2024.06.17

Manufacturing Re-envisioned: Keys to Digital Transformation Success

The manufacturing industry has navigated a host of challenges in recent years, responding to evolving market needs while contending with operational hurdles, including labor shortages and soaring material costs.

However, by integrating digital technology into production to streamline and optimize processes, digital manufacturing is opening doors to a new reality for manufacturing—and for Mitsubishi Electric. In its pursuit of flexible production, the electrical manufacturer seeks to erase the gap between digital and real-world applications as it bolsters its line-up of manufacturing solutions.

What is the future of manufacturing, from the perspective of this Japanese industry leader?

Together with Kazuya Mizushima, General Manager of Mitsubishi Electric’s FA Digital Engineering Department, we dive into the heart of digital transformation in manufacturing.

A member of Mitsubishi Electric since 1995, Mizushima oversaw the marketing of programmable logic controllers and facilitated the launch and subsequent promotion of e-F@ctory while at the Industrial Products Marketing Division/Nagoya Works. Beginning in 2015, he oversaw the launch and expansion of the e-F@ctory solution business at Mitsubishi Electric Automation (China) before moving to the Business Innovation Group in 2020 to engage in new business creation and the building of business growth infrastructure. Since 2023, he has led the FADigital Engineering Department at the Factory Automation Systems Group. (Information accurate as of December 6, 2023.)

A member of Mitsubishi Electric since 1995, Mizushima oversaw the marketing of programmable logic controllers and facilitated the launch and subsequent promotion of e-F@ctory while at the Industrial Products Marketing Division/Nagoya Works. Beginning in 2015, he oversaw the launch and expansion of the e-F@ctory solution business at Mitsubishi Electric Automation (China) before moving to the Business Innovation Group in 2020 to engage in new business creation and the building of business growth infrastructure. Since 2023, he has led the FADigital Engineering Department at the Factory Automation Systems Group. (Information accurate as of December 6, 2023.)

Contents

The Rising Relevance of Dynamic Capability

The business environment for manufacturing companies in Japan has seen significant changes in recent years, including geopolitical difficulties impacting parts procurement, soaring material prices, the push for carbon neutrality, fiercer global competition, a shrinking domestic workforce, and shifts to high-mix low-volume manufacturing. Navigating VUCA* has never been more pertinent.

- Volatility, uncertainty, complexity, and ambiguity. An acronym that reflects difficult situations like climate change and is used to characterize the unpredictable and rapidly changing nature of today’s business environment.

Mizushima observes, "To deal with such issues, businesses need to strengthen their dynamic capabilities."

Simply put, "dynamic capability," a term introduced in a 1997 journal article by Teece et al., is the capability of an organization or business to adapt to external changes in the business environment.

The Japanese government’s "FY2021 Measures to Promote Manufacturing Technology" presents dynamic capability as an aggregate of three elements, highlighting digital transformation as an effective tool to strengthen all three.

"Simulation technology will be used to streamline production lines and reduce construction times, while data generated throughout an organization—including that from production sites—will be linked to enable AI-powered data analysis. Such digital initiatives have become a significant trend as manufacturing companies look to bolster dynamic capabilities to respond to changes in the market environment," Mizushima states.

the manufacturing industry has turned to digital manufacturing to mitigate uncertainty as part of its efforts to enhance dynamic capability. This approach to manufacturing focuses on improving the efficiency, flexibility, and resilience of production processes through the integration of digital technology into manufacturing. Mizushima further explains, "The essence of digital manufacturing lies in creating a production system capable of swift responses in a volatile market, leveraging all pieces of manufacturing-related data to foster better alignment between plans [projections] and actuals [results]."

