Transforming Manufacturing with Digital Twins

Your journey towards the digital transformation of design and manufacturing starts with 3D simulation

![]() Process design optimization

Process design optimization

![]() Improvement of

Improvement of

productivity and cost

![]() Establish a design process

Establish a design process

that eliminates rework

![]() Virtual commissioning

Virtual commissioning

![]() Digitalization of knowledge

Digitalization of knowledge

For more details on our solutions and implementation case studies, click here

Download documentAre you facing productivity and maintenance challenges?

Do your design, engineering, and maintenance teams struggle with inefficiencies and unclear information that lead to delays in problem-solving?

3D simulation can help them overcome many of these challenges and related issues.

Challenges facing your process and machine design teams.

Before

- It is difficult to verify productivity and layout in advance.

- Having trouble during launch.

After

- With 3D simulation, it is now possible to verify productivity and layout in advance to create optimal designs.

- We were able to reduce problems during rework and launch, and the production line was launched as scheduled.

Before

- With 2D drawings, it's not possible to notice collisions between machines and other problems related to motion

- Rework due to miscommunication regarding specification

After

- With 3D simulation, it is possible to accurately understand the motion of the machine and check for any potential problems in advance.

- The 3D model improved communication between motion and programs, which in turn reduced rework and on-site adjustment

Solving manufacturing and maintenance challenges

Before

- We want to test the improvement plan, but can't stop the line to verify.

- It is difficult to implement improvement plans because its ROI is not clear.

After

- With 3D simulation, it is possible to try any number of test cases in a virtual space without need to stop the actual line.

- The effectiveness of improvement measures can be presented as data, making it easier to persuade the company.

Before

- Recovering equipment after sudden failures occur is time-consuming.

After

- 3D simulation increases the efficiency of cause investigation, which significantly reduces the time it takes for equipment recovery.

Solving challenges related to digital transformation (DX) promotion, management and sales issues

Before

- The reluctancy of shop floor workers to accept DX hinders its implementation.

- Tools have been introduced in the past, but they have not been used throughout the whole company.

After

- It is easy to show image and effect by the 3D simulation,and the understanding in the company was obtained.

- 3D models serve as a hub connecting each departments and this has strengthened corporate competitiveness.

Before

- We are worried about how to handle labor shortages and rising costs.

- We want to make optimal decisions and investment decisions swiftly.

After

- Through 3D simulation, layout and productivity can be verified in advance, and this enables us to make appropriate decisions, including investment decisions.

Before

- Each customers’ environment is unique, making it a challenge to present optimal proposals.

- Communication breakdowns create difficulties in mutual understanding.

After

- By reproducing the customer's shop floor in 3D simulation and visualizing effectiveness, we are able to present optimal proposals.

