Disaster Countermeasures

Development of a Response Framework for Large-scale Disasters

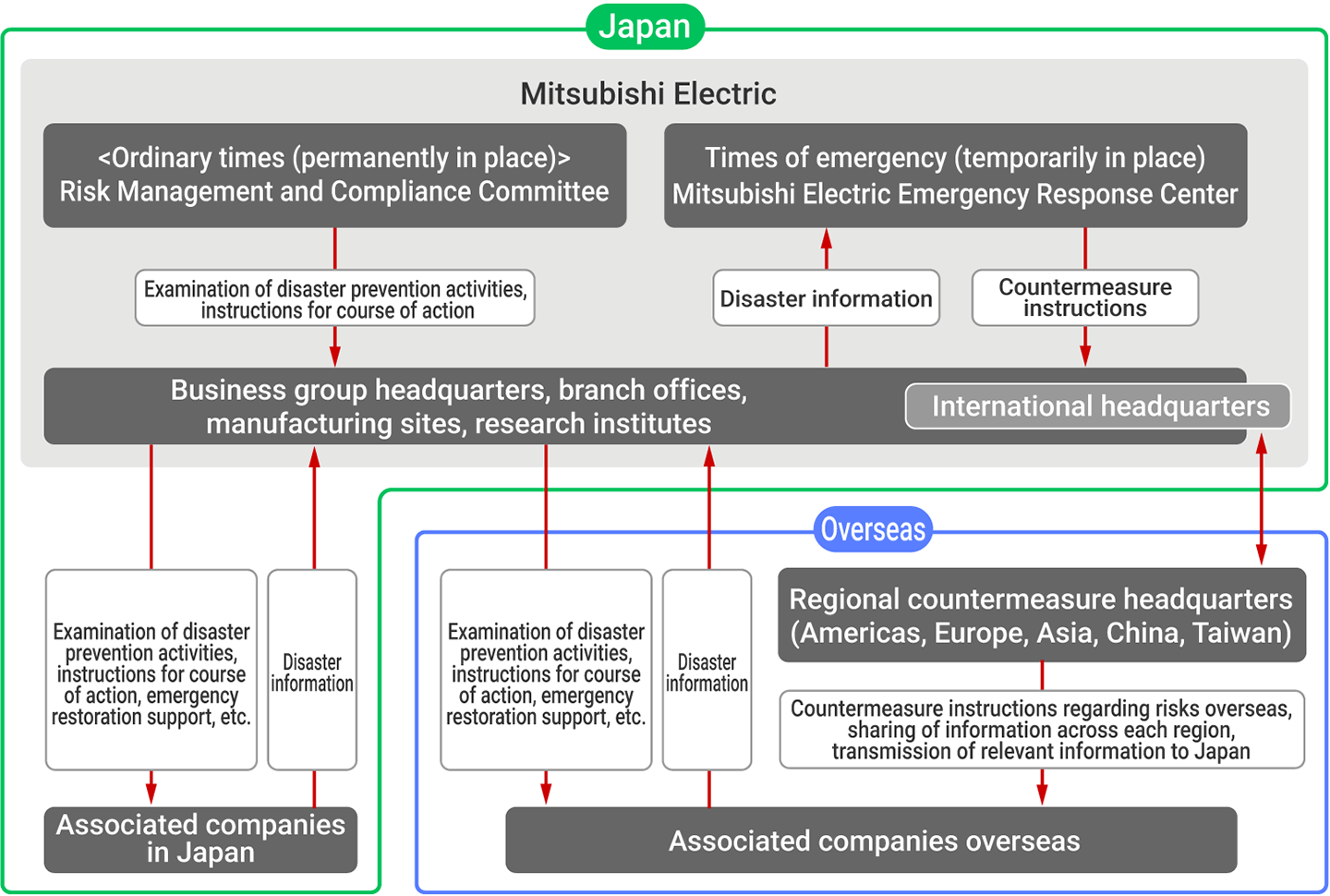

The Mitsubishi Electric Group has established a Risk Management and Compliance Committee chaired by the Chief Risk Officer (CRO) and conducts regular verification and review of the business continuity plan (BCP), including the Group’s disaster countermeasures, at least once a year.

