Transportation Systems

Overview

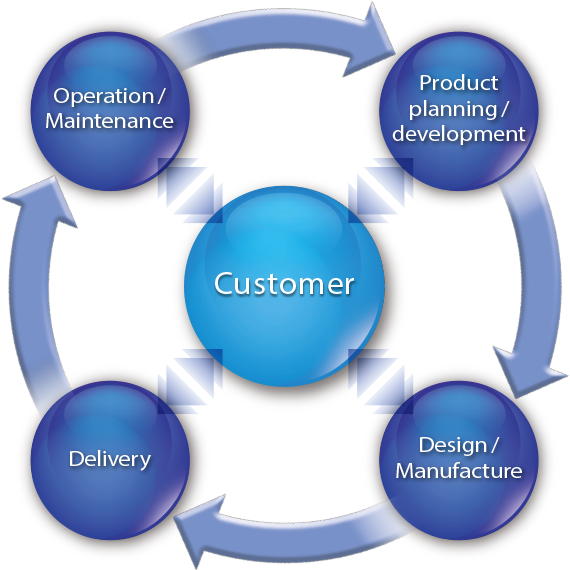

Systems Engineering Approach

Leveraging the technological power of a comprehensive electrical manufacturer to create rail systems in close engagement with customers.

Mitsubishi Electric’s proposal-based sales system, which allows us to grasp our customers’ real needs face-to-face, ensures a dedicated and speedy response. We work with you to create optimal rail transport systems, offering backup via a comprehensive range of support systems that encompass everything from the customer’s introduction plan to post-introduction maintenance and management.

Product planning / development

- Integration with the customer’s perspective to attend to it’s task

- Realization of quality at the development stage through evaluation tests and verification using a rich array of high-precision simulation technologies

- Collaboration with domestic and overseas research institutes to enable deployment of the very latest technologies

Design / Manufacture

- Cutting-edge manufacturing facilities employing Mitsubishi Electric’s outstanding factory automation technologies

- Constant efforts to realize manufacturing quality and a rigorous quality management

- A full array of test and verification facilities, conforming to international standards

Delivery

- Explanation of method of use of product following delivery

Operation / Maintenance

- Location of maintenance divisions in major overseas regions

- Provision of after-sales maintenance services in close collaboration with clients

- Regular maintenance to boost quality and improve function

- Support for condition-based maintenance (CBM)

-

Evaluation tests / Verification

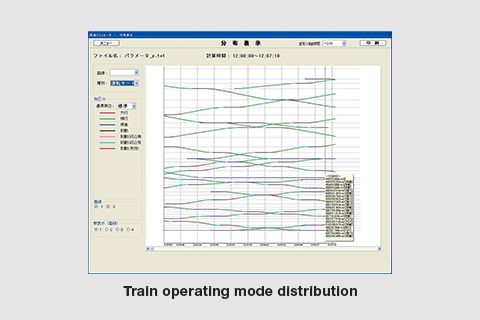

Actual train environment simulator

We are constantly working to improve the quality of our software in order to ensure exact reproduction of an operating train in the test environments employed in our factories.

Feeding network simulator

We conduct power simulations incorporating large-scale and complex feed circuit networks.

-

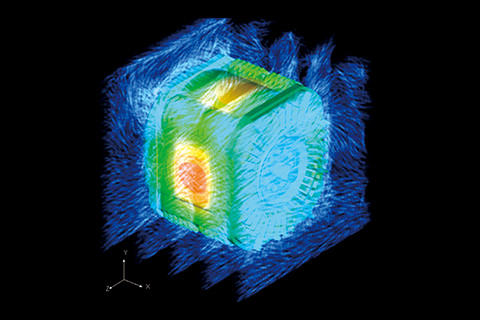

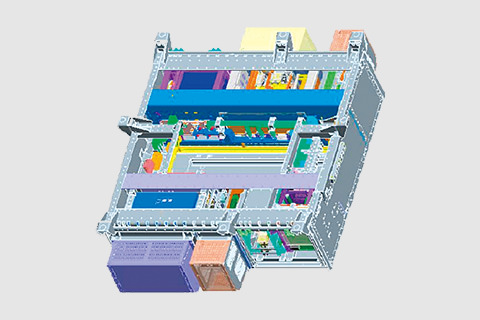

3D simulation

We have introduced 3D design in pursuit of even higher-quality development,

enabling us to achieve high quality from the initial stage.

Thermal distribution on motor

Digital mockup based on 3D design

-

Test verification equipment

Verification in combination with traction systems

We conduct verifications by applying inertial loads to propulsion control systems and traction motors.

Vibration test equipment

We verify vibration resistance using equipment conforming to international standards (IEC).

-

International certification

We have CMMI and certification through third-party certification organization including ISO9001 and IRIS and are able to respond to overseas projects.

CMMI certification

- [Subject of certification]

-

- Propulsion Systems

- Auxiliary Power Systems

- Brake Systems

- [Subject of certification]

-

- Onboard Train Control and Monitoring System

- Wayside Monitoring and Diagnostic Systems

- Test Equipment for Train Electric System

ISO9001:2015 certification

- [Subject of certification]

-

- Itami Works:Design / development, manufacture, field test, technical supporting activities for servicing, maintenance, and sales of propulsion control equipment, traction motors, brake control equipment, power supply equipment, transportation information systems (passenger information systems, train control and monitoring systems) and signaling systems / on-board safety systems.

- Transmission & Distribution Systems Center Ako Factory:Design, development and manufacture of main transformer for electric train.

- Nagasaki Works:Design, development, manufacturing, on the site testing and support for servicing of equipment and systems of railcar air-conditioning systems and equipment.

IRIS Certification® Conformity assessment:2020

- [Subject of certification]

-

- Transmission & Distribution Systems Center Ako Factory: Design, development, manufacture of main transformer for electric train.