First released June, 2025

As part of its commitment to reducing CO₂ emissions, Kagome Co., Ltd. has adopted Mitsubishi Electric’s EcoWebServerIII at its Fujimi Factory in Nagano Prefecture. The company also implemented EcoAdviser, Mitsubishi Electric’s energy-saving support software, at its newest production building, which began operation in 2021. By enabling on-site teams to take the lead in analyzing data and planning improvements through dashboards, reporting functions and AI-based diagnostics, Kagome has significantly lowered the site’s carbon emissions.

Key Points:

- 1. AI-based analysis of large energy datasets to identify inefficiencies and recommend improvements

- 2. On-site teams empowered to use visualized data to plan and implement energy-saving measures

- 3. CO₂ reduction far beyond the regulatory requirements under Japan’s Energy Conservation Act

Kagome Co., Ltd. Fujimi Factory

Kagome’s Fujimi Factory produces a variety of foods and beverages, including its well-known Yasai Seikatsu 100 brand of mixed vegetable and fruit juices. This production building was launched in October 2021, and is equipped with advanced smart energy-saving solutions.

Kagome’s Fujimi factory manufactures Yasai Seikatsu 100 brand of mixed vegetable and fruit juices.

The new facility, completed October 2021, incorporates advanced energy management and smart solutions.

The factory had already been using EcoWebServer to collect and monitor energy usage data. However, Ryota Takemura, Production Engineering Supervisor of Production Department 2, explains: “Although this showed us the numbers, numbers alone are not sufficient to make complete objective evaluations.”

Kagome turned to Tachibana Eletech Co., Ltd., a key Mitsubishi Electric distributor that had helped install the existing system. They also introduced EcoAdviser, an energy-saving support software application, to expand its capabilities.

Optimizing equipment start-up times based on data

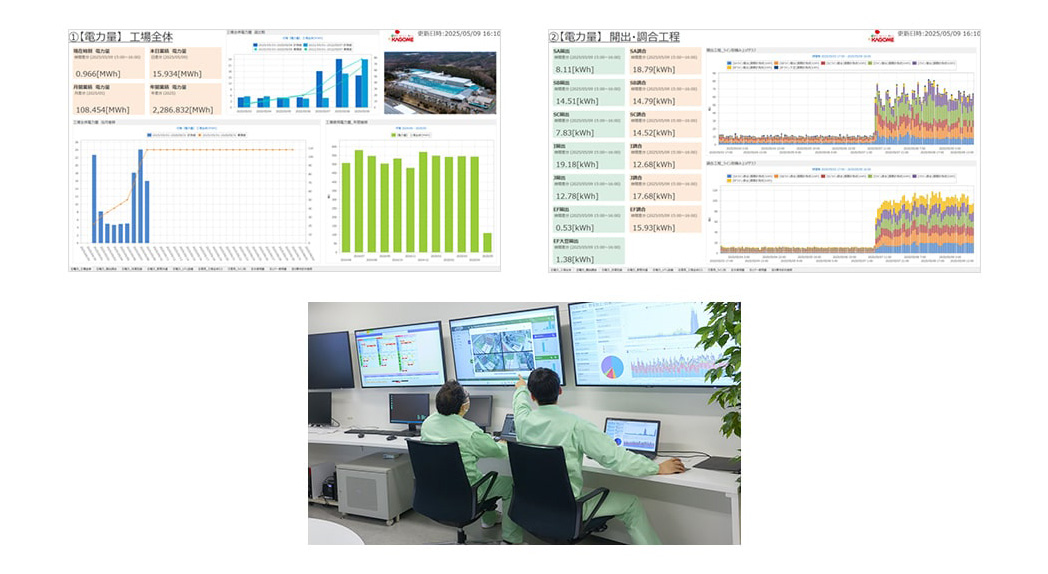

EcoAdviser displays data from EcoWebServer in a clear, user-friendly format, such as graphs and charts, making it accessible not only to energy managers but also to on-site teams. As measurement points can be visualized regardless of where they are physically located, it’s easy to compare devices to each other.

EcoAdviser enables integrated management of energy consumption information for the whole factory.

Ryota Takemura, Production Engineering Supervisor, Production Department 2, Fujimi Factory

Using this system, Kagome focused on the carton packaging process, which includes blowers to remove condensation, case packers that pack 24 cartons into boxes, and shrink wrappers to wrap the boxes in film.

“These machines are located at the end of the production process, so they don’t need to start until the filled juice cartons arrive,” explains Takemura.

By synchronizing machine operation with the production line, the team found it could save energy.

