Factory Automation

Circuit Breakers factories

Assembly lines of No-Fuse circuit breakers for which we have the No.1 market share in Japanese domestic market

After developing and releasing the first ever No-Fuse circuit breakers in Japan in 1933, we have been leading the industry with Mitsubishi molded case circuit breakers and earth leakage circuit breakers that are meeting the needs from users all the time and this is the production site of those products.

Circuit Breakers factories

Assembly lines of No-Fuse circuit breakers for which we have the No.1 market share in Japanese domestic market

After developing and releasing the first ever No-Fuse circuit breakers in Japan in 1933, we have been leading the industry with Mitsubishi molded case circuit breakers and earth leakage circuit breakers that are meeting the needs from users all the time and this is the production site of those products.

Take a look at activities

Efforts to improve productivity by reducing the times of stopping of the production facilities

This is about the effort to improve prodcuctivity by reducing the times of stopping of production facilities. We achieved that by visualiztion and analyzing of the information about the times of stopping and the causes of stopping with programmable logic controllers that are mounted in control panels of each assembly line.

Energy saving activities by specific consumption management of energy that is required to manufacture 1 unit of a product based on the power consumption of the facility.

This is about the energy saving activity by visualizing the power consumption that is required to manufacture 1 unit of a product for each assembly line with specific consumption management and find out how much amount of energy is being wasted.

Improvement of works by visualizing the indicator graphs with EcoAdviser

This is about the improvement that production progress information is shared with the local employees clearly. We have PLCs mounted in control panels at each assemly line. Also we use EcoAdviser to manage and visualize the production units and energy consumption via enery measuring devices from PLCs.

Applied products

Energy Saving Supporting Devices

Energy Saving Support Software

EcoAdviser

Energy Saving Supporting Devices

Energy-saving Data Collecting Server

EcoWebServer III

Energy Saving Supporting Devices

Energy Measuring Unit

EcoMonitorPlus

Energy Saving Supporting Devices

Energy Measuring Unit

EcoMonitorLight

Programmable Controllers MELSEC

Programmable Controllers MELSEC

Programmable Controllers MELSEC

MELSEC-Q Series

Low-voltage Circuit Breakers

Molded Case Circuit Breakers with MDU

Low-voltage Circuit Breakers

Circuit Breakers for Panelboard and Control board

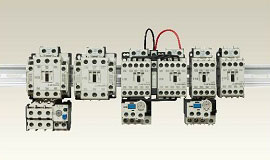

Contactors and Motor Starters

Contactors and Motor Starters