Solutions

Water

Mitsubishi Electric solutions optimise water treatment facilities, minimising initial deployment costs and contributing to more efficient and effective operation.

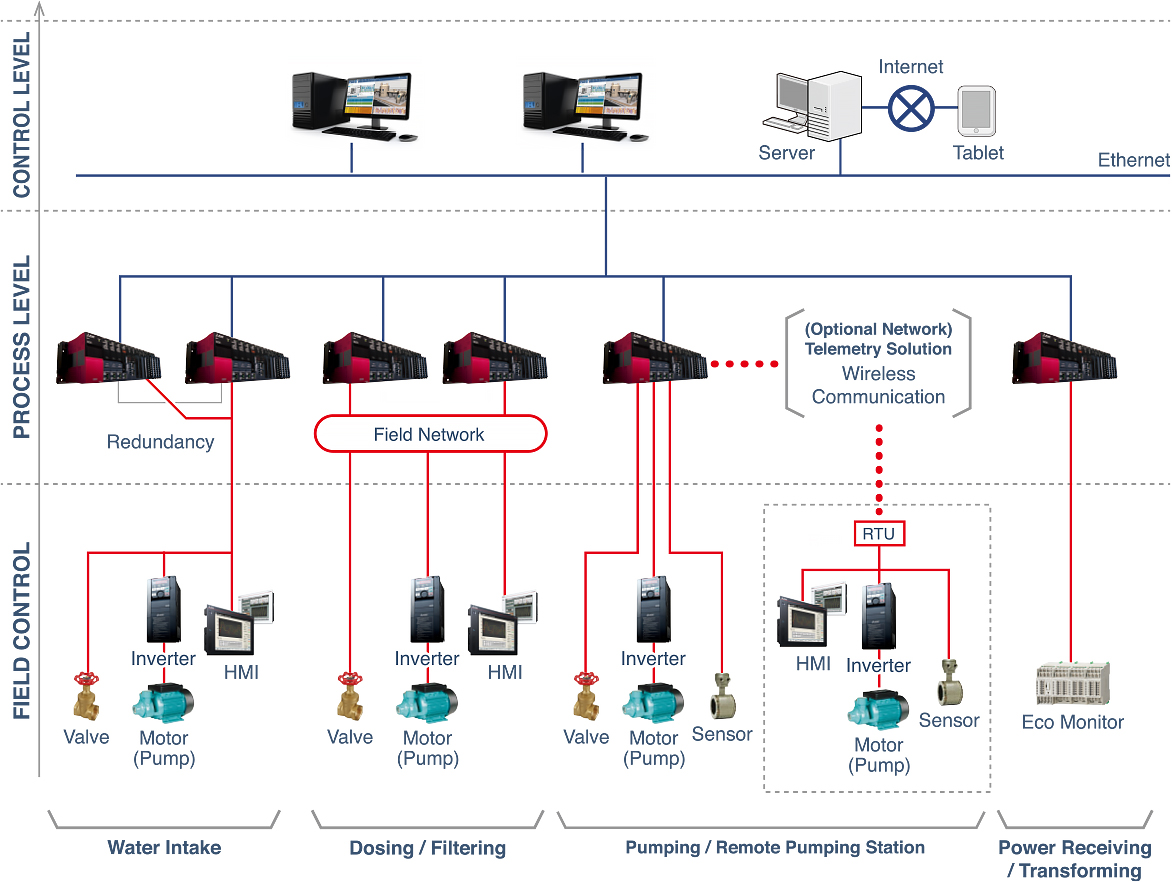

For over 50 years, we have provided cutting-edge, reliable solutions for water treatment automation in Japan and around the world. Mitsubishi Electric offers a broad lineup of energy-efficient inverters and monitoring & control systems that can seamlessly integrate high-performance SCADA systems with reliable automation products. Through open networks and high-reliability controllers, we deliver integrated, flexible systems with future-proof expandability, for streamlined data management, analysis and energy management in-field and upstream.

Water Treatment and Distribution

Advanced control and management is the key to ensuring uninterrupted water supply. Water automation solutions differ globally because, for example, the actual needs of customers in long-developed regions like Europe differ from those of the rapidly growing countries of Asia. In both cases, water providers turn to Mitsubishi Electric for an answer. Water treatment and distribution are the most vital of our lifelines.

Major Applications of Our Products:

- Intake flow rate control

- Screen control

- Pumping control

- Filtering flow rate

- Alkali builder injection control

- Chlorine density injection control

- Distribution delivery pressure control

- Distribution flow rate control

Wastewater Treatment

Wastewater treatment is an energy-intensive process. Mitsubishi Electric wastewater treatment solutions not only optimise and maintain the uninterrupted flow of operations with acclaimed reliability, but also contribute to improved efficiency in every area from man-hours to energy savings.

Major Applications of Our Products:

- Pump station control

- Aeration ratio/DO (dissolved oxygen) control

- Return sludge control

- Charge/pull-out sludge control

- Chlorine injection control

- Coagulant injection control

Irrigation

The delivery of water is a complex challenge involving tremendous distances from water source to agricultural end-users. Mitsubishi Electric's technologies provide automation solutions that deliver water where and when it is needed in the correct quantities, with minimal loss.

Downstream Productivity and Efficiency

In large-scale agriculture, automation can have a huge impact on conserving water, energy and labor. Our irrigation control solutions enable automatic monitoring and control of remote valves in ideal night conditions, saving water, energy and valuable man-hours.