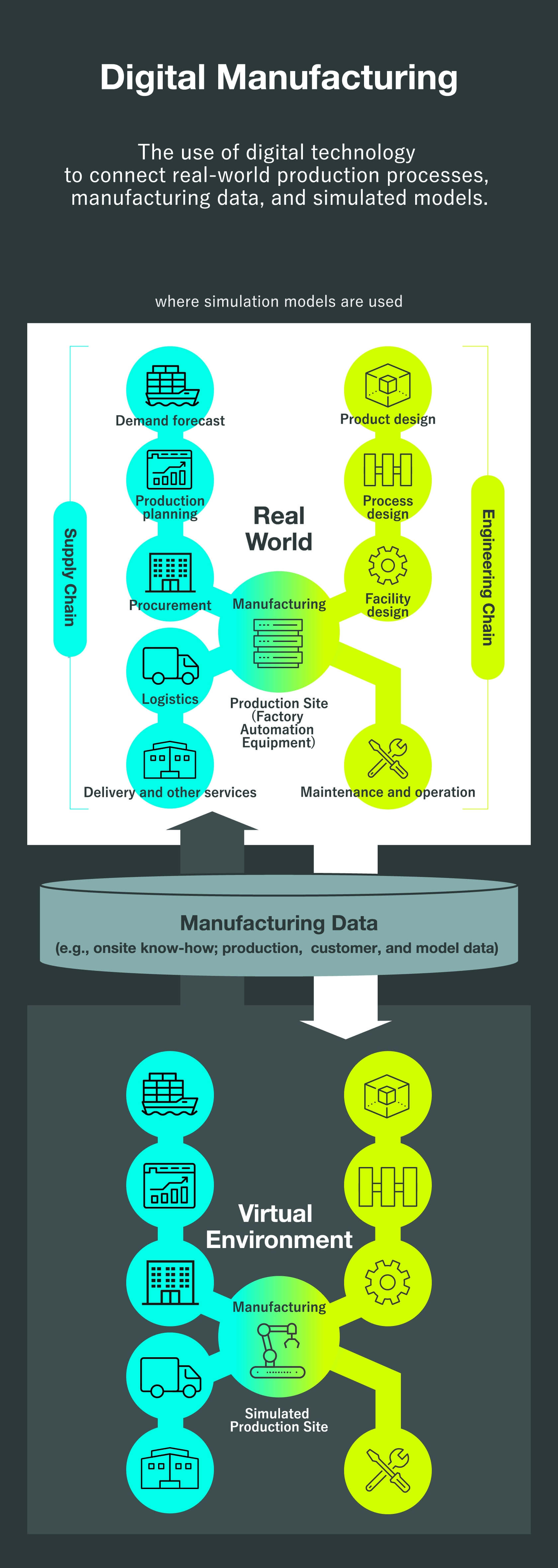

Generally, manufacturing is intertwined with engineering and supply chains. The former represents a sequence of activities in product development—from product design to production line design and construction, followed by the production process itself and subsequent maintenance services — while the latter represents a product’s journey in stages, from raw material and parts procurement to the final delivery to customers.

From these manufacturing-related activities, available data points are gathered to formulate plans to refine processes and enhance efficiency, leveraging both data and digital technology. The differences between a plan (projections) and the actuals (results) are visualized after onsite execution, with subsequent improvements realized by reducing discrepancies to strengthen operational efficiency, thereby reducing costs, and improving delivery times, quality, and other key manufacturing priorities in the process.

Integrating both physical and digital worlds—that is how Mitsubishi Electric envisions the future of manufacturing. It involves linking information from both engineering and supply chains, executing rapid analyses of large volumes of data, and actively using digital technology, factory automation (FA) equipment, and other tools to maximize overall effectiveness.

The results of this approach? The ability to accommodate variations in production—whether product type or quantity—and adapt to changes flexibly, optimize production planning and material procurement, oversee remote facility operation, implement predictive maintenance, and reduce carbon emissions. Digital manufacturing makes all this possible.

Pursuing Solutions for the Manufacturing Lifecycle

Manufacturing solutions developed and offered by Mitsubishi Electric are shaped by considerations of actual onsite production conditions and informed by extensive expertise developed in the Japanese manufacturing industry. Simulation software, for example, is one tool that develops model-based solutions that are aligned with real-world conditions and scenarios.

Traditionally, assessments of newly deployed equipment and systems (e.g., machine operation, control programs) have been carried out in person at manufacturing sites. However, the time required for such assessments and the correction of identified issues adds to costs and delays. Here, simulation software provides a solution by trimming overall construction time.

