2025.04.21

#Focus #Business #Interview #Factory Shaping the World with Precision: CNC, the Hidden Technology in 3 Simple Figures

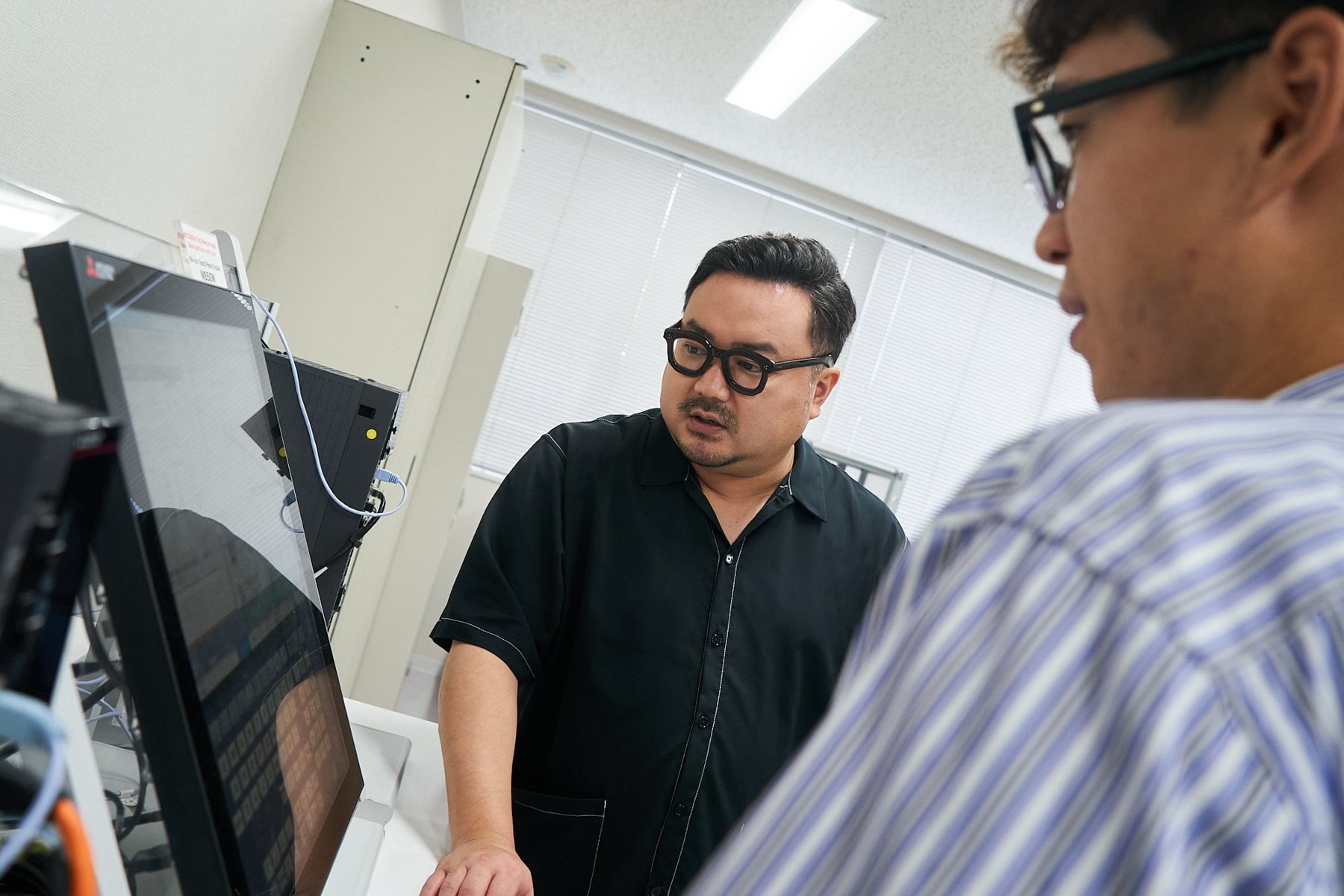

"You know, I’ve got a pretty strong science background!" Kyujitsu Kacho said, his eyes beaming. "Factories and machines are just intriguing to me.""And I, your humble guide for today, just so happen to be a humanities major," Kohei Banno replied, laughing sheepishly.

Kyujitsu Kacho is a musician. The former electrical and electronic engineering major, who later joined the manufacturing sector, has dropped by Mitsubishi Electric’s Mechatronics Solution Center East Japan to learn about "CNC".

While unfamiliar to Kyujitsu Kacho and many others, these initials represent an absolutely crucial technology.

"You’ll see how amazing CNC is after I’ve introduced you to three numbers," said Banno, opening the doors to Kyujitsu Kacho’s exploration of CNC. "Without this technology, the world might have turned out quite differently," mused Kyujitsu Kacho at the end of his visit.

Which raises the question—what exactly did the musician see?

INTERVIEWEE

KYUJITSU KACHO

A bassist, born on February 20, 1987, in Saitama Prefecture. After graduating from the graduate school of the Tokyo University of Agriculture and Technology in 2011, Kyujitsu was a company man taking band gigs on the side until 2014. He is currently active in four bands: Gesu no Kiwami Otome, DADARAY, ichikoro, and Raisan. He is also involved in food-related activities and published a book through Magazine House, titled "Homerareru to mata tsukuritakunaru! Mousou gohan" (Homemade Meals That Make You Want to Cook Again When Praised! Imaginary meal) in 2020. In 2021, the book was adapted for TV, as "My Imaginary Meal to Be Praised." Socials: @eninaranaiotoko on X; @kyujitsu_kacho on Instagram.