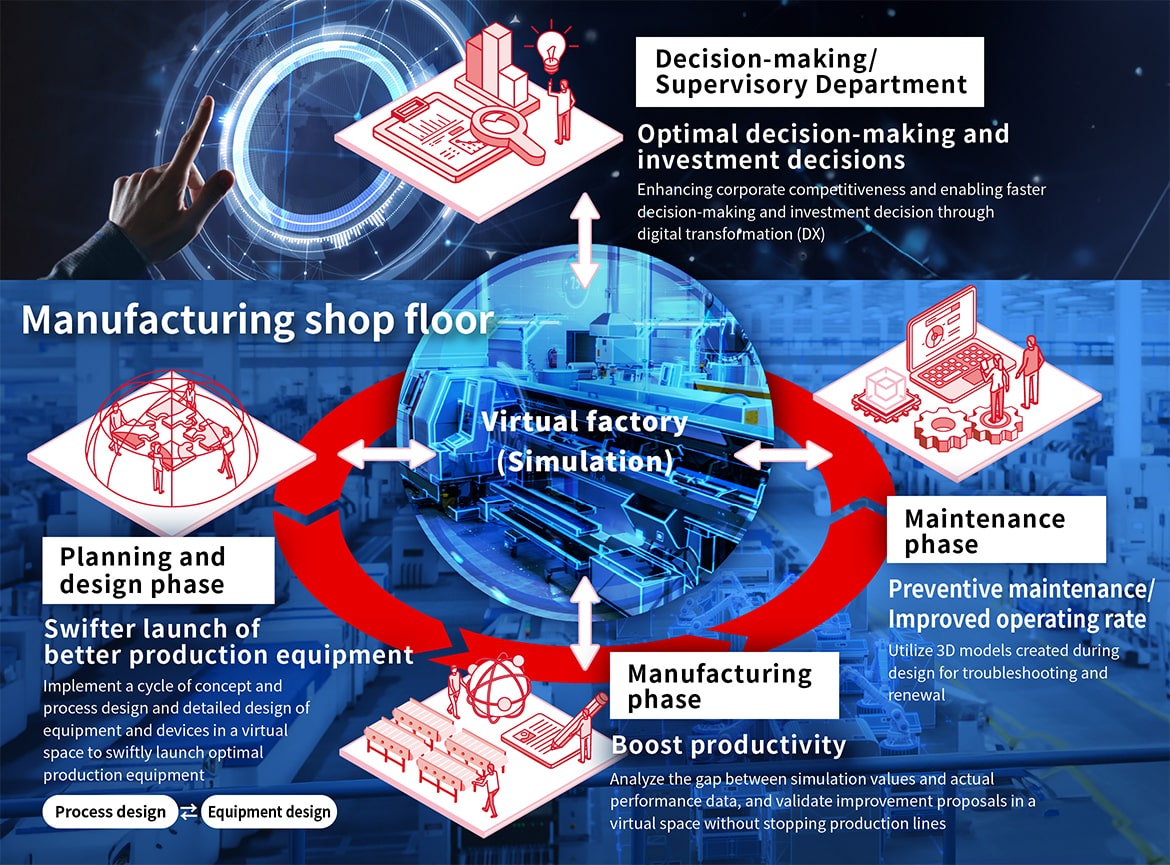

Overall improvement of the manufacturing process with 3D simulation

It is Mitsubishi Electric’s 3D simulator, MELSOFT Gemini, that solves these challenges.

Not only does it enable improvements at each process stage, but the virtual factory built in Gemini also serves as a hub. By allowing cross-functional teams—spanning design, manufacturing, and maintenance—to share a common 3D model, it helps standardize the entire manufacturing process and contributes to enhancing your company’s overall competitiveness.

