Contact Image Sensors (CIS)

Applications and Features of Surface Inspection CIS

| Applications | Features |

Applications

Ever struggle with time-consuming, cumbersome equipment adjustment when using a camera?

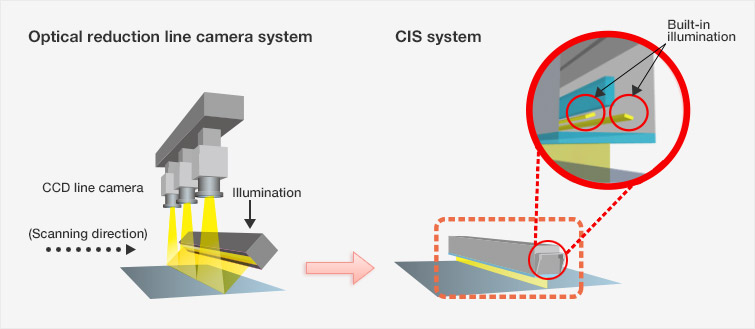

Using a Mitsubishi Electric CIS, which integrates illuminations lens, sensors, and other parts in one module, enables you to scan wide and flat objects instantly and easily.

Dimension inspection

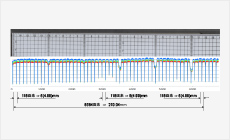

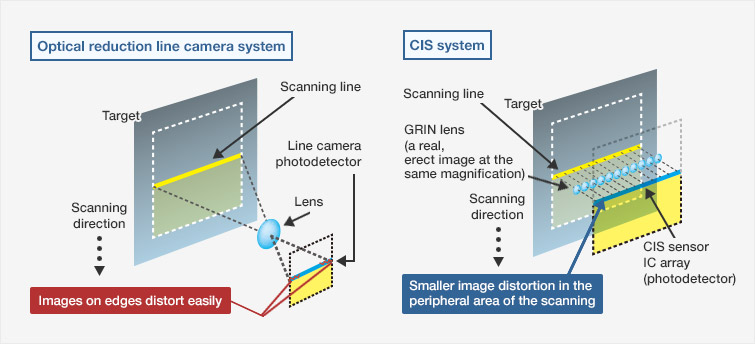

Compared to an optical reduction line camera system, CIS offer smaller distortion in the peripheral area of scanned image and are therefore suitable for length measurement.

All forms of surface inspection are supported, from printed material/label/package inspections to length measurement inspections. You can utilize the CIS to find scratches, dirt, part defects, and color defects by connecting it to your software.

Features

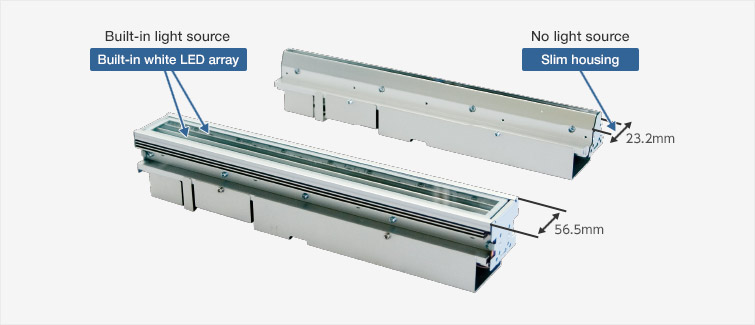

1. Ease of installation – Compact device (module)

The KD Series CIS includes the image sensor, lens and LED illumination in one package. The fixed focal distance saves installation time with the use of simple brackets and mounting.

2. One CIS captures a long, wide picture all at once

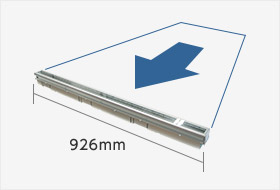

Three scanning widths are selectable, from 309㎜ to 926㎜, as a module for the application.

To suit each scanning width, the lens, light source and sensor (photodetector) have been integrated into one product, thereby eliminating the hassle of equipment adjustment when using multiple line cameras.

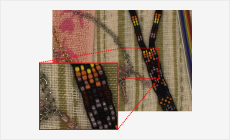

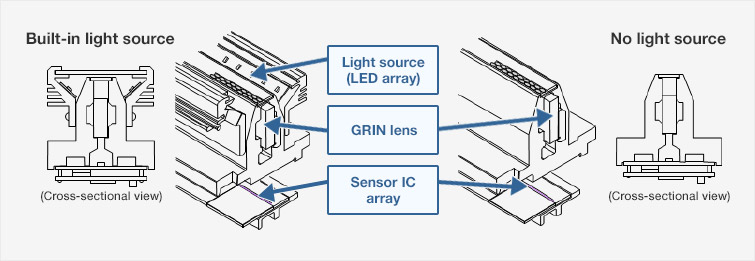

3. Distortion-free & uniform images

The GRIN lens system, which transfers a real, erect image at the same magnification and has same length as each scanning width, is used for Mitsubishi Electric CIS.

Thereby image distortion in the peripheral region of the scanning image is minimized and inspection accuracy is more stable compared to conventional line cameras and optical reduction scanning methods.

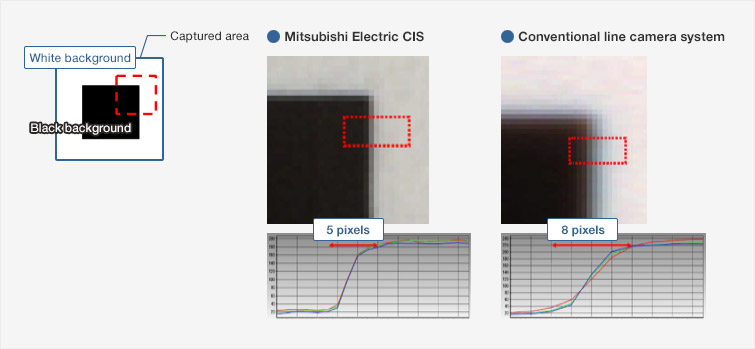

4. Clear edge detection

The CIS system captures clearer images than conventional line camera systems. This makes it easy to determine minor defects.