INTERVIEWEE

KOHEI BANNO

Banno joined Mitsubishi Electric Corporation in 2018. He was assigned to the Chubu Branch, Industrial Mechatronics Department, NC Systems Section, and was responsible for the sales of CNC systems in the Chubu region. In August 2022, he was stationed in Bangalore, India, at Mitsubishi Electric India for a year, where he supported the sales of CNC systems. Banno returned to Japan in August 2023 and was assigned to the head office’s Marketing Section C Numerical Controller Business Development Dept, Industrial Automation Machinery Marketing Division. He is currently responsible for business planning and sales strategy formulation for CNC-related operations.

Contents

Giving Form to Otherwise Impossible Shapes

Banno: Hi, Mr.Kyujitsu Kacho, welcome to the world of CNC. Here, please have a look at this.

Kyujitsu Kacho: Oh, a mold for a smartphone?

Banno: Got it in one!

Kyujitsu Kacho: It’s so elaborate. And was this made using CNC?

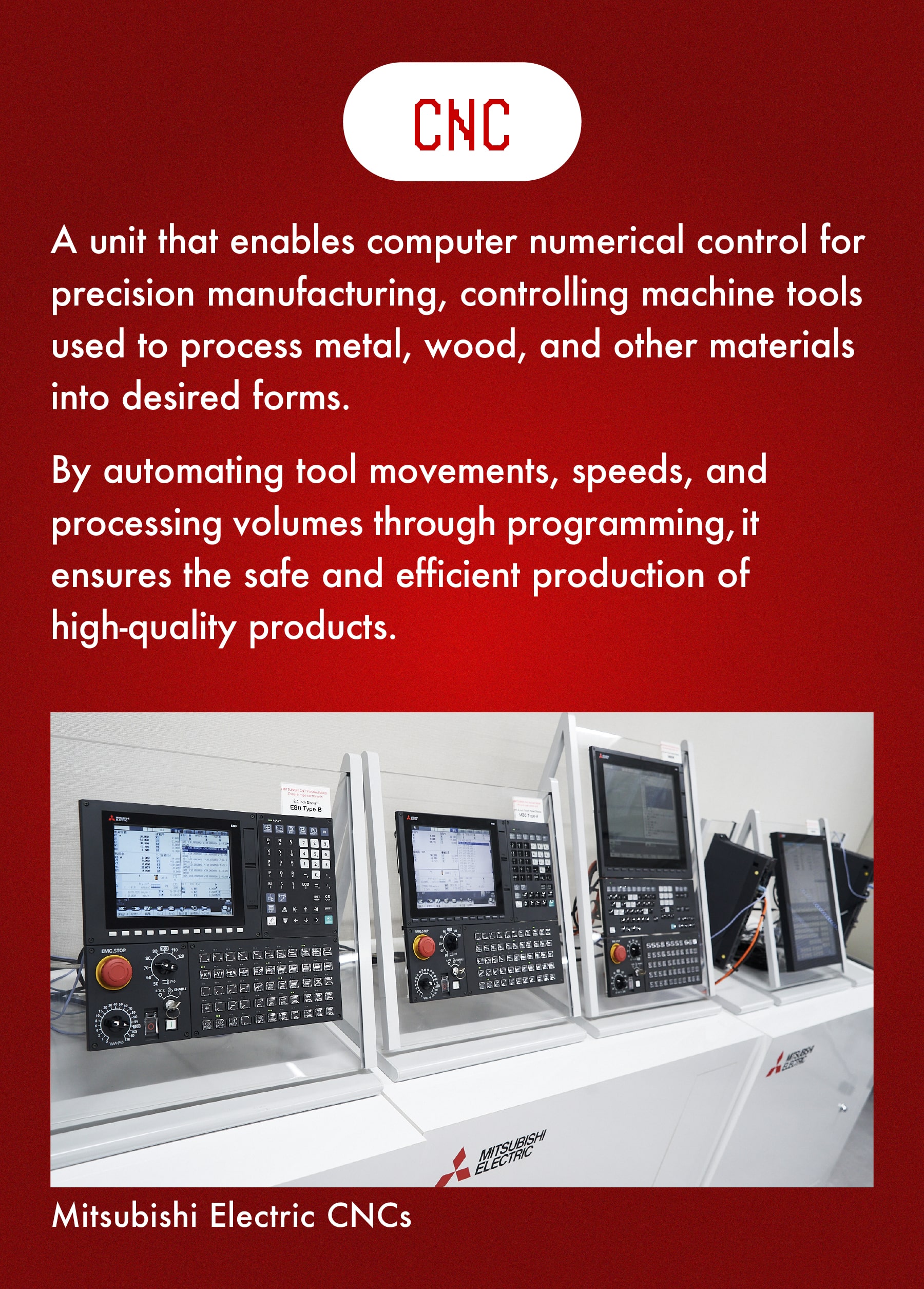

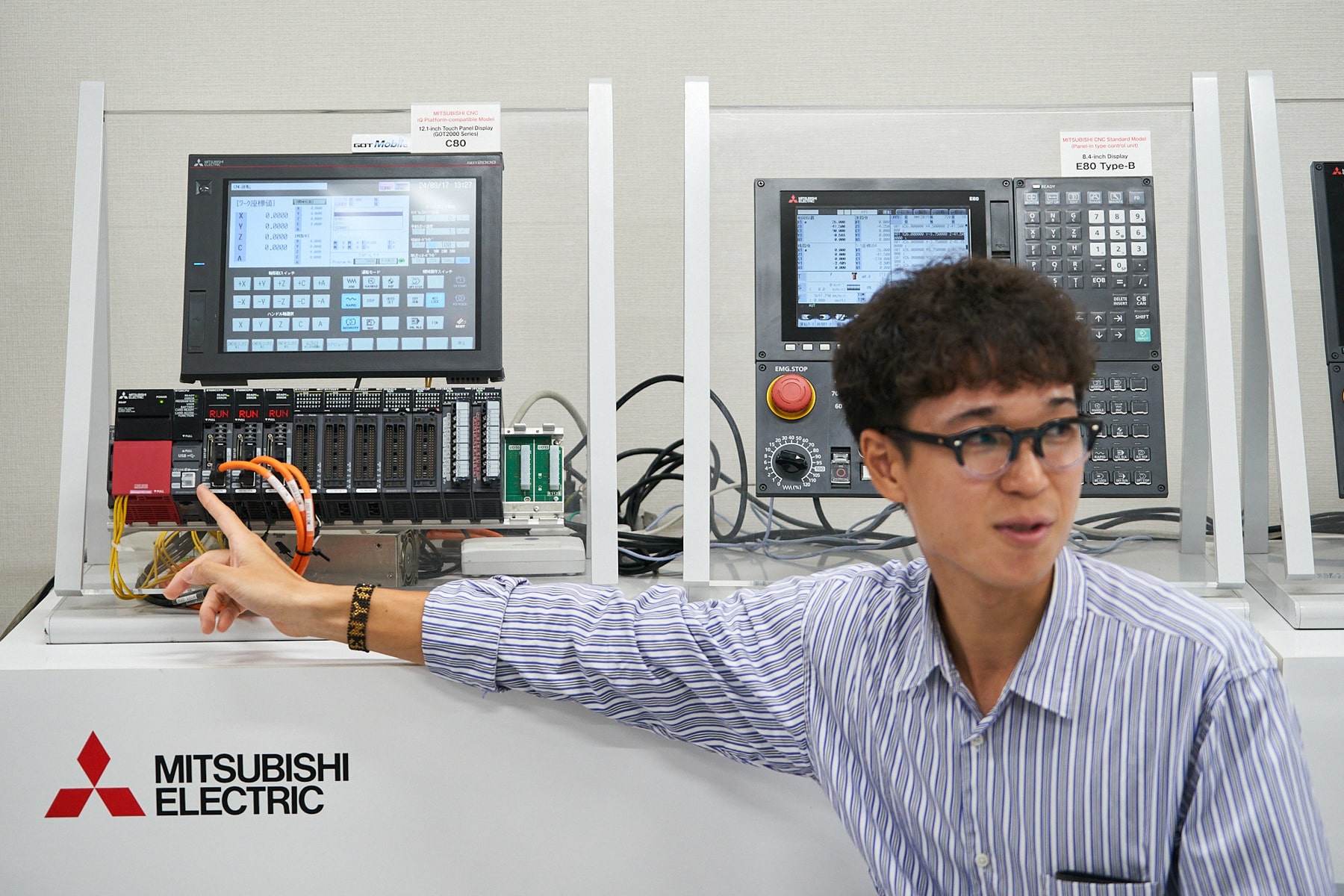

Banno: Right again. CNC here stands for Computerized Numerical Controller*1, a piece of technology used to operate machine tools*2 numerically via a computer.

Lined up behind me are some real CNC units. Manufacturers like automakers and smartphone makers use it to make parts.

- 1 CNC = Computerized Numerical Controller, or Computerized Numerical Control

- 2 Machines that cut, grind, and shape metals and other rigid materials to achieve desired forms.

Kyujitsu Kacho: So you’re saying you attach them to machine tools?

