MELSEC MX Controller MX-F model

Products -Improving productivity-

- Achieve multi-axis machine control with one controller

- Achieving high-speed and high-accuracy motion control

- Essential CC-Link IE TSN technology for large-scale equipment

- Optimizing control performance of entire system

- Precise mark input and cutting not dependent on scan time

- Optimize multi-axis system with graphical user interface

- Achieve high-speed, high-response, and stable pressure control

- Develop more advanced control loops

- Variety of devices available through our partnerships with leading manufacturers

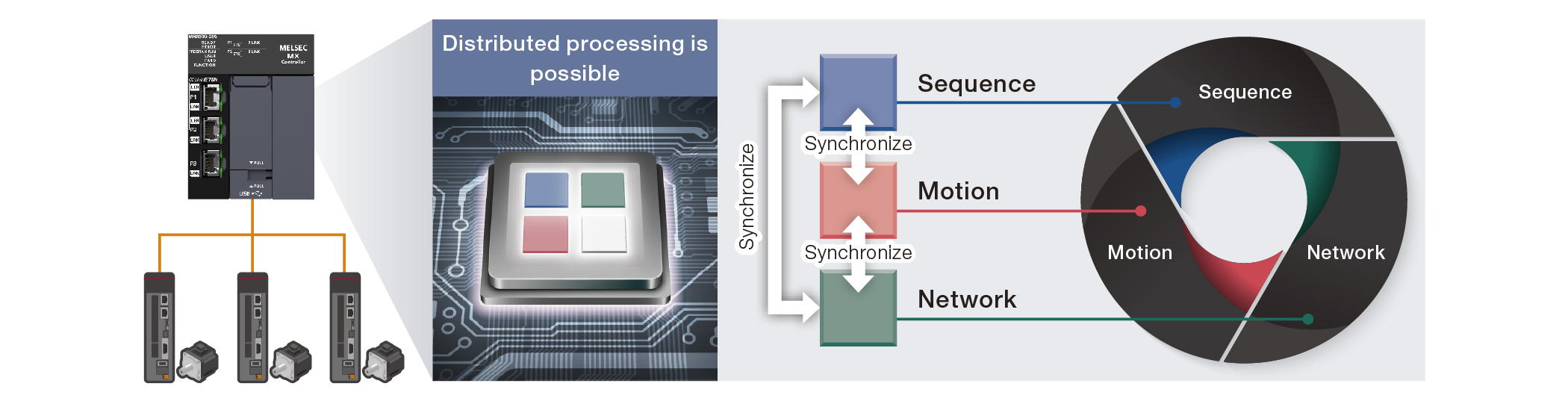

Achieve multi-axis machine control with one controller

The MX Controller, equipped with a high-performance multi-core MPU as standard, integrates sequence, motion, and network control, supporting up to 256 axes. It supports mixed operation cycles, ensuring high-speed control even with multiple axes. One controller delivers precise control of individual mechanisms and control of the entire production line.

Achieving high-speed and high-accuracy motion control

Multi-core MPU

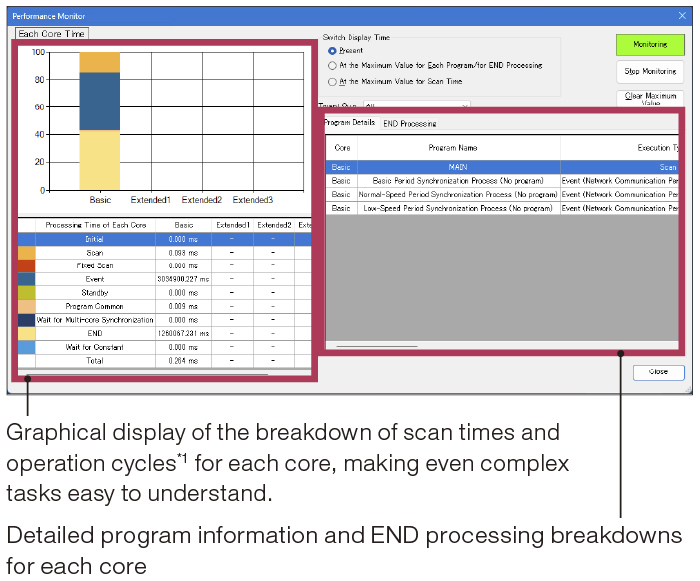

Core load can be monitored and adjusted for optimal machine control

The performance monitor visualizes the operation cycles and load status for each core assigned to run the program.

Optimize performance by distributing load through mixed operation cycles based on visualized load status.

Program example

| Item | Without load distribution | With load distribution |

|---|---|---|

| System configuration | One MXR500-□ + 98 axes of MR-J5 | |

| Setting of the number of axes and operation cycle | 98 axes (Operation cycle set to 250 μs) |