5. Lineup includes both built-in light source and no light source

CIS with built-in illumination are equipped with our standard white LED array. There are also non-LED options for backlight or other custom lighting strategies. It is flexible to set CIS and the illumination at any viewing angle.

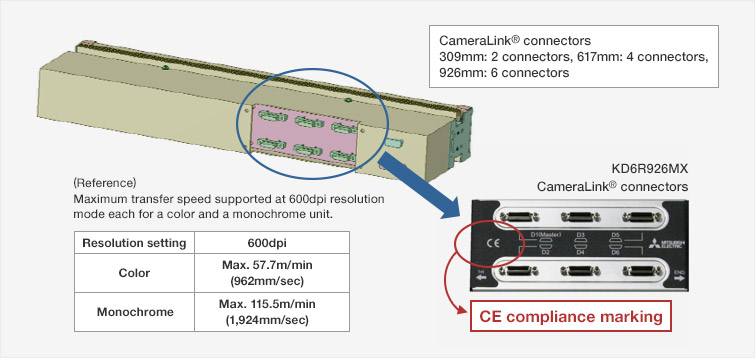

6. Monochrome output model

The new monochrome CIS has been proven complaint and carries the CE marking. It has a camera link connectors concentrated in one spot, and a transfer speed twice as fast as color models!

Easier cable routing is realized by placing the CameraLink® connectors in one place regardless of scanning width. The number of cables can be reduced for low-speed scanning, which helps to reduce peripheral costs.

7. KD series line speed Table

| Series/Condition | Line Rate[kHz] | Adaptable scanning speed (m/sec) | ||||||||

| 600dpi | 300dpi | 200dpi | 150dpi | 600dpi | 300dpi | 200dpi | 150dpi | |||

| KD-AX4 (*1) |

10bit color | 11.3 | 22.7 | 32.2 | 32.2 | 0.4 | 1.9 | 3.9 | 5.4 | |

| 8bit color | 22.7 | 32.2 | 0.9 | 2.6 | ||||||

| KD-MX | 10bit monochrome | 43.4 | - | 43.4 | 1.8 | 3.6 | - | 7.3 | ||

| 8bit monochrome | ||||||||||

| KD-CX (*2) |

10bit color | Internal | 55.0 | 96.2 | 130.6 | 159.1 | 2.3 | 8.1 | 16.5 | 26.9 |

| External | 50.6 | 80.9 | 100.9 | 115.2 | 2.1 | 6.8 | 12.8 | 19.5 | ||

| 8bit color | Internal | 55.0 | 96.2 | 130.6 | 159.1 | 2.3 | 8.1 | 16.5 | 26.9 | |

| External | 91.8 | 112 | 125.9 | 7.7 | 14.2 | 21.3 | ||||

| KD-CXS (*2) |

10bit color | 44.2 | 88.7 | 130.6 | 159.1 | 1.8 | 7.5 | 16.6 | 26.9 | |

| 8bit color | 55.0 | 96.2 | 2.3 | 7.7 | 14.2 | 21.3 | ||||

| KD-DXL (*3) |

10bit color | 1064 | 24.0 | 47.5 | 71.0 | 82.0 | 1.0 | 4.0 | 9.0 | 13.8 |

| 1247/1688 | 20.1 | 39.4 | 58.0 | 78.0 | 0.8 | 3.5 | 7.3 | 13.2 | ||

| 8bit color | 1064 | 35.1 | 72.1 | 104.4 | 134.5 | 1.4 | 6.1 | 13.2 | 22.7 | |

| 1247/1688 | 29.3 | 60.8 | 88.5 | 114.6 | 1.2 | 5.1 | 11.2 | 19.4 | ||

| KD-CXL (*4) |

10bit color | 1064 | 45.1 | 90.5 | 130.6 | 159.1 | 1.9 | 7.6 | 16.5 | 26.9 |

| 1247/1688 | 37.6 | 75.4 | 113.2 | 150.9 | 1.5 | 6.3 | 14.3 | 25.5 | ||

| 8bit color | 1064 | 55.0 | 96.2 | 130.6 | 159.1 | 2.3 | 8.1 | 16.5 | 26.9 | |

| 1247/1688 | 47.0 | 94.3 | 1.9 | 7.9 | 16.5 | 26.9 | ||||

| KD-CXF | 10bit color | 1064 | 45.1 | 90.5 | 130.6 | 159.1 | 1.9 | 7.6 | 16.5 | 26.9 |

| 8bit color | 1064 | 55.0 | 96.2 | 130.6 | 159.1 | 2.3 | 8.1 | 16.5 | 26.9 | |

| KD-SX | 8bit monochrome | 6.0 | - | - | - | 0.2 | - | - | - | |

- *1 Line rate and Transportation in KD-AX4 column refer to that of KD6R309AX4.

In case of CamereLink™ "Medium configuration" mode, Interpolation OFF,Internal sync. - *2 In the case of the external sync, Mode on KD-CX and calculate the minimum line period, other 4 to 5μ sec period for sending a trigger signal is necessary to add to internal all timing of CIS.

- *3 In the case of CameraLink™ "Full Congfiguration"mode, external sync.

- *4 In the case of CXP-6 Quad, external sync.