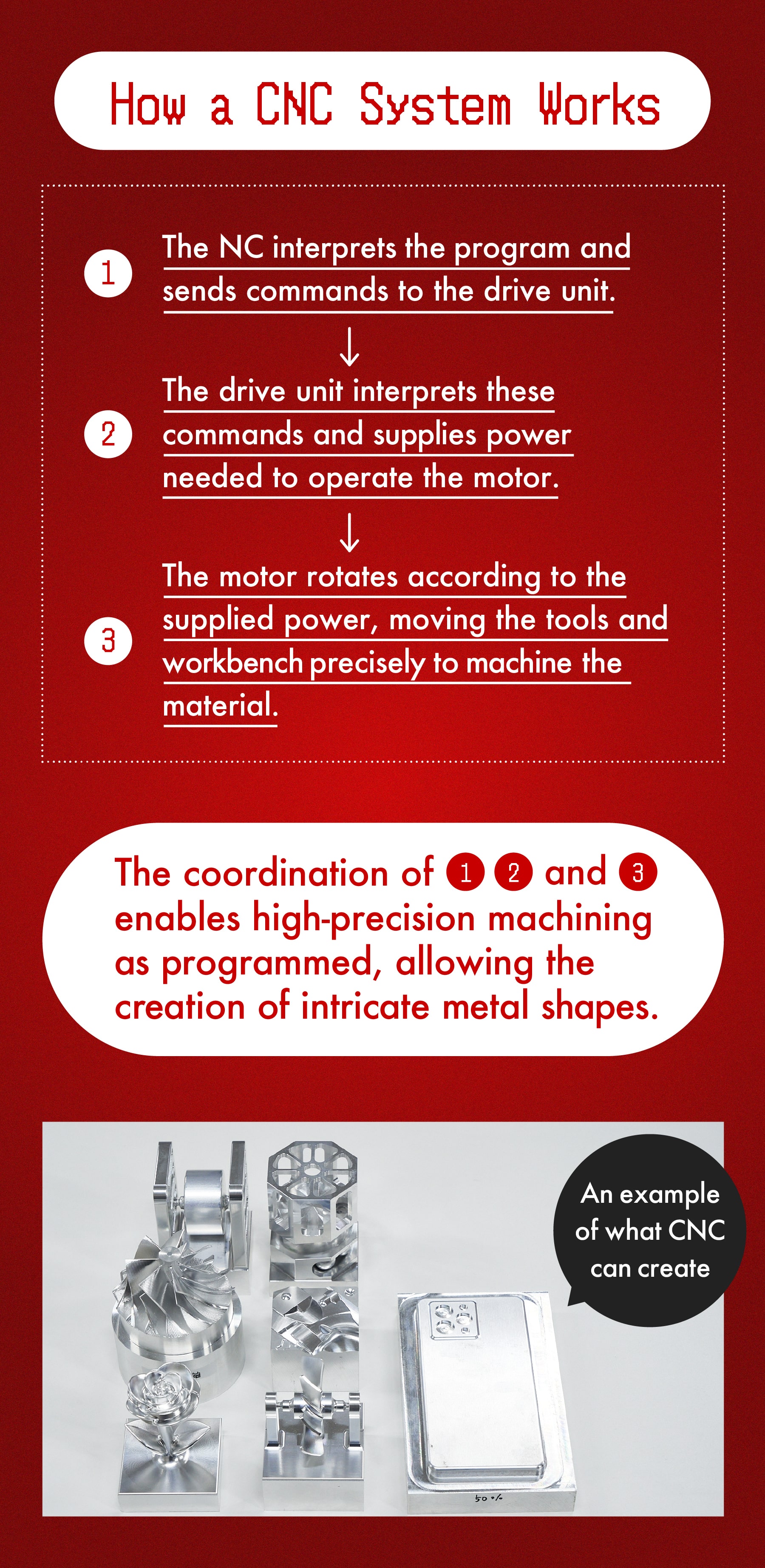

Banno: Sure, but to be more precise, a CNC system is made up of three components, including the type you see on display here. These are called machine control units (MCUs), otherwise known as the "brain" of a CNC system. MCUs are responsible for processing programmed instructions and translating them into machine tool movements.

Next, there’s the drive unit. Based on the instructions received from the MCU, a drive unit supplies the power needed to operate the motor accordingly. It also adjusts the power supply while monitoring the motor’s real-time behavior to ensure accurate operation.

The third and final component is the motor, where power received from the drive unit propels the rotation necessary to drive tool movement to machine a workpiece and produce parts. Think of it like this: one motor rotates a machine’s blade, another moves the blade up, down, left, and right, and a third controls the position of the workpiece. In this scenario, the motors are synchronized and controlled to cut intricate machine parts.

The precise coordination of multiple motors allows for the creation of elaborately shaped parts—stuff we couldn’t possibly make by hand.

Kyujitsu Kacho: Wow, that rose is awesome! But are there any parts that need that type of precision?

Banno: Sharp observation. The precision of CNC systems is one of the topics were going to be covering today. Let’s dig a little deeper into the numbers and look into the specifics of the world of CNCs.

Kyujitsu Kacho: One nano…sorry, I can’t really picture something that small.

Banno: It’s not a figure you come across every day, to be fair. 1 nanometer (nm) is one-millionth of a millimeter (mm). That is one ten-thousandth the width of a human hair and one hundredth the size of an influenza virus. I’m bringing this up because the latest Mitsubishi Electric’s latest CNC system can control machine tools within a nanometer of precision.

Kyujitsu Kacho: That’s amazing. It’s like there’s a whole world of super detailed precision that I didn’t know about…

Banno: It’s important for applications involving cutting-edge electronic devices, like smartphones.

Kyujitsu Kacho: I guess that makes sense, considering how small smartphones have gotten these days.

MstudioImages/Getty Images

MstudioImages/Getty Images

Banno: Products are constantly being updated to offer more functionality with a smaller footprint, which means there’s a push to shrink the size of every component contained inside. This is why the metal processing unit also needs to get smaller. But the smartphone example I shared earlier was just to highlight the need for precision machining. The actual demand for nano-level precision is limited to a specific application: optical equipment.

That said, smartphones are equipped with high-performance camera lenses. Since surface distortions on these lenses directly impact clarity and resolution, polishing them requires nano-level precision.

Kyujitsu Kacho: I’m really amazed. In all my life I’ve never come into contact with this world of microscopic detail. Getting it down to 1 nm, that’s impressive.

Banno: We managed to get here with the help of leading machine tool manufacturers in ultra-precision machining. I should mention, though, that not all components need nano-level precision, since machining at higher levels of precision is both more costly and more time-consuming.

Kyujitsu Kacho: It sounds like the current technology is a bit ahead of market needs. I wonder what other fields would need this kind of precision…maybe medical equipment?

Kkolosov/Getty Images

Kkolosov/Getty Images

Banno: Spot on. I mentioned earlier that nano-level control technology plays a crucial role in the field of optics. When optical equipment advances, it benefits the overall advancement of science and technology, including the medical field. It’s like how improvements in microscope performance are tied directly to the development of medical technology, ultimately serving as the launch pad for new discoveries in both basic research and the medical world.

It’s really fulfilling for me to see nano-level control technology making an impact in fields that can help make our society better. Now, let’s take a look at our second number!