High-speed axes:4 axes (set to 250 μs) Low-speed axes:94 axes (set to 4000 μs) |

*1: Future support

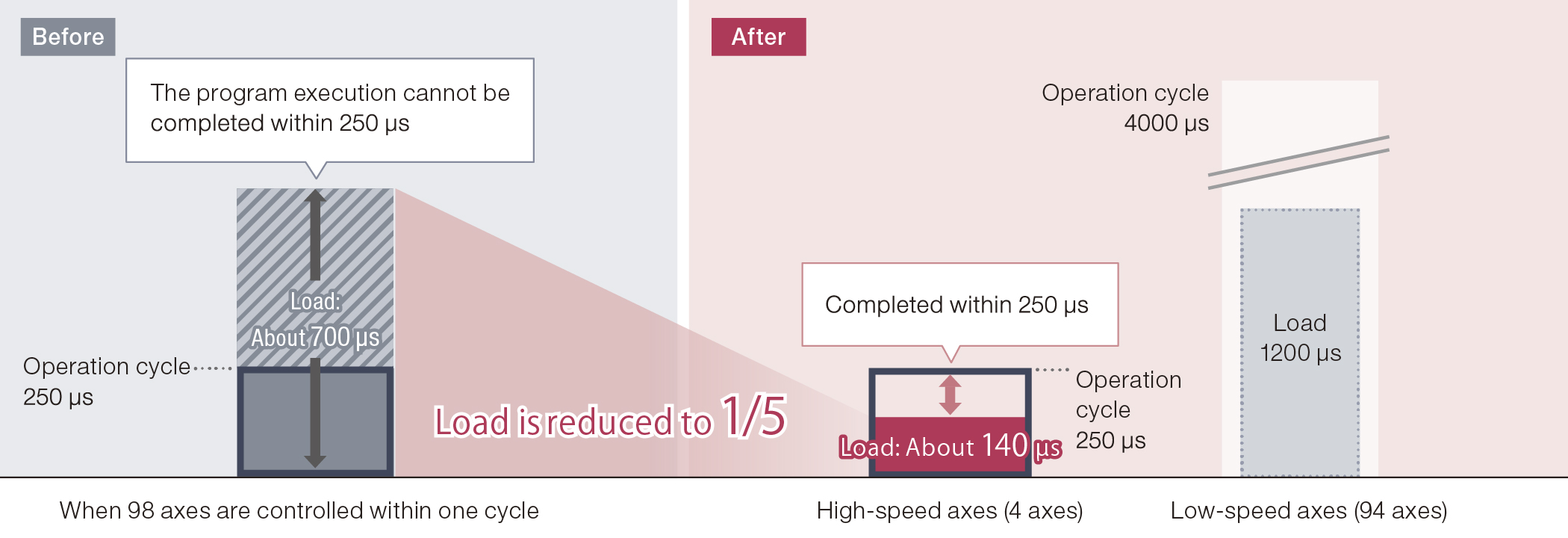

Essential CC-Link IE TSN technology for large-scale equipment

High-speed and high-accuracy coordination with a wide range of devices

With a single MELSEC MX controller, you can build a system that combines real-time control communication for factory automation equipment with information communication for IT systems.

What is TSN*1?

TSN is a set of international standards, which define the time synchronization method and the time sharing method. By adding these to Ethernet technology, control communications (ensuring real time reaction), which cannot be perform with conventional Ethernet, and information communications (non-realtime communications) can be performed together.

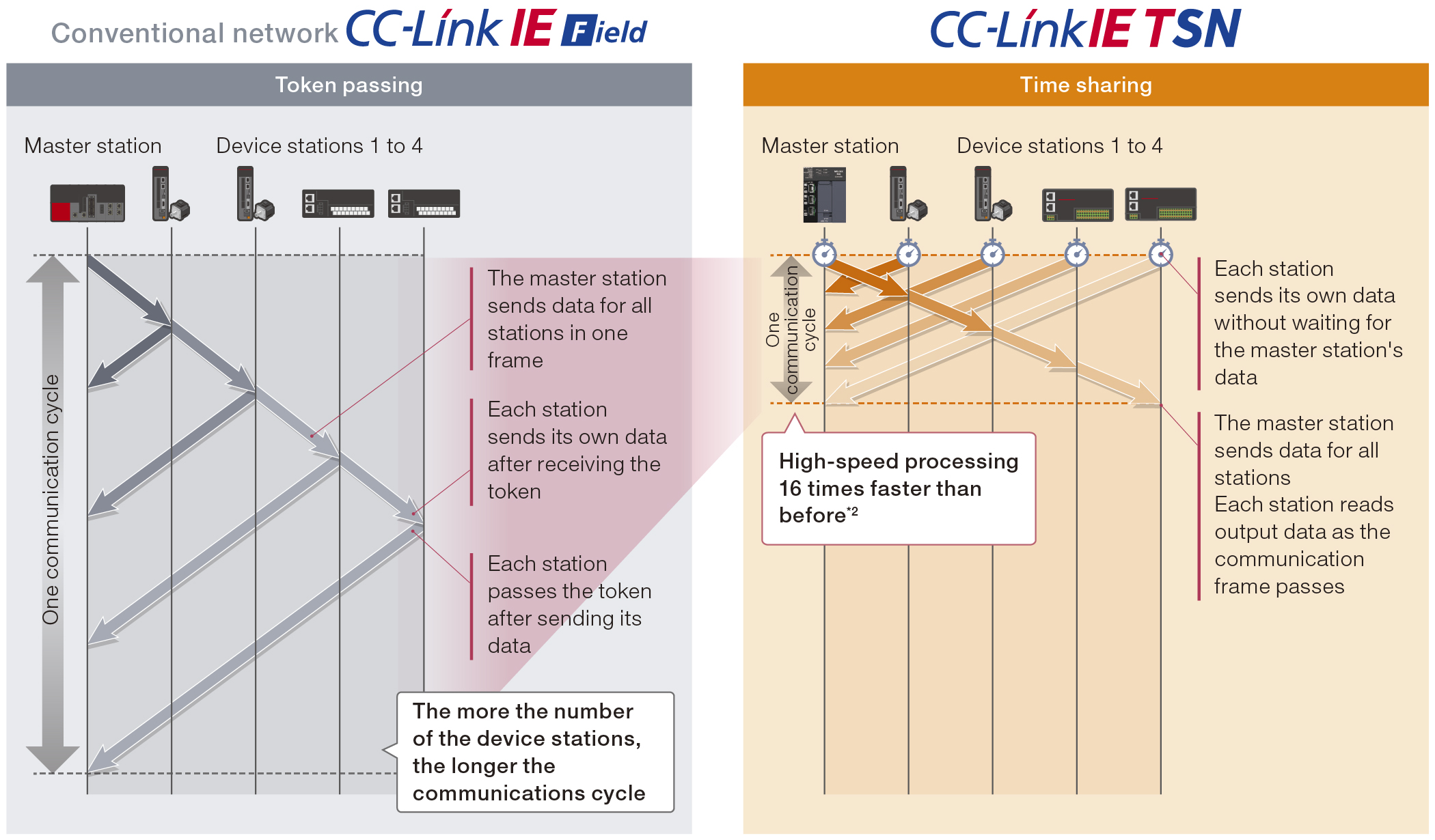

The CC-Link IE TSN time sharing method enables communications independent of the number of device stations

The time sharing method used as the communications protocol allows simultaneous input and output communication between connected stations.

High-speed link scan significantly reduces production cycles. Mixed communication cycles are also possible, ensuring fast and smooth communication even with many device stations.

