Air Conditioning and Refrigeration Systems

Compressors

Be Environmentally Friendly

for Sustainable World

R&D and

Production Bases

-

Mitsubishi Electric Corporation Shizuoka Works

Established: 1954

Place: Shizuoka, Japan -

Siam Compressor Industry Co., Ltd (A group company of Mitsubishi Electric)

Established: 1988

Place: Laem Chabang, Thailand -

Mitsubishi Electric (Guangzhou) Compressor Co., Ltd.

Established: 1994

Place: Guangzhou, China

Our Compressor Key Technology

Down-sizing technology for Rotary compressor

-

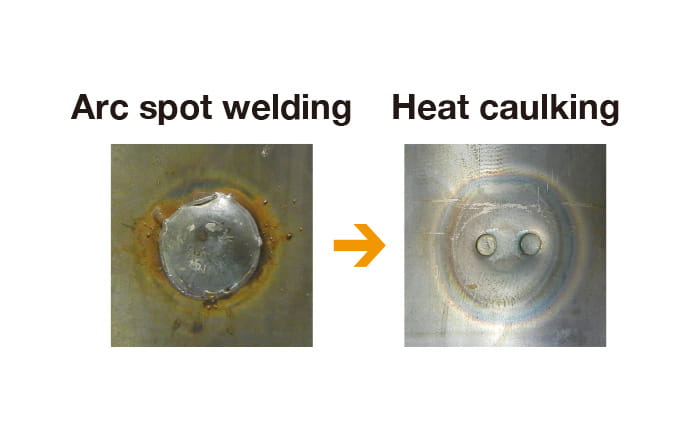

Heat Caulking

It is difficult to avoid deformation of compressor parts when producing small compressors in general. Heat caulking is our innovative welding technology for minimizing deformation and realizing down-sized compressors.

-

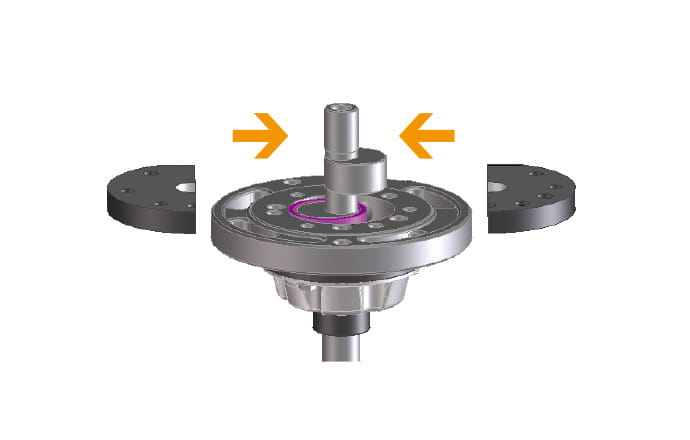

Scrum middle plate

Typically, there are assembly process limitations to realizing largerstroke volume compressors in small sizes. The scrum middle plate overcomes this complexity by dramatically changing the parts structure. (for some models of S, M, L and T series in Twin Rotary)

-

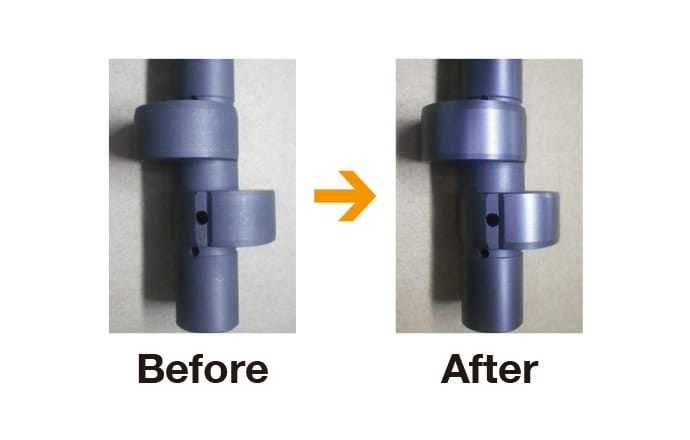

Special coated steel crankshaft

Using an innovative coating technology, we have strengthened the crankshaft so that thin crankshafts can be used to minimize compressor size.

