2025.01.14

Innovative Energy Storage Module for Railway is Accelerating New Possibilities Beyond Rail

In the railway industry, there is a growing movement toward further decarbonization by making effective use of the regenerative power generated when trains decelerate. To meet these needs, Mitsubishi Electric Corporation and Musashi Energy Solutions Co., Ltd. are jointly developing an Innovative Energy Storage Module named Mitsubishi High Power Battery (hereinafter abbreviated as MHPB) that is optimal for storing regenerative power. We interviewed the two key persons leading the development at each of these companies.

Contents

Pushing ahead with utilization of regenerative power for the reduction of CO2 emissions

Rail is known as a highly energy-efficient mode of transportation, and it emits only a fraction of CO2 per unit of transport compared to cars and planes, making it a forerunner for the environment.

Even still, there is a need to further reduce CO2 emissions in order to realize carbon neutral as a society on the whole. In its May 2023 report, "How Carbon Neutrality in the Railway Sector Should Look*," the Japanese government set a goal of reducing railway industry CO2 emissions to less than half of the fiscal 2013 level by the 2030s (from 11.77 million tons to 5.4 million tons).

There are various ways of reducing CO2 emissions; however, among these the one with seemingly the greatest potential in the railway sector is the effective utilization of regenerative power.

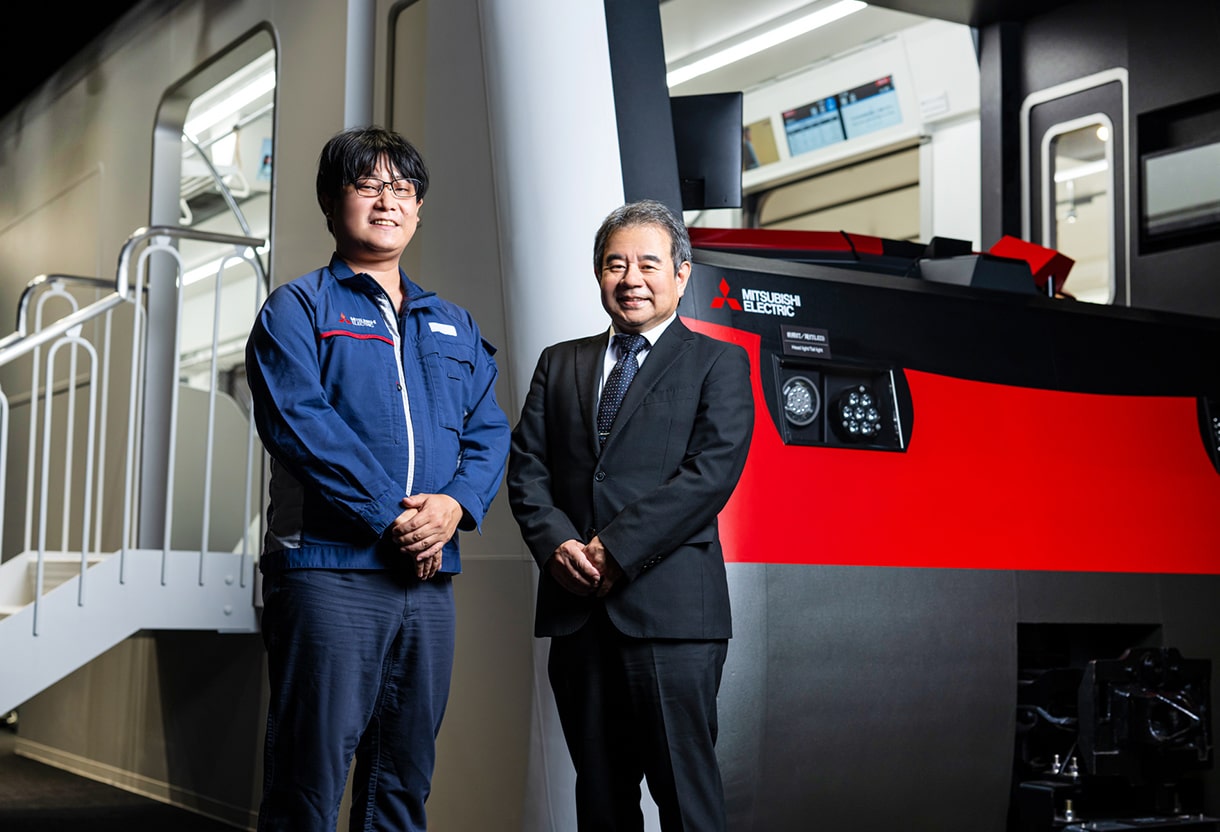

Yukihiro Yoshida

Yukihiro YoshidaPower Electronics Systems Development Section, Traction Systems Department,