Reasons to choose Mitsubishi Electric’s 3D simulator

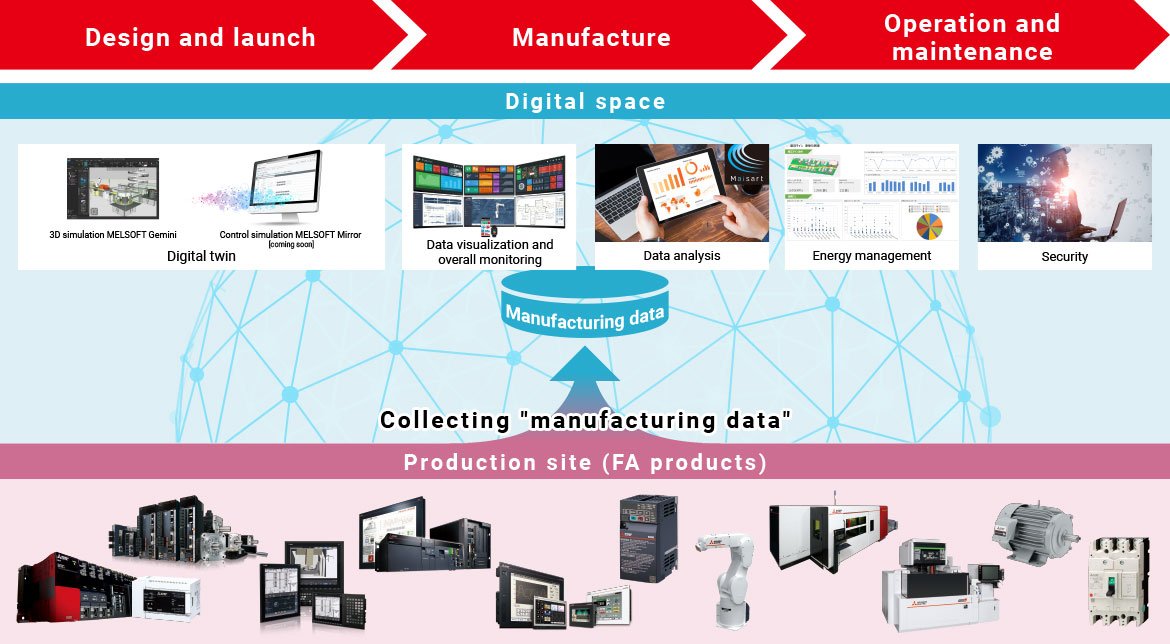

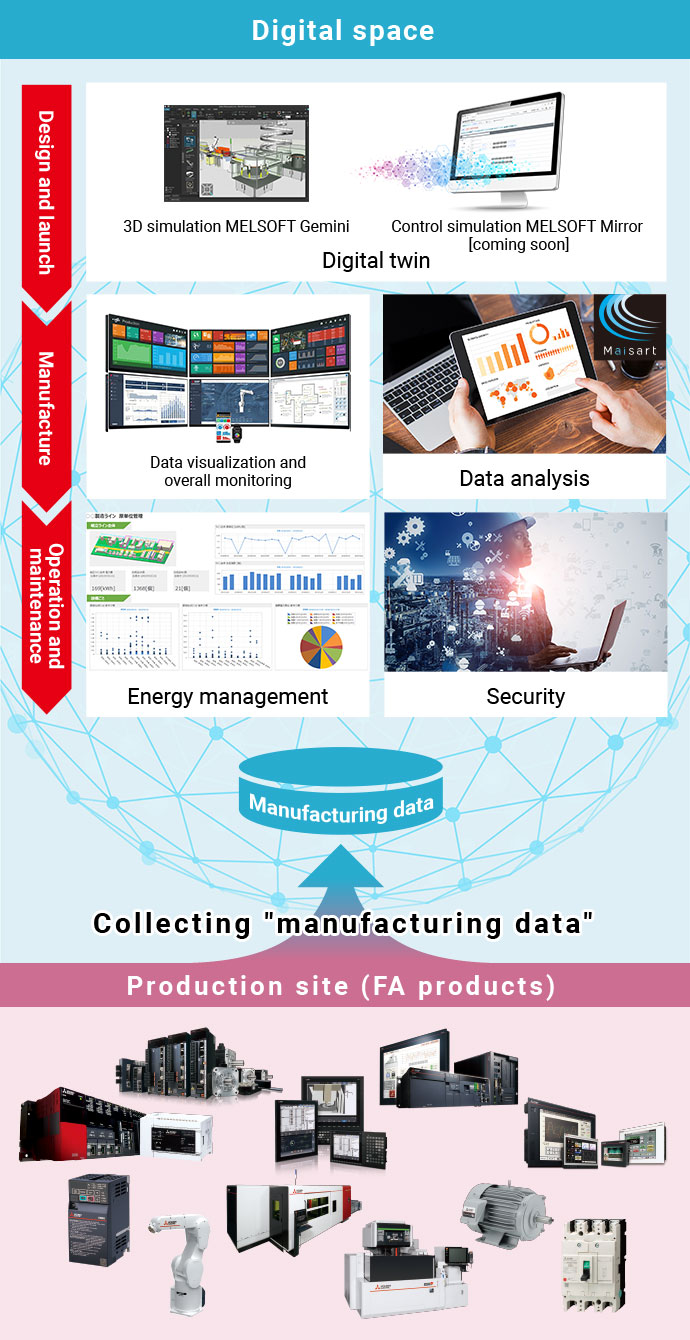

At Mitsubishi Electric, simulation does not end as mere simulation.

We enable simulation data to be leveraged for greater productivity in equipment design.

Because Mitsubishi Electric provides the key components for equipment control, we are uniquely positioned to support shop-floor-driven

digital transformation (DX)

Don’t Let Simulation End with Simulation

Simulation is a means to enhance real-world operations, and its true value lies in how well the results can be applied to actual sites. As Mitsubishi Electric provides both the key components for equipment control and advanced simulation technology, we deliver a one-stop software and hardware solution that makes true digital integration possible.

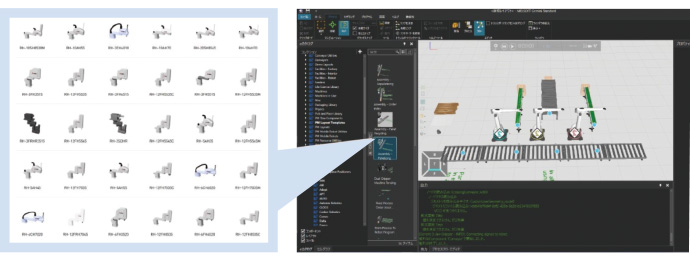

A rich library and no-code operation make it easy to use.