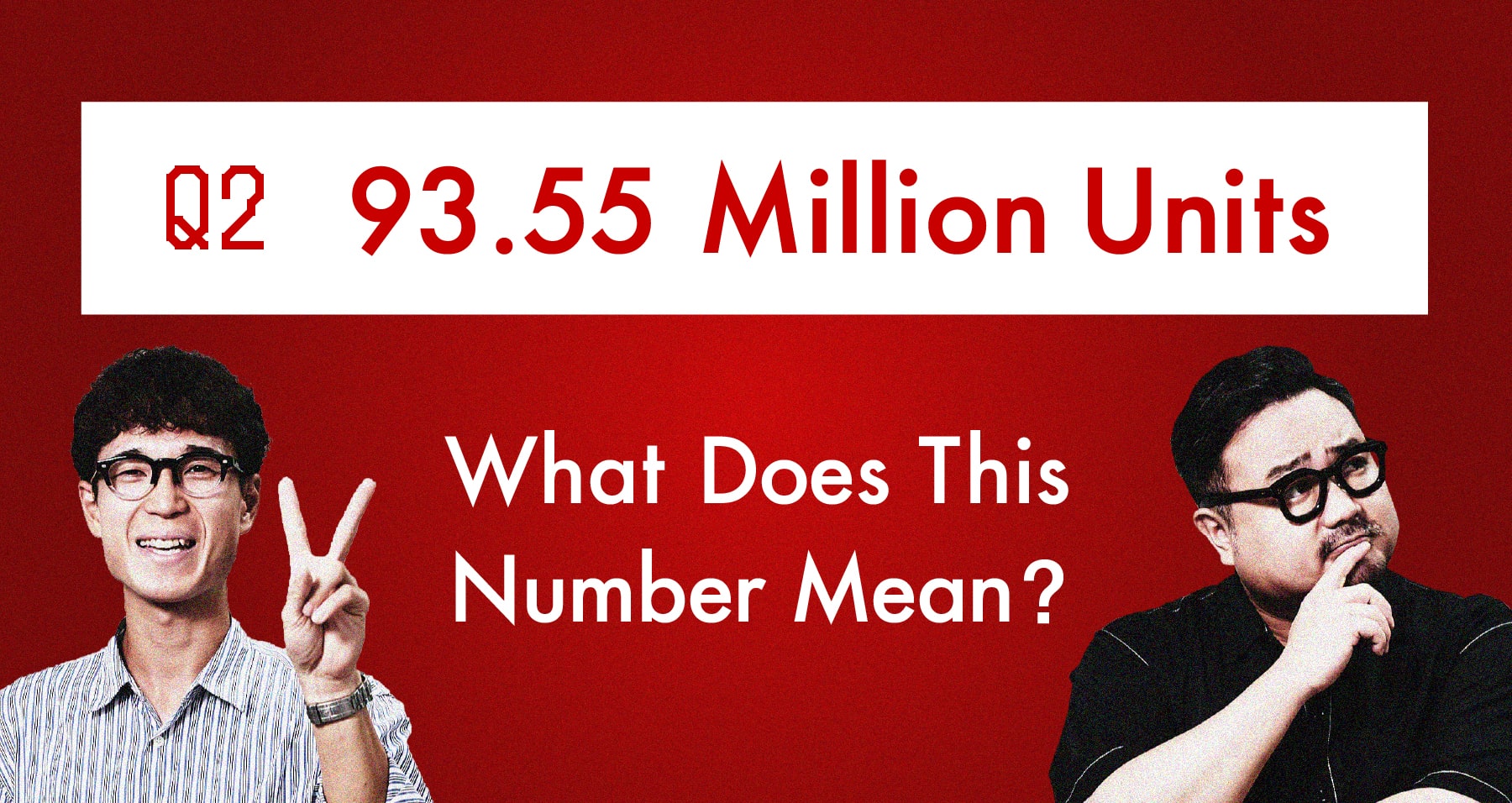

Kyujitsu Kacho: Units? Are we looking at production volume now? Hmmm,,, I don’t know.

Banno: The answer is: global automobile production.

Kyujitsu Kacho: Cars! A hundred million cars each year is quite a pace.