Itami Works, Mitsubishi Electric Corporation

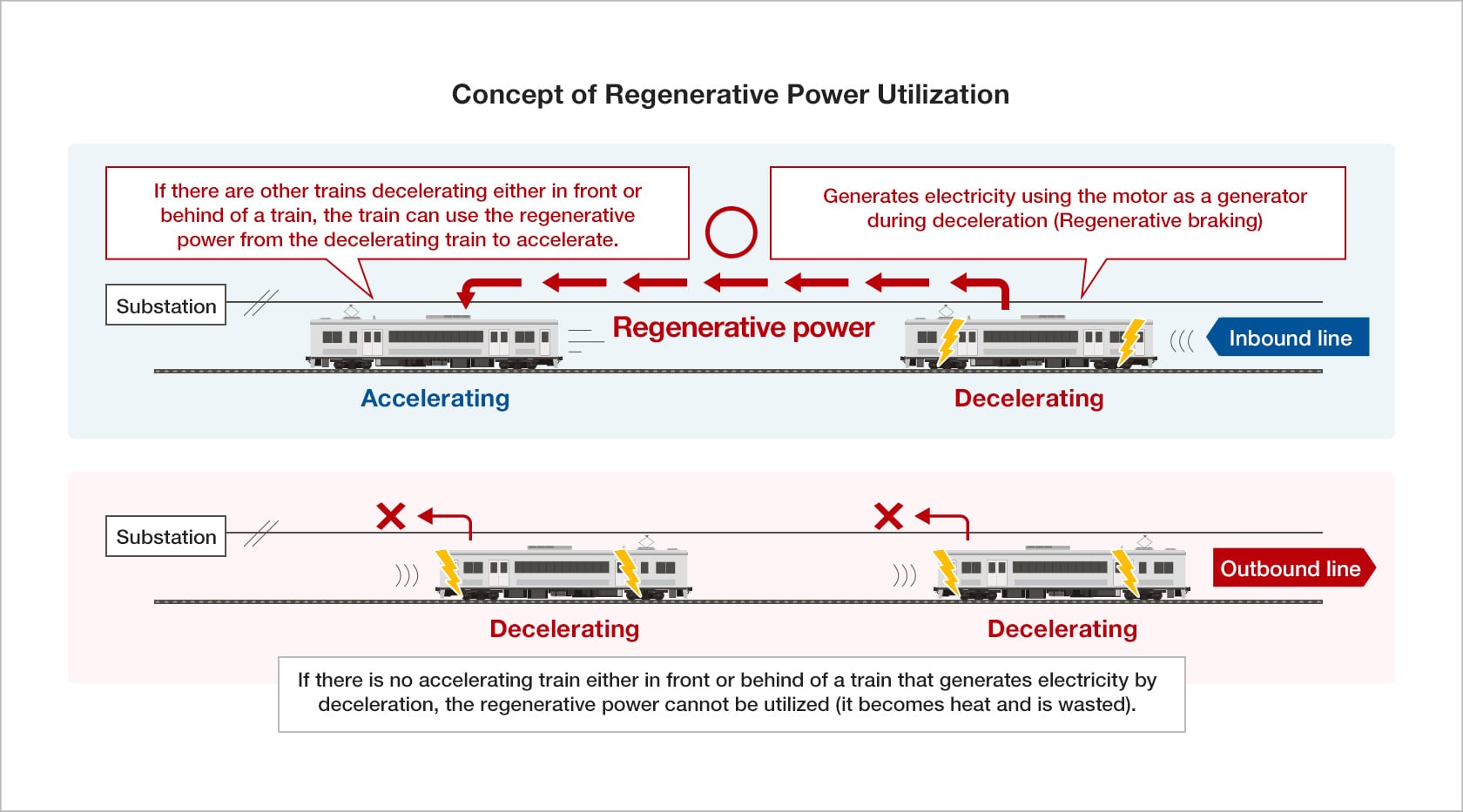

Yoshida: "Regenerative power" refers to the power obtained by utilizing the motor of a railcar as a generator upon the railcar’s deceleration. Rather than discarding the kinetic energy as heat, by converting it to electrical energy then utilizing it through the overhead catenary system for the acceleration of other trains, it is possible to minimize power consumption of the overall line.

The above explanation was offered by Mr. Yukihiro Yoshida of the Power Electronics Systems Development Section, Traction Systems Department, who has been involved in the development of power electronics devices for rolling stock and energy storage systems since he joined Mitsubishi Electric.

However, due to the fact that the regenerative power would go to waste and the overhead voltage would become too high if there are no other trains to use it, there is a need to devise ways to temporarily store the regenerative power in the batteries of vehicles or ground equipment to level out the power.

Regenerative braking obtains power by using the motor as a generator upon deceleration of a train. Regenerative power can be used in the acceleration of other trains (top-left in the above diagram). However, if there are no other trains in the process of acceleration at that time, the regenerative energy cannot be effectively utilized. (Source: "How Carbon Neutrality in the Railway Sector Should Look" by the Ministry of Land, Infrastructure, Transport -May 2023)

Regenerative braking obtains power by using the motor as a generator upon deceleration of a train. Regenerative power can be used in the acceleration of other trains (top-left in the above diagram). However, if there are no other trains in the process of acceleration at that time, the regenerative energy cannot be effectively utilized. (Source: "How Carbon Neutrality in the Railway Sector Should Look" by the Ministry of Land, Infrastructure, Transport -May 2023)