High-efficiency motor technology for Rotary compressor

-

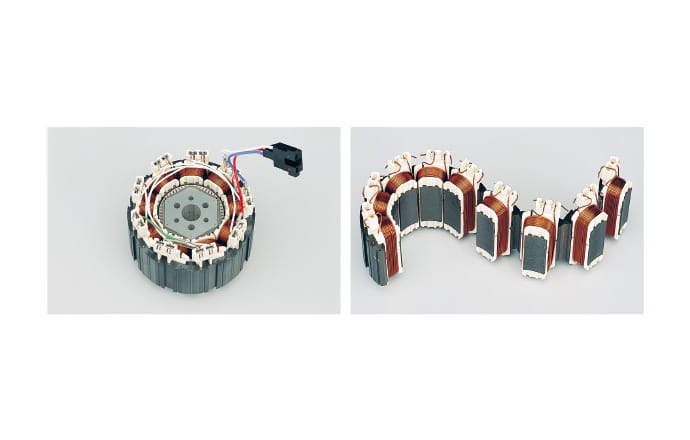

Joint lap motor "Pokipoki motor"

A joint lap motor is composed of jointed parts that can open up to enable each part to increase winding volume.

-

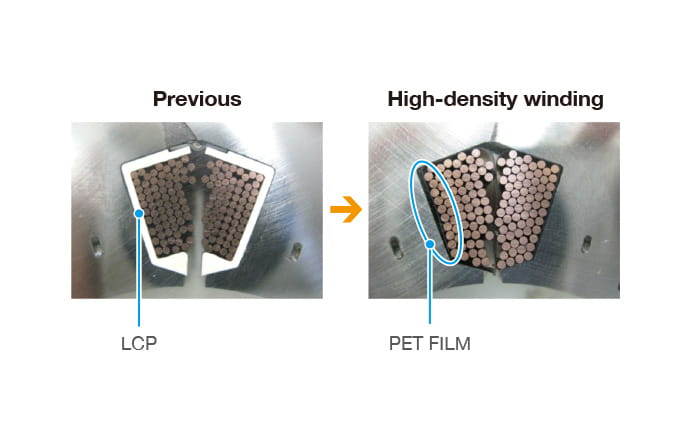

High-density winding

A new motor insulator PET FILM realizes high-density winding by creating additional space inside the winding area.

High-efficiency technology for Scroll compressor

-

Frame Compliance Mechanism

FCM could operate at higher condensing temperatures of up to 65℃ for an indefinite period of time, as well as higher compressor performance with lower power.

-

Oval Scroll

Changing the shape of the scroll from circle to oval makes it possible to ensure high compression efficiency and realize larger capacity compressors.

-

Oil level sensor

Oil level sensor technology can update the level of oil lubricant in the compressor component, making it more confident and reliable. (Eqquipped on some models)

-

Injection technology

It is the technology that enables injection of medium-temperature gas refrigerant into the compressor to increase the discharge refrigerant gas flow and decrease temperature, resulting in significant improvement of unit capacity and efficiency at low temperature.