*1: Time-Sensitive Networking

*2: Under the same conditions

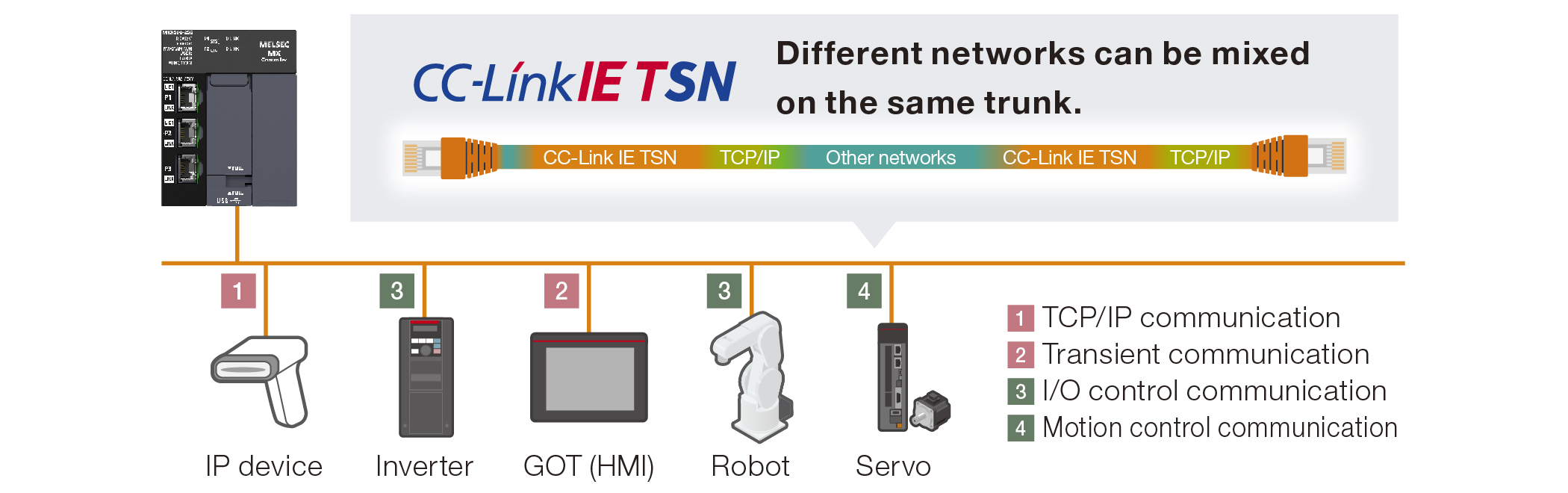

Optimizing control performance of entire system

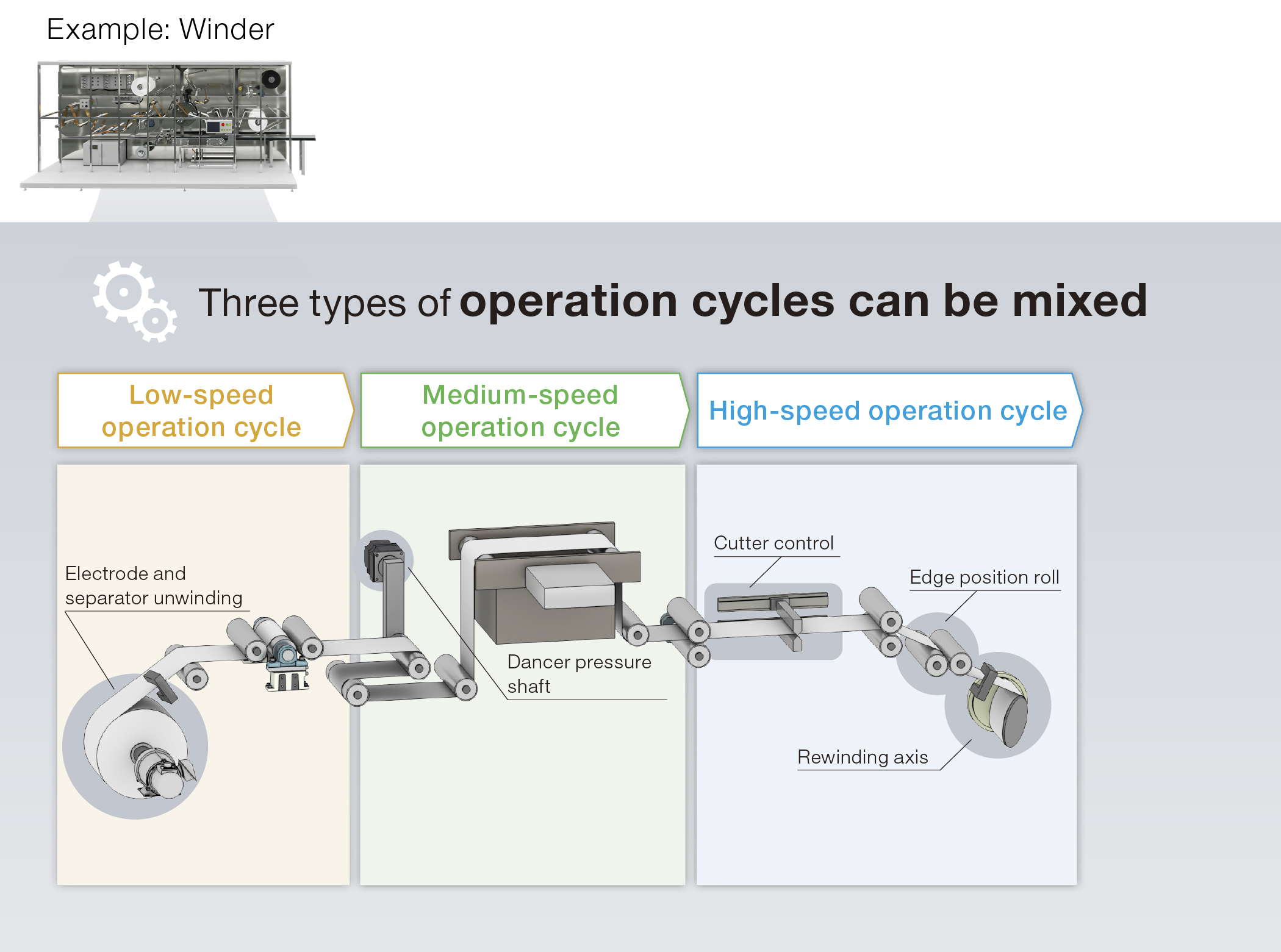

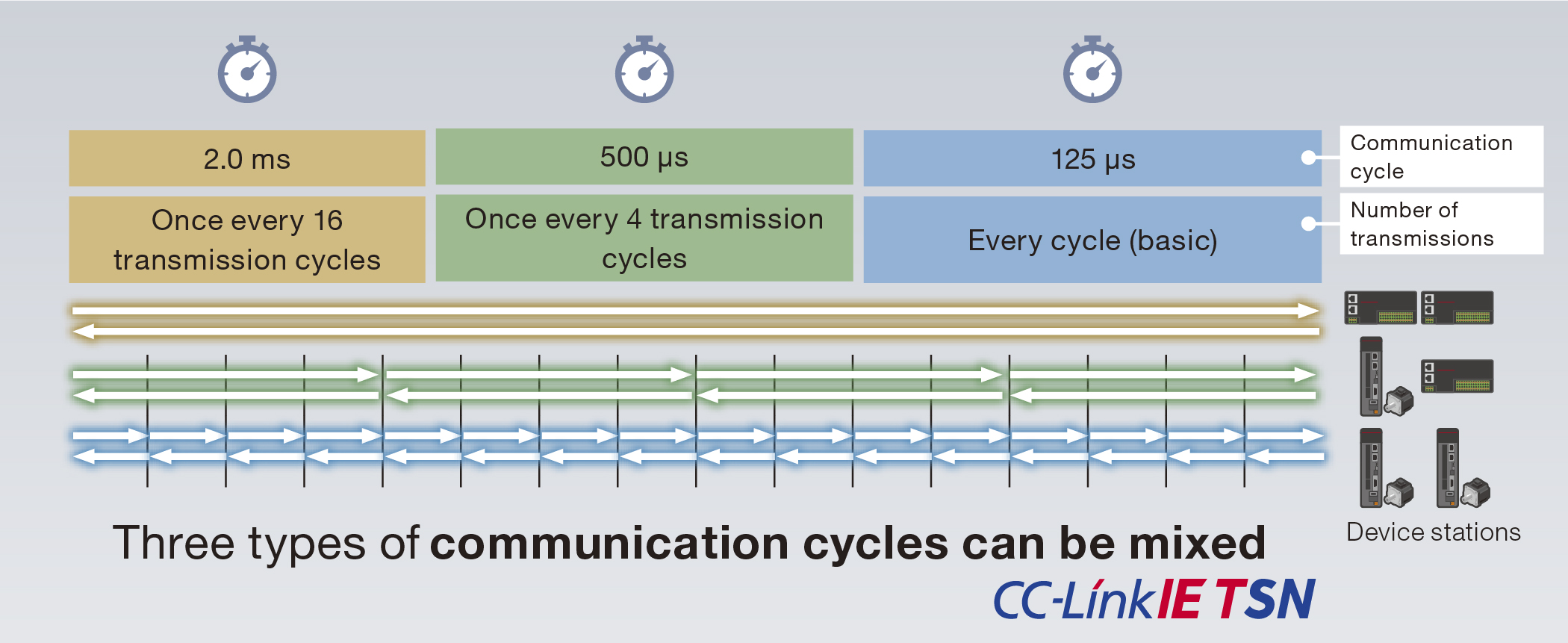

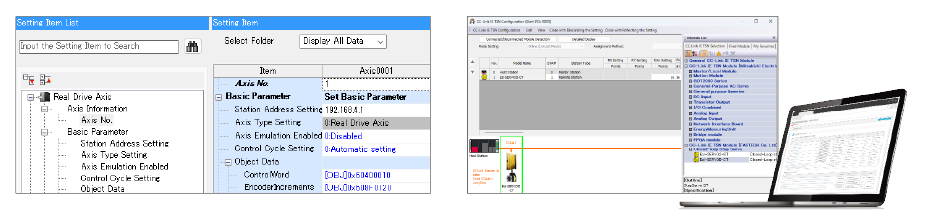

With one MELSEC MX Controller, up to three different operation and communication cycles can be set for each axis and device

station.*1

There is no need for multiple CPU modules. This greatly improves the cost efficiency of your equipment.

Even for multi-axis machines, the control performance at high-speed operation cycles can be partially secured, improving

accuracy in processes such as cutting.

*1: Using GX Works3, you can set communication cycles in the CC-Link IE TSN configuration setting window and operation cycles in the axis parameter settings.