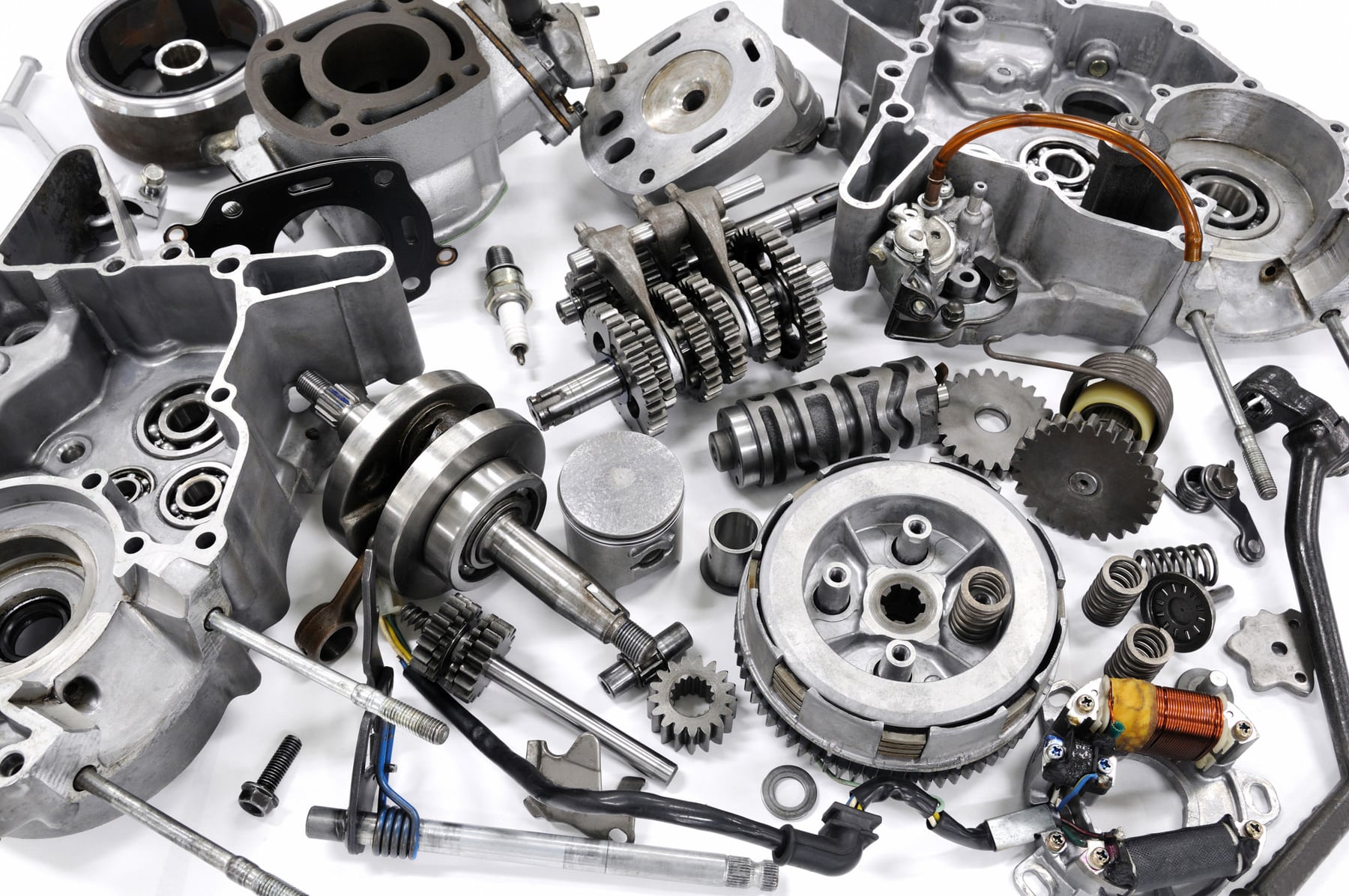

Banno: You know, a car is essentially a collection of metal parts, made up of as many as 20,000 metal pieces.

dreamnikon/Getty Images

dreamnikon/Getty Images

Kyujitsu Kacho: That’s new to me. CNC is used to manufacture all those parts?

Banno: Hmm, it’d be involved in 80% or so that are metal parts, but since CNC is also used in manufacturing molds for other parts, it’s probably around 90% in total.

There are a lot of processes involved in manufacturing metal parts. Metal can be melted, solidified or compressed. More recently, metal parts can even be formed by using 3D printers. CNC machine tools cut materials to shape, which is why they’re used for parts that require high precision or involve complex shapes.

Kyujitsu Kacho: If CNC can be used to make any part, shouldn’t it just use CNC for all the different parts?

Banno: Carving out a piece of metal from scratch is time-consuming. The most efficient method is chosen based on the required precision, material, and shape. Even when CNC machine tools are used, the process typically involves first compressing the metal material to create a shape close to the desired form, then finishing it with CNC machining.

Kyujitsu Kacho: That makes sense. To think that CNC is involved in producing the parts for nearly 100 million cars every year—that’s a huge contribution.

RainerPlendl/Getty Images

RainerPlendl/Getty Images

Banno: Actually, I believe the development of CNC machine tools has had a significant impact on the mass production of automobiles.

It might be a bit nonsensical to imagine, but without CNC, there’s no doubt the world wouldn’t be filled with cars as it is today. The production costs would be unimaginably high.