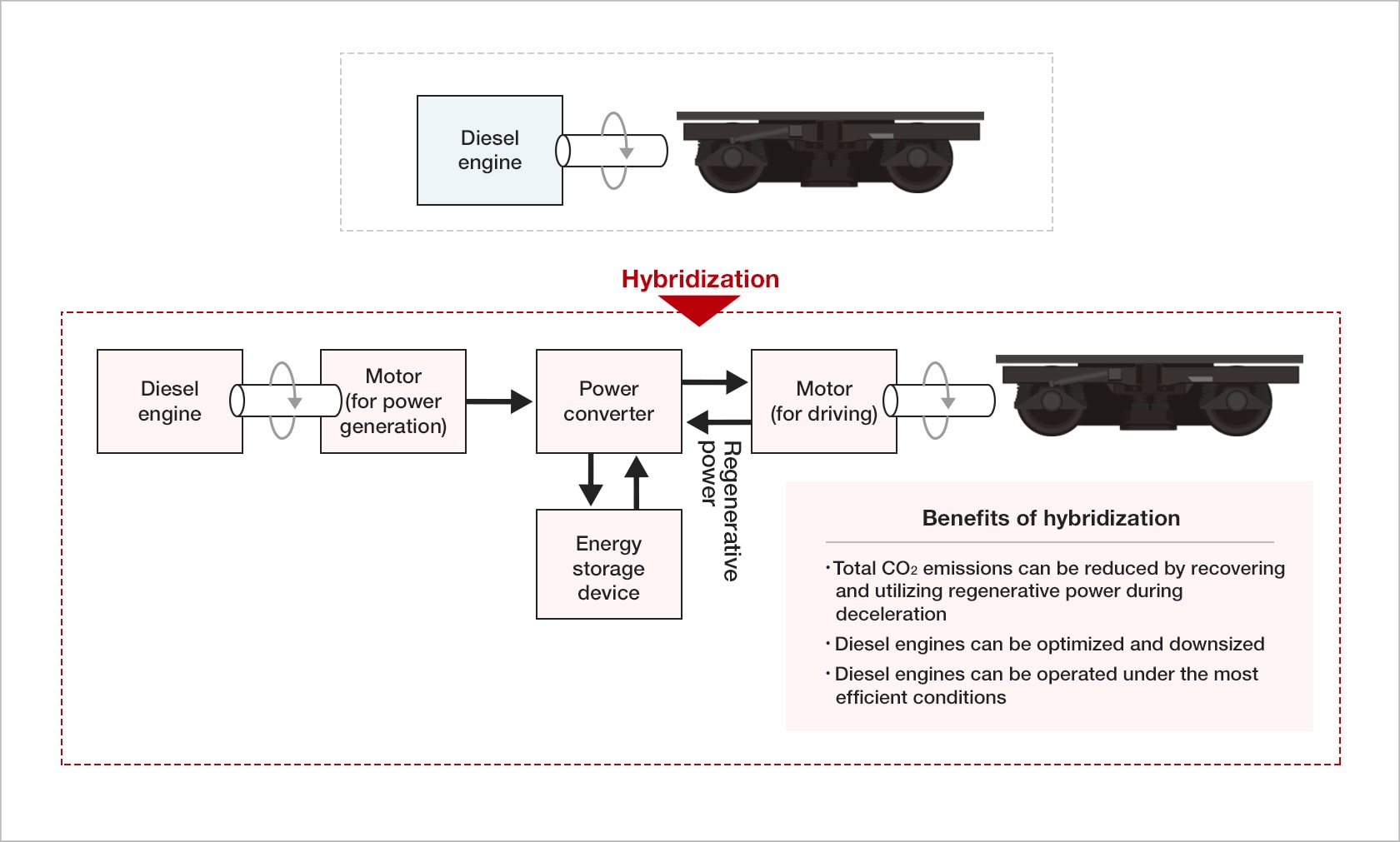

Yoshida: The hybridization of diesel railcars is effective in the reduction of CO2 emissions. The generator is run using the diesel engine, then by driving the railcar with the motor using that power, it is possible to recover the energy produced upon deceleration, store it in a battery, then utilize it for acceleration. Also, the engine can be stopped when the train is at a halt or running at low-speed, therefore CO2 emissions can be reduced even further.

CO2 emissions are reduced by recovering the energy upon deceleration through the hybridization of diesel railcars

CO2 emissions are reduced by recovering the energy upon deceleration through the hybridization of diesel railcars

In order to effectively utilize regenerative energy—only obtainable upon deceleration—it is necessary to temporarily store power in batteries or other storage devices. This is what motivated Mr. Yoshida to pursue a battery fit for storing regenerative power since 2022.

Yoshida: I looked into various products offered by approximately 20 companies in my search for a battery that could sufficiently store energy, instantaneously charge or discharge, and achieve downsizing/weight reduction of a system. However, I didn’t have much luck finding the right product.

Emergence of a new capacitor offering the "best of both worlds"

It was during this time that Mr. Yoshida met Mr. Nobuo Ando, the General Manager of Development for Musashi Energy Solutions.

Nobuo Ando

Nobuo AndoGeneral Manager of Development

Musashi Energy Solutions Co., Ltd.

Ando: It originally began when an acquaintance of mine who worked for Mitsubishi Electric asked me to give a technical lecture about the hybrid supercapacitor under development at Musashi Energy Solutions.

This paper introduces hybrid supercapacitors below, but for the meantime, they can be best described as a type of energy storage device and can be thought of as a super high-capacity version of the capacitors used in electronic circuits.

Yoshida: We had looked at Musashi Energy Solutions’ hybrid supercapacitors once but ultimately removed them as a candidate as the specifications at the time did not satisfy our requirements.

However, I couldn’t pass up the opportunity to attend Mr. Ando’s lecture, so when he said in closing "We are investigating how to achieve high-energy," I made up my mind to go and speak to him after the lecture.

Mr. Ando describes his impression of Mr. Yoshida at that time.

Ando: I could feel an overwhelming sense of passion coming from Mr. Yoshida (laughs). I’d actually given that lecture right at the time we’d discovered a new material and had prospects of increasing our energy and output by two-fold. It was very difficult to attract interest in our conventional hybrid supercapacitors in a world where lithium-ion batteries were mainstream. But Mr. Yoshida ardently told me that if there was a device capable of producing twice as much energy as the conventional hybrid supercapacitor then he wanted to give it a shot, and his enthusiasm made me determined to pour every ounce of technological capability we had into the project in order to meet his expectations.

Here, let’s take a moment to introduce Musashi Energy Solutions. As a pioneer leading the world in the mass production of hybrid supercapacitors, Musashi Energy Solutions was established in 2007 as a subsidiary of JSR. In 2020, it became a group company of Musashi Seimitsu Industry Co., Ltd.