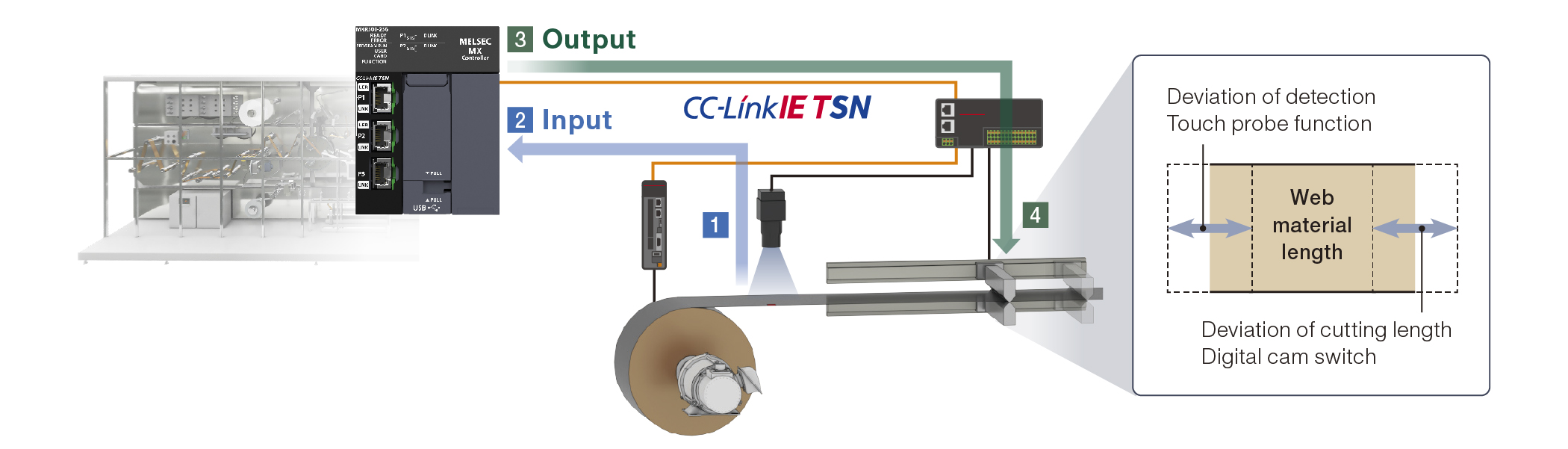

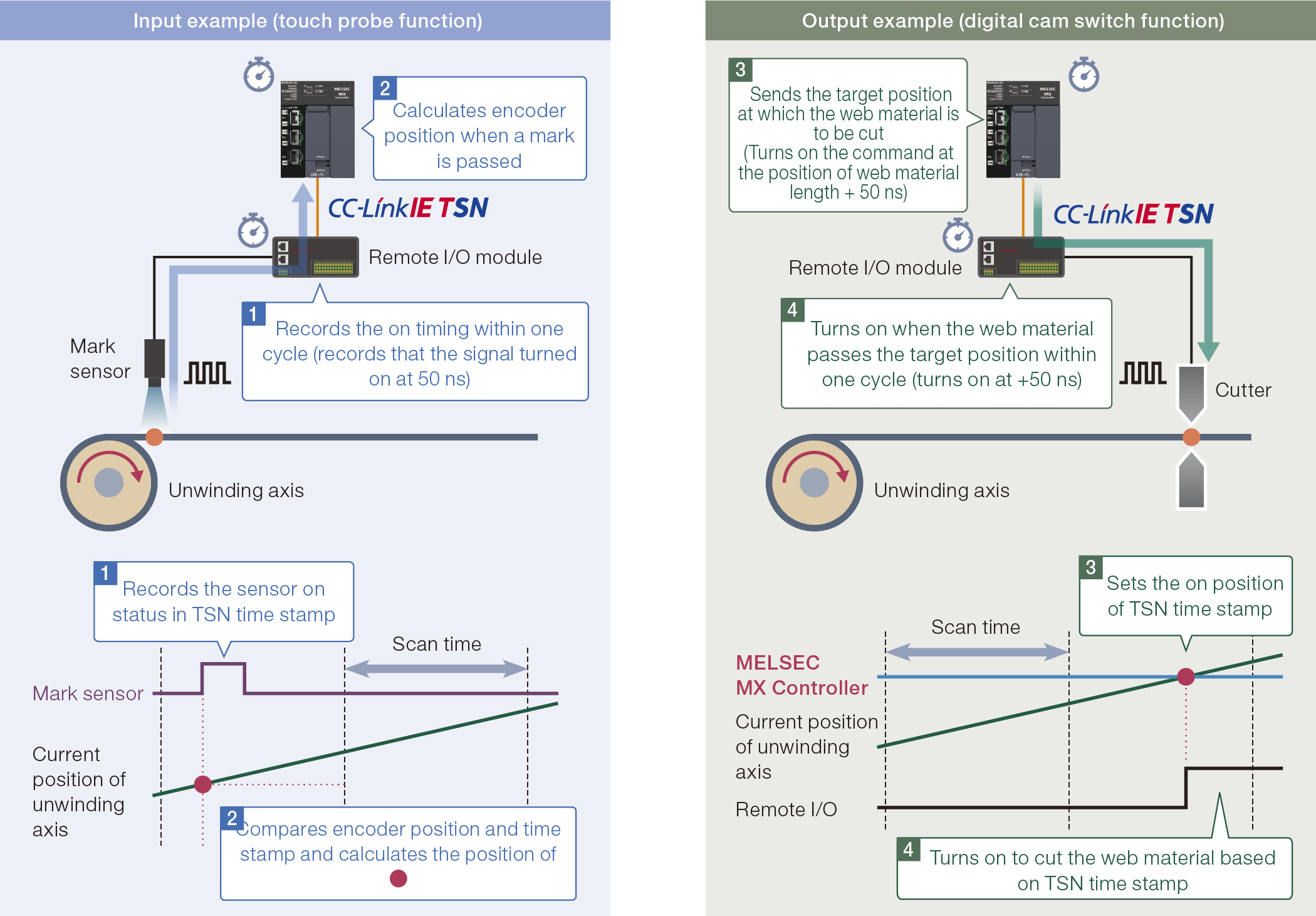

Precise mark input and cutting not dependent on scan time

Even in applications that require high-speed I/O control without variability, such as roll-to-roll control, the MX Controller provides precise I/O over the network that is not dependent on the scan time. Minimized jitter in the I/O timing of mark detection and cutting reduces variations in web material detection and cut length. This improves yield in high-speed production lines.

*1: The actual I/O timing varies depending on the device used.

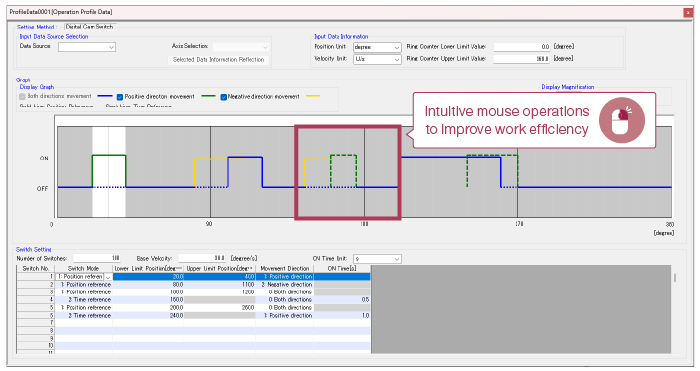

Intuitive operation with visual data

The digital cam switch settings can be configured using GX Works3.

Setting values by adjusting the graph on the screen with mouse operations eliminates the need to convert time,

significantly reducing working hours.

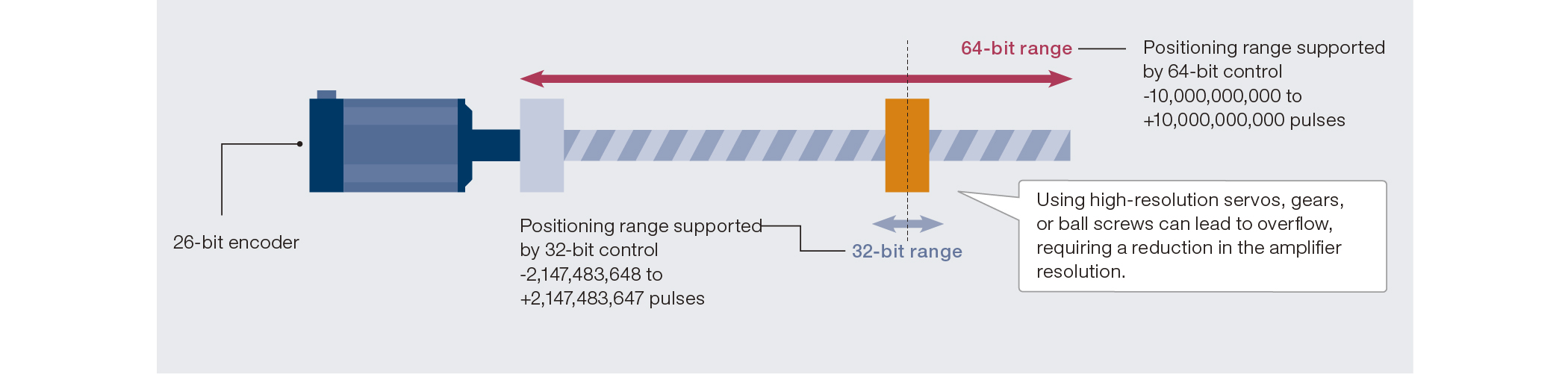

64-bit-compatible and highly accurate control

64-bit control minimizes rounding errors during calculations, ensuring highly accurate control.