In the event that any of the Mitsubishi Electric Group’s sites suffer or are at risk of suffering serious damage as the result of a large-scale disaster, we will establish the Mitsubishi Electric Emergency Response Center, headed by our president, which will serve as the central hub for the entire Mitsubishi Electric Group in responding to the emergency situation. In addition to verifying the (personal and physical) disaster situation, the Emergency Response Center will promptly examine and execute policies in response to business continuity initiatives and requests from society (support for affected areas, donations, etc.). Particularly with regard to overseas sites and associated companies overseas, it will work closely with each regional response headquarters to ensure employee safety (safety confirmation, livelihood support, etc.) and provide support for business restoration.

Disaster prevention framework (Mitsubishi Electric Group)

Disaster prevention framework (Mitsubishi Electric Group)

Initiatives for Business Continuity

Business continuity plan (BCP) Formulation and Regular (Annual) Review

To fulfill our responsibility as a product supplier, we had all Mitsubishi Electric Group offices formulate a BCP assuming the possible outbreak of a new strain of influenza in fiscal 2011 and a BCP assuming the risk of a large-scale earthquake in fiscal 2013 and urged major associated companies in Japan and overseas to formulate a BCP.

Each office and associated company in Japan and overseas where the BCP has been established, reviews it and upgrades countermeasures every year so that the BCP once developed will not turn into a mere formality.

Business Continuity in the Supply Chain

At Mitsubishi Electric, we pursue initiatives to avoid situations in which a large-scale disaster or other unavoidable circumstance imposes serious damage on suppliers, severs the supply of materials, or obstructs our production activities.

- Activities for Visualizing the Procurement Parts Supply Chain and Mitigating Procurement Risks in Addition to Procurement

To prepare for the risk of supply chain disruptions in the event of an emergency, we implement various measures, such as visualizing the supply chain per procured item and purchasing from multiple suppliers. In addition, we continue to educate and support our suppliers on disaster preparedness by holding BCP seminars for them.

- Activities for Ensuring a Prompt Initial Response and Efficient Response Tasks in Times of Emergency

We are restructuring our frameworks and systems to accelerate and streamline operations, including centralized management of supply chain information for purchased goods, supplier impact surveys in the event of an emergency, and automation of response tabulation.

Strengthening Disaster Responses

Each office and associated companies of the Mitsubishi Electric Group possesses a disaster response manual that is used to implement preliminary measures (disaster mitigation measures) and disaster prevention drills.

For example, Mitsubishi Electric carries out an emergency drill and safety confirmation training that involves the use of a safety confirmation system at each site. In addition, we have two separate data centers in the Greater Tokyo Area and the Kansai region and carry out an annual drill for switching between data centers in the event of an emergency.

We have also instructed associated companies to establish the same level of disaster countermeasures as those implemented by Mitsubishi Electric to strengthen their emergency preparedness through disaster-prevention drills at each site.

Pandemic Countermeasures

As the Mitsubishi Electric Group continues to expand its business globally, we are advancing initiatives in Japan aimed at (1) ensuring the safety of individuals, (2) maintaining operations that support essential social functions, and (3) minimizing economic losses to the company in the event of an outbreak of a novel influenza or similar threat. These efforts include the formulation of business continuity plans (BCPs) and monitoring the movements of business travelers and expatriates. For our overseas associated companies, we provide direction for establishing countermeasures suitable for the situation in each country, including the formulation of a BCP that anticipates the outbreak of a new strain of influenza.

Ensuring Safety Overseas

The Mitsubishi Electric Group’s Overseas Security Center works closely with overseas sites, including local associated companies and overseas offices of Mitsubishi Electric and associated companies in Japan, to grasp the dynamics and confirm the safety of overseas business travelers, convey various information (travel restrictions, etc., based on information gathered from the Ministry of Foreign Affairs and specialized agencies), and to provide employee education.

In addition, from a geopolitical risk perspective, each overseas site has developed a crisis management manual that stipulates evacuation procedures and routes in preparation for emergencies. Relevant risk information is also gathered weekly from overseas crisis management consultants and other sources, and shared with stakeholders.

We also participated in the public-private overseas safety cooperation conference sponsored by the Ministry of Foreign Affairs and exchanged information and views with other companies and organizations. The results of the conference have been incorporated into the risk management activities of our company and overseas sites.