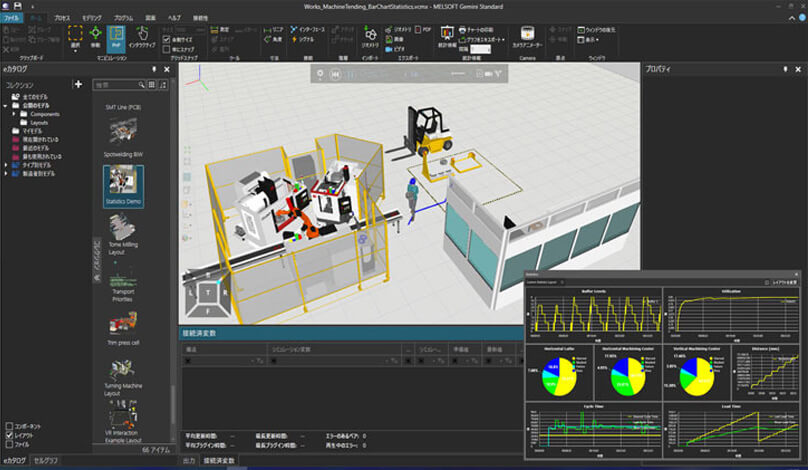

Developed by Mitsubishi Electric, the MELSOFT Gemini simulator can assess the data of a system under design, using 3D virtual simulation to examine not only the system’s shape and structure, but its operation as well. The simulator can also improve a given system by producing comparisons of discrepancies in pre-assessment and post-operation data.

MELSOFT Gemini enables the assessment of onsite manufacturing operations by allowing users to build production lines and facilities in 3D, eliminating the need to use the physical equipment or systems.

MELSOFT Gemini enables the assessment of onsite manufacturing operations by allowing users to build production lines and facilities in 3D, eliminating the need to use the physical equipment or systems.

According to Mizushima, the need to simulate manufacturing operations has increased significantly in recent years: "In particular, customers engaged in fields such as automobiles, LCDs, and lithium-ion batteries recognize the challenges involved in minimizing time investment in large-scale development. In addition to the 3D simulator, MELSOFT Gemini, we felt that we needed to develop software capable of simulating the control logic of the entire system at a production site." This resulted in the release of MELSOFT Mirror in 2024.

