News Release Archives

Note that the releases are accurate at the time of publication but may be subject to change without notice.

FOR IMMEDIATE RELEASE No. 2902

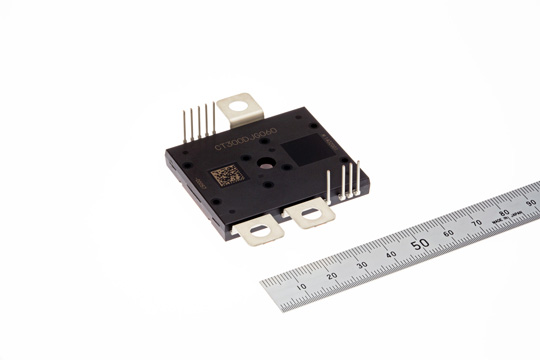

Mitsubishi Electric to Release Sample J-Series T-PM Extra Compact Type

Compact package will help realize small, lightweight and efficient EV/HEV inverters

TOKYO, February 12, 2015 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today it has developed a new J-Series transfer molded power semiconductor module (T-PM) mainly for motor drive applications in electric and hybrid vehicles. Samples of the J-Series T-PM extra compact type will be released starting February 19.

Sales of hybrid and electric vehicles are expanding in line with growing awareness of environmental issues. Automotive components must meet especially stringent safety standards, which creates demands for power semiconductor modules that provide greater reliability than modules for industrial equipment. Mitsubishi Electric pioneered the mass production of power semiconductor modules for hybrid vehicles in 1997.

The sample to be released this time is a compact power semiconductor module, the newest addition to Mitsubishi Electric's J-Series T-PMs mainly for electric and hybrid vehicle motor drive applications. The new module is expected to contribute to further compactness, weight reduction and reduced power consumption in inverters for electric and hybrid vehicles..

The sample to be released this time is a compact power semiconductor module, the newest addition to Mitsubishi Electric's J-Series T-PMs mainly for electric and hybrid vehicle motor drive applications. The new module is expected to contribute to further compactness, weight reduction and reduced power consumption in inverters for electric and hybrid vehicles..

Sale Schedule

| Series | Model | Ratings | Configuration | Sample Shipment |

| J-Series T-PM | CT300DJG060 | 300A/650V | 2-in-1 | Feb. 19, 2015 |

Product Features

| 1) | Reduced inverter size and weight achieved through the extra compact package with high integration

|

||||||||||

| 2) | Inverter power-loss reduction supported by low-loss power semiconductor chips

|

||||||||||

| 3) | Automotive-grade high quality

|

||||||||||