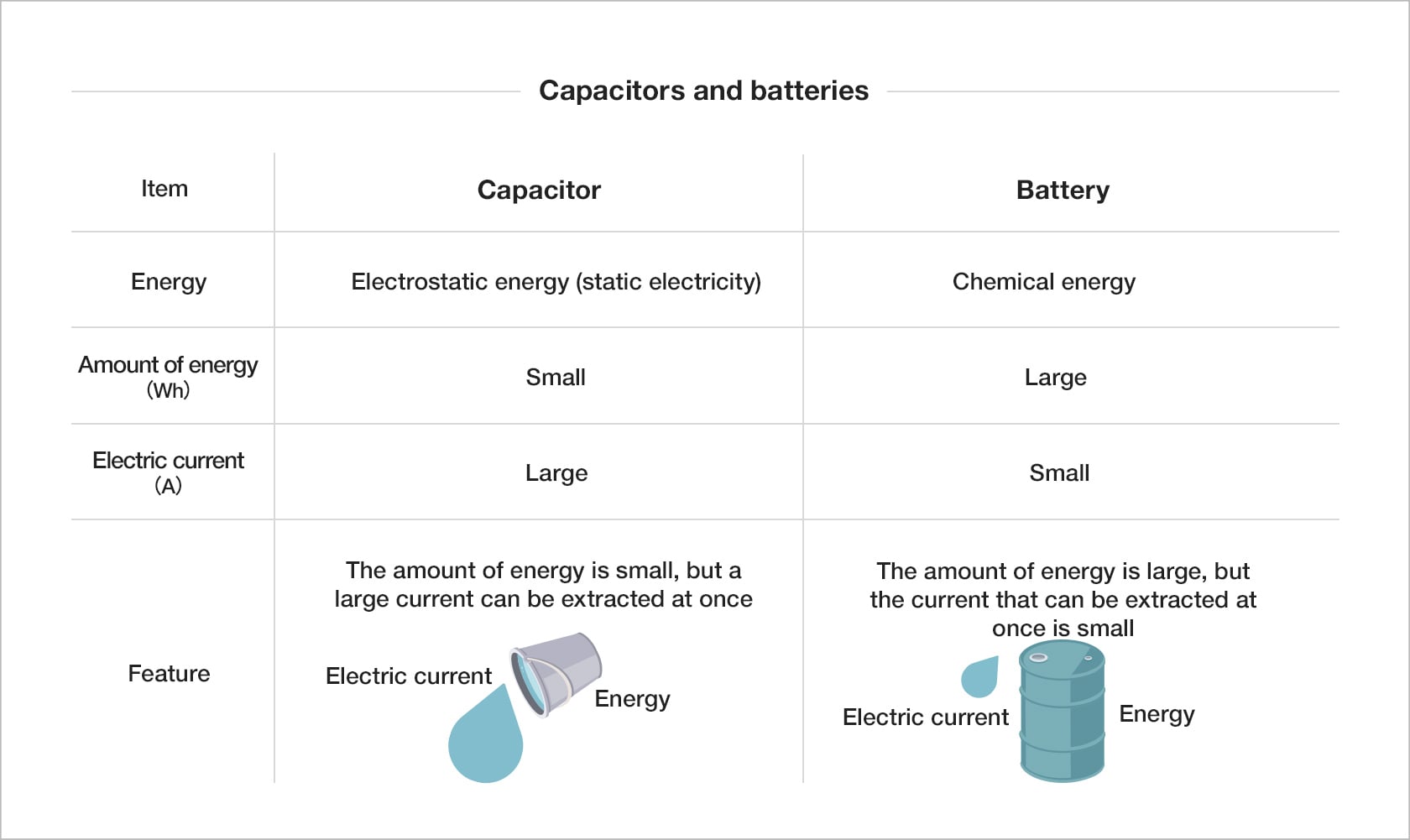

All batteries, including lithium-ion batteries, are storage devices utilizing chemical reaction.

While they are capable of storing a lot of energy, they are not good at instantaneously extracting large currents. Meanwhile, capacitors are storage devices that utilize the physical properties of their materials and, although they can only store a small amount of energy, they are able to instantaneously extract large currents. But perhaps the most significant feature of a capacitor is that, due to not using a chemical reaction, it does not deteriorate over time, therefore offers a long service life.

This figure shows the differences between a capacitor and a battery. Capacitors, which use physical phenomena, store less energy than batteries, but are capable of extracting larger currents quickly. Batteries, which utilize chemical reaction, have the opposite properties. (Figure provided by Musashi Energy Solutions)

This figure shows the differences between a capacitor and a battery. Capacitors, which use physical phenomena, store less energy than batteries, but are capable of extracting larger currents quickly. Batteries, which utilize chemical reaction, have the opposite properties. (Figure provided by Musashi Energy Solutions)