Positioning range and resolution

Compared to 32-bit control, 64-bit control offers a broader positioning range while maintaining high resolution.

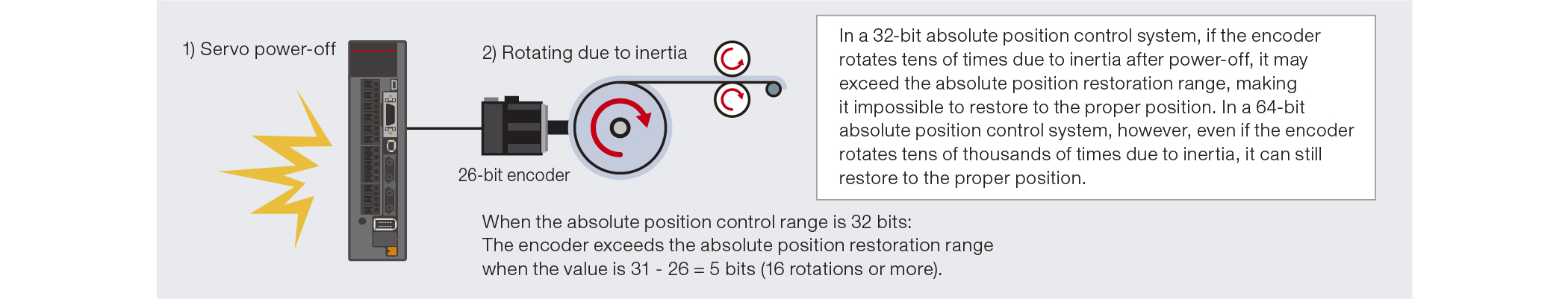

Absolute position control system and current position restoration

The MELSEC MX Controller performs 64-bit absolute position control, significantly reducing the risk of current position restoration error after poweroff.

Optimize multi-axis system with graphical user interface

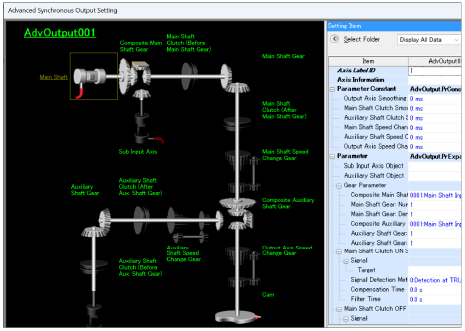

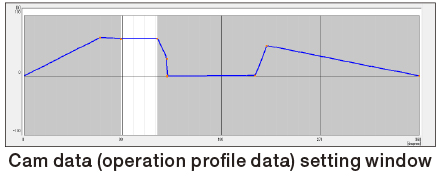

Advanced synchronous control*1

Software replaces machinery mechanisms (such as gears, shafts, speed change gears, and cams) for easier synchronous control. Even for machines that require multi-axis synchronization, such as winders and coaters, it is easy to adjust the cam control and operation pattern to eliminate position deviation. Fine-tuning the cutting position and adjusting the synchronization position according to the transportation speed can achieve high quality and high productivity.

Synchronous control parameters

The intuitive visual interface makes it easy to create cam data and configure parameters. This enables low-code development of complex multi-axis synchronization programs, significantly increasing work efficiency.

*1: Motion control FBs are used.