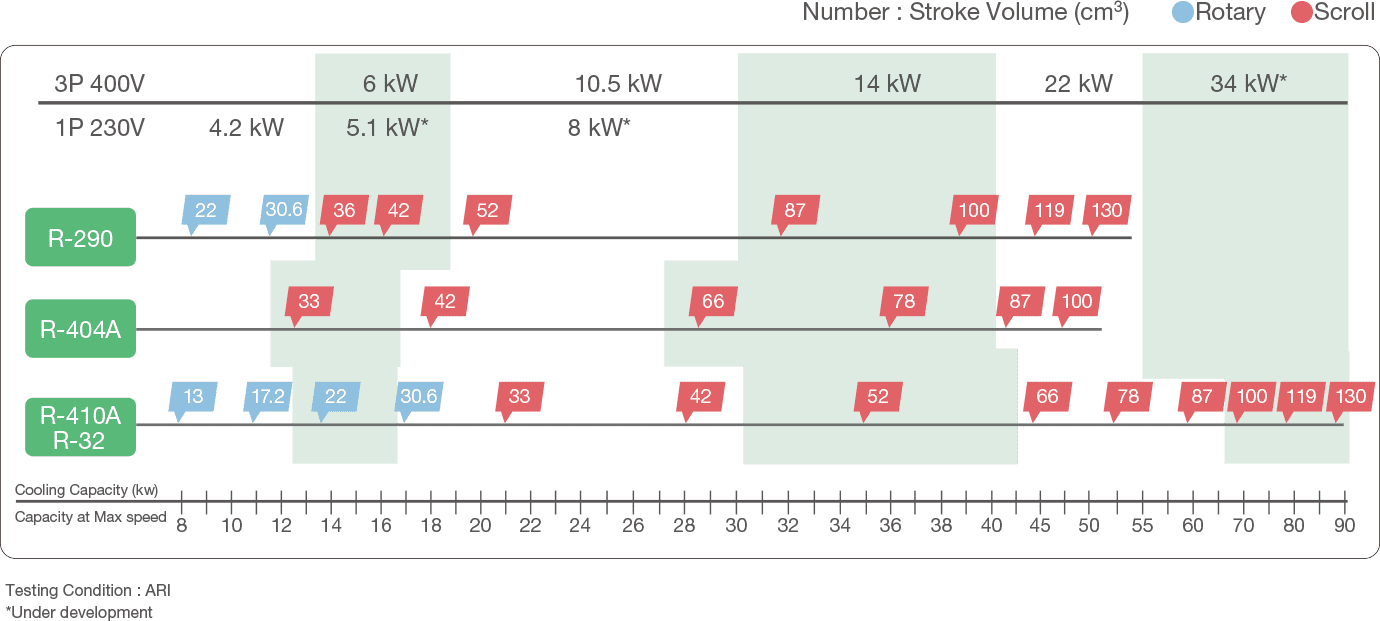

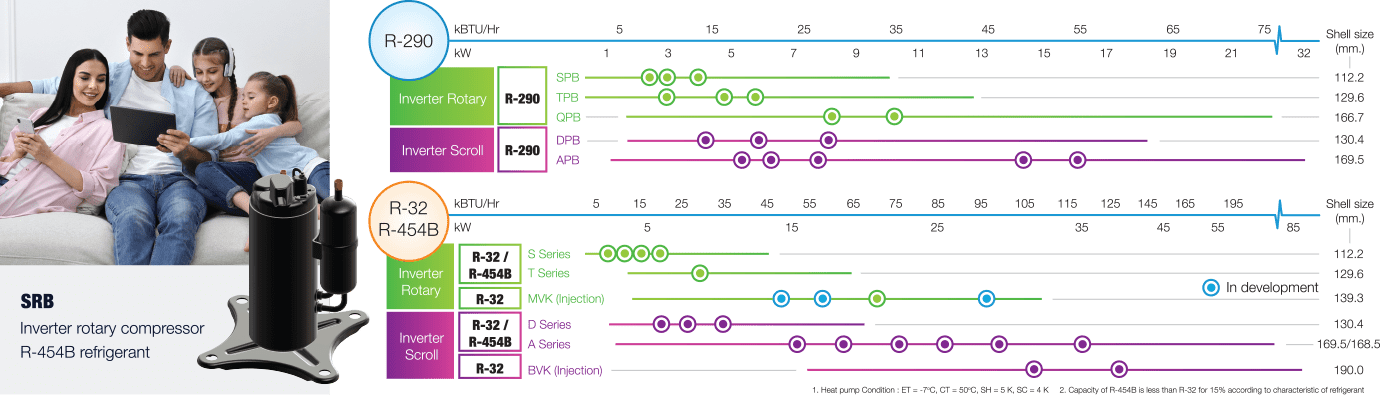

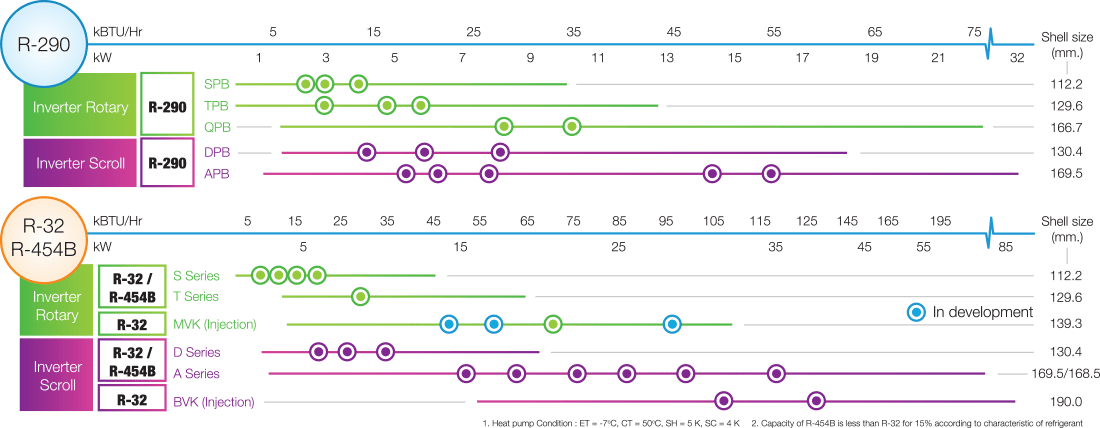

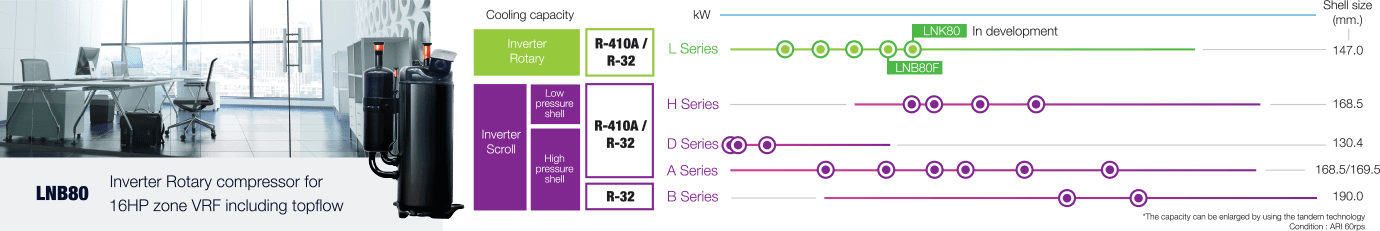

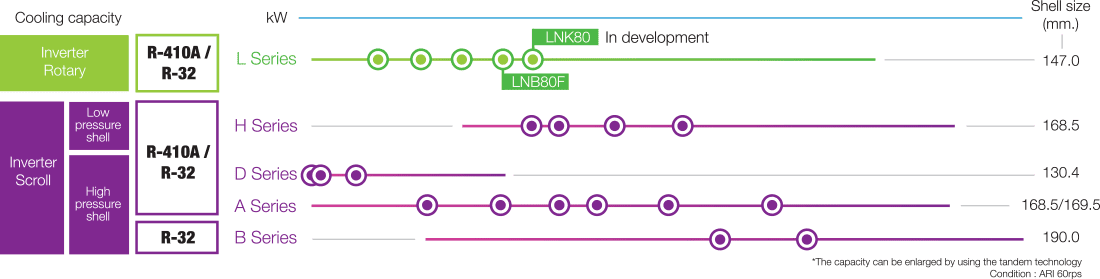

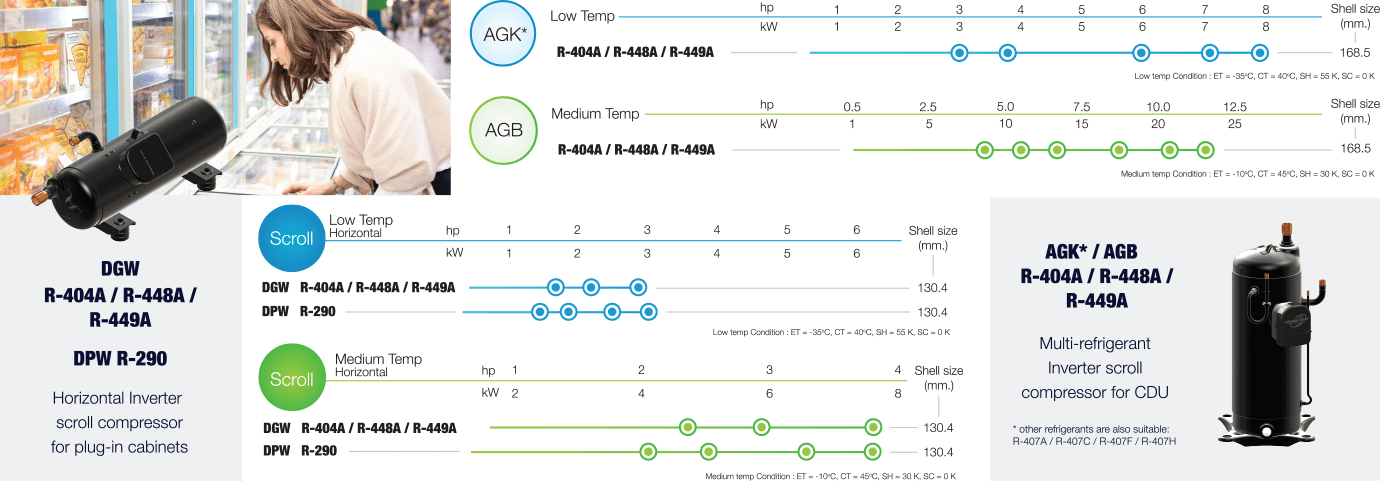

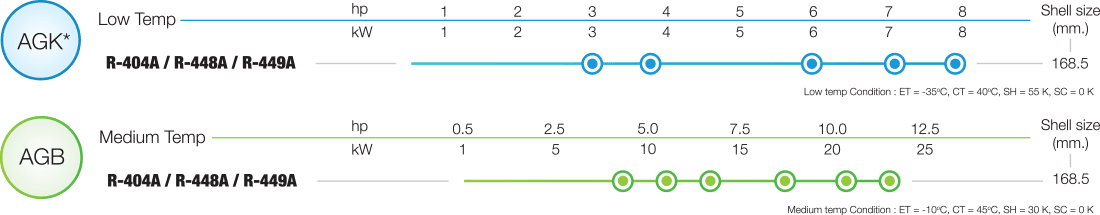

Line up for Compressors

Residential application

Commercial application

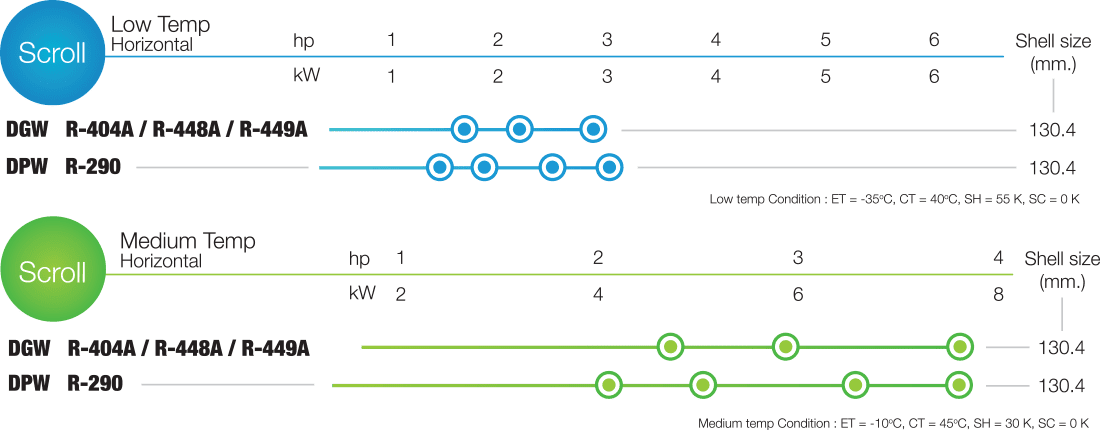

Refrigeration application

Launch of the industry's first ATW-oriented compressor