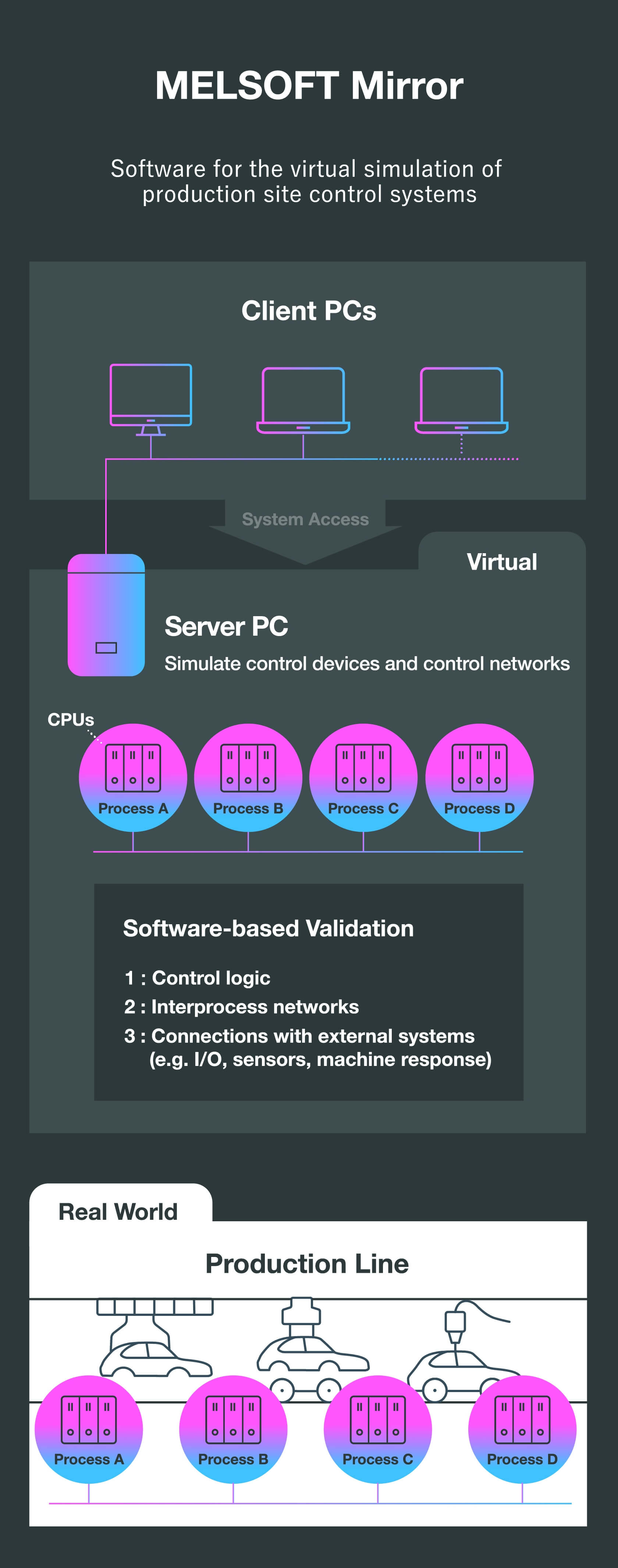

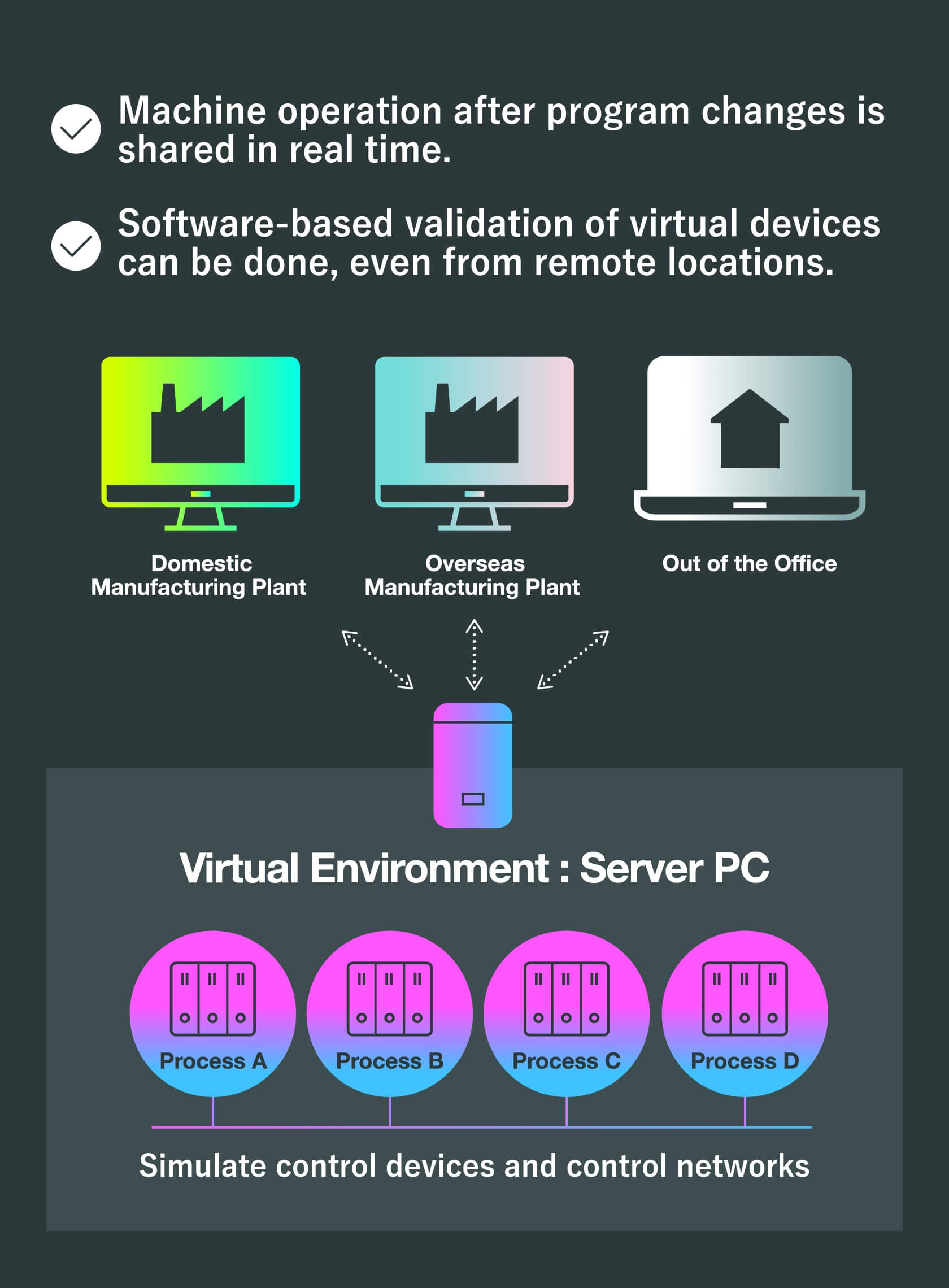

MELSOFT Mirror’s major advantage is its ability to run control programs in a virtual environment to simulate the entire control system of a manufacturing site, unlike MELSOFT Gemini, which merely visualizes line and machine operations in 3D.

"There are many processes that take place at a manufacturing site, and control network systems [control logic] need to be built to connect these processes. Because of the need for theoretical assessments, this has typically involved complex, physical work, such as the preparation of physical control devices and multiple control programs. This means that businesses face higher hurdles when it comes to pre-assessments of large-scale systems," Mizushima explains.

In the case of actual device assessments, malfunctions require onsite adjustments paired with repeated tests. However, assessments conducted via a virtual environment minimize the time used for onsite adjustments, resulting in significantly shorter construction schedules that help production proceed as planned.

MELSOFT Mirror’s virtual environments can also be shared with multiple users. For many machine builders and end users in global organizations, MELSOFT Mirror offers a shared platform for those involved to collaborate on the design and assessment of manufacturing systems in real time.

However, Mizushima emphasizes that digital manufacturing as envisioned by Mitsubishi Electric goes beyond the mere simulation or assessment of setups: "To us, it’s important that projections and reality are aligned by maximizing the use of data across the entire manufacturing lifecycle." Clearly, the company is committed to tackling manufacturing challenges through this digital approach.

Apart from simulation software aimed at the design and development phases, Mitsubishi Electric also offers the SCADA software GENESIS64™ and data science tool MELSOFT MaiLab. Designed to support the actual production stage of manufacturing, GENESIS64™ visualizes all manufacturing-related data, while MELSOFT MaiLab analyzes data using AI. Both products, while primarily developed to interpret production line data, can also be applied to reducing gaps between simulated and actual results and fine-tuning simulations based on actual values.

The Strength Behind Japanese Manufacturing

As Japan’s manufacturing industry navigates a VUCA world, it is also grappling with labor shortages and a shrinking pool of younger successors to inherit technical expertise. Digital manufacturing holds the key to responding to such challenges, addressing the reality of declining birth rates and an aging population.

"Compared to companies at the forefront in the West, digital transformation in Japan has lagged in certain aspects," Mizushima comments. For Japanese manufacturers looking to embrace digital manufacturing and evolve accordingly, he offers the following insights:

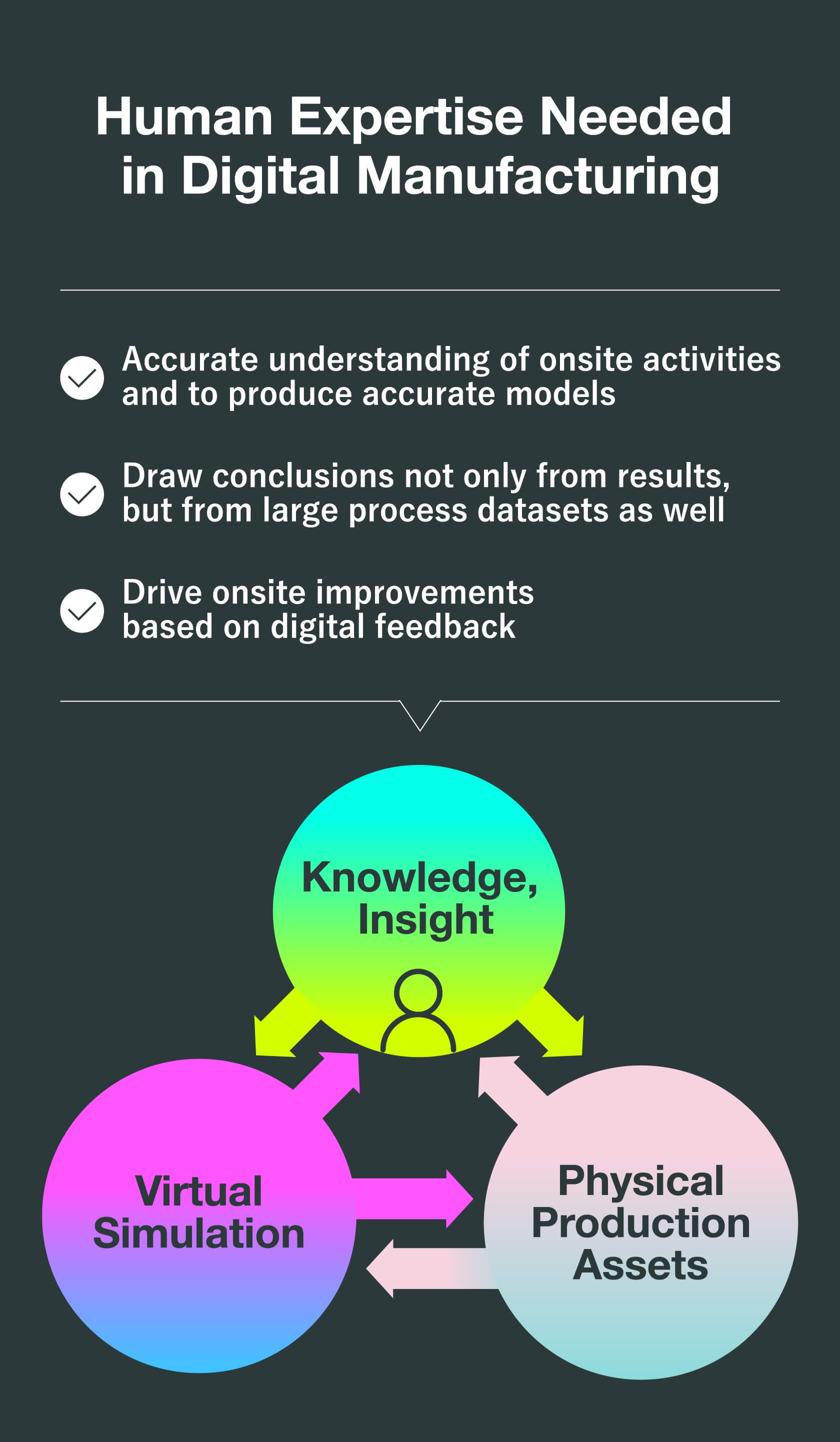

"People are the very cornerstone of Japanese manufacturing. Workers on each production line repeatedly test their hypotheses, perfecting each process and the technology involved. Productivity increases because people implement these improvements; in the process, these workers acquire unique skills and knowledge themselves. Speaking from experience, this is a formidable strength, and what makes Japanese manufacturing so different.

Mitsubishi Electric provides the tools to carry out digital manufacturing, but having the complete set doesn’t translate to instant improvements in onsite efficiency. Without people drawing on AI-powered insights to make improvements, transforming the production sites will remain a challenge. Without people building virtual environments based on a thorough understanding of the production sites, we cannot produce accurate simulations either. Digital manufacturing can only succeed when we fuse technology with the knowledge, intuition, and capabilities of people well-versed in what they do. And by doing that, our strength in manufacturing will shine."

Using human expertise to amplify the impact of manufacturing data and digital technology will spur flexibility and efficiency in manufacturing, but it must be noted that no two production sites are the same. The manufacturing industry is home not only to an array of manufacturing fields, but also companies of varying operation scales and business ideologies.

Through its robust line-ups of software and factory automation equipment, Mitsubishi Electric remains committed to developing digital manufacturing throughout the industry, and Mizushima’s vision of its future is one that embraces the diversity of production sites:

"We’d like to develop a platform that’s built with FA-related applications and other capabilities in the future. This platform will cater to manufacturers from different fields and deliver the same level of performance across the board, regardless of business ideology or manufacturing method. Through this platform, we hope to support the shift to flexible manufacturing and aid in the growth of the whole industry."

- This English translation was published in May 2024. As of this date, MELSOFT Mirror is only available in Japan.

Writer: Yumi Kobayashi

Photographer: Masashi Kuroha

Designer: Risa Yoshiyama

Editor: Akira Shimomoto