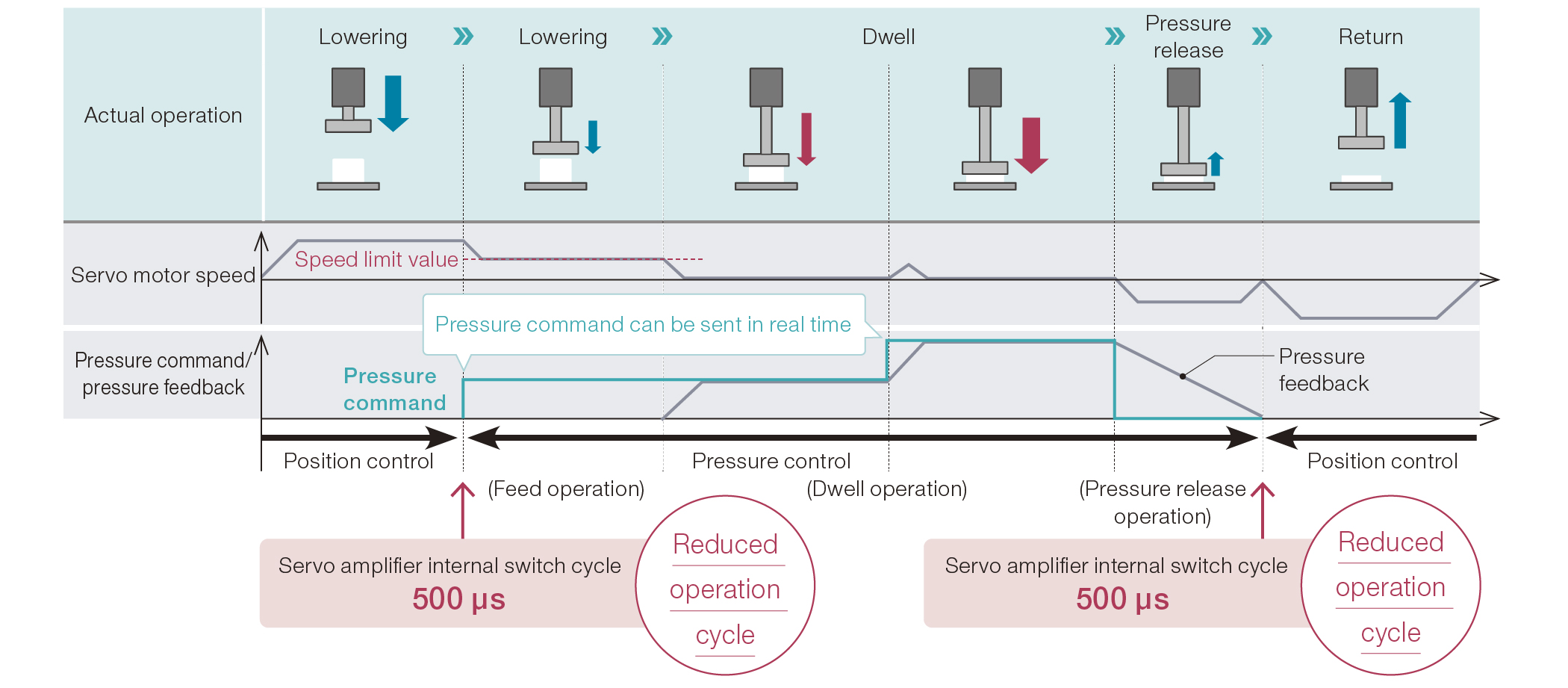

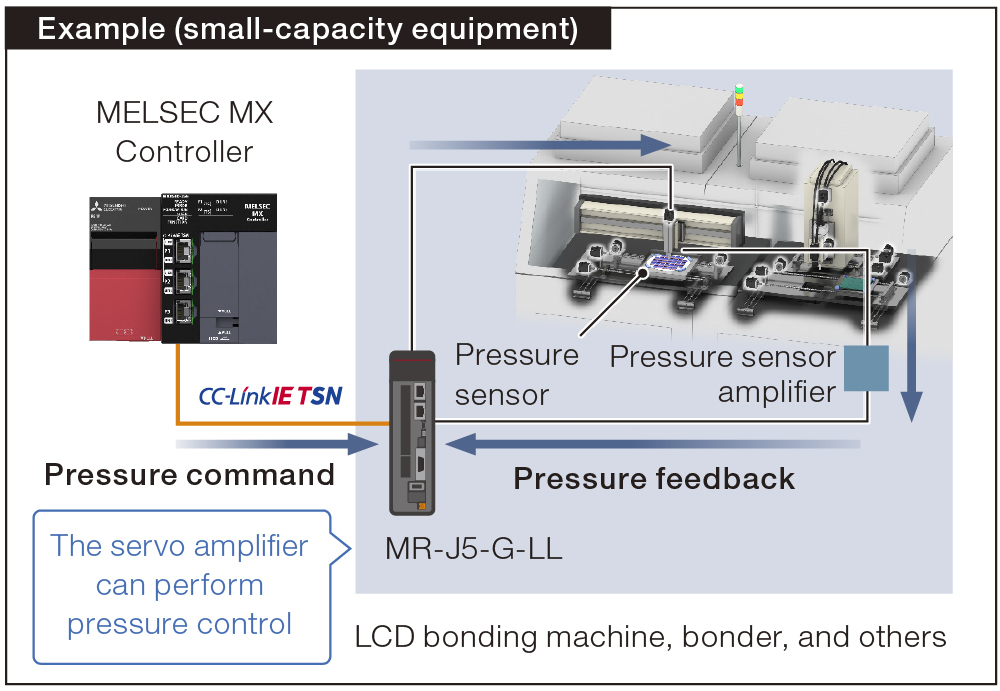

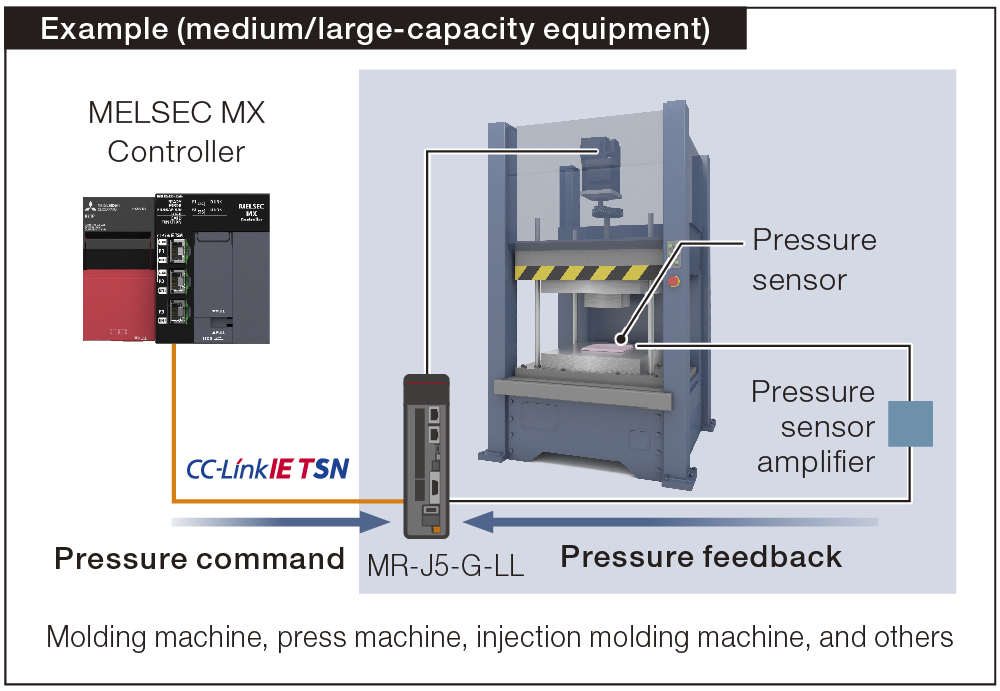

Achieve high-speed, high-response, and stable pressure controlFuture support

The analog signal from a pressure sensor (load cell*1) is input to the MR-J5-G-LL to control the pressure. The pressure can be kept constant even while the load is changing. High-response pressure control is possible by applying a pressure model to reduce over-pressing.

Example of pressure control

Supporting applications with high real-time reaction

By combining the MX Controller with the MR-J5-G-LL, which supports cyclic pressure control mode (cspr), the servo amplifier performs feedback control of pressure according to the pressure command of the function block. The pressure control loop operates independently of the controller, achieving high-speed and high-response control.