In compressors for ATW, We have a track record of being the first in the industry to develop and launch compressors with R290 technology, and earn the trust of major ATW manufacturers. Furthermore, Mitsubishi Electric Europe has engineers and a support system.

Mitsubishi Electric will continue to focus on the R290 and expand its production capacity to meet customer requirements.

*As of December 22nd, 2023 based on Mitsubishi Electric research.

Accessory

Inverter Drives

NEW GENERATION Driver Features

FOR BEST OPERATION AND FULL EFFECTIVENESS OF INVERTER COMPRESSORS

SCI drives is well-developed to support large capacity up to 22kW, available in 2 heat exchanging systems; liquid cooling and air cooling. Our driver offers longer lifetime and higher safety standard making it one of the worthiest in the market.

- INTELLIGENT RS485 PROTOCOL

IT CAN BE PROGRAMMED TP MATCH WITH USER CONTROLLER AND THERE IS NO NEED FOR NEW SOFTWARE DEVELOPMENT - PERFECTLY MATCHING WITH SCI COMPRESSOR

- OIL RECOVERY AND FUNCTION

- DIRECT HEAT MOTOR COMPRESSOR

- COMPRESSOR'S ENVELOP CONTROL

- WORLDWIDE SAFETY STANDARD

- HIGH RELIABILITY

- HIGH EFFICIENCY > 95%