Solutions

Data Collection/Analysis

The Cycle for shop floor Improvement With Data Utilization

Improving productivity, quality, and energy efficiency by utilizing shop floor data to find the key to solving production issues and promoting improvements

Case04 Collecting data from the equipment and devices made by various manufacturers

Data collection

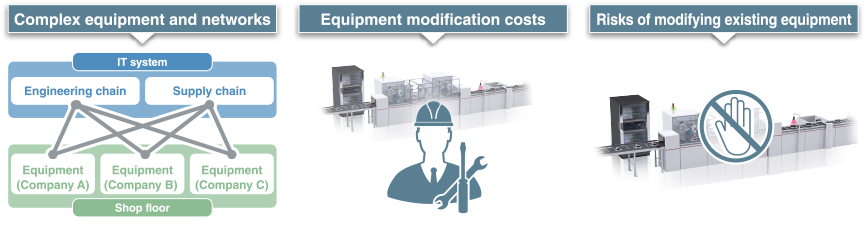

Issues

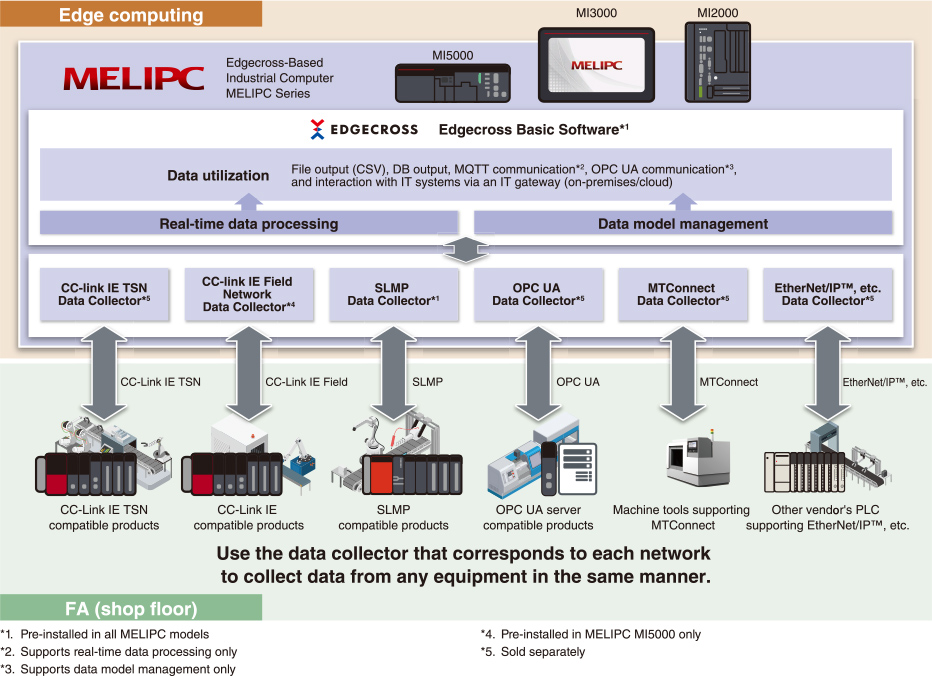

Solution

Install the industrial computer MELIPC to an existing system to enable the collection of data from various equipment and extend data utilization capabilities.