy current sensors for high precision displacement measurements and True Color sensors.

https://acsg.co.th/th/allproduct/micro-epsilon/ ![]()

NSD - Absocoder

Best Sensor Solution for Smart Factory and Advanced Factory Automation

NSD provides a wide selection of rugged position sensors, and customizable sensing solutions in tomorrow's factory automation industry. (Steel Making Industry, Paper and Film Making Industry, Tire Making Industry, Water Gate Industry)

https://acsg.co.th/th/allproduct/nsd/ ![]()

EUCHNER Safety Engineering MGB2

The MGB2 Modular secures access points in safety doors and fences protecting the danger zones of machines and installations. This highly functional door locking system is already a great success in many sectors. Users appreciate the system's modular design and its wide scope for customization. The diverse connection options are further proof. Alongside the PROFINET/PROFIsafe and EtherCAT P/FSoE bus protocols, an MBM bus module for connection to the safe EtherCAT/FSoE protocol is now also available.

EUCHNER CKS2 – One key, many functions

The CKS2 is a compact key system for installation in machines and can also be used as a submodule of the MGB2 safety door system. Diagnostics data and communication functions can be accessed via IO-Link with the appropriate EUCHNER gateway or, in the case of the submodules, directly via the bus module of the MGB2.

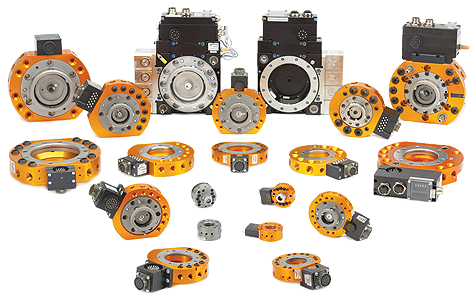

ATI - Robotic Tool Changer

The ATI Robotic Tool Changer provides the flexibility to automatically change end-effectors or other peripheral tooling. These tool changers are designed to function reliably for millions of cycles at rated load while maintaining extremely high repeatability. For this reason, the ATI Tool Changer has become the number-one tool changer of choice around the world.

ATI Tool Changer models cover a wide range of applications, from very small payloads to heavy payload applications requiring significantly large moment capacity.

https://acsg.co.th/th/allproduct/ati-industrial-automation/ ![]()

ATI - Robotic Tool Changer

Air-actuated compliance overcomes part variation.

Historically, deburring and material removal processes deploy manual techniques. This is largely due to the limited availability of deburring tools suited for automation. Conventional automated deburring tools exist and perform adequately along a straight line or path, but fail when part tolerances or geometries are not exact. Removing material from a part cavity or protrusion using a robot or other automated process challenges the most skilled of programmers and often leads to inconsistent quality. The Engineers at ATI have developed a family of compliant deburring tools that make automated deburring processes safe, reliable, and affordable. Pneumatic compliance built into these tools exerts a constant force and compensates for displacement. This ensures consistent results and facilitates easy programming.

https://acsg.co.th/th/allproduct/ati-industrial-automation/robotic-deburring-tools/ ![]()