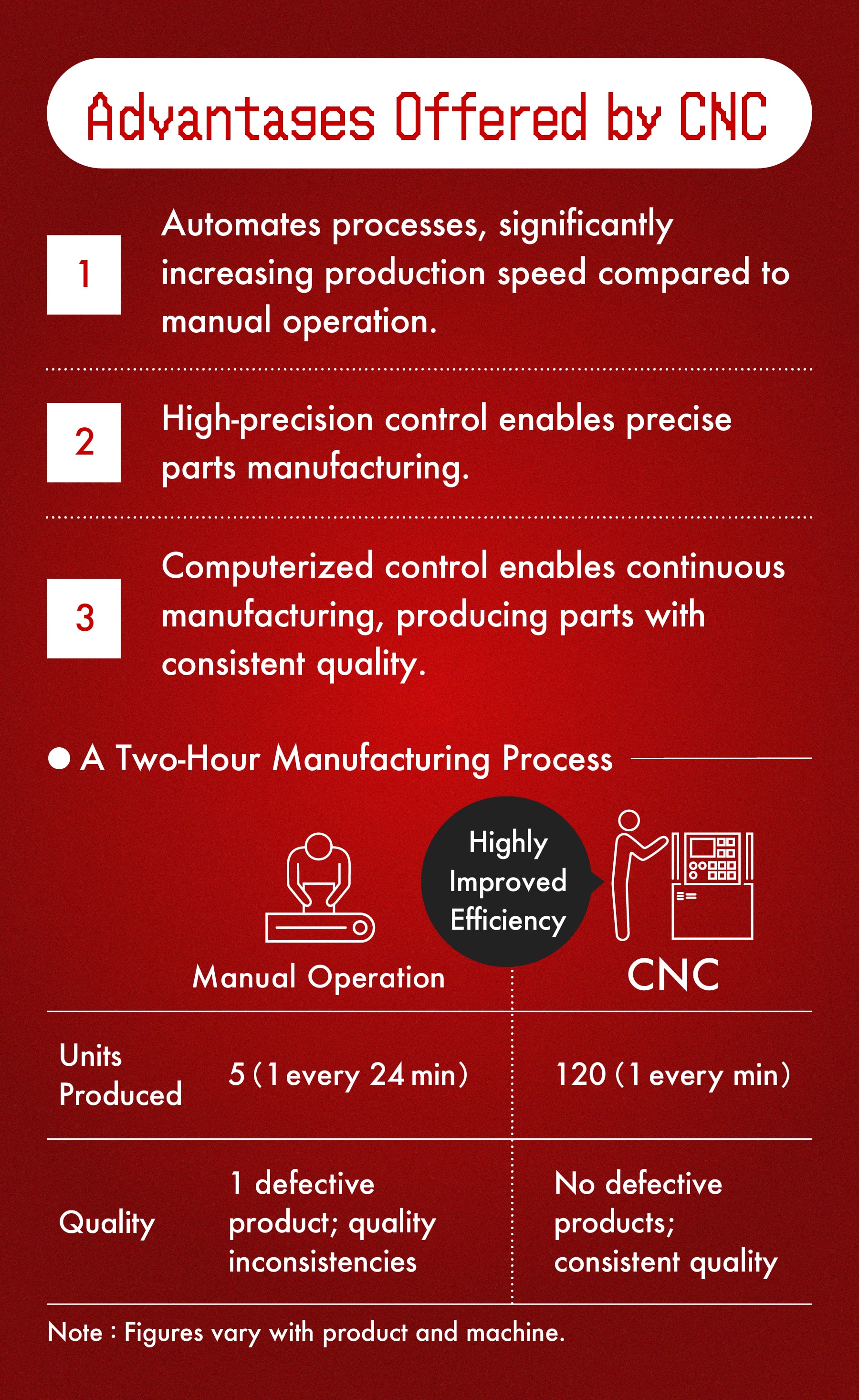

Kyujitsu Kacho: So basically, it’s a technology that enables mass production?

Banno: The true essence of CNC machine tools lies in their ability to produce parts with speed, precision, and unwavering consistency. Harnessing these capabilities makes the efficient production of countless components a reality.

Kyujitsu Kacho: But CNC contributes to just a part of automobile manufacture, right?

Banno: You’re absolutely right, there are other factors impacting production costs. One challenge in manufacturing is how seamlessly each process can be connected to one another. We’ve had user requests to integrate machine tools with equipment used further up and down the line. On that note, Mitsubishi Electric has a long history of manufacturing factory automation equipment which can be used to control a variety of systems. We also make sequencers used for production line control in factories. Bundling equipment together for installation in factories is one way we raise production efficiency.

Kyujitsu Kacho: Wow, that’s a big advantage.

Banno: Yep. And it’s something that only a diversified electronics manufacturer like Mitsubishi Electric can deliver.

All right, let’s move to the last number!

Kyujitsu Kacho: I know this one—this refers to the number of countries using Mitsubishi Electric CNCs!

Banno: You got it! And to be more precise, it’s the number of countries Mitsubishi Electric offers CNC services in.

Kyujitsu Kacho: What do you mean by services?

Banno: I mean the support we provide to our customers after delivery. When customers start using CNC machine tools, they may sometimes encounter issues where the CNC unit can’t operate according to the instructions programmed or face minor glitches.

Kyujitsu Kacho: Offering maintenance support in 100 countries… it’s really impressive that there is such a high demand for these products in so many countries in the first place. I was under the impression that CNCs weren’t replaced too frequently, and guessed they probably weren’t too profitable (laughs).