- A library of over 3,500 models, including robots and equipment from Mitsubishi Electric and other manufacturers. Each model can be intuitively placed using the drag-and-drop function.

- No-code (low-code) enables process simulation and swift integration into business processes.

Click here for details of the 3D simulator MELSOFT Gemini

Download documentUse Cases and Case Studies

MELSOFT Gemini can be used by companies across a broad range of business types and industries.

Machinery parts manufacturer

Used for the designing of a new factory

Battery manufacturers

Production line layout planning and productivity improvement / Reducing issues during launch through machine interference checks

Equipment suppliers

Strengthening global competitiveness, improving the company's business processes, streamlining equipment conceptual design, and making proposals to customers

Case Studies

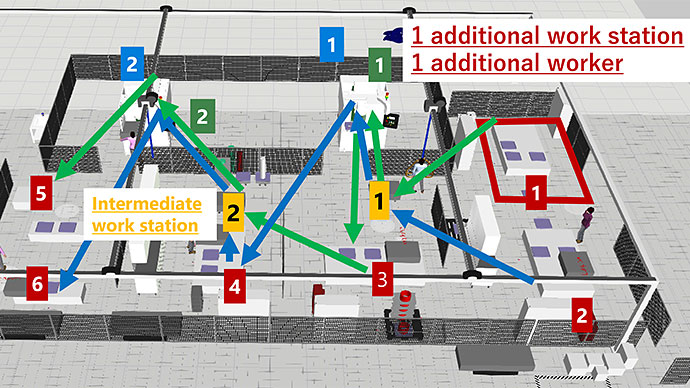

Case study of Mitsubishi Electric's factory. Process design simulation

- Reproduce the current line in 3D and verify multiple improvement ideas

- Check the improvement effect of idling loss reduction, etc. on the desk

- Can be applied on-site without rework and realizes verified production efficiency

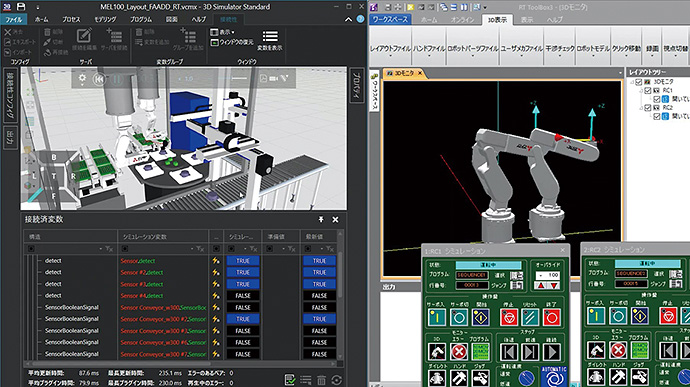

Case study of Mitsubishi Electric's factory. Equipment design simulation

- Since it can be checked with a 3D model, debugging time is shortened, reducing on-site engineering labor time

- Accurate and rapid interference checks reduce on-site survey and launch time

Case study of an automaker (Toyota Motor East Japan Inc.)

- Used to consider the optimal process to pursuit safety, quality, and productivity

- By reproducing the shop floor in 3D, enabled view of the entire process and consider issues and countermeasures.

- It was easy to use with a wide range equipment in the library and extensive technical support

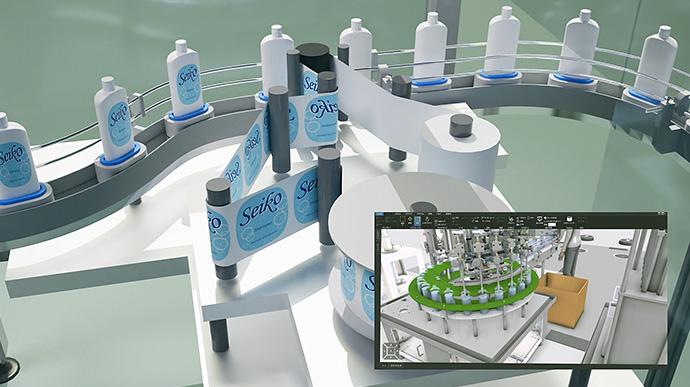

Case study of a packaging machinery manufacturer (Seiko Co.)

- Identify and address issues early through simulations not requiring physical equipment

- Can also be used as a tool for proposing shop floor improvements to customers

- Register original equipment to the library to establish an environment accessible to all responsible personnel

Click here for details of case studies such as the benefits of introduction

Download document