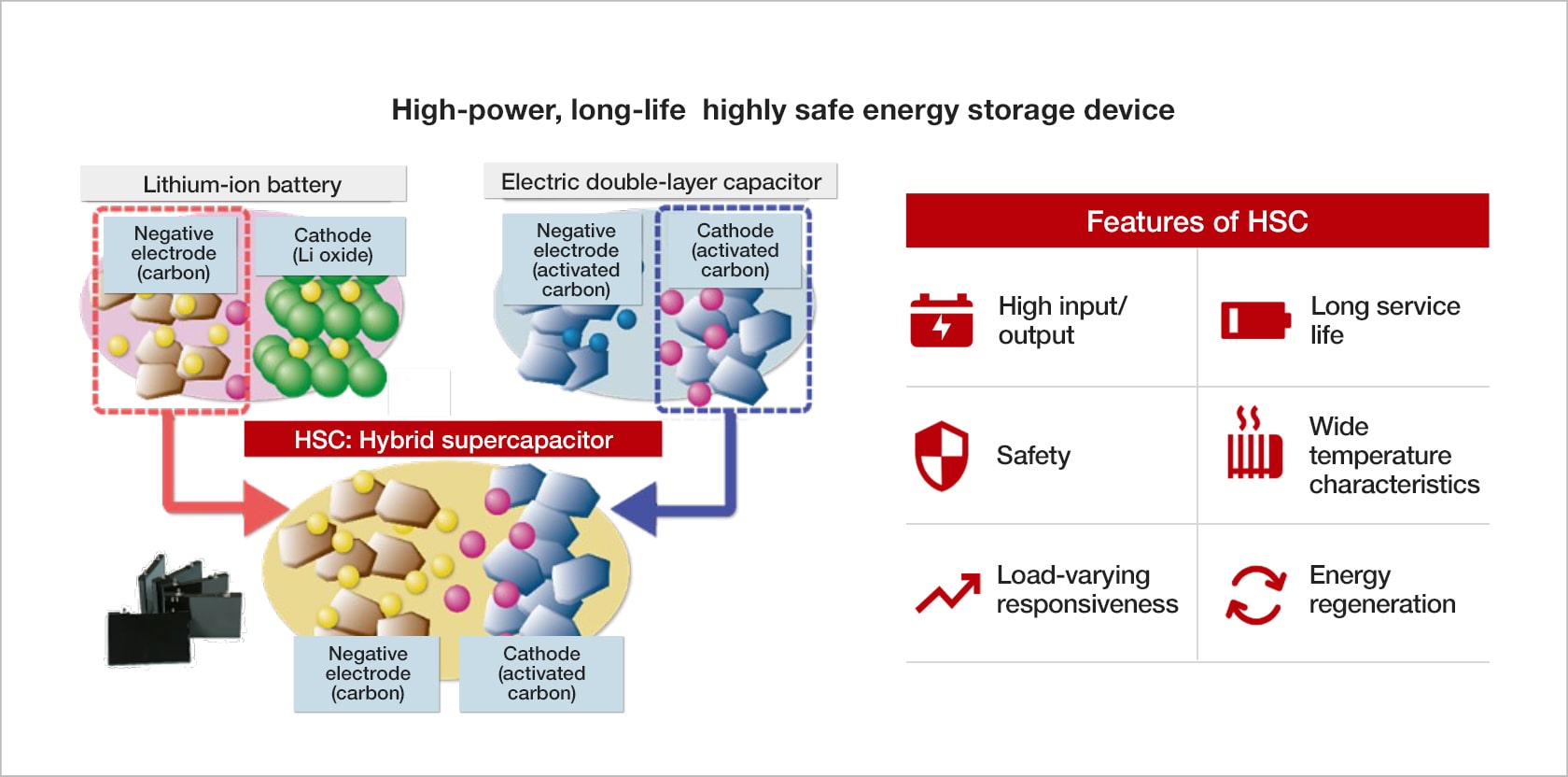

Musashi Energy Solutions’ conventional hybrid supercapacitors are energy storage devices combining capacitor material (activated carbon) for the positive electrode and lithium-ion battery material (carbon) for the negative electrode. Mr. Ando has dedicated over three decades to the development of this capacitor.

Musashi Energy Solutions’ hybrid supercapacitor combines electric double layer capacitor material (activated carbon) for the positive electrode and lithium-ion battery material (carbon) for the negative electrode. This achieves sufficient energy storage capacity and the ability to extract current instantaneously. (Figure provided by Musashi Energy Solutions)

Musashi Energy Solutions’ hybrid supercapacitor combines electric double layer capacitor material (activated carbon) for the positive electrode and lithium-ion battery material (carbon) for the negative electrode. This achieves sufficient energy storage capacity and the ability to extract current instantaneously. (Figure provided by Musashi Energy Solutions)

Ando: The Innovative Energy Storage Device able to store a lot of energy at the same time as charging and discharging instantaneously like a capacitor — in other words, it offers the best of both worlds. These two conditions—high storage capacity and instantaneous charge/discharge—are typically trade-off features, with batteries generally focused on energy and capacitors generally focused on output rate. However, our hybrid supercapacitor achieves a balance of both of these conditions at a high level.

Mr. Yoshida highly praises the Innovative Energy Storage Device.

Yoshida: With sufficient energy capacity and fast charging/discharging ability, I really feel this is an energy storage device born to absorb and store regenerative power. If using a lithium-ion battery that doesn’t offer high-speed charging/discharging or a conventional capacitor with a small energy capacity, there is a need to use a higher number of devices in order to compensate for the respective setbacks, however the Innovative Energy Storage Device achieves both downsizing and weight reduction, making them eco-friendly in the true sense of the word.