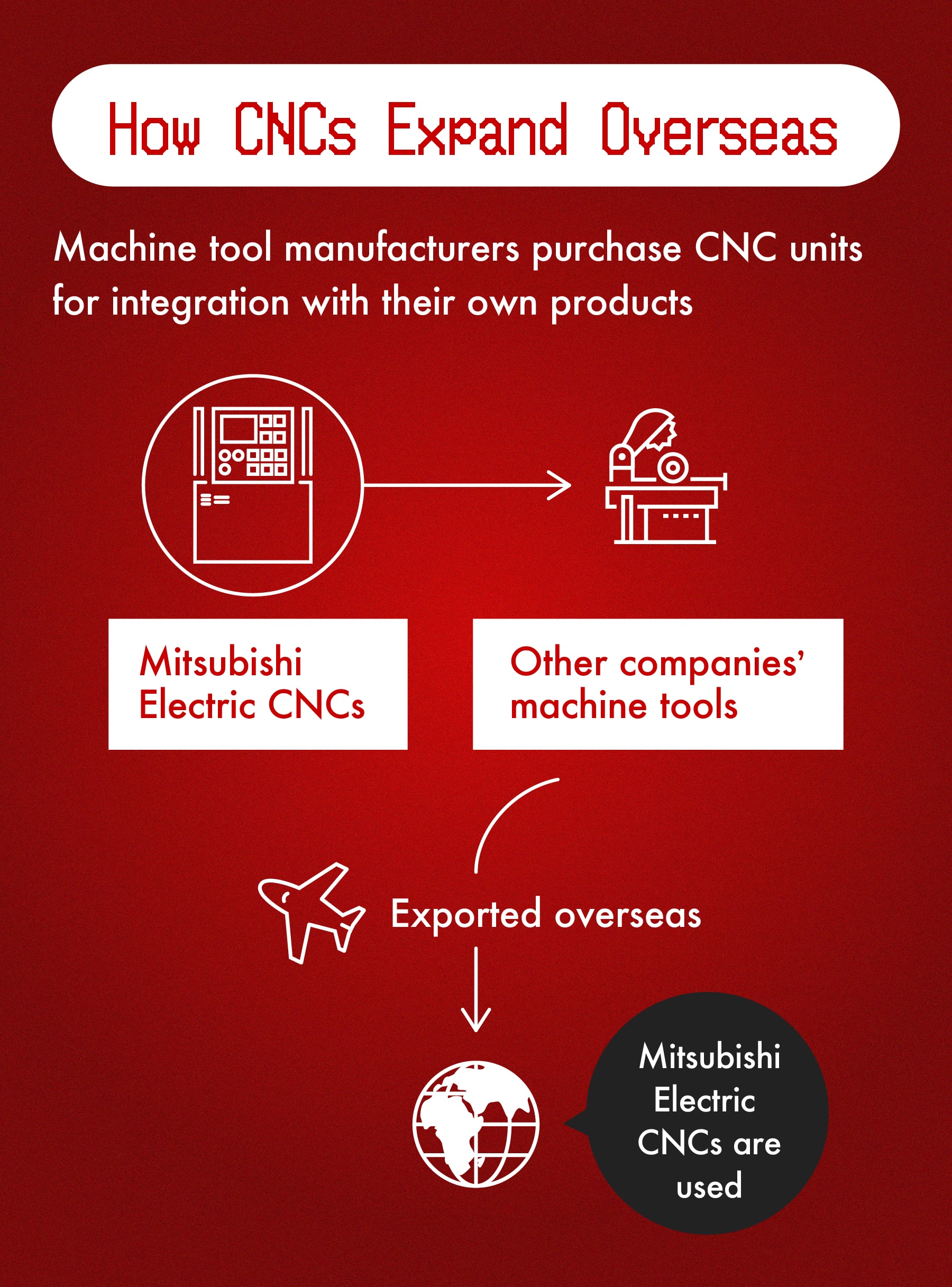

Banno: Sure, but CNCs generally see more demand when manufacturers scale up the production of certain products, or when they invest in equipment to develop new products. That being said, there’s global demand for tens of thousands of CNCs every year, although that doesn’t mean our company is exporting units to that list of over 100 countries.

Kyujitsu Kacho: In that case, how do that many CNC units make their way overseas?

Banno: Our customers, the machine tool manufacturers, integrate our CNC systems into their own products (i.e., machine tools) and sell them to end users, such as automotive manufacturers.

When these machine tool manufacturers export their machines overseas, our CNC systems naturally follow, expanding our reach globally.

As a result, our CNC systems are now operating in over 100 countries, with the majority of them currently in use outside of Japan.

Kyujitsu Kacho: So that’s how Mitsubishi keeps tabs on all those products scattered around the globe and provides after-sales service. It must be hard meeting all those specific market needs, since every country has its own culture and laws.

Banno: The 'right answer' varies from country to country.

When it comes to handling issues, speed is generally important, but preferences differ. Some countries prefer face-to-face visits no matter what, while others prioritize efficiency and prefer sending parts for repair by mail.

Of course, there are trends by country, but individual customers also have their own preferences, which.

Kyujitsu Kacho: A lot of variation, huh.

Banno: CNC manufacturers are also competing with one another in terms of global service capabilities. That’s why local service centers are becoming increasingly important, so our position as a diversified electronics manufacturer gives us a competitive advantage.

We got a head start overseas with home appliances, like air-conditioners, so we’ve already laid the groundwork for business in overseas markets before CNC-related demand truly emerged. This advantage helps us to establish services with fairly low risks, building on our familiarity with the local laws, culture, and business practices.

Kyujitsu Kacho: Ah, that makes sense. Being a major player in home appliances is a big advantage.

A Hidden Hero in Data Centers and Mask-Making

Banno: Thank you for taking the time to hear all about Mitsubishi Electric's CNC systems! What did you think?

Kyujitsu Kacho: Before today, I didn’t even know the name of "CNC", but now I understand that the world wouldn’t function without it, and neither smartphones nor cars would have become so widespread.

By the way, you mentioned that CNC sales are doing well—what industries have been driving demand recently?

Banno: One of the recent trends is the surge in data center construction, both domestically and internationally, driven by the advancement and widespread adoption of AI technologies.

In machine learning, massive amounts of data are processed, which causes the semiconductors in data centers to generate a significant amount of heat. To prevent these semiconductors from overheating and getting damaged, efficient cooling systems are essential.

Interestingly, these cooling systems are manufactured using precise machinery equipped with CNC systems. As the number of data centers increases, the demand for CNC technology is also on the rise.

Kyujitsu Kacho: So in the behind-the-scenes world of data centers, CNC is working even further behind the scenes.

Oselote/Getty Images

Oselote/Getty Images

Banno: Product trends like these tend to surface from time to time. During the COVID-19 pandemic, there was a surge in demand for mask manufacturing equipment. The molds used to press creases into the masks’ non-woven fabric are also controlled by CNCs.

Kyujitsu Kacho: Who’d have thought CNC would be involved in masks, too?

Speaking of trends, smartphones are constantly being upgraded, aren’t they? It wouldn’t be surprising if the next big thing after smartphones appears before too long.

Banno: Absolutely. In that sense, information on capital expenditures can sometimes reveal details about next-generation products 2 to 3 years before the general public learns about them.

Kyujitsu Kacho: Oh, that’s right! From what you’ve told me so far, capital expenditures and CNC technology go hand in hand.

Banno: While we can’t disclose that kind of information, one of the perks of being involved in CNC technology is getting the occasional glimpse into future trends slightly ahead of the general public.

NC MachiningAID, Powered by AI for Next-Generation Factory Monitoring

NC MachiningAID was created by Mitsubishi Electric to digitize human expertise in manufacturing. Skilled workers on the shop floor have traditionally served to ensure the condition of factory tools, providing the human experience and intuition necessary to manage them. However, modern manufacturing is facing a decline in such labor amid rising costs.

Leveraging the keen awareness of AI, NC MachiningAID offers manufacturers a solution to reduce costs while enhancing manufacturing quality. It continuously monitors subtle current fluctuations present during metal processing, comparing this data against baseline datasets, and triggers an alert at the first sign of abnormality.

The diagnostic tool helps manufacturers.

- Anticipate the optimal timing for tool replacement

- Promptly detect sudden machining issues

- Minimize product defects stemming from operational errors

Encapsulating the skills of veteran craftsmen using AI, NC MachiningAID is poised to become a new core technology that underpins the future of Japanese manufacturing.

- The information on this page is current as of October, 2024.

Layout: Daigo Horio

Photography: Masashi Kuroha

Design: Seisakujo inc.

Editor: Akira Shimomoto

Translator: Eliza Lim, Martin Triche