Synergy of Solutions

Mitsubishi Electric offers one-stop automation solutions. Through the right combination of our proprietary technologies, we can craft the ideal solution for any irrigation project of any scale, from automating the control of rivers to optimal irrigation of a vineyard.

Why Mitsubishi Electric?

Mitsubishi Electric's water processing systems offer unparalleled benefits. These advantages bring comfort and ease-of-use to customers, while ensuring the smooth operation of their business.

- 1.High-quality systems for high reliability

- 2.Mobile monitoring & operation

- 3.Energy savings (energy monitoring + inverter)

- 4.Easy system construction and maintenance plus security

- 5."Zero downtime" through preventative maintenance

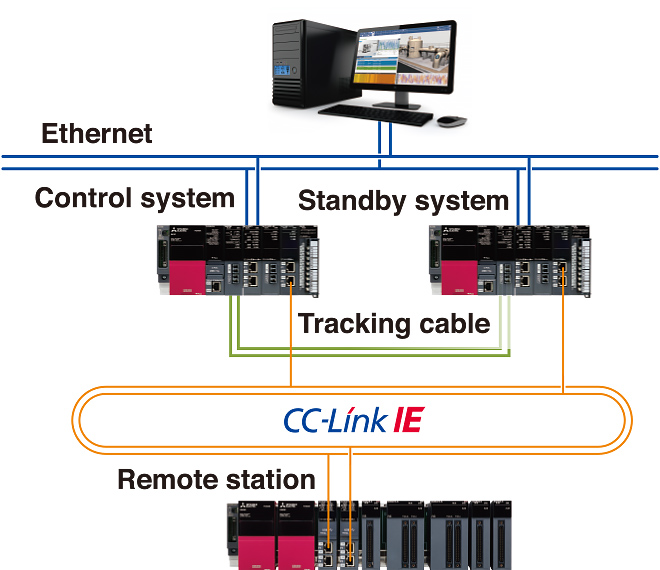

1.High-quality Systems for High Reliability

Viewed from any perspective, from their lifeline status and role in flood prevention to preserving the environment and biodiversity, water processing plants are vital social infrastructure. By providing a high-redundancy system and network for monitoring and control, Mitsubishi Electric realises "non-stop" facilities. Even if a component fails, operation can continue during repair or replacement. Using an array of engineering tools honed to a cutting edge by our wealth of experience in the design of redundant system architecture, we can easily design and construct a high-reliability system to fit your needs.

2.Mobile monitoring & operation

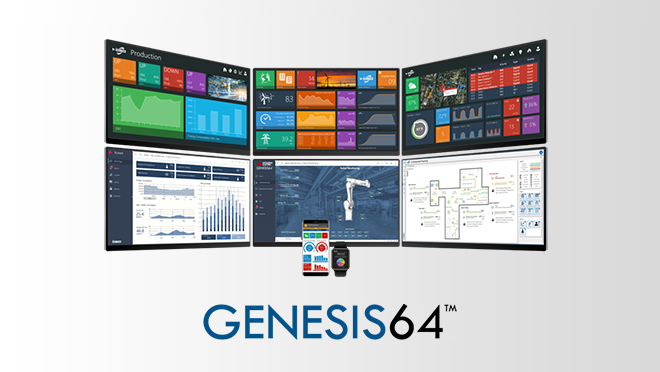

The lifeline status of water processing facilities elevates the importance of the role played by monitoring and control systems. Previously this demanded the midnight and holiday shifts of staff in the control room. Mitsubishi Electric's monitoring and control solutions are changing this model. Depending on the system settings, it is possible to monitor and operate systems from a PC in a remote office or even a mobile terminal. By tapping the power of the cloud, there is no need to construct and maintain the corresponding IT assets in your own company or organisation.

3.Energy Savings (Energy Monitoring + Inverter)

Equipment operation in water processing facilities is long or uninterrupted; therefore, energy savings have a tremendous impact on the reduction of not only electricity costs but also CO2 emissions. Mitsubishi Electric solutions enable you to visualise your energy usage. The amount and cost of energy consumed by pumps or other components can be analysed, and results can be expressed in any unit desired, for example, energy per cubic meter of irrigation water. Instant production of charts and tables can aid identification of ways to save energy. Optimally controlling voltage, current and frequency for fans, pumps and blowers and other equipment, our wide lineup of robust inverters are key to reducing electric power consumption at water processing facilities around the world.

More Information

4.Easy System Construction and Maintenance Plus Security

The choice of customers around the world, Mitsubishi Electric products boast general versatility to facilitate easy system configuration. Our control and monitoring systems can be combined with a broad range of third-party vendor equipment and are designed for maximum flexibility and expandability to respond to evolving needs. Beyond our high reliability, our global network of support and partner system integrators ensures a swift response if any problem occurs or spare parts are required. Another Mitsubishi Electric advantage is the robust security functionality we build into our solutions – a very important consideration for lifeline infrastructure like water processing plants. Security measures guard systems and equipment from unauthorised access and protect data integrity.

5."Zero downtime" through Preventative Maintenance

In recent years, facility management has moved away from a reactive model to problems, and adopted a predictive model that pre-empts problems before they occur. Water processing is not an exception to this trend. While incorporating the user's facility management knowhow, our systems support not only preventative maintenance, but also analysis of the cause of failure. Autonomous diagnostic functions enable alarms in advance of trouble and other features that ensure non-stop plant operation.

System Configuration