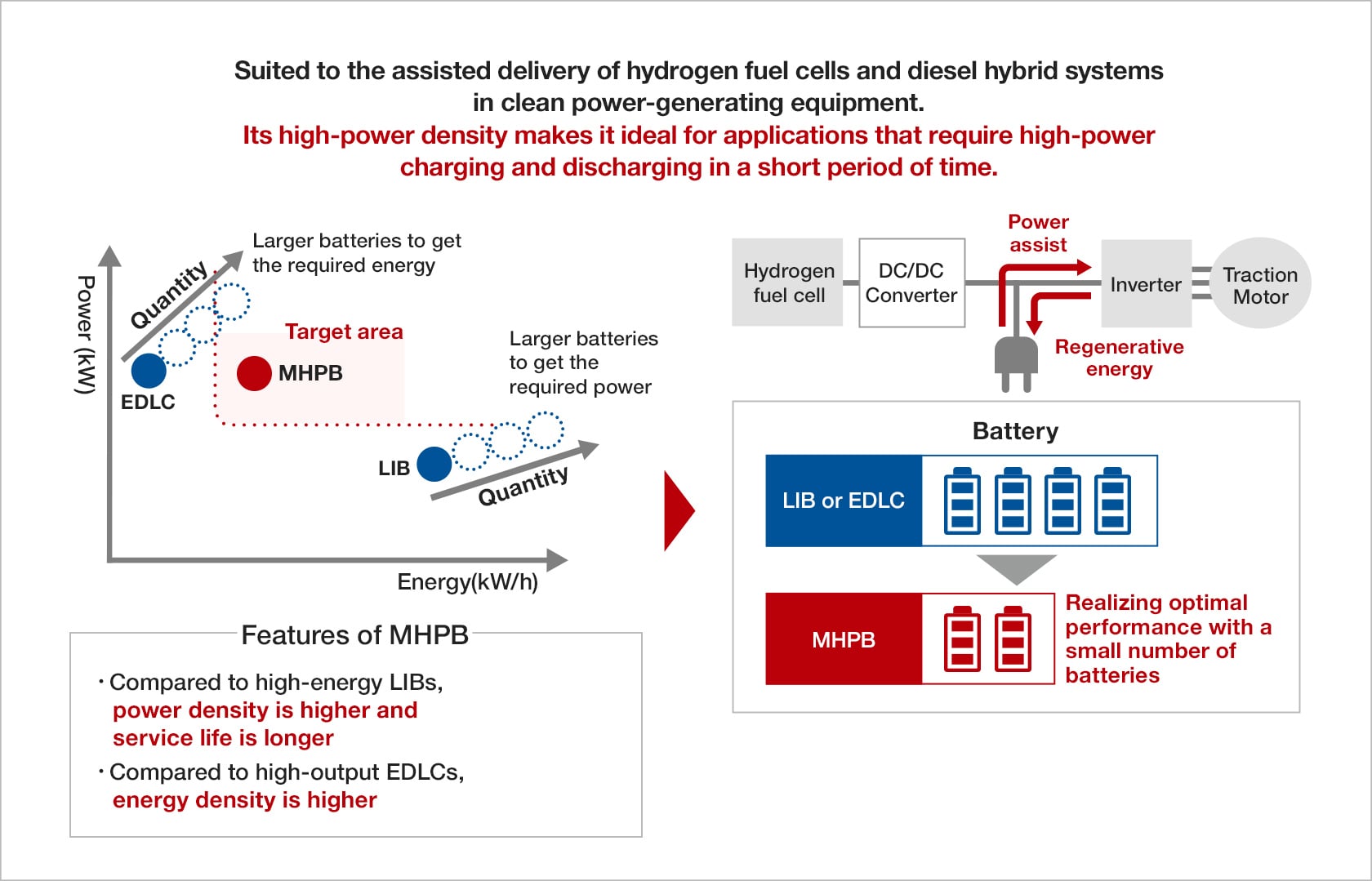

An Innovative Energy Storage Device (described as MHPB in the figure) offering the characteristics with an even balance of the conventional capacitor able to extract power (EDLC shown to the right) and a lithium-ion battery with excellent energy storage (LIB). It is now possible to achieve the downsizing and weight reduction of an energy storage module for regenerative power (right figure).

An Innovative Energy Storage Device (described as MHPB in the figure) offering the characteristics with an even balance of the conventional capacitor able to extract power (EDLC shown to the right) and a lithium-ion battery with excellent energy storage (LIB). It is now possible to achieve the downsizing and weight reduction of an energy storage module for regenerative power (right figure).

Innovative Energy Storage Module born from synergy between the two companies

On May 15, 2024, Mitsubishi Electric Corporation and Musashi Energy Solutions Co., Ltd. announced a business partnership and co-development agreement in relation to the Innovative Energy Storage Module MHPB (Mitsubishi High Power Battery) and Battery Management System (BMS) for the railway industry. This announcement was made a mere 16 months from when Mr. Yoshida and Mr. Ando became acquainted, marking an extremely rare occurrence for a company of Mitsubishi Electric’s size.

Above picture shows the announcement of the business partnership and co-development agreement between Mitsubishi Electric and Musashi Energy Solutions. (From left) Takayuki Tsuzuki, Senior General Manager, Itami Works, Mitsubishi Electric; Yoshio Nagatsuka, General Manager, Traction Systems Department, Itami Works, Mitsubishi Electric; Kouji Takahashi, Chief Executive Officer, Musashi Energy Solutions; Masaru Maeda, Managing Executive Officer, Musashi Seimitsu Industry. (Positions are current as of May 2024)

Above picture shows the announcement of the business partnership and co-development agreement between Mitsubishi Electric and Musashi Energy Solutions. (From left) Takayuki Tsuzuki, Senior General Manager, Itami Works, Mitsubishi Electric; Yoshio Nagatsuka, General Manager, Traction Systems Department, Itami Works, Mitsubishi Electric; Kouji Takahashi, Chief Executive Officer, Musashi Energy Solutions; Masaru Maeda, Managing Executive Officer, Musashi Seimitsu Industry. (Positions are current as of May 2024)

Yoshida: I attended a meeting run by a department responsible for conceiving new ideas and proposed an energy storage module adopting the Innovative Energy Storage Device. If we are able to achieve this hand-in-hand with Musashi Energy Solutions moving forward, then it could be applied to not only railway, but also various other industries. Not to mention, it has a long service life so it can be used in a cyclical manner due to its long lifespan. I reported to the executives at our head office regarding this presentation which held the potential of a solution never before seen. They were quite interested in the idea, and that is when we were able to begin formal discussions.

Mr. Ando reveals how this partnership with Mitsubishi Electric also offered great advantages for Musashi Energy Solutions.

Ando: Musashi Energy Solutions has limited sales channels and insufficient capacity to create systems and solutions. It would make me very happy to be able to enhance synergism through Mitsubishi Electric’s technological strength and knowledge relative to various fields including railway.

Innovative Energy Storage Module (left) and the Innovative Energy Storage Device (right) currently under co-development.

Innovative Energy Storage Module (left) and the Innovative Energy Storage Device (right) currently under co-development.

After obtaining internal approvals, Mr. Yoshida and his team are now in the process of developing the Innovative Energy Storage Module MHPB, which is made by integrating Musashi Energy Solutions’ Innovative Energy Storage Device. The product will also incorporate Mitsubishi Electric's power electronics technologies, such as low-loss charge/discharge circuits and highly accurate charge rate estimation control.