*1: A force sensor that enables force measurement by converting force into an electrical signal

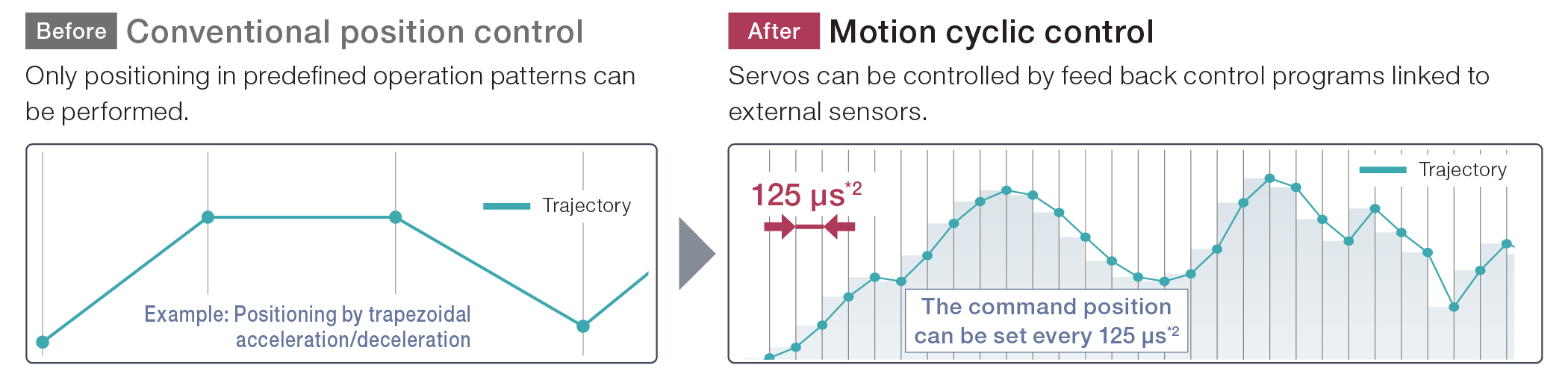

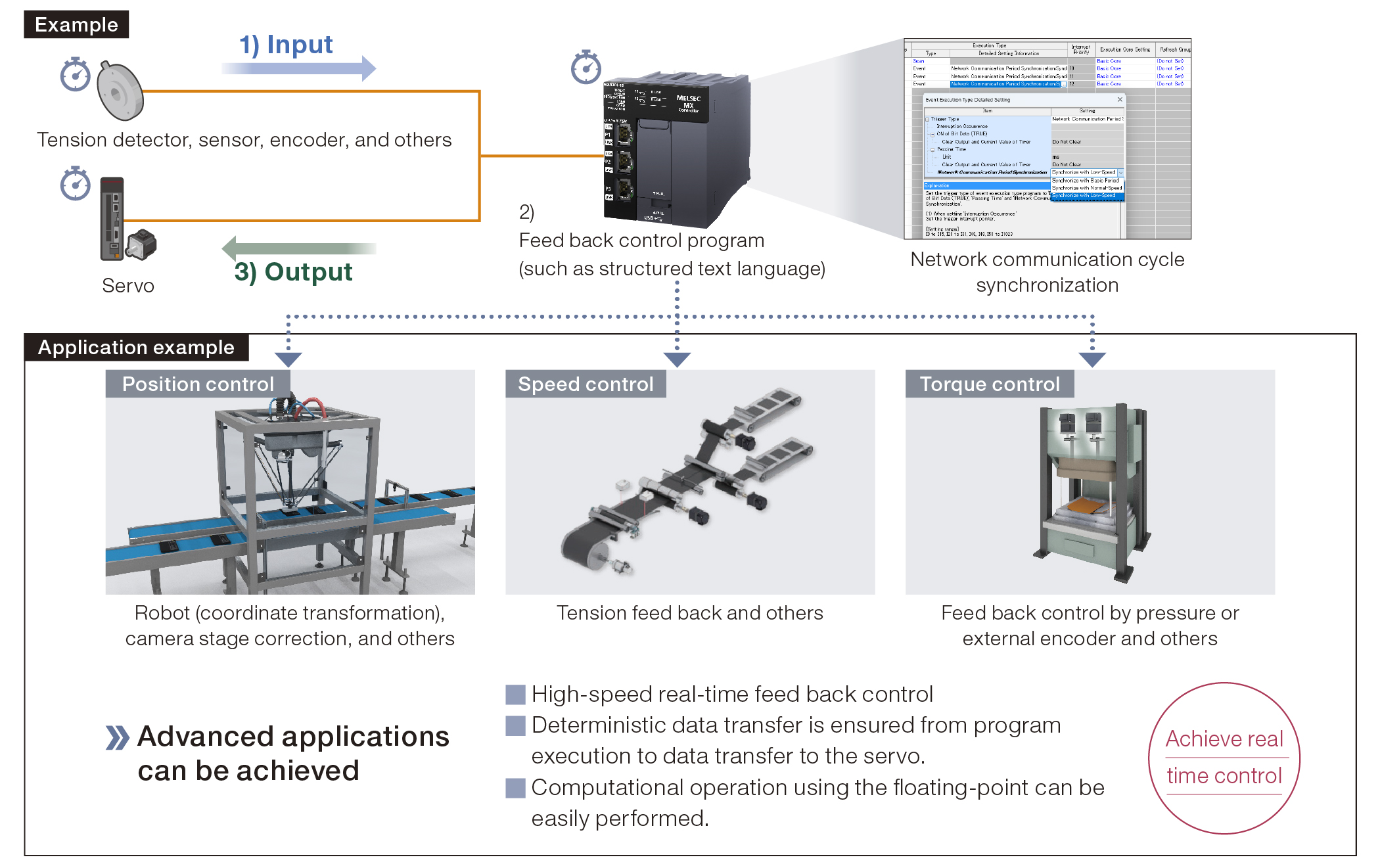

Develop more advanced control loops

Motion cyclic control

- ●The MX Controller supports motion cyclic control, allowing the transmission of target torque, position, and speed with each operation cycle, in addition to standard positioning operation.

- ●Setting the task type to "network communication cycle synchronization" ensures deterministic performance from programmable controller tasks to network transmission.

- ●The floating-point operation performance is improved by about 15 times*1.

These allow program execution, motion operation, and network send/receive to be performed within the same communication cycle. This makes it possible to implement advanced control loops that generate control commands from the user program in real time and instantly transmits sensor values to drives.

is assured using network communication cycle synchronization tasks.

*1: Comparison with the MELSEC iQ-R Series

*2: The maximum operation cycle for an MX-F model is 250 μs.

Variety of devices available through our partnerships with leading manufacturers

Drive motors from partner manufacturers with MELSERVO-J5

By using MELSERVO-J5, you can standardize your servo amplifiers and reduce the number of spare parts needed.

Through cooperation with various partner manufacturers, suitable products can be chosen from various types of motors.*1

Combination with drive units from other manufacturers

The MELSEC MX Controller can work not only with MELSERVO but also with drive units from other manufacturers that support CC-Link IE TSN.

Setting image

*1: For details on individual motor drives, please consult your local Mitsubishi Electric representative.