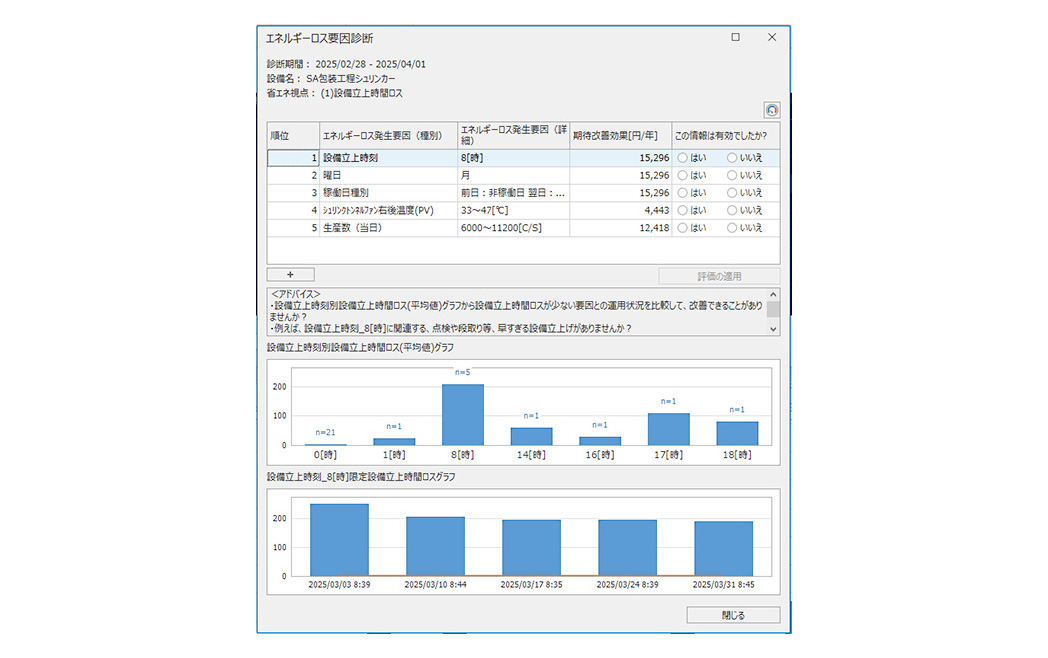

Previously, the timing of when to start up each piece of equipment had been left up to the on-site operators. The company decided to optimize start-up times based on the flow of the whole production line, and with EcoAdviser’s AI diagnostic function analyzing the power consumption and production quantity information in detail, they were able to build up a clear picture of the energy loss for each piece of equipment. Through a process of trial and error, Kagome used this data to develop new work procedures and save energy.

Kagome saved energy by optimizing the start-up timing of each piece of equipment in the packaging process, based on data from EcoAdviser.

Scaling energy saving across the factory

Encouraged by results from the packaging line, Kagome expanded its focus to other stages such as sterilization and shipment preparation. Toshimasa Miyairi, currently head of Blending Section 1 in Production Department 1, was originally part of Production Department 2 when EcoAdviser was introduced. “Reducing steam use is crucial for energy savings in sterilization. Having data on steam and electricity use gave us more visibility,” he says.

Another case involved two compressors used for pallet transport, which were consuming significant power. A system review showed one compressor could handle the workload, resulting in further energy savings.

Toshimasa Miyairi, Production Department 1, Fujimi Factory, who oversaw the project at the Production Engineering Section when EcoAdviser was introduced.

EcoAdviser’s graphs and charts clearly show changes in energy consumption, making it easy to keep track of which stations are using more electricity. This has helped the company to effectively implement a PDCA (Plan, Do, Check, Act) cycle to promote energy saving. Miyairi says it has also boosted motivation among on-site staff: “They can immediately see how effective their actions have been by comparing before and after data.”

In addition, production staff have been trained to use EcoAdviser themselves, and have been using it independently to develop their own energy saving efforts.

Kagome is planning to use the AI functions of EcoAdviser to uncover further improvement opportunities. “We have about a thousand energy measurement points at the factory,” says Takemura. “Looking at monthly data would mean thirty days’ worth of measurements. It would be practically impossible for a human to go through that amount of data and spot inefficiencies.”

AI diagnostic function shows energy losses in the shrink-wrapping process. These factors are analyzed and shown in order of priority.

Reducing CO₂ emissions beyond regulatory requirements

These AI functions have accelerated Kagome’s energy saving activities. The company submitted over 30 improvement proposals in FY2023, with many already implemented. These improvements have resulted in a reduction in CO₂ emissions of around 190 tonnes over the course of three years.

“To meet our obligations under the Energy Conservation Act, we need to cut around 50 tonnes of CO₂ annually at this factory,” says Takemura. “We have implemented various measures to achieve this, including using solar power and biomass energy, and our use of EcoAdviser has helped us exceed that figure several times over.”

Miyairi, who is now directly involved in the on-site production process, says most people working on the factory floor like to make improvements. “All that is needed to put that enthusiasm into action is a way of making the data accessible. EcoAdviser gives people a new perspective, even among those who previously didn’t take much interest in energy saving. Used the right way, I believe it will prompt even more ideas.”

Miyairi and Takemura use EcoAdviser to empower workers to take the lead in energy saving

Products and Solutions

Kagome Co., Ltd.

- Company founded:1899

- Business areas: Manufacture and sale of condiments, preserved foods and beverages; purchase, production and sale of seeds, seedlings, fruits and vegetables; development and sale of health support services

- URL:https://www.kagome.co.jp/

Sales Agent of Mitsubishi Electric Factory Automation

TACHIBANA ELETECH CO., LTD.

- Founded:1921

- Business areas:System Integration

- URL:https://www.tachibana.co.jp/en/