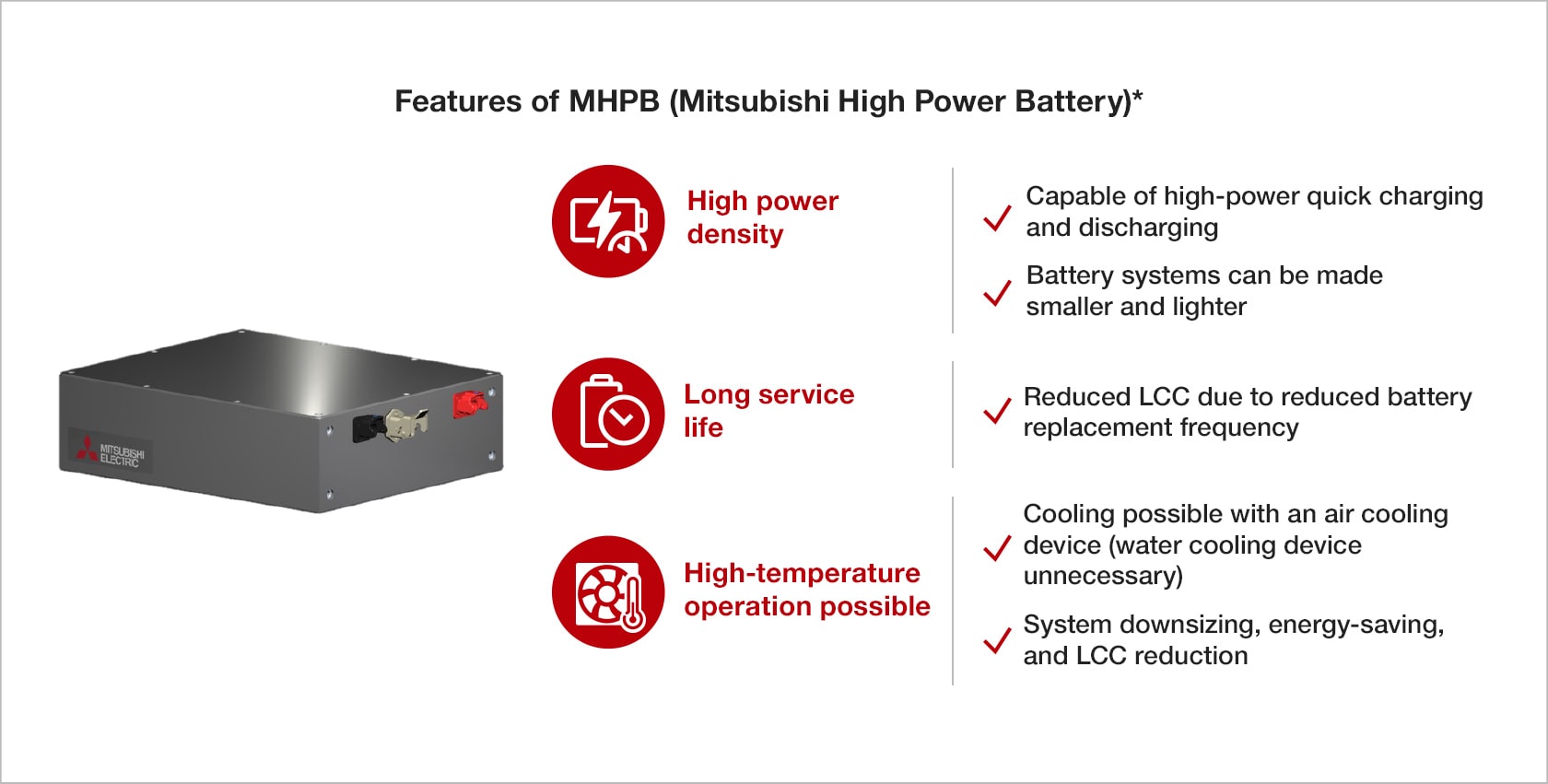

Overview of Mitsubishi Electric’s MHPB featuring Musashi Energy Solutions’ Innovative Energy Storage Device. It features high power density, long life, and high temperature operation, making it ideal for regenerative power storage and other applications.

Overview of Mitsubishi Electric’s MHPB featuring Musashi Energy Solutions’ Innovative Energy Storage Device. It features high power density, long life, and high temperature operation, making it ideal for regenerative power storage and other applications.

During the product’s development, Mr. Yoshida and his team are proactively approaching railway operators and rolling stock manufacturers to make them aware of this new technology. Interest is particularly high in the EU, where initiatives to change people’s means of transportation from cars and planes to railways are outlined in the 2021 European Year of Rail, and when Mr. Yoshida or one of his team explains how the MHPB is an excellent balance between energy and output, apparently sometimes the reaction is one of surprise, with exclamations such as "Is such an ideal energy storage device really possible?" Moreover, only a small number of MHPBs are required to configure a system, therefore they can easily be fitted on existing railcars, offering customers the advantage of only a slight increase in the train’s weight.

Many possibilities for resource conservation and regional revitalization

Various business discussions are being held both in Japan and other countries around the globe regarding utilization of the Innovative Energy Storage Module MHPB for purposes such as increasing transportation density by power leveling in substations, hybridization of diesel railcars and fuel-cell railcars, and the realization of overhead catenary-less streetcars. As such, there are high expectations that MHPB will contribute to decarbonization in the railway sector. The project is scheduled for completion in 2026.

Meanwhile, Mr. Ando of Musashi Energy Solutions has expectations for the future from a different perspective.

Ando: Lithium-ion batteries deteriorate as they age, and ultimately require replacement. What this means is that their operation currently requires mass production and mass disposal. During the production and disposal cycle, CO2 is emitted, and resources are consumed. Meanwhile, the long-life hybrid supercapacitor essentially does not require replacement, nor does it require a system to ensure safety or a mechanism for attachment/removal, meaning it is capable of saving resources and reducing CO2 on the whole. I truly hope that the hybrid supercapacitor will be an opportunity to make improvements to the status quo and translate into new values.

