Solutions Carbon neutral

Aiming for a decarbonized society

As a leading manufacturer, Mitsubishi Electric considers contributing to carbon neutrality our major mission.

In addition to FA equipment and power distribution control equipment,

we support our customers' sustainable business activities by utilizing IoT platforms as well as applications for visualization, analysis, and diagnosis.

Buildings and Utility Equipment

Case01 To automatically collect and manage CO 2 emissions from electricity, gas, and heavy oil

- Visualization

- Issues

- The higher-ups are saying “Strengthen management to reduce CO 2 emissions!” but where should we begin?

- Solution

-

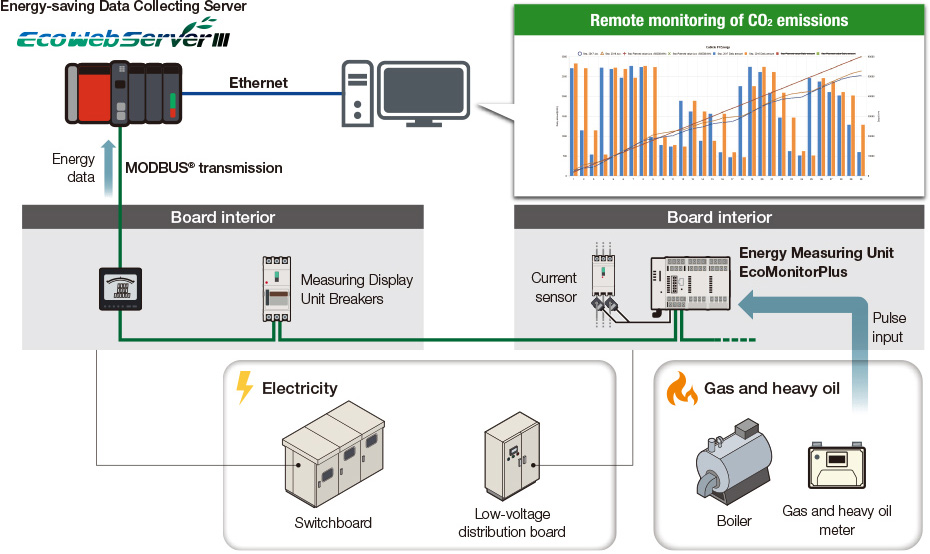

- Measures the amount of electricity, gas, and heavy oil used in the factory with various measuring instruments

- Measured data is automatically collected by a special-purpose data collection server, and CO 2 emissions are checked on a special-purpose screen on a web browser

EcoWebServerⅢ, an Energy-saving Data Collection Server,

provides a solution for CO

2

emissions management

Electrical equipments, such as sweitchboards and switchboards and low-voltage distribution boards, as well as gas and heavy oil consumed in boilers, etc., are measured. The energy data collected by EcoWebServerIII is used in calculations with CO 2 conversion factors to manage CO 2 emissions.

- Benefits

-

- Energy management is centralized by measuring electricity with measuring instruments suited to the site and collecting the amount of gas, heavy oil, etc. consumed

- By automating data collection and CO 2 conversion, the amount of labor time required to aggregate energy and CO 2 emissions is reduced