As for Mr. Yoshida of Mitsubishi Electric, he has other expectations of the MHPB.

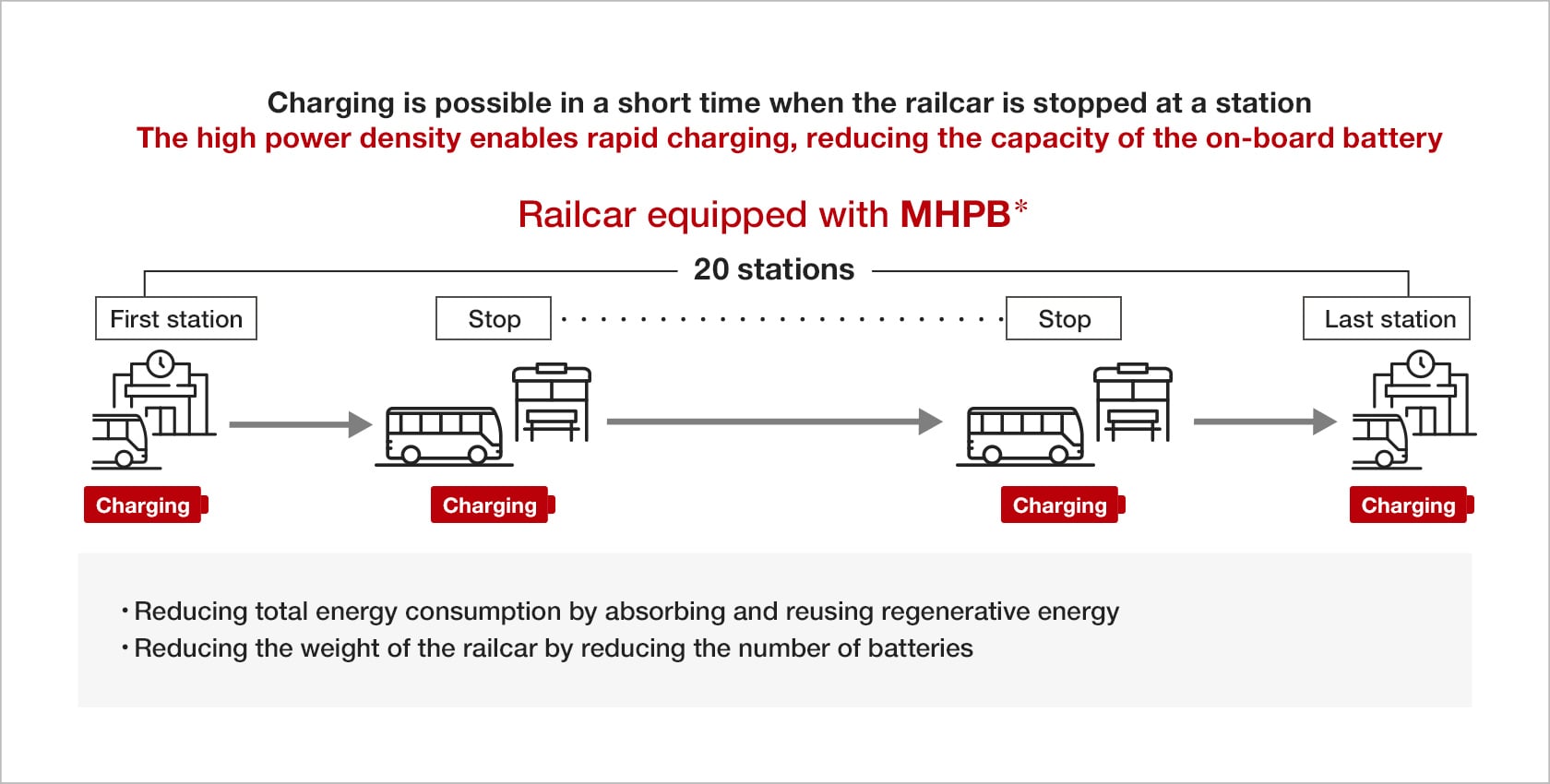

Yoshida: The new energy storage module can be employed for running streetcars which have short distances between stations. There is a need for a charging setup at each station; however, if we can succeed at eliminating the overhead catenary, the construction cost can be lowered, including the cost of substation equipment — not to mention the aesthetic benefits of removing the catenary. The module is lightweight; therefore, the railcar will not require a large volume of energy for acceleration due to the additional mass. If it is possible to lower the barriers for installing and maintaining streetcars in regional towns, it may ultimately lead to revitalization of those areas. I see that kind of potential in the MHPB.

The MHPB module could be used on streetcars with a short distance between stations. With rapid charging at the station, it would be possible to eliminate overhead catenaries without requiring large-capacity batteries.

The MHPB module could be used on streetcars with a short distance between stations. With rapid charging at the station, it would be possible to eliminate overhead catenaries without requiring large-capacity batteries.

When Mr. Yoshida was searching for an energy power device, it just so happened that he attended a lecture Mr. Ando was giving at Mitsubishi Electric. Later, Mr. Yoshida’s passion for co-development of this new technology resonated with the company’s executives, and now an unprecedented energy storage module is on the brink of manifestation. When something new is born, it often seems to be due to a combination of coincidence and passion.

The new energy storage module could potentially be applied to construction machinery, factory equipment (FA equipment), uninterruptible power supplies (UPS), backup power generation equipment and more, and this technology is being introduced to various business divisions within Mitsubishi Electric.

MHPB is anticipated to lead to the emergence of new applications not covered by the current mainstream lithium-ion batteries, and by extension, another step toward decarbonization.

- Information on products, services, and affiliations in this article is current at the time of the interview (August 2024).

Interview and text by Yukihiro Seki